DOI: 10.11817/j.ysxb.1004.0609.2021-37902

高强高韧非等原子(FeCoNiCr)100-xMnx高熵合金的组织结构和力学性能

赵 堃1,艾桃桃1, 2,冯小明1, 2,王沛锦1,包维维1, 2,李文虎1, 2,寇领江1, 2,董洪峰1, 2,邹祥宇1, 2,邓志峰1, 2,赵中国1, 2

(1. 陕西理工大学 材料科学与工程学院,汉中 723000;

2. 陕西理工大学 矿渣综合利用环保技术国家地方联合工程实验室,汉中 723000)

摘 要:

设计开发了一种非等原子(FeCoNiCr)100-xMnx(x=0、12、20)高熵合金的制备工艺。结果表明:采用真空热压烧结技术制备的含Mn型(FeCoNiCr)100-xMnx合金由面心立方(FCC)和体心立方(BCC)相组成,并析出大量的纳米级金属间化合物。经650 ℃退火1h后,(FeCoNiCr)88Mn12合金的综合力学性能最佳,压缩屈服强度为873.65 MPa,极限抗压强度为1813.98 MPa,断裂应变为41.03%,弯曲强度为1573.69 MPa,断裂韧性为49.45 MPa·m1/2。优异的力学性能归因于BCC相的强化作用以及低堆垛层错能区域所形成的大量退火孪晶。孪晶诱导塑性(TWIP)辅助的非等原子双相高熵合金设计理念,为高熵合金成分设计提供了一种新的思路。

关键词:

文章编号:1004-0609(2021)-xx-- 中图分类号: 文献标志码:A

引文格式:赵 堃, 艾桃桃, 冯小明, 等. 高强高韧非等原子(FeCoNiCr)100-xMnx高熵合金的组织结构和力学性能[J]. 中国有色金属学报, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37902

ZHAO Kun, AI Tao-tao, FENG Xiao-ming, et al. Microstructure and mechanical properties of (FeCoNiCr)100-xMnx non-equiatomic high-entropy alloys with high strength and ductility[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(x): xxxx-xxxx. DOI: 10.11817/j.ysxb.1004.0609.2021-37902

高熵合金(HEAs)因其独特的成分构成、特殊的组织结构及优异的力学性能而备受研究人员的广泛关注[1-2],被认为是一类极具应用潜力的新型结构材料,在核工业、航空航天、汽车等领域具有广阔的应用前景。但是,HEAs依然存在一些科学问题亟待进一步解决,例如,室温下具有单相FCC结构的HEAs[3]表现出优异的可塑性但强度不高,而单相BCC结构的HEAs[4]具有高强度但塑性较低。

众所周知,通过调节HEAs中不同合金元素占比,往往会导致HEAs的晶体结构、微观组织和力学性能发生显著的变化。因此,通过成分设计有望实现合金性能最优化。例如,非等原子CoCrFeNiMo0.3 HEA[5]通过形成硬而脆的金属间化合物实现了增强效果,抗拉强度高达1.2 GPa,应变为19%;CoCrFeNiTi0.2 HEA[6]通过两种成分相似的相干纳米沉淀相而达到增强目的,在室温下具有700 MPa和1.2 GPa的屈服强度和极限抗拉强度,应变达36%;CoCrFeNiCu4 HEA[7]具有富铜和富CoCrFeNi的双FCC相结构,轧制后屈服强度达 890 MPa;Fe67CoCrMnNiHEA[8]具有BCC/FCC双相结构,拉伸屈服强度和极限抗拉强度分别为148 MPa和604 MPa,断裂应变高达61%。随着研究的不断深入,除了成分设计外,更多的性能优化方法脱颖而出,例如孪晶诱导塑性(TWIP)效应[9]、共晶HEAs[10]、细晶强化、固溶强化[11]、相变诱发塑性(TRIP)效应[12]、第二相强韧化[13]等手段均可以通过其不同的作用机理进一步改善HEAs的综合性能。

