DOI: 10.11817/j.ysxb.1004.0609.2021-36432

热处理对Mg-6Zn-xCe合金组织与导热性能的影响

代晓腾,马鸣龙,李永军,袁家伟,石国梁

(有研工程技术研究院有限公司 有色金属材料制备加工国家重点实验室,北京 101499)

摘 要:利用扫描电镜(SEM)、能谱仪(EDS)、X射线衍射仪(XRD)、透射电镜(TEM)等分析实验手段研究热处理对Mg-6Zn-xCe合金微观组织的影响,同时利用激光热导仪测试不同热处理状态下该系列合金的热扩散系数,并计算合金的热导率,探讨组织变化对合金导热性能的影响规律。结果表明:铸态Mg-6Zn合金主要由α-Mg相及Mg7Zn3相组成,共晶组织随着Ce含量的增加而不断增多;经过固溶处理,合金Mg7Zn3相基本回溶,Mg-Ce-Zn三元相发生转变,由Ce5(Mg,Zn)41相转变为Mg17Ce2相,呈颗粒状,断续分布于晶界,同一成分合金固溶后,基体中Zn含量明显升高;时效处理后,基体中过饱和的Zn原子以MgZn和MgZn2相形式析出;不同热处理状态合金热导率由大到小依次为时效态、铸态、固溶态,随Ce含量升高,不同状态的合金热导率呈下降趋势。

关键词:Mg-Zn-Ce合金;热处理;微观组织;热导率

文章编号:1004-0609(2021)-03-0639-10 中图分类号:TF11.31 文献标志码:A

引文格式:代晓腾, 马鸣龙, 李永军, 等. 热处理对Mg-6Zn-xCe合金组织与导热性能的影响[J]. 中国有色金属学报, 2021, 31(3): 639-648. DOI: 10.11817/j.ysxb.1004.0609.2021-36432

DAI Xiao-teng, MA Ming-long, LI Yong-jun, et al. Effect of heat treatment on microstructure and thermal conductivity of Mg-6Zn-xCe alloy[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 639-648. DOI: 10.11817/j.ysxb.1004.0609.2021-36432

随着电子通讯、航空航天事业的不断发展,高精密、大功率新型装备的应用日益频繁,为了满足装备小型化的需求,大多部件采用集成化设计,随之带来了散热困难的问题,另外,装备轻量化是航空航天领域发展的趋势,需要发展具有高导热特性的新型轻量化材料,以提高和保证产品的寿命及工作稳定性,而高导热镁合金能够同时满足轻量化与高导热的需求,因此成为当前镁合金领域的研发热点之一[1-3]。

Mg-Zn系合金是当前重点研发的导热镁合金体系之一,该系列合金的典型优势之一是时效后力学性能与导热性能均有显著提高[4-8],合金的时效析出序列为:SSSS(过饱和固溶体)→G.P.区→  (MgZn2)→

(MgZn2)→ (MgZn2)→β(MgZn),其中,G.P.区和β′相与基体共格。合金中析出相与基体的点阵总会有一定的差别,那么要产生共格关系,在界面附近必然产生弹性应变,因此,与非共格的β相相比,G.P.区和β′相对界面附近基体的晶格影响较大,晶格畸变程度较大,对电子的散射作用强,不利于电子的传导,对导热性能的不利影响较大[9-10]。因此,单纯从导热方面考虑,析出相为β相时,合金可能拥有更高的导热性能。通过改变Mg-Zn系合金的时效工艺,可以实现对析出相的尺寸及分布进行调 控[11],协调合金的力学性能与导热性能。

(MgZn2)→β(MgZn),其中,G.P.区和β′相与基体共格。合金中析出相与基体的点阵总会有一定的差别,那么要产生共格关系,在界面附近必然产生弹性应变,因此,与非共格的β相相比,G.P.区和β′相对界面附近基体的晶格影响较大,晶格畸变程度较大,对电子的散射作用强,不利于电子的传导,对导热性能的不利影响较大[9-10]。因此,单纯从导热方面考虑,析出相为β相时,合金可能拥有更高的导热性能。通过改变Mg-Zn系合金的时效工艺,可以实现对析出相的尺寸及分布进行调 控[11],协调合金的力学性能与导热性能。

Mg-Zn系相图和相变过程复杂,工艺性较强,其中热处理方案是关键的影响因素之一,对其深入理解有助于协调合金的微观组织及性能,充分发挥Mg-Zn合金的优势,基于此,本文以Mg-6Zn-xCe合金为研究对象,研究了不同热处理方式对合金微观组织及导热性能的影响规律,希望进一步扩大及发展导热镁合金的体系,为最终产品的应用提供必要的理论基础及实验数据[12]。

