Wear resistance of ceramic coating on

AZ91 magnesium alloy by micro-arc oxidation

ZHAO Hui(赵 晖)1, 2, LIU Zheng(刘 正)1, CHEN Li-jia(陈立佳)1, CHEN Ji(陈 吉) 3, HAN Zhong(韩 忠)3

1. College of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110023, China;

2. College of Materials Science and Engineering, Shenyang Ligong University, Shenyang 110168, China;

3. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China

Received 25 September 2006; accepted 7 Oct 2006

Abstract: The ceramic coating formed on AZ91 magnesium alloy by micro-arc oxidation (MAO) was characterized. The results show that the ceramic coating(3.4-23 μm in thickness)on the surface of AZ91 alloy was attained under different micro-arc oxidation treatment conditions, which consist mainly of MgO, Mg2SiO4 and MgSiO3 phases. Nano-hardness in a cross-sectional specimen was determined by nano-indentation experiment. The MAO coatings exhibit higher hardness than the substrate. Dry sliding wear tests for the MAO coatings and AZ91 alloy were also carried out using an oscillating friction and wear tester in a ball-on-disc contact configuration. The wear resistance of the MAO coatings is improved respectively under different treatment time as a result of different structures of ceramic coatings formed on AZ91 alloy.

Key words: AZ91 alloy; magnesium alloy; ceramic coating micro-arc oxidation; wear resistance

1 Introduction

Many researches have been focused on magnesium and magnesium alloys in recent years due to their low density, high specific strength and great machinability[1], but they are sometimes limited in applications because of their moderately poor corrosion resistance and tribological properties[2-3]. Therefore, the surface modification techniques of Mg alloys have been paid much attention. As an example, micro-arc oxidation (MAO), characterized by higher voltage and current than anodic oxidation and spark discharge at the sample surface, has been successfully developed, with which a plasma environment is generated and a ceramic coating can thus be synthesized on the metal surface through plasma chemical interactions[4-5]. The tribological performance of ultra-hard ceramic coatings obtained through microarc oxidation has been paid more attention in recent years[6]. Most investigation was focused on aluminum alloy[7-10] and titanium alloy[11].

At present, the most commonly used magnesium alloy is AZ91 alloy which has good castability[12]. In certain applications, such AZ91 alloy used for automotive components of brakes and some parts in engine is subjected to sliding motion. Sliding wear is also an important consideration in materials processing by rolling, extrusion, forging etc. [13]. Therefore, the tribological behavior of micro-arc oxidized ceramic coatings on magnesium alloy was investigated recently[14, 15], but it is less common.

The objective of this work is to evaluate the wear resistance of ceramic coatings on the AZ91 alloy obtained under different micro-arc oxidation treatment conditions.

2 Experimental

The die cast AZ91 magnesium alloy plates with size of 100 mm×45 mm×3 mm were used as the substrate. The MAO coatings were prepared with 10 kW DC pulse microarc oxidation system. An aqueous solution, comprising mainly Na2SiO3 and some other substances to adjust its alkalinity and increase the electric conductivity, was used as the electrolyte. The temperature of the solution was controlled below 40 ℃ and the oxidation time was 30 s, 2 min, 6 min and 10 min, respectively. The thickness of the coatings was measured using a coating thickness gauge. SEM was used to investigate the cross-section of the specimen. Dmax diffractometer was used to characterize the phase constituent of the coatings.

In order to determine the nano-hardness in a cross-sectional specimen, the nano-indentation experiments were performed using Hysitron Triboindenter with a diamond pyramid indenter whose tip radius is 160 nm. The maximum load in this experiment was 9 mN. At the maximum load, a dwell period of 5s was introduced before unloading.

