Sensitivity of springback and section deformation to process parameters in rotary draw bending of thin-walled rectangular H96 brass tube

来源期刊:中国有色金属学报(英文版)2012年第9期

论文作者:朱英霞 刘郁丽 杨合

文章页码:2233 - 2240

关键词:H96薄壁矩形管;绕弯成形;敏感性分析;回弹;截面畸变

Key words:thin-walled rectangular H96 brass tube; rotary draw bending; sensitivity analysis; springback; section deformation

摘 要:为了研究工艺参数对回弹和截面畸变的作用,结合多参数敏感性分析法和回弹/截面畸变预测三维有限元模型,建立敏感性分析系统模型,并利用此模型研究回弹和截面畸变对工艺参数的敏感性。结果表明:回弹最敏感的工艺条件是助推速度和助推压力,截面变形最敏感的工艺条件是芯头的个数;当夹紧力、助推速度与助推压力被用来控制绕弯过程的截面畸变时,必须同时考虑这些参数对回弹的影响;在任何情况下利用工艺参数控制绕弯过程回弹都必须同时考虑截面畸变。

Abstract: In order to study the effects of the process parameters on springback and section deformation, a sensitivity analysis model was established based on the combination use of the multi-parameter sensitivity analysis method and the springback/section deformation prediction finite element model, and by using this model the sensitivities of the springback and the section deformation to process parameters were analyzed and compared. The results show that the most sensitive process conditions for springback angle are the boost speed and the pressure of pressure die, and the most sensitive process condition for section deformation is the number of cores. When the clamp force, the boost speed and the pressure of pressure die are utilized to control section deformation, the effect of these process parameters on springback should be considered. When the process parameters are mainly used to control springback, the effect of these process parameters on the section deformation should be always considered.

![]()

Trans. Nonferrous Met. Soc. China 22(2012) 2233-2240

ZHU Ying-xia, LIU Yu-li, YANG He

State Key Laboratory of Solidification Processing, School of Materials Science and Engineering,

Northwestern Polytechnical University, Xi’an 710072, China

Received 24 August 2011; accepted 30 September 2011

Abstract: In order to study the effects of the process parameters on springback and section deformation, a sensitivity analysis model was established based on the combination use of the multi-parameter sensitivity analysis method and the springback/section deformation prediction finite element model, and by using this model the sensitivities of the springback and the section deformation to process parameters were analyzed and compared. The results show that the most sensitive process conditions for springback angle are the boost speed and the pressure of pressure die, and the most sensitive process condition for section deformation is the number of cores. When the clamp force, the boost speed and the pressure of pressure die are utilized to control section deformation, the effect of these process parameters on springback should be considered. When the process parameters are mainly used to control springback, the effect of these process parameters on the section deformation should be always considered.

Key words: thin-walled rectangular H96 brass tube; rotary draw bending; sensitivity analysis; springback; section deformation

1 Introduction

Springback and section deformation are the two main defects influencing the forming quality of thin-walled rectangular H96 brass tube in rotary draw bending process [1]. Springback is inevitable for there is always residual stress to release the elastic deformation after the rotary draw bending process. Section deformation is inevitable too, for the resultant force of tangential stress will cause section sag. Research shows that the stress of a bending tube mainly depends on the process conditions, such as clamping force, boost speed and pressure of pressure die [2]. Therefore, to realize the control of springback and section deformation, both the effect trends and the effect degrees of the process parameters on them should be analyzed, which can be expressed by the sensitivity degrees of the springback and the section deformation to process parameters. So, the multi-parameter sensitivity analysis method combined with the finite element (FE) simulation is used to study the effects of process parameters. In Ref. [3], a sensitivity analysis was performed to study the contributions of various factors to the springback behavior of bending sheet metal. A sensitivity analysis was also carried out to find the optimum process variables that can minimize the springback of bending sheet metal [4]. Based on the multi-parameter sensitivity analysis method, ZHANG et al [5] took the maximum principal strain as a measure of disturbance degree of simulation results, and analyzed the sensitivity of controllable simulation parameters to the maximum principal strain of L-bending sheet. A sensitivity study was performed by CLAUSEN et al [6] using the numerical simulation and statistical tools, and the main model parameters influencing springback and cross- section deformation were obtained for the rectangular tube of stretch bending. All of these researches show that the sensitivity analysis method is a simple, robust and effective way to study the effects of model parameters to the simulation results, such as springback and section deformation. On the other hand, previous researches on the section deformation of the bending tube always unilaterally studied the variation trends with the process parameters [7-10] as well as how to control the section deformation by changing the process parameters [11,12]. They ignored that there are coupling effects between springback and section deformation [13], and the cross-section distortion should be measured after the springback; the trends of springback with process parameters may be just opposite with the trends of section deformation, which may lead to the control of section deformation but the increase of springback; section deformation includes both the cross-section distortion and the longitudinal-section ovalization. Previous researches on the springback of bending tube always unilaterally took the springback as a study subject, while ignored the impact of process parameters on section deformation [14-17].

