Topological dependence of mechanical responses of solidification microstructures in aluminum brazed joints

来源期刊:中国有色金属学报(英文版)2003年第6期

论文作者:高峰 钱乙余 D. P. Sekulic 马鑫 F. Yoshida

文章页码:1296 - 1300

Key words:nano-indentation; solidification microstructure; aluminum brazing; mechanical response

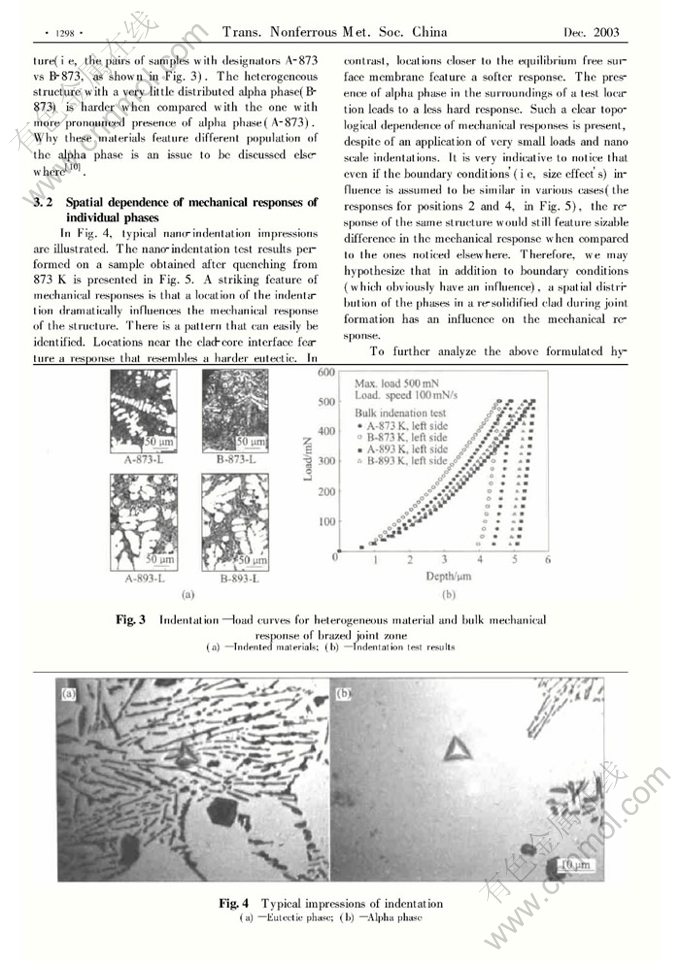

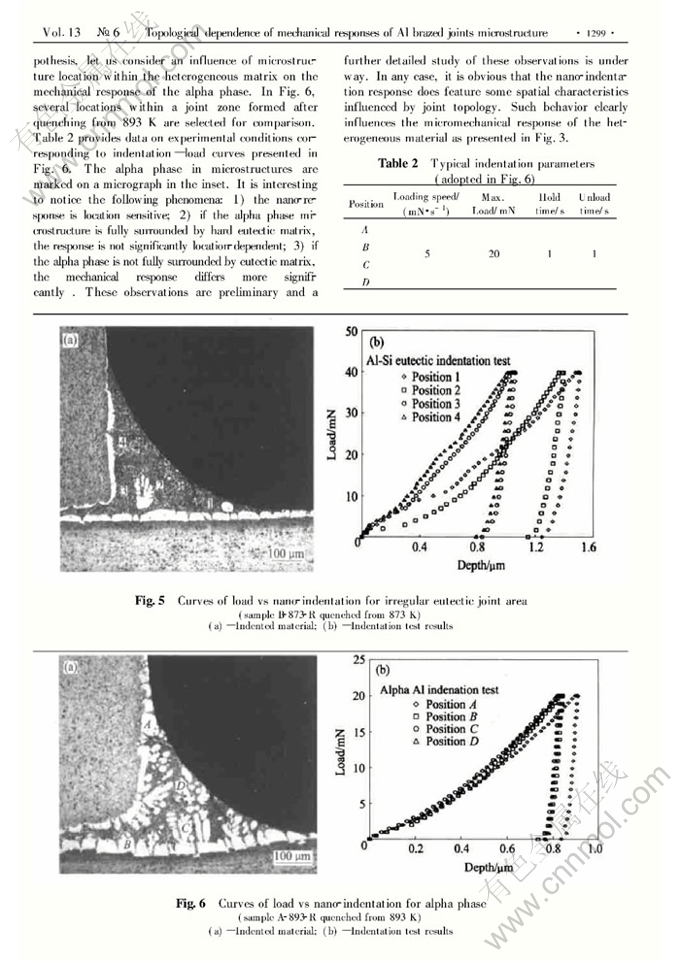

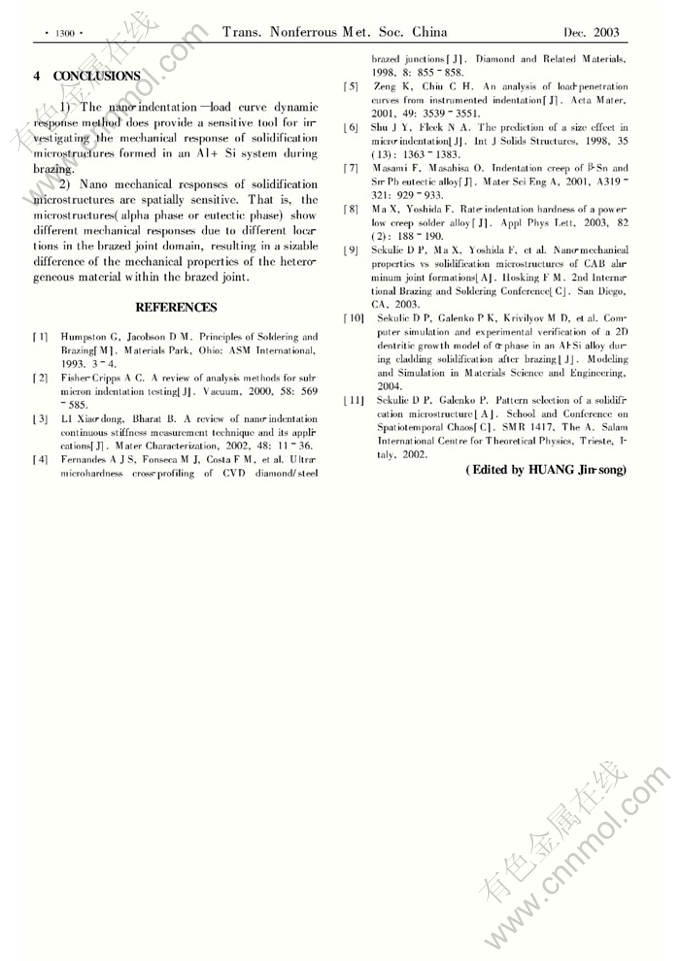

Abstract: The main objective is to provide an evidence of spatial dependence of mechanical responses of a heterogeneous aluminum brazed joint re-solidified clad, and to confirm a sufficient sensitivity of a nano-indentation—load curve method for identifying the dependence. Topological features of a network of solidification microstructures(α phase and eutectic), formed during quench in a brazing process of aluminum alloy, influence significantly dynamic mechanical responses of resulting heterogeneous material. Nano/micro indentation depth vs load characteristics of differing phases suggest a spatially sensitive mechanical response of a re-solidified fillet in the joint zone. Hence, a spatial distribution, pattern formations and other morphological characteristics of microstructures have a direct impact on an ultimate joint integrity. Topology-induced variations of indentation—load curves was presented. A hypothesis involving microstructures spatial distribution vs mechanical response was formulated.