1 实验

本研究中所用合金原材料为纯镁(99.98%)、纯锌(99.98%)和纯铈(99.99%),采用中频感应炉在氩气和四氟乙烷(体积比为20:1)保护气氛中加热熔炼。将纯镁投入到低碳钢制坩埚中加热至760 ℃,加入纯锌和纯铈并搅拌,持续加热至780 ℃,然后静置冷却至760 ℃,用d 64 mm×70 mm不锈钢取样器从熔体中心取样并进行快速冷却。采用电感耦合等离子体发射光谱仪(ICP-AES)对合金实际成分进行了测试,结果如表1所列,实测成分与设计值接近,满足实验需求。在不同成分Mg-6Zn-xCe合金(质量分数,%,下同)铸锭的中部1/2半径处取样,对试样进行(420 ℃,8 h)的固溶处理(水淬),随后对试样进行时效处理,处理温度160 ℃,保温时间2~48 h (水淬)。对不同热处理状态的合金进行组织分析与性能测试。X射线衍射分析在X-PertPro型多晶X射线衍射仪上进行,扫描范围10°~90°,靶材为铜靶;采用附带能谱仪的JSM-7001F型扫描电子显微镜观察合金背散射组织形貌并对合金进行能谱分析;透射电镜实验所用试样为d 3 mm×50 μm圆形薄片,实验前在Gatan model 691型离子减薄仪上进行离子减薄处理,利用Tecnai G2 F20-TWIN型高分辨透射电子显微镜观察合金的明场像和选区电子衍射花样;合金的热扩散系数在LFA-427型激光热导仪上进行,试样为d 12.7 mm×2.5 mm的圆片;按照GB/T 1423—1996测试试样的密度[13];用WD-Z型数字式涡流电导仪测试了不同状态下Mg-6Zn-xCe合金室温时的电导率。

2 结果与讨论

2.1 铸态Mg-6Zn-xCe合金微观组织

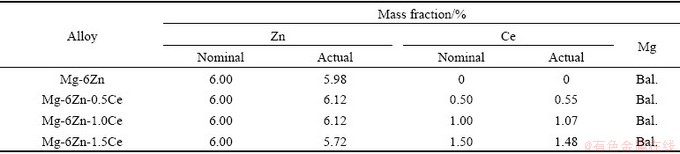

图1所示为铸态Mg-6Zn-xCe合金SEM背散射图像。由图1(a)可见,Mg-6Zn合金由α-Mg基体和分布于晶界的共晶组织组成,晶界处除了共晶组织之外,还偏聚着大量溶质元素。图1(b)、(c)和(d)为添加Ce元素的三元合金,由图可见,随着Ce含量的升高,共晶组织分布的连续性增强,形状逐渐向网状过渡,偏聚在晶界处的溶质元素逐渐减少。

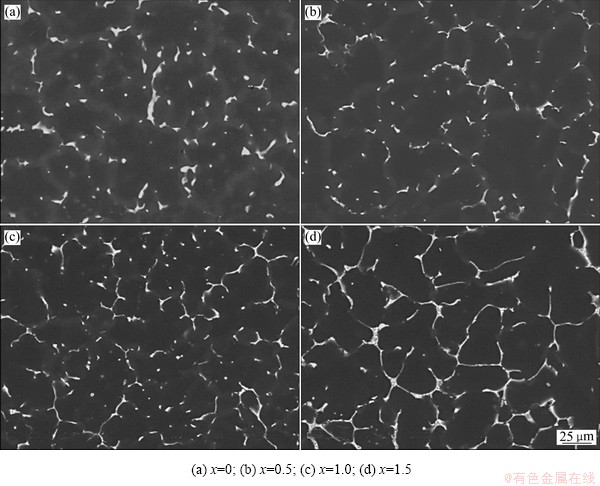

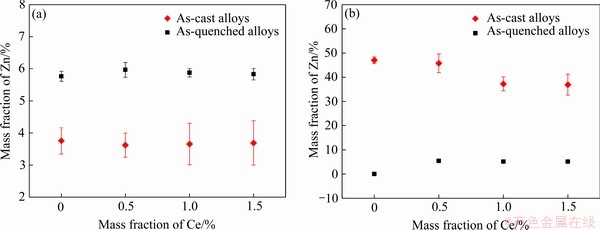

对铸态Mg-6Zn-xCe合金中的Zn元素进行能谱测试,并对测试结果进行统计,其结果如图2所示,Zn在基体和第二相中均有分布,且第二相中的Zn含量远高于基体中的Zn含量。