So, based on the FE simulation and the multi-parameter sensitivity analysis method, not only the effects of process parameters on springback and section deformation were studied, but also the sensitivity degrees of the process parameters on springback and section deformation were analyzed and compared for rotary draw bending of thin-walled rectangular H96 brass tube. The research can provide a support to determine whether the springback should be considered when the process parameters are mainly used to control the section deformation, and vice versa.

2 Establishment of sensitivity analysis model for thin-walled rectangular H96 brass tube in rotary draw bending process

2.1 Description of multi-parameters sensitivity analysis method

Sensitivity analysis is one kind of the system analysis method concerning about the stability of the system, which shows the variation degree of system characteristics with various factors. The various factors need to have a dimensionless disposal first. The relative errors δP and ![]() of the system characteristics P and the various factors αk (k=1, 2, …, N) are defined as Eq. (1) [18], and parameter N is the number of various factors.

of the system characteristics P and the various factors αk (k=1, 2, …, N) are defined as Eq. (1) [18], and parameter N is the number of various factors.

![]() ,

, ![]() (1)

(1)

Their ratio is the sensitivity value Sk(αk), as shown in Eq. (2).

![]() (2)

(2)

When |?αk|/αk is small, Sk(αk) can be expressed as:

![]() (3)

(3)

where Sk(αk) (k=1, 2, …, N) are a set of dimensionless non-negative real number, and the higher the value, the more sensitive the P to αk, namely, the higher the effect of αk on P [19].

2.2 Modification of multi-parameter sensitivity analysis

In Eq. (3), the function relationship f(α) between the system characteristic P and the effecting factor αk must be created before a sensitivity analysis. But its fitting precision relies too much on the number of fitting data and a lot of data should be adopted to ensure the accuracy, so Eq. (3) is replaced by Eq. (4), namely, every two adjacent fitting data will have a slope solution between them, and finally the average value of these slopes is taken as the sensitivity value.

![]() (4)

(4)

where m is the number of process parameters under each process condition, ![]() is the process parameter value, and

is the process parameter value, and ![]() represents the springback value and section deformation value corresponding to the process parameter αk.

represents the springback value and section deformation value corresponding to the process parameter αk.

For the sensitivity analysis of thin-walled rectangular H96 brass tube in rotary draw bending process, the system characteristics P refers to the springback and section deformation, and the effect factor αk (k=1, 2, …, N) refers to the process condition. All of the analysis was carried out by using the FE simulation, and the FE model will be established based on the ABAQUS platform.

2.3 Establishment of final FE model for springback and section deformation prediction and its validation

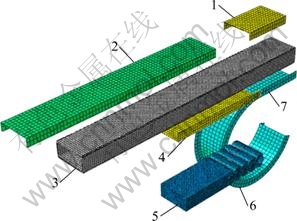

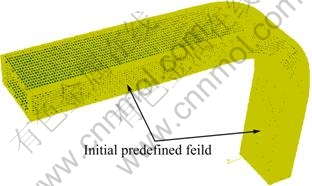

A new FE model for rotary-draw bending process of thin-walled rectangular H96 brass tube is established, as shown in Fig. 1. The key modeling techniques were consistent with those in the original shell element model in Ref. [20], such as geometry modeling, assembly modeling, boundary condition and load definition. But the C3D8R solid element is adopted here for the solid element can make a more precise prediction to springback than the shell element [21]. The simulation for rotary-draw bending process is under the platform of ABAQUS/Explicit. Finally, the output files of the results in the rotary-draw bending process are imported into ABAQUS/Standard software, then the final FE model is established as shown in Fig. 2, from which the springback angle and the ultimate section deformation can be obtained.