Sliding wear tests for the MAO coatings on AZ91 alloy under different treated time were conducted using an Optimol SRV III oscillating friction and wear tester in a ball-on-disc contact configuration. The wear samples of the MAO coatings, were cut from the treated specimens into discs with dimension of 8 mm×8 mm×3 mm and slid against 100Cr6 steel balls with a diameter of 10 mm and a hardness of HRC 60. The tests were carried out at 25oC and humidity of 45% with no lubricant. During sliding wear tests, an oscillating stroke of 2 mm, a normal load of 5 N, an oscillating frequency of 5 Hz and a duration of 20 min were imposed. The friction coefficients were continuously recorded automatically. Following the wear tests, the profiles of the worn surfaces were measured using a surface profilometer to determine the wear volume, which was expressed as V=AL (where A refers to the worn area determined by its profile, L is the oscillating stroke).

3 Results and discussion

3.1 Growth characteristic of MAO coatings

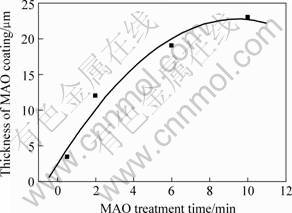

The variation of the thickness of the MAO coatings

on AZ91 alloy is shown in Fig.1 as a function of oxidation time. With increasing oxidation time, the thickness of the coatings increases. An approximately polynomial growth of the coatings was observed. The growth rate of the coatings is very fast at the initial stage, and the coating thickness can reach 12 μm at 2 min. However, in the period of 6 to 10 min, the thickness only goes up from 19 to 23 μm.

Fig.1 Variation of thickness of MAO coatings on AZ91 alloy with oxidation time

3.2 Microstructure and hardness

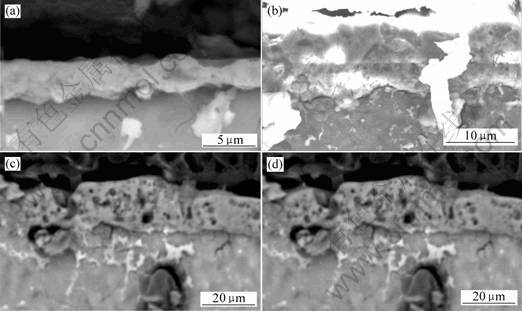

Fig.2 shows the SEM images of the cross section for the AZ91 alloys subjected to the MAO treatment for different periods. It can be noted that all of the MAO coatings have good adhesion to the AZ91 alloy substrate. When the oxidation time is shorter, the coatings are much thinner and much more compact, as shown in Figs.2(a) and (b). With the increase of oxidation time, the coatings become thicker, but are characterized by micropores with different sizes. The porous feature strongly depends on the discharging nature involved in MAO treating[5]. At the beginning, uniformly dispersed micro-discharge is easier to occur on the surface of alloy, so that the size of micropores is significantly small, and the coatings are compact. With increasing oxidation time, the voltage increases, which will lead to an enlargement of the pores, and the coatings become porous and loose.

Fig.2 SEM images of cross-section for AZ91 alloy subjected to MAO treatment for 30 s(a), 2 min(b), 6 min(c) and 10 min(d)

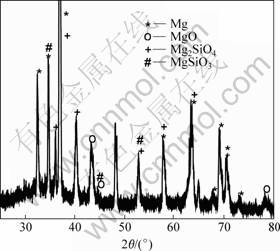

Fig.3 shows the XRD pattern of the coating on AZ91 alloy after MAO treating for 10 min. It can be determined that the MAO coating is composed of MgO, Mg2SiO4, MgSiO3 and Mg substrate.

Fig.3 XRD pattern of MAO coating on AZ91 alloy after treatment for 10 min

The cross-sectional samples of the AZ91 alloy subjected to the MAO treatment for 2 and 10 min were used for nano-indentation test. Fig.4 shows the distri-

bution profiles of nano-hardness under the load of 9 mN. There is an obvious enhancement of nano-hardness for the MAO coatings, compared with the AZ91 substrate. It is worthy of notice that the coating subjected to MAO treatment for 2 min has higher hardness than the one after MAO treating for 10 min, even though it is thinner. This may be correlated to compactness of the MAO coatings.