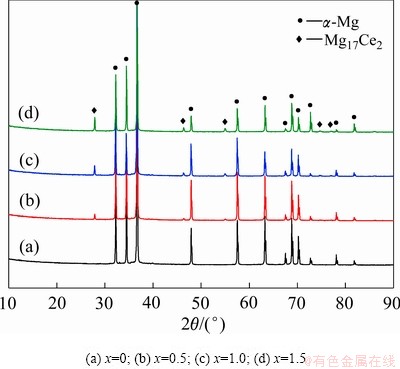

对铸态Mg-6Zn-xCe合金进行X射线衍射分析,其结果如图3所示,由Mg-6Zn合金的XRD谱可以看出,合金的主要相为α-Mg相和Mg7Zn3相。Mg-Zn-Ce三元合金中,随Ce含量增多,Mg7Zn3相衍射峰逐渐减弱,该相的形成受到抑制。除了α-Mg相和Mg7Zn3相,三种成分的Mg-Zn-Ce三元合金在相同的扫描角度出现了微弱的Ce5(Mg,Zn)41相衍射峰,且该衍射峰随Ce含量升高强度略有增加。

2.2 热处理对Mg-6Zn-xCe合金微观组织的影响

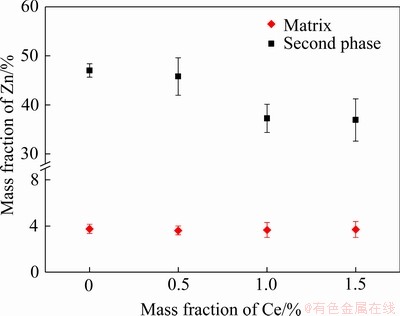

对铸态Mg-6Zn-xCe合金进行固溶处理,图4所示为固溶处理后合金的SEM背散射图像。

表1 合金设计成分与实测成分对比

Table 1 Comparison of nominal components and actual components of alloys

图1 铸态Mg-6Zn-xCe合金的SEM背散射图像

Fig. 1 SEM backscattered images of as-cast Mg-6Zn-xCe alloy

图2 铸态Mg-6Zn-xCe合金Zn含量

Fig. 2 Zn content of as-cast Mg-6Zn-xCe alloy

由图4(a)可见,Mg-Zn二元合金第二相在固溶处理后几乎完全消失,图4(b)、(c)和(d)中,随着Ce含量提高,合金中的未回溶相数量逐渐增多,但与铸态合金相比,相同成分的固溶态合金第二相体积分数明显减小,第二相形态发生明显变化,呈现颗粒状,断续分布于晶界。

图3 铸态Mg-6Zn-xCe合金XRD谱

Fig. 3 XRD patterns of as-cast Mg-6Zn-xCe alloy

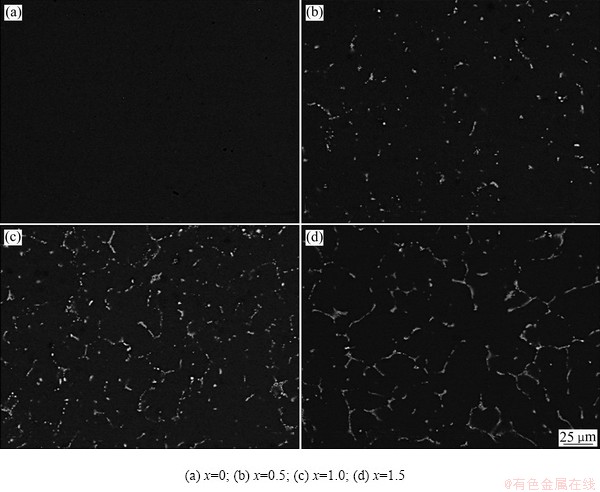

对固溶态Mg-6Zn-xCe合金中的Zn元素进行能谱测试并进行统计,将所得结果与铸态合金进行对比,其结果如图5所示。由图5可以发现,与铸态合金相比,固溶态合金基体中Zn含量升高,而第二相中的Zn含量大幅降低。经过固溶处理,第二相中Zn原子发生了明显回溶。

图4 固溶态Mg-6Zn-xCe合金SEM背散射图像

Fig. 4 SEM backscattered images of as-quenched Mg-6Zn-xCe alloy

图5 铸态和固溶态Mg-6Zn-xCe合金Zn含量能谱结果

Fig. 5 Test results of Zn content of matrix (a) and second phase (b) in as-cast and as-quenched Mg-6Zn-xCe alloys

图6所示为固溶态Mg-6Zn-xCe合金XRD谱。由图6可见,Mg-6Zn合金中仅存在α-Mg相衍射峰。添加Ce后,合金中出现Mg17Ce2相衍射峰。随着Ce含量升高,Mg17Ce2相衍射峰逐渐增强,合金中Mg17Ce2相含量增加。

