DOI:10.19476/j.ysxb.1004.0609.2017.05.008

AlTiN-Cu涂层的组织结构和性能

易继勇1, 2,潘晨曦1, 2,陈康华1, 2,徐银超1, 2, 3,王云志3,陈 浩1, 2 祝昌军1, 2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中南大学 有色金属先进材料协同创新中心,长沙 410083;

3. 株洲钻石切削刀具股份有限公司,株洲 412000)

摘 要:

采用阴极弧离子镀法在硬质合金基体上分别沉积AlTiN与AlTiN-Cu涂层,利用XRD、SEM、EDS、XPS、纳米压痕与切削实验等对比研究AlTiN涂层和AlTiN-Cu涂层的显微组织与切削性能。结果表明:AlTiN涂层为典型柱状晶粒结构,Cu的引入改变AlTiN涂层的晶粒生长方式与择优取向,细化晶粒组织,降低涂层硬度。对比AlTiN与AlTiN-Cu涂层可转位硬质合金刀片的切削性能发现,由于金属铜的润滑作用,AlTiN-Cu涂层在干式切削时切削寿命提高44%;Cu的引入导致涂层硬度降低,AlTiN涂层在湿式切削时性能更佳。

关键词:

文章编号:1004-0609(2017)-05-0935-06 中图分类号:TG174.4 文献标志码:A

随着科技的进步,特别是机械制造领域中干式或者半干式金属加工、高速切削技术的发展,对切削刀具提出了更高的要求。TiAlN涂层具有硬度高、氧化温度高、热硬性好、附着力强、摩擦因数小和导热率低等优良特性, 逐渐取代传统的TiN涂层刀具,广泛用于切削高温合金、淬硬钢、不锈钢、镍合金、钛合金等难加工材料[1-5]。随着高性能新材料技术的发展,特别是高速及干式切削过程,接触区域温度高于TiAlN涂层的抗氧化与热分解温度,导致涂层刀具氧化失效[6-7]。近年来,许多研究者开始探究在TiAlN涂层添加合金元素的方法来提高涂层的性能。

Cu是优良的热导体,同时金属Cu具有较好的润滑性能。ELYUTIN等[8]研究将Cu引入TiN涂层发现:能细化晶粒,降低摩擦因素,提升涂层的抗磨损性能。FOX-RABINOVICH等[9]研究AlTiN/Cu多层涂层对Inconel 718合金切削性能,发现与普通AlTiN涂层相比,涂层热导率、摩擦因数降低,切削寿命提高。因此,将Cu引入AlTiN涂层中,利用其优良的润滑性能,有期望能显著改善AlTiN涂层的切削和磨损性能。

本文作者通过阴极弧离子镀在硬质合金刀具上制备了AlTiN、AlTiN-Cu涂层。对比研究AlTiN与AlTiN-Cu涂层组织结构与性能,为进一步提升AlTiN涂层的性能提供指导意见。

1 实验

采用工业化生产的阴极弧离子镀设备,在型号为CNMG120408-DM的硬质合金刀片上沉积了AlTiN与AlTiN-Cu涂层,刀片基体为WC-6%Co(质量分数),靶材选用粉末冶金制备的Ti0.33Al0.67与(Ti0.33Al0.67)0.97Cu0.03合金靶,通入氮气作为反应气体,沉积温度为400~500 ℃,沉积压力为2.2 Pa。

利用SEM检测AlTiN、AlTiN-Cu涂层的表面与截面形貌,采用EDX分析AlTiN-Cu涂层表面元素分布及含量,采用X射线衍射仪分析AlTiN、AlTiN-Cu涂层的相结构,采用X射线光电子能谱仪对AlTiN-Cu涂层中Cu元素化合状态分析,采用瑞士CSM公司生产的纳米硬度测试仪测试涂层纳米硬度。

在数控机床CK7525上进行分别进行干、湿切削实验,刀片基体为WC-6%Co(质量分数),切削工件为316不锈钢。干式切削实验参数为:切削速度v=160 m/min,切深ap=1 mm,进给量f=0.2 mm/r;湿式切削实验参数为:切削速度v=200 m/min,切深ap=1 mm,进给量f=0.2 mm/r。每隔一定时间暂停切削,并取下刀片在EV3020光学影像测量仪下测量刀具后刀面的平均磨损量,磨纯标准为VB=0.2 mm。