本文以FeCoCrNiMn HEA为研究对象,选择Mn作为成分设计中可调节的合金元素,综合考虑其原子半径在五种元素中最小,通过改变其含量可能会对合金结构和性能产生积极的影响。LI等[14]研究发现,Mn含量在相组成中发挥了重要作用,可以调节相稳定性以激活特定的置换转化机制,例如TWIP或TRIP效应。鉴于此,本文设计了一类非等原子(FeCoNiCr)100-xMnx(x=0, 12, 20)HEAs,采用“球磨干混+真空热压烧结+退火”工艺实现HEAs的制备,研究合金的微观组织与力学性能。

1 实验过程

实验使用商用Fe、Co、Cr、Ni、Mn金属粉末(纯度≥99.9%,平均粒度约为100~200目)为原料,设计了三种不同成分的(FeCoNiCr)100-xMnx(x=0、12、20)高熵合金,即FeCoNiCr、(FeCoNiCr)88Mn12、(FeCoNiCr)80Mn20,分别简称为Mn0、Mn12、Mn20。采用干法球磨对粉末进行混合,球磨机转速为150 r/min,混粉时间为4 h。利用真空热压烧结系统进行烧结,从室温以10 ℃/min的升温速率升温至900 ℃,然后调节压力至3.0 T,并在900 ℃保温30 min,最后随炉冷却即可。退火工艺是将烧结后的样品在650 ℃退火1 h,然后随炉冷却至室温。

采用配备能谱仪(EDS)和电子背散射衍射仪(EBSD)的扫描电子显微镜(SEM)观察样品的微观结构和化学成分。用X-射线衍射仪(XRD)进行样品的相组成鉴定。显微结构观察之前,将样品打磨抛光后,用稀释的王水进行腐蚀。

采用三点弯曲法测试合金的弯曲强度和断裂韧性,样品尺寸为25 mm(长)×4 mm(宽)×8 mm(高),跨距为20 mm。断裂韧性样品切口深度为0.4W(其中W是试样宽度)。测量3次取其平均值。

弯曲强度的计算公式为:

(1)

(1)

式中:σb是强度(MPa);P是试样破裂或失效时的最大载荷(N);L是跨度(mm);b是宽度(mm);h是试样高度(mm)。

断裂韧性的计算公式为:

(2)

(2)

式中:P是载荷;S是跨度;B是试样厚度;W是试样宽度;a是裂纹长度。f(a/W)的计算公式为:

(3)

(3)

压缩强度测试样品为圆柱状,样品尺寸为5 mm(直径)×8 mm(高)。测量3次取其平均值。压缩工程应力-应变的计算公式为:

(4)

(4)

(5)

(5)