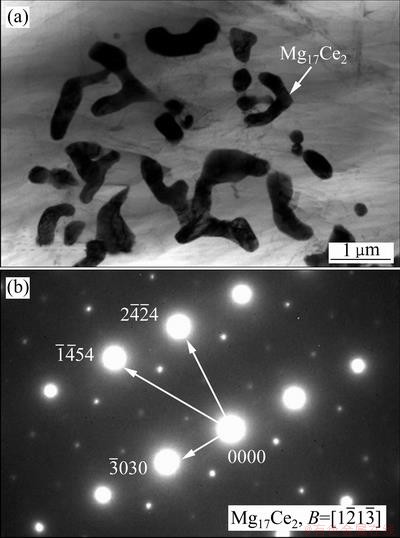

为了进一步分析确认固溶态含Ce合金中第二相的相种类,选取固溶态Mg-6Zn-1.0Ce合金进行透射电镜分析,其结果如图7所示。对图7(a)中第二相进行衍射花样标定,结果如图7(b)所示,该相具有六方结构特征,晶格常数a=1.025 nm,c=1.036 nm,与Mg17Ce2晶体结构相吻合,可以确定该相是Mg17Ce2相,即为固溶后未溶相。

图6 固溶态Mg-6Zn-xCe合金XRD谱

Fig. 6 XRD patterns of as-quenched Mg-6Zn-xCe alloy

图7 固溶态Mg-6Zn-1.0Ce合金TEM明场像和第二相衍射斑点

Fig. 7 TEM bright field image (a) and second phase diffraction spots (b) of as-quenched Mg-6Zn-1.0Ce alloy

将固溶态Mg-6Zn-xCe合金进行时效处理,对不同时效时间的Mg-6Zn-xCe合金进行电导率测试,用电导率随时效时间的变化规律来表征热导率的变化规律,以此来确定合金热导率达到终态所需时效时间,其结果如图8所示。由图8可见,随时效时间延长,Mg-6Zn-xCe合金电导率呈上升趋势,时效时间4~16 h的合金电导率随时效时间延长增长率最高,时效时间为16~30 h时,随时效时间延长,电导率增速放缓,时效时间超过30 h,合金电导率基本不再升高。Mg-Zn系合金时效析出序列为:SSSS→G.P.区→ →

→ →β,时效过程中同时存在基体中溶质原子析出与析出相转化两个过程,溶质原子析出对导热性能有积极影响。G.P.区、

→β,时效过程中同时存在基体中溶质原子析出与析出相转化两个过程,溶质原子析出对导热性能有积极影响。G.P.区、 相、

相、 相均为共格相,造成的基体晶格畸变程度较大,对合金导热性能的不利影响较大,而β相为非共格相,造成的基体晶格畸变程度较小,对合金导热性能的不利影响较小。当析出相由G.P.区、β′相转化为β相时,对合金热导性能的不利影响会有所降低,因此,当热导率不再随时效时间增加而增加时,说明基体中溶质原子已经达到了动态平衡。因此,下文对时效态合金的组织性能测试均选取导电性能相对较高的时效时间为48 h的合金。

相均为共格相,造成的基体晶格畸变程度较大,对合金导热性能的不利影响较大,而β相为非共格相,造成的基体晶格畸变程度较小,对合金导热性能的不利影响较小。当析出相由G.P.区、β′相转化为β相时,对合金热导性能的不利影响会有所降低,因此,当热导率不再随时效时间增加而增加时,说明基体中溶质原子已经达到了动态平衡。因此,下文对时效态合金的组织性能测试均选取导电性能相对较高的时效时间为48 h的合金。

图8 Mg-6Zn-xCe合金电导率随时效时间变化

Fig. 8 Electrical conductivity changes with aging time of Mg-6Zn-xCe alloy

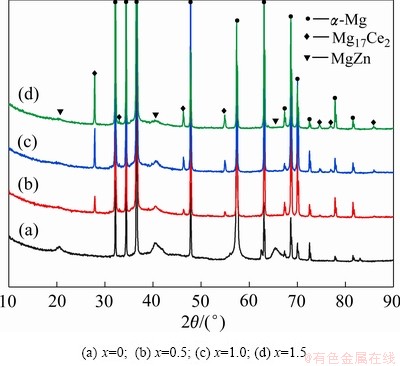

图9 时效态Mg-6Zn-xCe合金XRD谱

Fig. 9 XRD patterns of aged Mg-6Zn-xCe alloy

对时效态Mg-6Zn-xCe合金进行XRD分析,其结果如图9所示。与固溶态合金相比,时效态Mg-6Zn合金中出现了MgZn相衍射峰。含Ce合金中也出现MgZn相衍射峰,但衍射峰强度弱于Mg-6Zn合金,且随Ce含量升高,MgZn相衍射峰强度进一步减弱。除了MgZn相衍射峰,含Ce合金X射线衍射图与固溶态合金基本相同,存在α-Mg相和Mg17Ce2相,且随着合金中Ce含量升高,Mg17Ce2相衍射峰逐渐增强。