2 结果与分析

2.1 组织结构

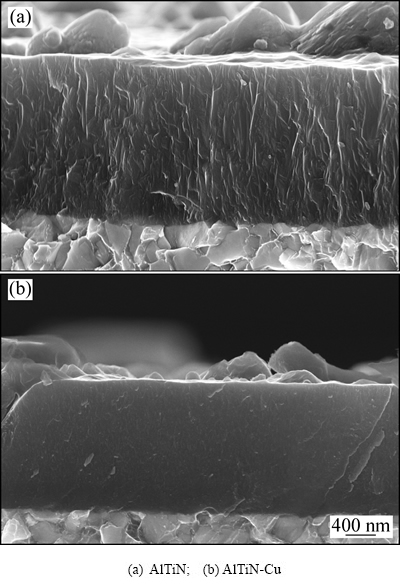

图1所示为WC-6%Co硬质合金基体上沉积的AlTiN与AlTiN-Cu涂层的截面形貌。由图1可知,采用阴极弧沉积法能在硬质合金基体上沉积组织致密,结合面良好的AlTiN与AlTiN-Cu涂层。AlTiN涂层的晶粒组织沿垂直于基体的方向生长,并呈典型的柱状晶结构,部分柱状晶贯穿了整个涂层(见图1(a))[10]。随着Cu元素的引入(见图1(b)),AlTiN涂层晶粒显著细化,涂层组织中柱状晶结构消失,形成纳米晶结构。这是由于在沉积过程中,Cu分布在AlTiN晶粒周围,阻碍了晶粒生长,致使柱状晶消失,晶粒明显细化[11]。

图1 涂层的截面形貌

Fig. 1 Cross-sectional morphologies of coatings

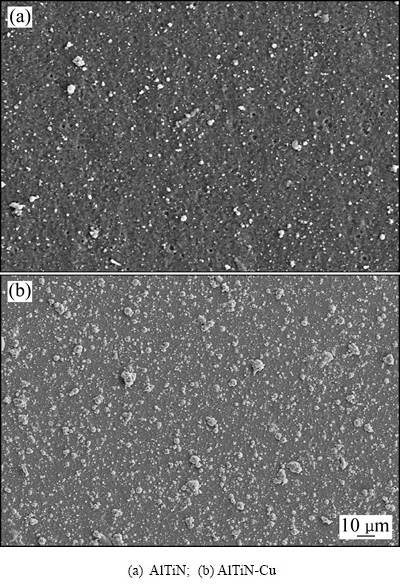

图2所示为AlTiN 与AlTiN-Cu 涂层表面形貌。由图2可知,涂层表面均有大固体颗粒出现。这是由于阴极弧法制备涂层过程中易引起靶材中粒子的蒸发,出现“液滴”,“液滴”随离子一起沉积在硬质合金基体上,造成涂层缺陷[12-13]。对比图2(a)与(b)可发现:与普通AlTiN 涂层相比,AlTiN-Cu 涂层表面“液滴”数量多,颗粒大。一方面可能由于TiAl 熔点较高,依据Ti-Al 二元相图知,在Al含量为67%(摩尔分数)时,TiAl 熔点为1454 ℃,较Cu的熔点(1084 ℃)高;另一方面Cu 的导热性较Al、Ti的好,靶材受热更快,温度更高,在沉积过程中更容易引起靶材中粒子蒸发。因此,Cu 的引入使涂层表面出现“液滴”数量多,且颗粒大。