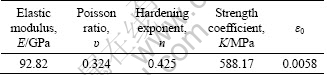

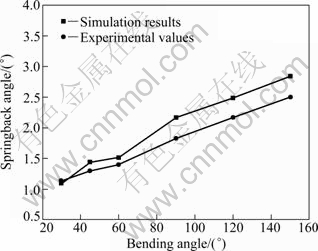

To validate the reliability of the final FE model, the rectangular H96 brass tube was used. Its cross-section sizes are 24.86(b) mm×12.20(h) mm, the thickness is 1 mm, the length is 200 mm, and the bending radius for simulation is 40 mm. The power exponent hardening model σ=K(ε0+ε)n is used to express the material hardening behavior, whose values are obtained through the tensile text, as shown in Table 1. The final FE model is validated by comparing the simulated springback angles with the experimental ones, which is shown in Fig. 3. It can be seen that the simulation results are very close to the experimental values. The maximum relative error is 18.48%, and the average error is only 11.48%. Therefore, the established final FE model is valid and reliable.

Fig. 1 FE model of rotary-draw bending process: 1—Clamp die; 2—Pressure die; 3—Rectangular tube; 4—Wiper-bend die; 5—Mandrel and flexible cores; 6—Bending die; 7—Insert die

Fig. 2 Final FE model for springback and section deformation prediction

Table 1 Property parameters of H96 brass

2.4 Description of springback and section deformation

2.4.1 Description of springback

The amount of springback can be expressed as the value of springback angle ?θ. In Eq.(5), θ and θ′ are the bending angles before and after springback, respectively.

?θ=θ-θ′ (5)

Fig. 3 Comparison between simulative and experimental values of springback angle

2.4.2 Description of section deformation

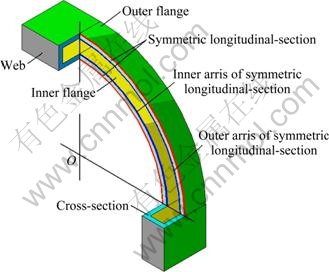

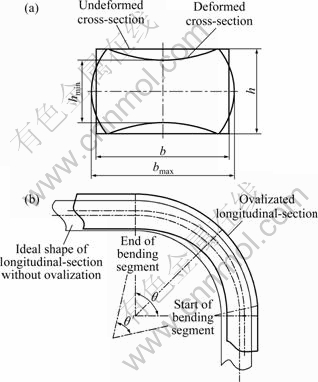

The four walls of rectangular tube are named as the inner flange, the outer flange and the webs respectively, as shown in Fig. 4. After the bending process, the section of rectangular tube is deformed, as shown in Fig. 5. The minimum height (hmin) and the maximum width (dmax) of the cross-section all appear in section symmetry line (Fig. 5(a)). The longitudinal-section also has the maximum deformation in the symmetric longitudinal-section (Fig. 5(b)). So the deformation located on the symmetric longitudinal-section is the study subject.

Fig. 4 Definition of outer/inner flange, webs, cross-section, symmetric longitudinal-section, inner arris of symmetric longitudinal-section

1) Cross-section distortion after springback

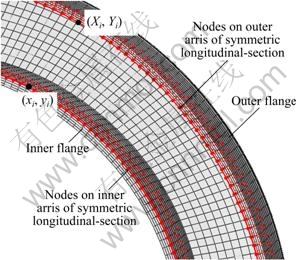

After bending process, the coordinate of nodes on the inner arris of symmetric longitudinal-section is set as (xi, yi) (i=1, 2, …, n), and the coordinate of nodes on the outer arris of symmetric longitudinal-section is set as (Xi, Yi) (i=1, 2, …, n), as shown in Fig. 6. After springback, the coordinates (xi, yi) and (Xi, Yi) are changed to (x′i, y′i), (X′i, Y′i) respectively. The cross-section distortion Dc is defined as the average cross-section distortion after springback, as shown in Eq. (6),

![]() (6)

(6)

where![]() (i=1, 2, …, n) is the ratio of the node distances before and after being deformed, which is measured after springback, as:

(i=1, 2, …, n) is the ratio of the node distances before and after being deformed, which is measured after springback, as:

![]() (7)

(7)

Fig. 5 Segment deformation after bending process: (a) Cross- section distortion; (b) Longitudinal-section ovalization

Fig. 6 Coordinate of nodes on symmetric longitudinal-section inner arris

In Eq.(7), h′=h-2t, h is the height of rectangular tube, and t is the thickness.