式中:P是载荷;A是原始截面积; 是伸长量; l是原始长度。

是伸长量; l是原始长度。

2 结果和讨论

2.1 (FeCoNiCr)100-xMnx(x=0、12、20)合金的微观组织结构分析

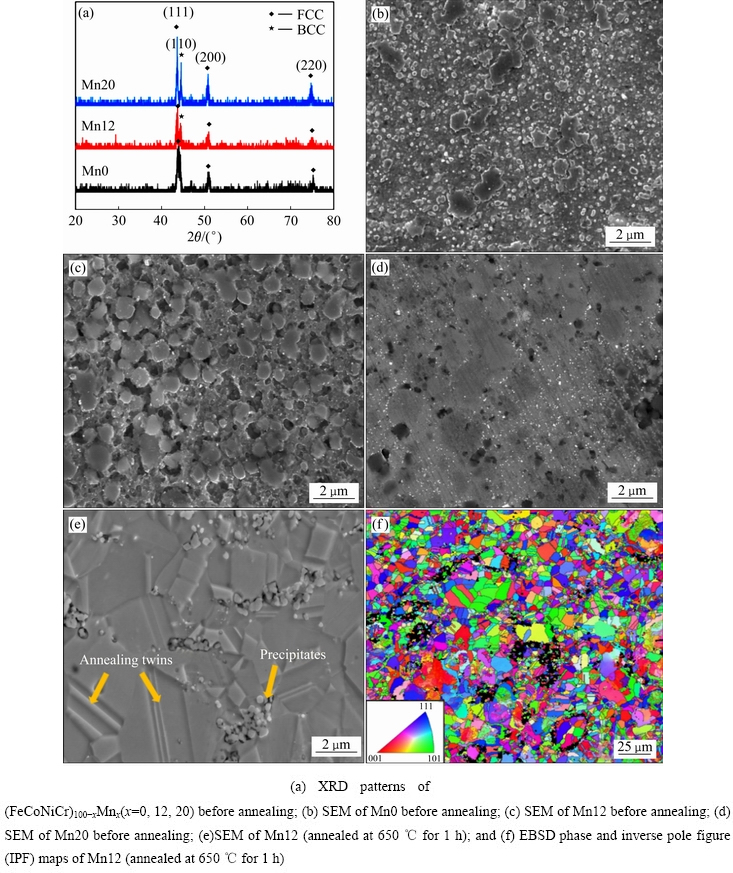

图1所示为(FeCoNiCr)100-xMnx(x=0、12、20)合金的XRD谱和微观组织结构。其中图1(a)为真空热压烧结后合金的XRD谱,由图1可见,Mn0合金烧结后主要为FCC单相固溶体,Mn12和Mn20合金烧结后由FCC/BCC双相组成。图1(b)、(c)和(d)微观组织观察发现,Mn0、Mn12和Mn20合金微观形貌差别较大,Mn0合金主要为FCC组织,同时析出大量的细小金属间化合物粒子;Mn12和Mn20合金主要为FCC/BCC双相组织,随Mn含量的增大,BCC相含量及尺寸不断增大,同时析出大量的纳米级金属间化合物(白色亮点)。图1(e)为Mn12合金经650 ℃退火1 h后的组织结构,由图可见纳米级金属间化合物颗粒明显长大,同时出现了退火孪晶。图1(f)为Mn12合金(650 ℃退火1 h)晶粒取向分布图,由图可见晶粒尺寸分布并不均匀,经统计平均晶粒尺寸约为4.59 μm,晶粒呈随机取向分布。

图1 (FeCoNiCr)100-xMnx(x=0、12、20)合金的XRD谱和微观组织结构

Fig. 1 XRD patterns and microstructure of (FeCoNiCr)100-xMnx(x=0, 12, 20) alloys

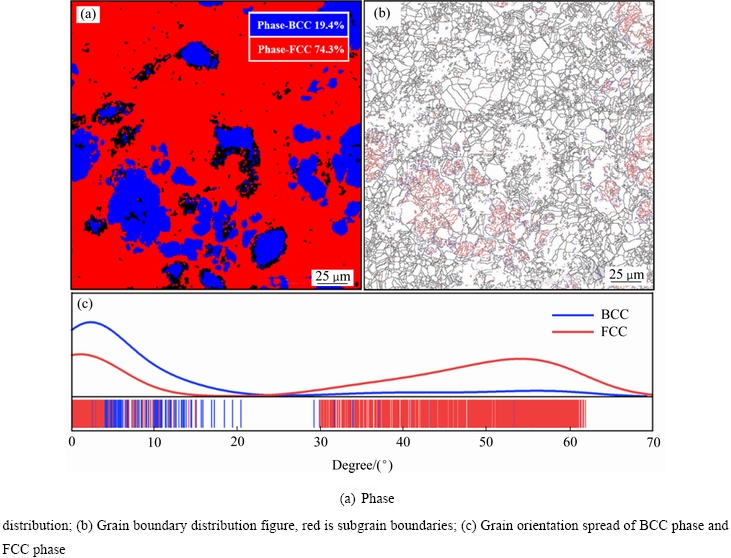

图2所示为Mn12合金(650 ℃退火1 h)的相分布与晶界分布图。由图2(a)可见,合金主要由FCC和BCC两相组成,含量分别为74.3%和19.4%。图2(b)为相界和晶界图,红色为小角度晶界,可以看出小角度晶界基本分布在BCC相区域,小角度晶界对优化组织和调节力学性能具有重要的作用,同时还发现FCC相中的大角度晶界中存在许多孪生结构,各晶粒的孪生特征不同,呈现出二次或者三次对称性。孪生结构是FCC相在退火过程中形成的,其形成使原粗大的FCC相晶粒得以细化[15]。退火孪晶界两侧晶粒具有特殊的位向关系,可以阻碍位错滑移。与普通高角度界面相比,退火孪晶界由于原子排列规则,畸变小,界面能低,稳定性好,能够改善合金的抗氧化、抗腐蚀、抗裂纹扩展等性能[16]。图2(c)所示为晶粒取向分布图,由图可见,BCC相晶粒取向大部分小于5°,为小角度晶界或亚晶界,FCC相晶粒取向部分小于5°,大部分分布于30°~60°之间,为大角度晶界。