图2 涂层的表面形貌

Fig. 2 Surface morphologies of coatings

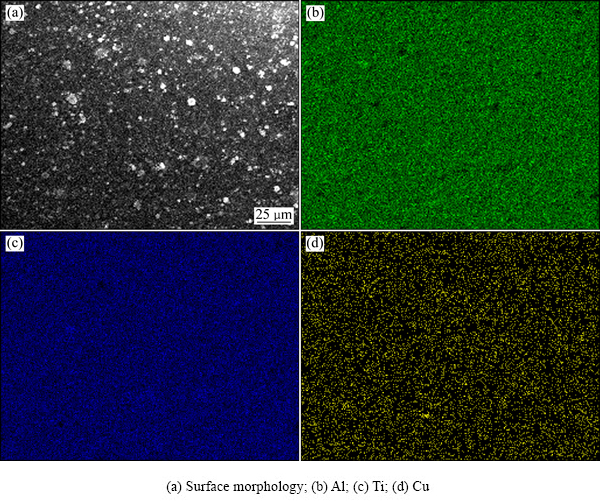

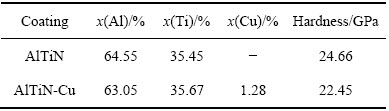

图3所示为AlTiN-Cu涂层表面形貌及Al、Ti、Cu等元素面扫描分布图。由图3可知,涂层表面存在大量“液滴”缺陷,涂层中Ti、Al、Cu 等元素粒子均匀分布在涂层表面,在“液滴”较多区域不存在单一元素富集情况。表1所列为AlTiN 与AlTiN-Cu 涂层中各元素含量,AlTiN-Cu涂层中Cu 含量为1.28%。采用纳米压痕法测得AlTiN 涂层的硬度为24.66 GPa,AlTiN-Cu涂层的硬度为22.45 GPa,Cu 引入后致使涂层硬度略微下降。Cu 对AlTiN 涂层硬度的影响主要为如下两种机制:一方面Cu 的加入细化了涂层晶粒有利于涂层硬度的提升;另一方面起主导作用的是,Cu 在 AlTiN 涂层中以软的金属相形态存在,降低了涂层整体的硬度。

图3 AlTiN-Cu涂层的表面形貌

Fig. 3 Surface morphology and element distribution of AlTiN-Cu coating

表1 涂层中Al、Ti、Cu元素摩尔分数与硬度

Table 1 Mole fraction of Al, Ti, Cu and hardness of coatings

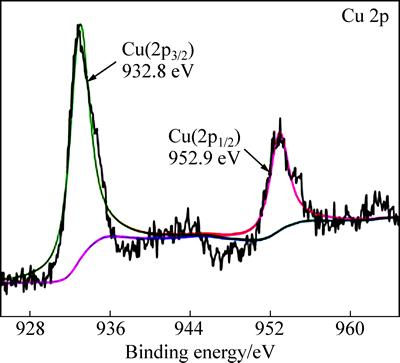

图4 AlTiN-Cu涂层的XPS分析

Fig. 4 XPS fitted spectra of AlTiN-Cu coating

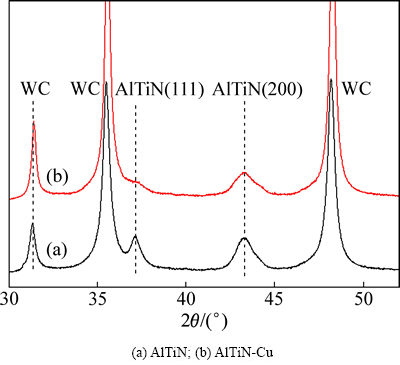

图5 涂层的XRD谱

Fig. 5 XRD patterns of coatings

图4所示为AlTiN-Cu涂层Cu的光电子能谱(XPS)图。最高Cu2p3/2 峰位于932.8 eV处,表明在涂层中Cu 并未形成其他形式化合物。图5显示AlTiN-Cu 涂层涂层中没有Cu 相峰出现,表明Cu 主要以非晶金属相结构存在[14-15],BELOV等[16]研究发现,Cu在TiN-Cu涂层中以非晶金属相形态分布在TiN 颗粒周围。图5所示为AlTiN与AlTiN-Cu表面XRD 能谱图,由图5可知,AlTiN涂层呈面心立方结构;同时,Cu 元素引入,AlTiN涂层(111) 面取向减小,而(200)取向增强,呈现明显的(200)生长织构;此外,随着Cu 元素的引入,AlTiN 峰宽化,表明涂层中晶粒细化与内应力提高[17]。