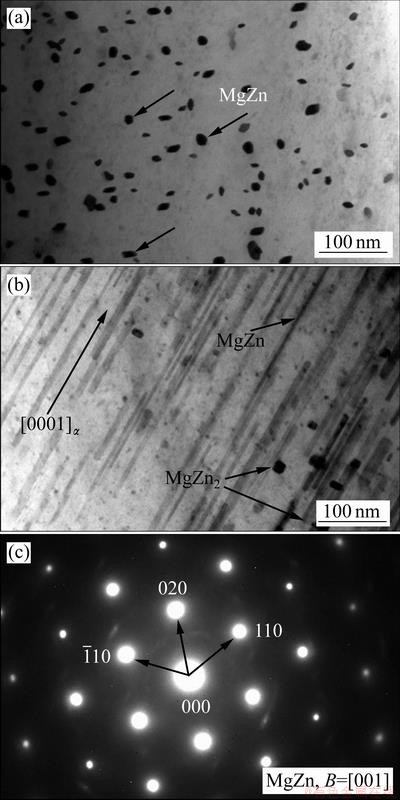

对Mg-6Zn-1.0Ce合金时效析出相进行透射电镜分析,结果如图10所示。当沿[0001]α方向观察时,析出相呈不规则的颗粒状,尺寸约10~30 nm,如图10(a)所示;当沿垂直于[0001]α方向观察时,析出相主要是沿[0001]α方向生长的杆状相,该相与图10(a)中颗粒状相为同一种相,对其进行衍射斑点标定,结果显示,该相为β相MgZn相,与图9所示XRD衍射标定结果一致。除了MgZn相,图10(b)中还存在少量沿(0001)α析出的盘状相,该相由于尺寸较小,数量较少,难以进行衍射花样标定。通过文献调研[14-15],发现该相与MgZn2相的尺寸、形状、生长方向等均相同,且盘状MgZn2相是Mg-Zn系合金中常见的析出相,因此,推测图10(b)中盘状相为MgZn2相。

2.3 Ce含量对Mg-6Zn-xCe合金导热性能的影响

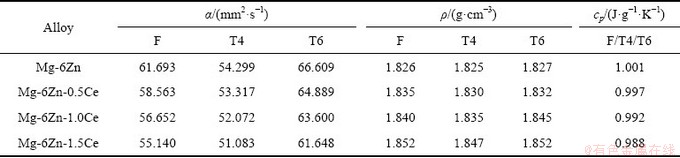

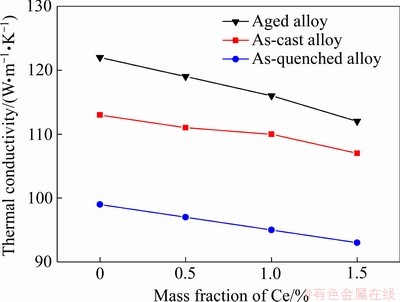

合金热导率利用闪光法测得。对Mg-6Zn-xCe合金热扩散系数、密度和比热容进行测试计算,其结果如表2所列。根据表2所得数据分别求得合金在铸态、固溶态、时效态下的室温热导率,如图11所示,3种状态合金热导率随Ce含量增加变化规律相同,Mg-6Zn合金室温热导率最高,添加Ce元素后,合金热导率降低,且Ce含量越高的合金室温热导率越低;相同成分合金室温热导率进行对比,时效态合金的最高,铸态合金的次之,固溶态合金的最低。

图10 时效态Mg-6Zn-1.0Ce合金TEM明场像和第二相衍射斑点

Fig. 10 TEM bright field image ((a), (b)) and precipitates diffraction spots (c) of aged Mg-6Zn-1.0Ce alloy

表2 Mg-6Zn-xCe合金的热扩散系数、密度和比热容

Table 2 Thermal diffusion, density and specific heat of Mg-6Zn-xCe alloy

图11 Mg-6Zn-xCe合金室温热导率

Fig. 11 Thermal conductivity of Mg-6Zn-xCe alloy at room temperature

3 分析与讨论

根据现有的理论,电子是镁合金中主要的热能传导介质[16],电子的导热能力主要取决于金属中电子的平均自由行程。在理想晶体中,电子运动不受阻碍,电子平均自由行程趋近无穷大,金属导热能力强。而在实际情况下,金属的晶格存在各种各样的缺陷,这些缺陷或是对电子有散射作用,降低了电子的自由行程,或是直接阻断电子的传播路径,使得金属热导率下降[5]。在镁合金中,热导率与合金中的微观组织密切相关,影响导热性能的因素主要有温度、合金元素、变形、热处理等。