2) Reduction ?Dc of cross-section distortion caused by springback

As known springback can average the stress distribution and reduce its value, which leads to the reduction of cross-section distortion at last. Thus the reduction ?Dc of cross-section distortion caused by springback is studied too, which can be expressed as:

![]()

i=1, 2, …, n (8)

where ![]() is a sign function, as shown in Eq.(9), which means that if the reduction of cross-section distortion caused by springback is positive, then the sign function is equal to the positive sign, and vice versa.

is a sign function, as shown in Eq.(9), which means that if the reduction of cross-section distortion caused by springback is positive, then the sign function is equal to the positive sign, and vice versa.

(9)

(9)

where ![]() is the ratio of distance between node (xi, yi) and (Xi, Yi), as shown by Eq.(10):

is the ratio of distance between node (xi, yi) and (Xi, Yi), as shown by Eq.(10):

![]() (10)

(10)

dc is the cross-section distortion before springback, shown as Eq. (11):

![]() (11)

(11)

3) Longitudinal-section ovalization Dl(dl) of outer flange (inner flange)

Elliptic curve with two parameters is used to fit the inner arris of symmetric longitudinal-section after springback, as shown in Eq. (12). The parameters a and b are obtained and used. Eq. (13) is used to solve the ovalization of longitudinal-section, which expresses the deviation of the real longitudinal-section from the ideal circular longitudinal-section.

![]() (12)

(12)

![]() (13)

(13)

where Dl(dl) is the longitudinal-section ovalization of the outer flange (the inner flange) in rectangular tube, and r is the standard radius of the outer arris (the inner arris) of symmetric longitudinal-section.

4) Ovalization increment ?D1 of outer flange

It is found that the springback can increase the longitudinal-section ovalization, especially for the ovalization of outer flange. Thus the ovalization increment ?D1 of outer flange is studied and defined as:

![]() (14)

(14)

where D′l is the longitudinal-section ovalization of the outer flange before springback. If ?Dl>0, it shows that the springback makes an increment on the ovalization of outer flange; while if ?Dl<0, it shows that the springback reduces the ovalization of outer flange.

3 Results and discussion

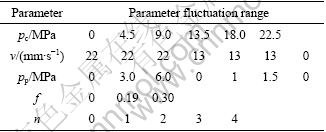

3.1 Fluctuation ranges of process parameters

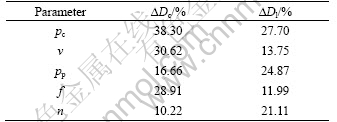

The process conditions for analysis include the clamping force pc, the boost speed ν and the pressure pp of the pressure die, the friction coefficient f between wiper-bend die and tube, and the number n of flexible cores. The boost speed and the pressure were analyzed together. According to the actual situation, the fluctuation ranges of parameters are selected as shown in Table 2.

Table 2 Range of process parameters for analysis

3.2 Analysis on variation trends of springback and section deformation with process parameters

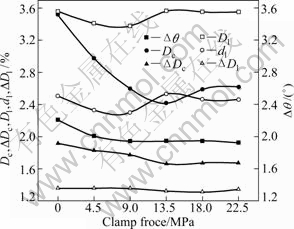

3.2.1 Variation trends of springback and section deformation with clamp force

Figure 7 shows variation trends of the springback angle ?θ, the cross-section distortion Dc, the longitudinal-section ovalization Dl and dl, the reduction of cross-section distortion ?Dc caused by springback and the increment of ovalization ?Dl caused by springback with clamp force. It can be seen that Dc decreases first then increases with increasing the clamp force; the clamp force has a little influence on Dl, dl and ΔDl; both Δθ and ΔDc decrease with the increase of the clamp force.

Fig. 7 Impact of clamp force on springback and section deformation

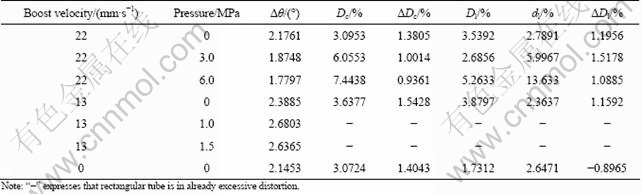

3.2.2 Variation trends of springback and section deformation with booster velocity and pressure

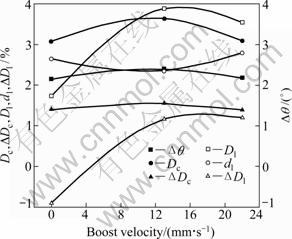

The effects of boost velocity and pressure on springback angle and section deformation are shown in Table 3, from which it can be seen that the process parameters of pressure of 1.0 MPa and 1.5 MPa make the bending tube excessively distort when the boost velocity is 13 mm/s. So the two process parameters are excluded from the study scope. Figure 8 shows the variation trends of the springback angle and section deformation with the boost velocity. Figure 8 shows that Δθ, Dc, Dl, ΔDc and ΔDl increase first then decrease as the boost velocity increases; dl decreases first then increases with the increase of booster velocity, which is opposite with all of the above.