2.2 切削性能

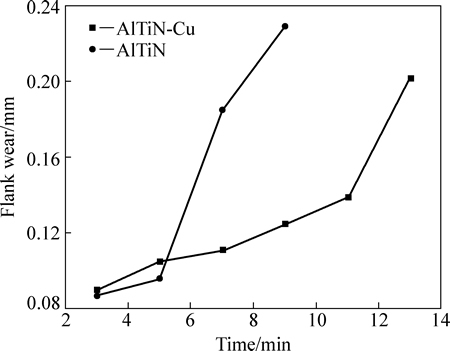

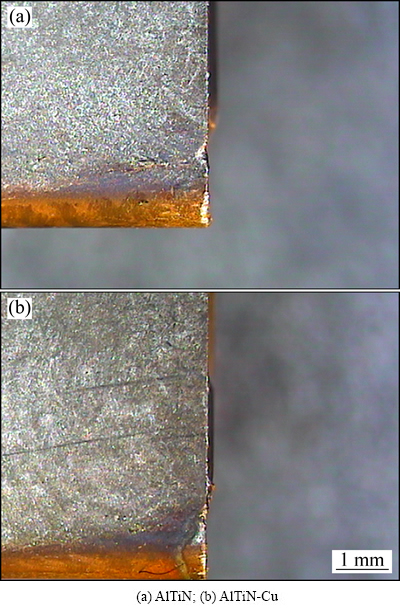

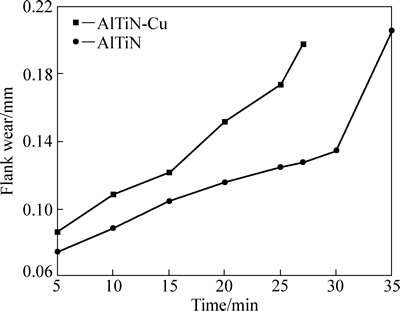

图6所示为AlTiN 与AlTiN-Cu 涂层硬质合金刀具干式切削316 不锈钢后刀面平均磨损量随切削时间的变化曲线。由图6可知,在干切削情况下,AlTiN 涂层刀具在连续切削9 min 时涂层的后刀面平均磨损量超过0.2 mm,判定涂层失效;而AlTiN-Cu 涂层刀具在连续切削13 min时涂层后刀面平均磨损量超过0.2 mm。对比可知:AlTiN-Cu 涂层刀具较AlTiN涂层刀具的切削寿命提升约44%。图7所示为涂层刀具在干式切削7 min 后端面的磨损形貌图。由图7可知,Cu 引入AlTiN 能显著降低涂层后端面磨损量。干式切削条件下,切削温度较高,金属Cu 具有较好的润滑性能,显著降低涂层摩擦因数[18],进而降低接触区域温度,提高刀具的使用寿命。图8所示为AlTiN与AlTiN-Cu涂层刀具湿式切削316 不锈钢后刀面平均磨损量随切削时间的变化曲线,与干式切削相比,刀具的使用寿命显著提高。这是由于切削液能带走工件接触区域产生的大量热量,且对工件与刀具有较好的润滑作用,因而能极大地降低切削温度,提升刀具切削寿命。湿式切削时,AlTiN-Cu 涂层刀具的切削寿命比AlTiN 涂层刀具的低,这是由于在湿式切削不锈钢时金属铜的润滑效果不明显,同时,Cu 的加入降低了涂层的硬度,致使涂层切削寿命下降。

图6 干式切削后刀面平均磨损量随时间的变化曲线

Fig. 6 Changing curves of average flank wear with time during dry cutting

图7 涂层刀具在干式切削7 min后刀面的磨损形貌

Fig. 7 Micrographs of flank wear region of coating tool after dry cutting for 7 min

图8 湿式切削后刀面最大磨损量随时间的变化曲线

Fig. 8 Changing curves of maximum flank wear with time during wet cutting

3 结论

1) 采用阴极弧离子镀法在硬质合金基体上沉积出组织致密,结合状态良好的AlTiN与AlTiN-Cu涂层,涂层表面存在“液滴”缺陷,Cu的加入会导致涂层表面“液滴”增多。AlTiN 涂层组织呈典型柱状晶结构,Cu引入AlTiN涂层后能细化晶粒,提高涂层内应力,降低涂层硬度,晶面(111)取向强度减弱。

2) AlTiN-Cu涂层中Al、Cu、Ti等元素均匀分布在涂层表面,Cu在涂层中,主要以金属形式存在。由于金属Cu有优良的润滑性能,AlTiN-Cu涂层刀具干式切削不锈钢的寿命较普通AlTiN涂层刀寿命提升44%;由于在湿式切削不锈钢时金属铜产生的自润滑效应不明显,且AlTiN-Cu涂层较AlTiN涂层硬度低,致使湿式切削不锈钢AlTiN-Cu涂层寿命较AlTiN涂层低。

REFERENCES

[1] WILSON S, ALPAS A T. Effect of temperature and sliding velocity on TiN coating wear[J]. Surface & Coatings Technology, 1997, 94/95: 53-59.