Fig.4 Distribution of nano-hardness along cross-section of MAO coatings on AZ91 alloy under 9 mN

3.3 Friction and wear behaviors

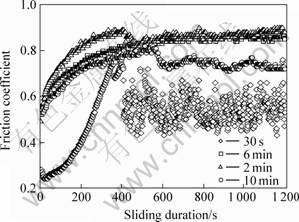

Fig.5 shows the relation between the friction coefficient and sliding time for the MAO coatings against 100Cr6 steel ball under dry friction condition. Usually, the friction coefficient of ceramic coating is much higher than that of the Mg alloy[2]. For the coating subjected to MAO treatment of 30 s, the friction coefficient increases with increasing sliding time, and decreases obviously to a value of the AZ91 alloy (about 0.5) when the thinner MAO coating (with a thickness of 3.4 μm) is worn off. For the coating subjected to MAO treatment of 2 and 6 min, the friction coefficient increases with the increase of sliding time, and maintains at a stable value of about 0.85, which is the friction coefficient of ceramic coating. However, for the coating subjected to MAO treatment of 10 min, the friction coefficient increases with the increase of sliding time, and decreases obviously to a value of about 0.75 just close to that of the coating after MAO treating for 30 s.

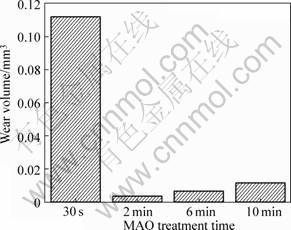

Fig.6 shows the wear volume of the coatings sub- jected to MAO treatment for different time under a load 5 N and a wear duration of 20 min. For the coating after MAO treating for 30 s, the wear volume is much higher. Because the coating is very thin, it can be worn off within very short time, so that the wear volume of the coating is near to that of the AZ91 alloy. The wear volume of the other MAO coatings shows obviously low wear volume, which is only one-tenth to one-thirtieth as large as that of the coating subjected to MAO treatment of 30 s. This indicates that the MAO coating on the AZ91 alloy exhibits an excellent load-bearing ability. It implies that the wear resistance of the AZ91 alloy can be enhanced by MAO treatment.

Fig.5 Variation of friction coefficient with sliding time for MAO coatings after different treatment time

Fig.6 Wear volume of MAO coatings after different treatment time

Fig.7 shows the profiles of wear scars for the MAO coatings under a load of 5 N and a wear duration of 20 min. It is obvious that the depth and the cross section area of the wear scars on the MAO coatings subjected to MAO treatments of 2, 6, 10 min are much smaller than those of the coating after MAO treating for 30 s. Table 1 lists the characteristic and the wear resistance of the MAO coatings on the AZ91 alloy. The wear depth and wear volume of the coating subjected to MAO treatment of 30 s are the biggest as a result the MAO thickness of the coating is very small. However, the coating after a MAO treatment for 2 min shows the smallest wear depth and the wear volume. The wear depth and the wear volume of the coatings subjected to MAO treatment for 6 and 10 min are much lower than those of the coating after a MAO treatment of 30 s. It can be indicated that the wear depth of the coatings subjected to MAO treatment for 2 and 6 min is always less than the thick- ness of the MAO coatings, which leads to their good wear resistance. It can also be proved that the MAO coatings on AZ91 alloy have an excellent load-bearing capacity. Especially, even though the coating after a MAO treatment of 2 min is not very thick, it exhibits the best wear resistance, which is attributed to higher hardness as a result of compact microstructure.

Table 1 Characteristic and wear resistance of MAO coatings on AZ91 alloy

Fig.7 Profiles of wear scars of coatings on AZ91 alloy after different MAO treatment time(In each square the horizontal direction presents 100 μm and the vertical direction present 10 μm): (a) 30s; (b) 2 min; (c) 6 min; (d) 10 min

4 Conclusions

1) The ceramic layer formed on the surface of the AZ91 alloy is obtained by different micro-arc oxidation treatment conditions, which consists mainly of MgO, Mg2SiO4 and MgSiO3 phases.

2) The thickness (3.4-23 μm) of MAO coatings on the AZ91 alloy increases with the increase of MAO treating time.