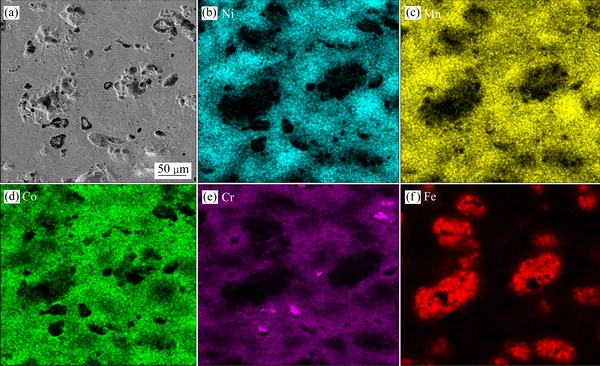

Mn12合金(650 ℃退火1 h)EDS面扫描结果如图3所示,由图可知,除Fe团聚形成富Fe的BCC相外,Ni、Mn、Co、Cr元素分布相对较为均匀,形成了FCC相的基体,其中Ni和Mn由于具有最低的混合焓[17],容易聚集,分布呈正相关,而Co、Cr呈均匀分布,即Mn12合金(650 ℃退火1 h)组成为FCC相(分为Ni、Mn聚集区域和其他区域)、富Fe的BCC相,与XRD分析结果一致。

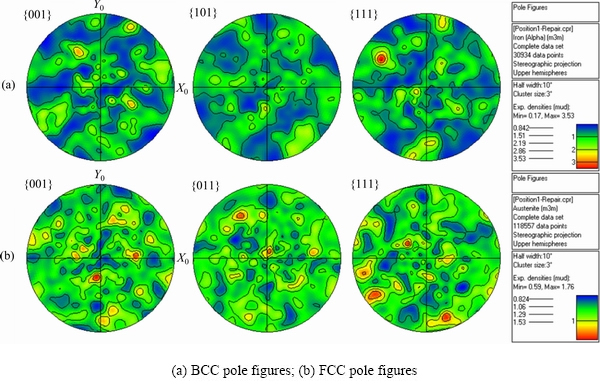

图4所示为Mn12合金(650 ℃退火1 h)的极图。其中图4(a)为BCC相的极图,从图中可以看出BCC相最大织构强度为3.53,晶粒取向较为明显,说明晶粒内部存在织构;图4(b)为FCC相的极图,从图中可以看出FCC相的晶粒织构强度范围为0.59~1.76,晶粒取向性并不明显,说明FCC相晶粒取向是随机分布的,晶粒内部织构特征不明显。此与图2(c)晶粒取向差分布图结果一致,即BCC相取向差大部分小于5°,晶粒间取向差角度小,晶粒取向明显,而FCC相晶粒间取向差角度大,呈随机分布状态。

2.2 (FeCoNiCr)100-xMnx(x=0、12、20)合金的力学性能

图2 Mn12合金(650 ℃退火1 h)的相分布与晶界分布图

Fig. 2 Phase distribution and grain boundary distribution figures of Mn12 alloy (annealed at 650 ℃ for 1 h)

图3 Mn12合金(650 ℃退火1 h)EDS面扫描结果

Fig. 3 EDS of Mn12 alloy (annealed at 650 ℃ for 1 h)

图4 Mn12合金(650 ℃退火1 h)的极图

Fig. 4 Pole figures of Mn12 alloy (annealed at 650 ℃ for 1 h)