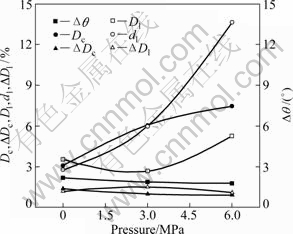

Figure 9 shows the variation trends of the springback angle and section deformation with the pressure. Form Fig. 9 it can be seen that both Dc and dl increase as the pressure increases; Dl decreases first then increases with the pressure, which is opposite with Dc and dl; ?θ and ?Dc decrease with the increase of pressure; ?Dl keeps little change.

Table 3 Impact of boost velocity and pressure on springback and section deformation

Fig. 8 Impact of boost velocity on springback and section deformation

Fig. 9 Impact of pressure on springback and section deformation

3.2.3 Variation trends of springback and section deformation with friction coefficient between wiper-bend die and tube

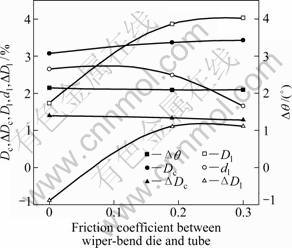

Figure 10 shows the effects of friction coefficient between wiper-bend die and tube on springback angle and section deformation. It can be seen that: Dc, Dl and ?Dl keep increasing with the increase of friction coefficient; dl decreases with the increase of friction coefficient, which is just opposite with Dc and Dl; the variation trends of both ?θ and ?Dc are downward.

Fig. 10 Impact of friction coefficient between wiper-bend die and tube on springback and section deformation

3.2.4 Variation trends of springback and section deformation with number of cores

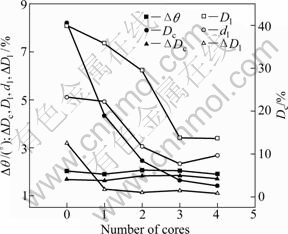

Figure 11 shows the variation trends of springback and section deformation with the number of cores. From Fig. 11 it can be seen that Dc is much larger than others, so it is shown by using the coordinate of right side; Dc, Dl, dl and ?Dl decrease with the increase of the number of cores; ?θ and ?Dc have little change.

Fig. 11 Impact of number of cores on springback and ovalization

In sum, it can be concluded that the variation trends of springback with process parameters are usually contrary to the cross-section distortion or the longitudinal-section ovalization. Besides, the ovalization trend of inner flange and outer flange are sometimes contrary to each other, so that how to control springback and section deformation by using the process parameters is a large difficulty for the rotary-draw bending rectangular tube. The variation trends of ?Dc and ?θ are the same. This is to say the reduction of cross-section distortion is decided mainly by the magnitude of springback, and the larger the springback, the more positive its effect on cross-section distortion. The variation trend of ?Dl is always concordant with Dl. It can be considered the magnitude of outer flange ovalization has more effects on its increment than the springback.

3.2.5 Effect of springback on section deformation

The average values of ?Dc and ?Dl are shown in Table 4, which were obtained under all of the process conditions respectively. It can be seen the springback makes a maximum reduction on cross-section distortion by 38.30%, yet it increases the longitudinal-section ovalization by 27.70% in maximum.

Table 4 Average values of ?Dc and ?Dl

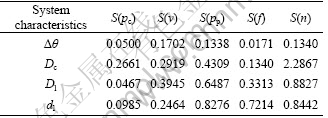

3.3 Sensitivity analysis for springback and section deformation

The springback angle and cross-section deformation do not have the same dimension. Thus the effects of the process parameters on them cannot be compared directly. But the sensitivity analysis method can make a comparison between them due to the dimensionless processing in analysis.