[2] WANG C F, SHIH-FU O U, CHIOU S Y. Microstructures of TiN,TiAlN and TiAlVN coatings on AISI M2 steel deposited by magnetron reactive sputtering[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2559-2565.

[3] 曹华伟, 张程煜, 乔生儒, 曹晓雨. 物理气相沉积TiAlN涂层的研究进展[J]. 材料导报, 2011, 25(6): 25-29.

CAO Hua-wei, ZHANG Cheng-yu, QIAO Sheng-ru, CAO Xiao-yu. Recent Progresses in physical vapor deposited TiAlN coating[J]. Materials Review, 2011, 25(6): 25-29.

[4] 黄自谦, 贺跃辉, 蔡海涛, 肖逸锋, 黄伯云. TiAlN涂层的热残余应力分析[J]. 中国有色金属学报, 2007, 17(6): 897-902.

HUANG Zi-qian, HE Yue-hui, CAI Hai-tao, XIAO Yi-feng, HUANG Bai-yun. Thermal residual stress analysis of TiAlN coating[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(6): 897-902.

[5] PRENGEL H G,SANTHANAMB A T,PENICH R M, JINDAL P C, WENDT K H. Advanced PVD-TiAlN coatings on carbide and cermet cutting tools[J]. Surface & Coatings Technology, 1997, 94/95: 597-602.

[6] VAZ F, REBOUTA L, ANDRITSCHKY M, SILVA M F D, SOARES J C. Thermal oxidation of Ti1-xAlxN coatings in air[J]. Journal of the European Ceramic Society, 1997, 17(15/16): 1971-1977.

[7] CHEN L, PAULITSCH J, DU Y, MAYRHOFER P H. Thermal stability and oxidation resistance of Ti-Al-N coatings[J]. Surface & Coatings Technology, 2012, 206(11/12): 2954-2960.

[8] ELYUTIN A V,BLINKOV IV, VOLKHONSKY AO, BELOV D S. Properties of nanocrystalline arc PVD TiN-Cu coatings[J]. Inorganic Materials, 2013, 49(11): 1106-1112.

[9] FOX-RABINOVICH G S, YAMAMOTO K, AGUIRRE M H, GAHILLD D G, VELDHUISA S C, BIKSAA A, DOSBAEVAA G, SHUSTERE L S. Multi-functional nano-multilayered AlTiN/Cu PVD coating for machining of Inconel 718 superalloy[J]. Surface & Coatings Technology, 2010, 204(15): 2465-2471.

[10] 陈 利, 吴恩熙, 尹 飞, 王社权, 汪秀全. (Ti,Al)N涂层的微观组织和性能[J]. 中国有色金属学报, 2006, 16(2): 279-283.

CHEN Li, WU En-xi, YIN Fei, WANG She-quan, WANG Xiu-quan. Microstructure and properties of (Ti, Al)N coating[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 279-283.

[11] IVANOV YU F, KOVA N N, KRYSINA O V, BAUMBACH T, DOYLE S, SLOBODSKY T, TIMCHENKO N A, GALIMOV R M, SHMAKOV A N. Superhard nanocrystalline Ti-Cu-N coatings deposited by vacuum arc evaporation of a sintered cathode[J]. Surface & Coatings Technology, 2012, 207: 430-434.

[12] HARRIS S G, DOYLE E D, WONG Y C, MUNROE P R, CAIRNEY J M, LONG J M. Reducing the macroparticle content of cathodic arc evaporated TiN coatings[J]. Surface & Coatings Technology, 2004, 183(2): 283-294.

[13] SANDERS D M, ANDERS A. Review of cathodic arc deposition technology at the start of the new millennium[J]. Surface & Coatings Technology, 2000, 133/134: 78-90.