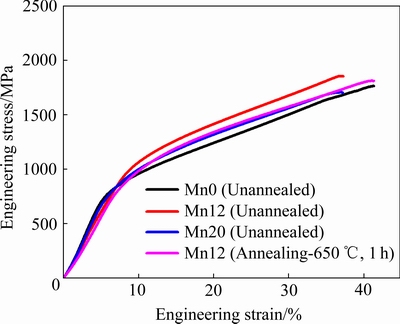

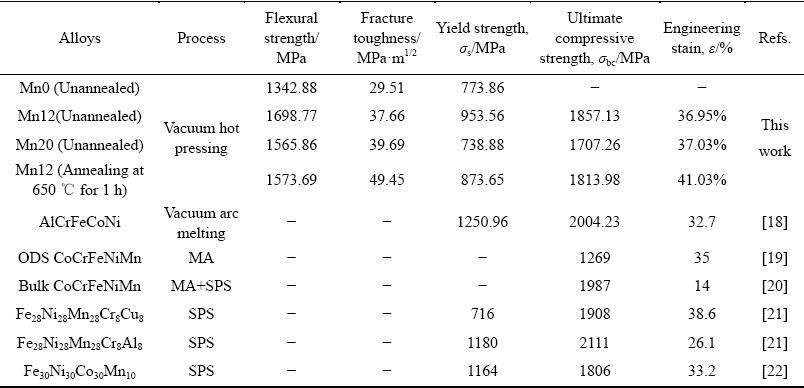

图5所示为Mn0、Mn12、Mn20和Mn12合金(650 ℃退火1 h)的压缩应力-应变曲线。由图5可知,本实验所制备的Mn0、Mn12、Mn20和Mn12合金(650 ℃退火1 h)均表现出优异的压缩性能。Mn0合金在工程压缩应变达43%时未断裂,表现出优异的塑性。Mn元素的加入改善了合金的力学性能,其中Mn12合金具有最佳的综合力学性能,压缩屈服强度σs为953.56 MPa,与Mn0合金相比,提高了23.22%;极限抗压强度σbc达1857.13 MPa,断裂应变为36.95%;弯曲强度为1698.77 MPa,较Mn0合金提高了26.5%;断裂韧性为37.66 MPa·m1/2,较Mn0合金提高了27.62%。Mn12合金在650 ℃退火1 h后性能得到进一步提升,在弯曲强度、σs和σbc降低幅度不大的情况下,断裂韧性和断裂应变分别为49.45 MPa·m1/2和41.03%,比退火前提高了31.31%和11.04%;与用真空电弧熔炼制备的AlCrFeCoNiHEA[18]相比,极限抗压强度略低,但断裂应变提高了25.47%;与HADRABA等[19]开发的纳米氧化钇增强CoCrFeNiMnHEA相比,极限抗压强度提高42.95%,断裂应变提高17.23%;与Ji等[20]通过机械合金化和放电等离子烧结技术并辅以退火工艺制备的大块状CoCrFeNiMn HEA相比,极限抗压强度相近,断裂应变提高了193.07%;与XIA等[21]采用“机械合金化+放电等离子烧结法”制备的 Fe28Ni28Mn28Cr8Cu8和 Fe28Ni28Mn28Cr8Al8两种HEAs合金相比,压缩屈服强度、极限抗压强度相差不大,断裂应变分别提高了6%和57%;与WU等[22]通过放电等离子烧结法制备的Fe30Ni30Co30Mn10HEA相比,极限抗压强度相近,断裂应变提高了23.58%。优异的综合性能主要归因于富Fe第二相的强化作用和退火工艺形成的大量退化孪晶。

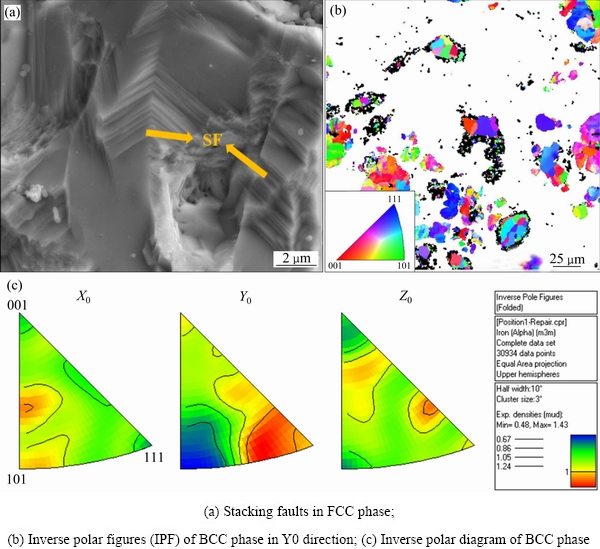

图6所示为Mn12合金(650 ℃退火1 h)FCC相和BCC相特征。图6(a)清晰可见堆垛层错(SF),层错具有一定的宽度,使得位错的交叉滑移和爬升变得困难,塑性变形机制转变为孪生,对提高强度和塑性有利[23]。图6(b)和(c)为BCC相的织构特征,由图6(b)可见,晶粒取向部分平行于(111)晶面,由图6(c)亦可看出,BCC相在Y0方向 织构相对较强,织构强度为1.43。众所周知,BCC相合金,滑移通常发生在{110}、{112}或{123}的任一平面上,BCC相合金在上述三个平面上沿着共同的