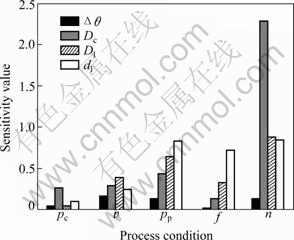

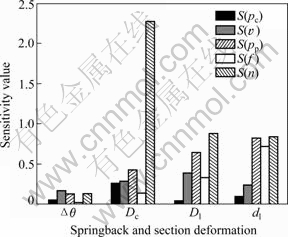

The sensitivity values Sk of springback angle and section deformation are obtained by using Eq. (4), as shown in Table 5. To get a more direct analysis, the sensitivity values in Table 5 are further expressed in Fig. 12 and Fig. 13.

There are five groups of data in Fig. 12, and all of them were obtained based on the column data in Table 5. So Fig. 12 shows the sensitivity comparison between springback and cross-section deformation to the process parameters under the same process conditions. According to their sensitivity values it can be concluded that the clamp force has the greatest impact on cross-section distortion, while it has a little impact on springback. The boost velocity of pressure die has the greatest impact on longitudinal-section ovalization of outer flange, and its effect on springback is also large enough. The pressure of pressure die has the greatest impact on longitudinal- section ovalization of inner flange, yet its effect on springback also should be considered. The friction coefficient between wiper-bend die and tube has the greatest impact on longitudinal-section ovalization of inner flange, while it has little impact on springback. The number of cores has the greatest impact on cross-section distortion.

There are four groups of data in Fig. 13, and all of them were obtained based on the row data in Table 5. So Fig. 13 shows the springback sensitivity and the section deformation sensitivity under the different process conditions. Two results can be obtained: the cross-section distortion has the highest sensitivity to process parameters, the next are the inner flange ovalization and the outer flange ovalization, while springback has the minimum sensitivity. The most sensitive process conditions for springback angle are the boost speed and the pressure, and the most sensitive process condition for section deformation is the number of cores. The clamp force has the least influence on both springback and section deformation.

Table 5 Sensitivity of springback and section deformation for process parameters

Fig. 12 Sensitivity comparison between springback and section deformation under same process conditions

Fig. 13 Sensitivity of springback and section deformation under different process conditions

4 Conclusions

1) Section deformation includes not only the cross-section distortion but also the longitudinal-section ovalization of inner flange and outer flange. The variation trends of them are always opposite with each other, which leads to difficulty to control section deformation by using process parameters.

2) The variation trends of springback are always inconsistent with the cross-section distortion or the longitudinal-section ovalization. The springback makes a maximum reduction in cross-section distortion by 38.30%, yet it increases the longitudinal-section ovalization by 27.70% in maximum.

3) When the clamp force, the boost speed and the pressure of pressure die are utilized to control section deformation, the effects of these process parameters on springback should be considered, due to the fact that the sensitivity of springback to these process parameters is large enough.

4) When the process conditions are utilized to control springback, the effects of these process parameters on section deformation should be always considered for the sensitivity of section deformation to these process parameters is always larger than that of springback.

References

[1] LI H, YANG H, YAN J, ZHAN M. Numerical study on deformation behaviors of thin-walled tube NC bending with large diameter and small bending radius [J]. Computational Materials Science, 2009, 45: 921-934.

[2] YANG H, LI H, ZHAN M. Friction role in bending behaviors of thin-walled tube in rotary-draw-bending under small bending radii [J]. Journal of Materials Processing Technology, 2010, 210: 2273-2284.

[3] MEINDERS T, KONTER A W A, MEIJERS S E, ATZEMA E H, KAPPERT H. A sensitivity analysis on the springback behavior of the unconstrained bending problem [J]. International Journal of Forming Processes, 2006, 9(3): 365-402.

[4] PALANISWAMY H, NGAILE G, ALTAN T. Optimization of blank dimensions to reduce springback in the ?exforming process [J]. Journal of Materials Processing Technology, 2004, 146: 28-34.

[5] ZHANG Ke, ZANG Shun-lai, GUO Cheng. Parameters sensitivity analysis of sheet bending based on numerical simulation [J]. Forging & Stamping Technology, 2007, 32(2): 126-129. (in Chinese)

[6] CLAUSEN A H, HOPPERSTAD O S, LANGSETH M. Sensitivity of model parameters in stretch bending of aluminium extrusions [J]. International Journal of Mechanical Sciences, 2001, 43: 427-453.