由图11可见,成分相同的Mg-6Zn-xCe合金的热导率相比较,时效态>铸态>固溶态,这主要是由溶质原子在基体中的固溶度变化引起的,该因素较其他因素的贡献大[17]。铸态合金经过固溶处理后热导率降低,主要原因在于固溶处理时Zn原子向基体中扩散,基体中Zn的固溶程度增大,由图5(a)可见,固溶态合金基体的Zn含量明显高于铸态合金的。在一定范围内,溶质原子固溶度与基体晶格畸变程度成正比,基体中Zn的固溶度增大导致基体晶格畸变程度增大,对电子的散射作用增强,电子的平均自由行程降低,导热能力降低。除此之外,合金经420 ℃热处理后立即水淬,由于试样体积很小,冷却时间很短,冷速极快,溶质原子扩散不及时形成大量空位[15, 18],这些空位同样会与电子相互作用,降低自由电子的能量和密度,导致热导率下降。经过时效处理,固溶在α-Mg基体中的Zn原子析出,最终主要以MgZn相的形式存在于晶粒中。溶质原子的析出使得基体晶格畸变程度降低,除此之外,MgZn相与基体不共格,二者界面处的应力场较弱,对电子运动的附加散射作用也较弱[9],对导热的不利影响较小,因此,时效态合金热导率较高。

不同成分的Mg-6Zn-xCe合金热导率均随Ce含量的升高逐渐降低。首先考虑到的原因是基体中溶质原子Zn固溶度的影响,对Mg-6Zn-xCe合金基体晶格畸变程度进行计算,将XRD实验结果导入数据处理软件,计算出合金的实际晶格常数a1,将该结果与纯镁晶格常数a代入公式(1)进行计算晶格畸畸变( )。

)。

(1)

(1)

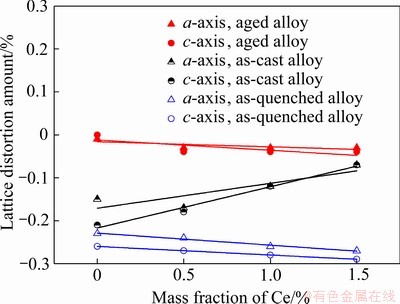

图12所示为合金基体晶格畸变量计算结果。由图12可见,固溶态合金基体晶格畸变程度最高,铸态合金次之,时效态合金最低,与上文Zn的固溶度变化趋势一致。

图12 Mg-6Zn-xCe合金基体晶格畸变量计算结果

Fig. 12 Lattice distortion of matrix of Mg-6Zn-xCe alloy

固溶态与时效态合金基体晶格畸变程度均随Ce含量升高而升高,但铸态合金基体晶格畸变程度随Ce含量升高而降低,理论上合金的热导率应该是升高的,但结果却相反,说明晶格畸程度并不是热导率的唯一判断标准。

铸态合金中,Ce元素对Zn元素有吸引效应,一定程度上减少了基体中的Zn总量[12],因此,就铸态合金而言,晶格畸变随Ce含量升高而降低,而固溶与时效态合金中Zn原子经历了再分配过程,Ce原子对Zn的吸引效应在热处理过程中被弱化;对于固溶态合金,晶格畸变的增加可能与少量Ce原子的回溶与分布状态相关[19]。上述原因导致合金表现出图12的结果。

除了基体中Zn原子的固溶度,合金中Ce含量变化引起的共晶组织体积分数和分布的变化,同样会对合金热导率产生影响。通过观察合金SEM像可以发现,随Ce含量升高,第二相体积分数逐渐升高,且连续性增强。第二相含量升高,相界面增多,相界面对电子的传导有阻碍作用,不利于热传导,且通常情况下第二相的热阻远高于基体,依据热传导中的最低能量耗散原理[20],电子会优先绕过共晶组织沿热阻较小的基体传导,传导路径延长,致使热导率降低。

通过上文的分析可以发现,在Mg-6Zn-xCe合金中,同种合金在不同热处理状态下热导率大幅升降的主要原因是溶质原子固溶度发生变化,导致基体的晶格畸变程度不同;不同成分合金随Ce含量升高热导率降低的主要原因是第二相体积分数增大及分布的连续性增强。

4 结论

1) 铸态Mg-6Zn-xCe合金经过固溶处理,第二相中Mg7Zn3相几乎完全回溶,含Ce第二相中Zn原子回溶,相种类由Ce5(Mg,Zn)41相转变为Mg17Ce2相,呈弥散的的颗粒形态,分布于晶界,第二相体积分数随Ce含量升高而增大。