织构相对较强,织构强度为1.43。众所周知,BCC相合金,滑移通常发生在{110}、{112}或{123}的任一平面上,BCC相合金在上述三个平面上沿着共同的 方向滑动,该行为被称之为“铅笔滑动”[24]。Mn12合金经退火处理后,BCC相在

方向滑动,该行为被称之为“铅笔滑动”[24]。Mn12合金经退火处理后,BCC相在 滑移方向上织构相对较强,因此滑移变形易于发生,从而使合金具有高强高韧力学性能。

滑移方向上织构相对较强,因此滑移变形易于发生,从而使合金具有高强高韧力学性能。

对于(FeCoNiCr)100-xMnx合金,Ni含量愈高,堆垛层错能(SFE)愈大,可能与Ni的SFE值大有关(γNi=125 mJ/m2[25])。由此可见,调节组成元素对SFE的影响较大,增加具有低SFE的成分或减少具有高SFE的成分会导致HEA通过孪生显性过程变形。因此,本研究随着Mn含量的增加,Ni含量较低的FCC相所在区域会具有较低的SFE,退火孪晶更容易产生,如图1(e)所示。SFE低,HEAs表现出了强度和塑性的良好平衡[26]。随着SFE的减少,变形机制会从位错滑动转变为变形孪生,有效地增加了位错储存能力,并提供了稳定的加工硬化源,从而提高了强度和塑性[27]。

图5 Mn0、Mn12、Mn20和Mn12合金(650 ℃退火1 h)的压缩应力-应变曲线

Fig. 5 Compressive stress-strain curves of Mn0, Mn12, Mn20 and Mn12 (annealed at 650 ℃ for 1 h) alloys

表1 几种HEAs合金的室温力学性能对比

Table 1 Mechanical properties of several HEAS at room temperature prepared by different technologies

图6 Mn12合金(650 ℃退火1 h)中FCC相和BCC相特征

Fig. 6 Characteristics of FCC and BCC phases in Mn12 alloy (annealed at 650 ℃ for 1 h)

3 结论

1) (FeCoNiCr)100-xMnx(x=0、12、20)合金经900 ℃真空热压烧结后,Mn0合金的微观组织为FCC单相固溶体,Mn12和Mn20合金为FCC/BCC双相组织,并析出纳米级金属间化合物,Mn12合金经650 ℃退火1h后织构得到优化,出现退火孪晶组织。

2) (FeCoNiCr)100-xMnx(x=0、12、20)合金均表现出优异的力学性能,Mn12在650 ℃退火1 h后具有最佳的综合力学性能,压缩屈服强度为873.65 MPa,极限抗压强度为1813.98 MPa,断裂应变为41.03%,弯曲强度为1573.69 MPa,断裂韧性为49.45 MPa·m1/2。

3) 退火Mn12合金优异的力学性能归因于BCC相的第二相强化作用和优化的组织结构,以及退火后FCC相中低堆垛层错能区域孪晶诱导塑性效应(TWIP);与此同时,BCC相中与滑移方向平行的晶粒取向,亦是其具有高强高韧力学性能的原因之一。

REFERENCES

[1] YEH J W, CHEN S K, LIN S J, et al. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes[J]. Advanced Engineering Materials, 2004, 6: 299-303.

[2] ZHANG W R, LIAWP, ZHANG Y. Science and technology in high-entropy alloys[J]. Science CHINA Materials, 2018, 61: 2-22.

[3] WU Z, BEI H, OTTO F, et al. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys[J]. Intermetallics, 2014, 46: 131-140.

[4] SENKOV O N, SCOTT J M, SENKOVA S V, et al. Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy[J]. Journal of Alloys and Compounds, 2011, 509: 43-60.