[7] ZHANG Jin, LIU Yu-li, ZHAO Gang-yao, YANG He. Influence of material parameters on rectangular tube cross section deformation in rotary-draw bending process [J]. Hot Working Technology, 2009, 38(13): 1-7. (in Chinese)

[8] ZHAO Gang-yao, LIU Yu-li, YANG He, LU Cai-hong. Cross-sectional distortion behaviors of thin-walled rectangular tube in rotary-draw bending process [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(3): 484-489.

[9] PAULSEN F, WELO T. Cross-sectional deformations of rectangular hollow sections in bending: Part II—Analytical models [J]. International Journal of Mechanical Sciences, 2001, 43: 131-152.

[10] MILLER J E, KYRIAKIDS S, CORONA E. On bend-stretch forming of aluminum extruded tubes II—Analysis [J]. International Journal of Mechanical Sciences, 2001, 43: 1319-1338.

[11] ZHU H, STELSON K A. Three-dimensional tube geometry control for rotary draw tube bending, Part1: Bend angle and overall tube geometry control [J]. Journal of Manufacturing Science and Engineering, 2001, 123: 258-265.

[12] LI Jia-jia, LIU Yu-li, ZHAO Gang-yao, YANG He. Study on significant influence of process parameters on wrinkling of rotary-draw bending formation of thin walled rectangular tube [J]. Hot Working Technology, 2010, 39(13): 77-80. (in Chinese)

[13] LIU Y F, E D X. Effects of cross-sectional ovalization on springback and strain distribution of circular tubes under bending [J]. Journal of Materials Engineering and Performance, 2011, 20: 1-9.

[14] ZHAN M, YANG H, HUANG L. A numerical-analytic method for quickly predicting springback of numerical control bending of thin-walled tube [J]. Journal of Materials Science and Technology, 2006, 22: 713-720.

[15] GU R J, YANG H, ZHAN M, LI H, LI H W. Research on the springback of thin-walled tube NC bending based on the numerical simulation of the whole process [J]. Computational Materials Science, 2008, 42: 537-549.

[16] MEINDERS T, BURCHITZ I A, BONTE M H A, LINGBEEK R A. Numerical product design: Springback prediction, compensation and optimization [J]. International Journal of Machine Tools and Manufacture, 2008, 48: 499-514.

[17] REN S L, LAI Y N, WU G F, GU J T, LI Z L. Intelligent prediction of process parameters for cold bending [J]. Advanced Materials Research, 2011, 154-155: 74-78.

[18] CHEN Li-zhou. Robust design [M]. Beijing: China Machine Press, 2000: 11-15. (in Chinese)

[19] ZHANG Guang, ZHU Wei-shen. Parameter sensitivity analysis and optimizing for test programs [J]. Rock and Soil Mechanics, 1993, 14(1): 51-58. (in Chinese)

[20] ZHAO G Y, LIU Y L, YANG H, LU C H, GU R J. Three-dimensional finite-elements modeling and simulation of rotary-draw bending process for thin-walled rectangular tube [J]. Materials Science and Engineering A, 2009, 499: 257-261.

[21] LI K P, CARDEN W P, WAGONER R H. Simulation of springback [J]. International Journal of Mechanical Sciences, 2002, 44: 103-122.

朱英霞,刘郁丽,杨 合

西北工业大学 材料科学与工程学院,凝固技术国家重点实验室,西安 710072

摘 要:为了研究工艺参数对回弹和截面畸变的作用,结合多参数敏感性分析法和回弹/截面畸变预测三维有限元模型,建立敏感性分析系统模型,并利用此模型研究回弹和截面畸变对工艺参数的敏感性。结果表明:回弹最敏感的工艺条件是助推速度和助推压力,截面变形最敏感的工艺条件是芯头的个数;当夹紧力、助推速度与助推压力被用来控制绕弯过程的截面畸变时,必须同时考虑这些参数对回弹的影响;在任何情况下利用工艺参数控制绕弯过程回弹都必须同时考虑截面畸变。

关键词:H96薄壁矩形管;绕弯成形;敏感性分析;回弹;截面畸变

(Edited by LI Xiang-qun)

Foundation item: Project (50975235) supported by the National Natural Science Foundation of China; Project (B08040) supported by the 111 Project

Corresponding author: LIU Yu-li; Tel: +86-29-88460212-803; Fax: +86-29-88495632; E-mail: lyl@nwpu.edu.cn; xia166109@163.com

DOI: 10.1016/S1003-6326(11)61454-4