[14] WANG X Q, ZHAO Y H, YU B H, XIAO J Q, LI F Q. Deposition, structure and hardness of Ti-Cu-N hard films prepared by pulse biased arc ion plating[J]. Vacuum, 2011, 86: 415-421.

[15] ZHANG L, MA G J, LIN G Q, HAN K C, MA H. Synthesis of Cu doped TiN composite films deposited by pulsed bias arc ion plating[J]. Nuclear Instruments & Methods in Physics Research, 2014, 320: 17-21.

[16] BELOV D S, BLINKOV I V, VOLKHONSKII A O, KUZNETSOV D V, KIRYUKHANTSEV-KORNEEV F V, PUSTOV YU A, SERGEVNIN V S. Thermal stability and chemical resistance of (Ti,Al)N-Cu and (Ti,Al)N-Ni metal-ceramic nanostructured coatings[J]. Applied Surface Science, 2016, 388: 2-12.

[17] ZHU YAOCAN, FUJITA K, IWAMOTO N, NAGASAKA H, KATAOKA T. Influence of boron ion implantation on the wear resistance of TiAlN coatings[J]. Surface & Coatings Technology, 2002, 158/159: 664-668.

[18] MYUNG H S, LEE H M, SHAGINYAN L R, HAN J G. Microstructure and mechanical properties of Cu doped TiN superhard nanocomposite coatings[J]. Surface & Coatings Technology, 2003, 163/164: 591-596.

Microstructure and properties of AlTiN-Cu coating

YI Ji-yong1, 2, PAN Chen-xi1, 2, CHEN Kang-hua1, 2, XU Ying-chao1, 2, 3 WANG Yun-zhi3, CHEN Hao1, 2, ZHU Chang-jun1, 2

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Collaborative Innovation Center of Advanced Nonferrous Structural Materials and Manufacturing, Central South University, Changsha 410083, China;

3. Zhuzhou Cemented Carbide Cutting Tools Co. Ltd., Zhuzhou 412000, China)

Abstract: AlTiN and AlTiN-Cu coatings were deposited on cemented carbide substrates with cathodic arc ion plating. The properties of coatings were studied by X-ray diffractometry (XRD), scanning electron microscopy(SEM), energy dispersive X-ray spectroscopy(EDX), X-ray photoelectron spectroscopy(XPS), nanoindentation and cutting tests. The results show that AlTiN coating is typical columnar structure, Cu changes the grain growth way and preferred orientation, refines the grain sizes of the coating and reduces the coating hardness. AlTiN layer and AlTiN-Cu layer applied on the indexable inserts were compared in cutting tests. The AlTiN-Cu coatings cutting life is improved by 44% under conditions of dry cutting, which is caused by the effect of the lubrication of copper. Whereas, the AlTiN coatings are more successful at wet cutting, it can be attributed to the addition of Cu decreases the hardness of the coatings.

Key words: AlTiN-Cu coating; cathodic arc-evaporation; microstructure; cutting performance

Foundation item: Project(2014ZX04012011) supported by the Major National Science and Technology

Received date: 2016-04-15; Accepted date: 2016-10-09

Corresponding author: CHEN Kang-hua; Tel: +86-731-88830714; E-mail: khchen@csu.edu.cn

(编辑 龙怀中)

基金项目:国家科技重大专项资助项目(2014ZX04012011)

收稿日期:2016-04-15;修订日期:2016-10-09

通信作者:陈康华,教授,博士;电话:0731-88830714;E-mail:khuachen@mail.csu.edu.cn

摘 要:采用阴极弧离子镀法在硬质合金基体上分别沉积AlTiN与AlTiN-Cu涂层,利用XRD、SEM、EDS、XPS、纳米压痕与切削实验等对比研究AlTiN涂层和AlTiN-Cu涂层的显微组织与切削性能。结果表明:AlTiN涂层为典型柱状晶粒结构,Cu的引入改变AlTiN涂层的晶粒生长方式与择优取向,细化晶粒组织,降低涂层硬度。对比AlTiN与AlTiN-Cu涂层可转位硬质合金刀片的切削性能发现,由于金属铜的润滑作用,AlTiN-Cu涂层在干式切削时切削寿命提高44%;Cu的引入导致涂层硬度降低,AlTiN涂层在湿式切削时性能更佳。