[5] LIU W H, LU Z P, HE J Y, et al. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases[J]. Acta Materialia, 2016, 116:332-342.

[6] TONG Y, CHEN D, HAN B, et al. Outstanding tensile properties of a precipitation-strengthened FeCoNiCrTi0.2 high-entropy alloy at room and cryogenic temperatures[J]. Acta Materialia, 2019, 165: 228-240

[7] XU Z, LI Z, TONG Y, et al. Microstructural and mechanical behavior of a CoCrFeNiCu4 non-equiatomic high entropy alloy[J]. Journal of Materials Science and Technology, 2020, 60: 35-43.

[8] ZHANG T, XIN L J, WU F F, et al. Microstructure and mechanical properties of FexCoCrNiMn high-entropy alloys[J]. Journal of Materials Science and Technology, 2019, 35: 213-217.

[9] LIU T K, WU Z, STOICA A D, et al. Twinning-mediated work hardening and texture evolution in CrCoFeMnNi high entropy alloys at cryogenic temperature[J]. Materials & Design, 2017, 131: 419-427.

[10] GAO X Z, LU Y P, ZHANG B, et al. Microstructural origins of high strength and high ductility in anAlCoCrFeNi2.1 eutectic high-entropy alloy[J]. Acta Materialia, 2017, 141: 59-66.

[11] STEPANOV N D, SHAYSULTANOV D G, CHERNICHENKO R S, et al. Effect of thermomechanical processing on microstructure and mechanical properties of the carbon-containing CoCrFeNiMn high entropy alloy[J]. Journal of Alloys and Compounds, 2017, 693: 394-405.

[12] HUANG H L, WU Y, HE J Y, et al. Phase-transformation ductilization of brittle high-entropy alloys via metastability engineering[J]. Advanced Materials, 2017, 29: 1-7.

[13] ROGAL L, KALITA D, LITYNSKA-DOBRZYNSKA L. CoCrFeMnNi high entropy alloy matrix nanocomposite with addition of Al2O3[J]. Intermetallics, 2017, 86: 104-109.

[14] LI Z M, PRADEEP K G, DENG Y, et al. Metastable high- entropy dual-phase alloys overcome the strength-ductility trade-off[J]. Nature, 2016, 534: 227-230.

[15] FULLMAN R L, FISHER J C. Formation of annealing twins during grain growth[J]. Journal of Applied Physics, 1951, 22: 1350-1355.

[16] XIA S, LI H, ZHOU B X, et al. Control and application of annealing twins in metallic materials: Grain boundary engineering[J]. Chinese Journal of Nature, 2010, 32: 36-42.

[17] TAKEUCHI A, INOUE A. Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element[J]. Materials Transactions, 2005, 46: 2817-2829.

[18] WANG Y P, LI B S, REN M X, et al. Microstructure and compressive properties of AlCrFeCoNi high entropy alloy[J]. Materials Science & Engineering A, 2008, 491: 154-158.

[19] HADRABA H, CHLUP Z, DLOUHY A, et al. Oxide dispersion strengthened CoCrFeNiMn high-entropy alloy[J]. Materials Science & Engineering A, 2017, 689: 252-256.

[20] JI W, WANG W M, WANG H, ET A L. Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering[J]. Intermetallics, 2015, 56: 24-27.

[21] 夏泽邦, 陈维平, 蒋珍飞, 等. 粉末冶金制备Fe28Ni28Mn28Cr8Cu8与Fe28Ni28Mn28Cr8Al8高熵合金的微观组织与力学性能[J]. 中国有色金属学报, 2020, 30(5): 1049-1056.

XIA Ze-bang, CHEN Wei-ping, JIANG Zhen-fei, et al. Microstructure and mechanical properties of Fe28Ni28Mn28Cr8Cu8 and Fe28Ni28Mn28Cr8Al8 high entropy alloys prepared by powder metallurgy[J]. The Chinese Journal of Nonferrous Metals, 2020, 30(5): 1049-1056.

[22] WU B Y, CHEN W P, JIANG Z F, et al. Influence of Ti addition on microstructure and mechanical behavior of a FCC-based Fe30Ni30Co30Mn10 alloy[J]. Materials Science & Engineering A, 2016, 676: 492-500.