2) 经过时效处理,α-Mg基体中过饱和的Zn原子以MgZn和MgZn2相形式析出,时效处理后的合金含Ce第二相种类与固溶态合金相同,仍为Mg17Ce2相。

3) 不同热处理状态合金热导率相比,时效态>铸态>固溶态;时效态、铸态、固溶态合金热导率均随Ce含量升高而降低。同种合金在不同热处理状态下热导率大幅升降的主要原因是溶质原子固溶度发生变化,导致基体的晶格畸变程度不同;不同成分合金随Ce含量升高热导率降低的主要原因是第二相体积分数增大及分布的连续性增强。

REFERENCES

[1] 丁文江, 曾小勤. 中国Mg材料研发与应用[J]. 金属学报, 2010, 46(11): 1450-1457.

DING Wen-jiang, ZENG Xiao-qin. Research and applications of magnesium in China[J]. Acta Metallurgica Sinica, 2010, 46(11): 1450-1457.

[2] 王春明, 陈云贵, 肖素芬. 导热镁合金的研究与开发现 状[J]. 稀有金属材料与工程, 2015, 44(10): 2596-2600.

WANG Chun-ming, CHEN Yun-gui, XIAO Su-fen. Situation of research and development of thermal conductive magnesium alloys[J]. Rear Metal Materials and Engineering, 2015, 44(10): 2596-2600.

[3] 游国强, 白世磊, 明 玥, 等. 镁合金导热性能研究进 展[J]. 功能材料, 2016, 47(5): 30-35.

YOU Guo-qiang, BAI Shi-lei, MING Yue, et al. Research progress on thermal conductivity of magnesium alloys[J]. Journal of Functional Materials. 2016, 47(5): 30-35.

[4] 李旭东, 毛萍莉, 刘晏宇, 等. 高应变速率下Mg-3Zn-1Y镁合金的各向异性及变形机制[J]. 金属学报, 2018, 54(4): 557-565.

LI Xu-dong, MAO Ping-li, LIU Yan-yu, et al. Anisotropy and deformation mechanisms of as-extruded Mg-3Zn-1Y magnesium alloy under high strain rates[J]. Acta Metallurgica Sinica, 2018, 54(4): 557-565.

[5] YING T, ZHENG M Y, LI Z T, et al. Thermal conductivity of as-cast and as-extruded binary Mg-Zn alloys[J]. Journal of Alloys & Compounds, 2014, 608(38): 19-24.

[6] YUAN J, ZHANG K, LI T, et al. Anisotropy of thermal conductivity and mechanical properties in Mg-5Zn-1Mn alloy[J]. Materials & Design, 2012, 40: 257-261.

[7] MENDIS C L, OH-ISHI K, OHKUBO T, et al. Microstructures and mechanical properties of extruded and heat treated Mg-6Zn-1Si-0.5Mn alloys[J]. Materials Science & Engineering A, 2012, 553(36): 1-9.

[8] 张思倩, 吴伟, 陈丽丽, 等. 热处理对挤压变形Mg-7%Zn-0.6%Zr-0.5%Y合金低周疲劳行为的影响[J]. 金属学报, 2014, 50(6): 700-706.

ZHANG Si-qian, WU Wei, CHEN Li-li, et al. Influence of heat treatment on low-cycle fatigue behavior of extruded Mg-7%Zn-0.6%Zr-0.5%Y alloy[J]. Materials Science & Engineering A, 2014, 50(6): 700-706.

[9] 熊庭辉, 罗 岚, 刘 勇, 等. Mg-Zn合金的时效处理研究进展[J]. 材料热处理学报, 2017, 38(6): 1-9.

XIONG Tign-hui, LUO Lan, LIU Yong, et al. Research progress of aging treatment on Mg-Zn alloy[J]. Transactions of Metal Heat Treatment, 2017, 38(6): 1-9.

[10] MIMA G, TANAKA Y. The aging characteristics of magnesium-4wt% zinc alloy[J]. Transactions of the Japan Institute of Metals, 1971, 12(2): 71-75.

[11] 张万鹏. Cu元素对Mg-Zn系合金显微组织及热物性能影响研究[D]. 北京: 北京有色金属研究总院, 2018.

ZHANG Wan-peng. Effect of Cu addition on microstructure and thermalphysical properties of Mg-Zn alloys[D]. Beijing: General Research Institute for Nonferrous Metals, 2018.

[12] 代晓腾. Mg-Zn-xCe合金导热性能研究[D]. 北京: 北京有色金属研究总院, 2019.

DAI Xiao-teng. Study on thermal conductivity of Mg-6Zn-xCe alloy[D]. Beijing: General Research Institute for Nonferrous Metals, 2019.

[13] GB/T 1423—1996, 贵金属及其合金密度的测试方法[S].