3) The nano-hardness of MAO coatings shows higher hardness than that of AZ91 alloy substrate.

4) The wear resistance of the AZ91 alloy can be enhanced under different MAO treatment time as a result of different structure of ceramic coatings formed on AZ91 alloy.

References

[1] KOJIMA Y. Platform science and technology for advanced magnesium alloys[J]. Mater Sci Forum, 2000, 350-3: 3-17.

[2] LIANG J, GUO B G, TIAN J, LIU H W, ZHOU J F, XU T. Effect of potassium fluoride in electrolytic solution on the structure and properties of microarc oxidation coatings on magnesium alloy[J]. Applied Surface Science, 2005, 252(2): 345-351.

[3] GRAY J E, LUAN B. Protective coatings on magnesium and its alloys—A critical review[J]. J Alloys Compd, 2002, 336(1-2): 88-113.

[4] YRROKHIN A L, NIE X, LEYLAND A, MATTHEWS A, DOWEY S J. Plasma electrolysis for surface engineering[J]. Surf Coat Technol, 1999, 122(2/3): 73-93.

[5] YRROKHIN A L, LYUBIMOV V V, ASHITOV R V. Phase formation in ceramic coating during plasma electrolytic oxidation of aluminium alloys[J]. Ceram Int, 1998, 24(1): 1-6.

[6] KRISHNA L R, SOMATAJU K C, SUNDARARAJAN G. The tribological performance of ultra-hard ceramic composite coatings obtained through microarc oxidation[J]. Surface and Coating Technology, 2003, 163-164: 484-490.

[7] WEI Tong-bo, TIAN Jun, YAN Feng-yuan. Structure and wear resistance of ceramic layer on LY12 Al alloy by micro-arc oxidation[J]. Chinese Journal of Materials Research, 2004, 18(2): 161-166.(in Chinese)

[8] VOEVODIN A A, YEROKHIN A L, LYUBIMOV V V, DONLEY M S, ZABINSKI J S. Characterization of wear protective Al-Si-O coatings formed on Al-based alloys by micro-arc oxidation discharge treatment[J]. Surf Coat Technol, 1996, 86/87: 737-743.

[9] WEI T B, YAN F Y, TIAN J. Characterization and wear- and corrosion-resistance of microarc oxidation ceramic coatings on aluminum alloy[J].J Alloys Compd, 2005, 389 (1/2): 169-176.

[10] XUE W B, DU J C, WU X L, LAI Y C. Tribological behavior of microarc oxidation coatings on aluminum alloy[J].ISIJ International, 2006, 46 (2): 287-291.

[11] WANG Y M, JIANG B L, GUO L X, LEI T C. Controlled synthesis of microarc oxidation coating on Ti6Al4V alloy and its antifriction properties[J]. Mater Sci Technol, 2004, 20(12): 1590-1594.

[12] HU H. Squeeze casting of magnesium alloys and their composites[J]. J Mater Sci, 1998, 33 (6): 1579-1589.

[13] CHEN H, ALPAS A.T. Sliding wear map for the magnesium alloy Mg-9Al-0.9 Zn (AZ91)[J]. Wear, 2000, 246(1/2): 106-116.

[14] WANG Ji-hui, YANG Jing. Properties of microarc oxidation coating of magnesium alloy oxidized in silicate system[J]. Transactions of Materials and Heat Treatment, 2006, 27(3): 95-99.

[15] CHEN F, ZHOU H, YAO B, YANG Y G, LU J X, LU F X.. Study on the tribological behavior of micro-arc oxidized ceramic coatings on magnesium alloy surfaces[J].Rare Metal Materials and Engineering, 2006, 35(5): 806-809.

(Edited by LI Xiang-qun)

Foundation item: Project (5133001B) supported by the Ministry of Science and Technology of China; Project(1053125-1-09) supported by the Bureau of Science and Technology of Shenyang, China

Corresponding author: ZHAO Hui; Tel: +86-24-24682056; E-mail: zhaohui_1968@sina.com