[23] SUWAS S, RAY R K. Crystallographic texture of materials[M]. Springer London, 2014.

[24] ARGON A S. Strengthening mechanisms in crystal plasticity[M]. Oxford University Press, 2008.

[25] CARTER C B, HOLMES S M. The stacking-fault energy of nickel[J]. Philosophical Magazine, 1977, 35: 1161-1172.

[26] SUN S J, TIAN Y Z, LIN H R, et al. Temperature dependence of the Hall-Petch relationship in CoCrFeMnNi high-entropy alloy[J]. Journal of Alloys and Compounds, 2019, 806: 992-998.

[27] AN X H, WU S D, WANG Z G, et al. Significance of stacking fault energy in bulk nanostructured materials: insights from Cu and its binary alloys as model systems[J]. Progress in Materials Science, 2019, 101: 1-45.

Microstructure and mechanical properties of (FeCoNiCr)100-xMnx non-equiatomic high-entropy alloys with high strength and ductility

ZHAO Kun1, AI Tao-tao1, 2, FENG Xiao-ming1, 2, WANG Pei-jin1, BAO Wei-wei1, 2, LI Wen-hu1, 2, KOU Ling-jiang1, 2, DONG Hong-feng1, 2, ZOU Xiang-yu1, 2, DENG Zhi-feng1, 2, ZHAO Zhong-guo1, 2

(1. School of Materials Science and Engineering, Shaanxi University of Technology, Hanzhong 723000, China;

2. National & Local Joint Engineering Laboratory for Environmental Protection Technology for Comprehensive Utilization of Slag, Shaanxi University of Technology, Hanzhong 723000, China)

Abstract: Non-equiatomic (FeCoNiCr)100-xMnx(x=0, 12, 20) high-entropy alloys were studied. The results indicated that (FeCoNiCr)100-xMnx alloys containing Mn prepared by vacuum hot pressing sintering presented dual-phase microstructure composed of the face centered cubic (FCC)/body centered cubic (BCC) phases, and precipitated a lot of nanometer intermetallic compounds. The (FeCoNiCr)88Mn12 alloy after annealed at 650 ℃ for 1 h had the best comprehensive mechanical properties, with compressive yield strength of 873.65 MPa, ultimate compressive strength of 1813.98 MPa, fracture strain of 41.03%,flexural strength of 1573.69 MPa and fracture toughness of 49.45 MPa·m1/2. The excellent comprehensive mechanical properties were attributed to the second phase strengthening effect of BCC phases and a large number of annealing twins formed in the low stacking fault energy region. The design concept of TWIP-assisted non-equiatomic dual-phase high-entropy alloys can provide a new idea for the composition design of high-entropy alloys.

Key words: high-entropy alloy; microstructure; mechanical properties; second phase strengthening; annealing twin

Foundation item: 陕西理工大学人才项目(SLGQD1801)

Received date: 2021-03-04; Accepted date: 2021-08-02

Corresponding author: AI Tao-tao; Tel: ; E-mail: aitaotao0116@126.com

(编辑 )

基金项目:陕西理工大学人才项目(SLGQD1801)

收稿日期:2021-03-04;修订日期:2021-08-02

通信作者:艾桃桃,教授,博士;电话: ;E-mail:aitaotao0116@126.com

摘 要:设计开发了一种非等原子(FeCoNiCr)100-xMnx(x=0、12、20)高熵合金的制备工艺。结果表明:采用真空热压烧结技术制备的含Mn型(FeCoNiCr)100-xMnx合金由面心立方(FCC)和体心立方(BCC)相组成,并析出大量的纳米级金属间化合物。经650 ℃退火1h后,(FeCoNiCr)88Mn12合金的综合力学性能最佳,压缩屈服强度为873.65 MPa,极限抗压强度为1813.98 MPa,断裂应变为41.03%,弯曲强度为1573.69 MPa,断裂韧性为49.45 MPa·m1/2。优异的力学性能归因于BCC相的强化作用以及低堆垛层错能区域所形成的大量退火孪晶。孪晶诱导塑性(TWIP)辅助的非等原子双相高熵合金设计理念,为高熵合金成分设计提供了一种新的思路。