GB/T 1423—1996, Test method for density of precious metals and their alloys[S].

[14] 张丁非, 赵霞兵, 石国梁, 等. Zn含量及热处理对Mg-Zn-Mn变形镁合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2011, 40(3): 418-423.

ZHANG Ding-fei, ZHAO Xia-bing, SHI Guo-liang, et al. Effects of Zn content and heat treatment on microstructures and mechanical properties of Mg-Zn-Mn wrought magnesium alloys[J]. Rear Metal Materials and Engineering, 2011, 40(3): 418-423.

[15] LANGELIER B, ESMAEILI S. Effects of Ce additions on the age hardening response of Mg-Zn alloys[J]. Materials Characterization, 2015, 101: 1-8.

[16] GAO X, NIE J F. Structure and thermal stability of primary intermetallic particles in an Mg-Zn casting alloy[J]. Scripta Materialia, 2007, 57(7): 655-658.

[17] 潘虎成. 镁合金导热性能研究[D]. 重庆: 重庆大学, 2013.

PAN Hu-cheng. Investigations on thermal conductivity of magnesium alloys[D]. Chongqing: Chongqing University, 2013.

[18] NIE J F. Precipitation and hardening in magnesium alloys[J]. Metallurgical & Materials Transactions Part A, 2012, 43(11):3891-3939.

[19] 郭学锋, 杨文朋. Mg-Zn-Y-Ce合金微细组织[M]. 徐州: 中国矿业大学出版社, 2012.

GUO Xuefeng, YANG Wen-peng. Microstructure of Mg-Zn-Y-Ce alloy[M]. Xuzhou: China University of Mining and Technology Press, 2012.

[20] 程新广, 朱宏晔, 过增元. 热质的运动和传递—最低热质能耗散原理和热质运动方程[J]. 工程热物理学报, 2006, 27(s1): 73-75.

CHENG Xin-guang, ZHU Hong-ye, GUO Zeng-yuan. Motion and transfer of thermal mass—Principle of minimum thermal mass energy disspation and momentum equation of thermal mass[J]. Journal of Engineering Thermophysics, 2006, 27(s1): 73-75.

Effect of heat treatment on microstructure and thermal conductivity of Mg-6Zn-xCe alloy

DAI Xiao-teng, MA Ming-long, LI Yong-jun, YUAN Jia-wei, SHI Guo-liang

(State Key Laboratory of Nonferrous Metals and Processes, GRIMAT Engineering Institute Co., Ltd., Beijing 101499, China)

Abstract: As the continuous development of electronic communication and aerospace industry, the application and update of new equipment with high-precision and high-power are becoming more and more frequent. In order to meet the needs of miniaturization of equipment, most components adopt integrated design, which brings difficulties in heat dissipation. Therefore, it is necessary to develop new lightweight materials which have high thermal conductivity to improve and ensure the life and work stability of equipment. The high thermal conductivity magnesium alloy can simultaneously meet the demand for lightweight and high thermal conductivity, it has become one of the research hot spots in the current magnesium alloy field. The effect of heat treatment on the microstructure of Mg-6Zn-xCe alloy was investigated by SEM, EDS, XRD, TEM, the thermal diffusivity of the alloy under different heat treatment conditions was tested by laser thermal conductivity tester, and the thermal conductivity of the alloy was calculated and the influence of microstructure changes on the thermal conductivity of the alloy was discussed. The results show that the as-cast Mg-6Zn alloy is mainly composed of α-Mg and Mg7Zn3 phases, and the eutectic structure increases with the increase of Ce content. After solution treatment, the Mg7Zn3 phase is basically dissolved back, and the binary phase Ce5(Mg,Zn)41 is transformed into Mg17Ce2 phase, which is granular and intermittently distributes in the grain boundary. The Zn content in the matrix of the same alloy increases significantly after solid solution. After aging treatment, supersaturated Zn atoms in the matrix precipitate as MgZn and MgZn2 phases. The aging alloy has the highest thermal conductivity while the solid solution alloy has the lowest. The thermal conductivity of alloys in different states shows a downward trend with the increase of Ce content.

Key words: Mg-Zn-Ce alloy; heat treatment; microstructure; thermal conductivity

Foundation item: Project(BA2017044) supported by the Jiangsu Achievements Transformation Project, China

Received date: 2019-06-26; Accepted date: 2020-10-26

Corresponding author: MA Ming-long; Tel: +86-10-60662665; E-mail: maminglong@grinm.com

(编辑 李艳红)

基金项目:江苏省成果转化项目(BA2017044)

收稿日期:2019-06-26;修订日期:2020-10-26

通信作者:马鸣龙,高级工程师,博士;电话:010-60662665;E-mail:maminglong@grinm.com