文章编号:1004-0609(2010)12-2274-09

等通道角挤压制备细晶ZK60镁合金的组织与力学性能

何运斌1,潘清林1,覃银江1,刘晓艳1,李文斌1,Yu-lung CHIU2,John J J CHEN2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. Department of Chemical and Materials Engineering, University of Auckland, Auckland 1102, New Zealand)

摘 要:

利用两种等通道角挤压(ECAP)方法(普通单步ECAP和两步ECAP)制备细晶ZK60合金。采用金相显微镜、扫描电镜、透射电镜和X射线衍射仪对合金的组织和织构进行观察,通过拉伸试验研究不同ECAP方法对合金力学性能的影响。结果表明:与单步ECAP变形相比,两步ECAP变形,由于降低了变形温度,晶粒细化效果更好;经过(240 ℃,4道次)+(180 ℃,4道次)两步ECAP变形后,合金晶粒细化至约0.8 μm;合金的力学性能与材料的织构密切相关,由于存在织构软化效应,与挤压态相比,经单步ECAP变形后合金的强度有所降低,而伸长率明显提高;但经两步ECAP变形后,由于细晶强化和亚结构强化的作用,合金的强度得到提高。

关键词:

ZK60 镁合金;等通道角挤压; 显微组织;力学性能;动态回复;再结晶;织构;

中图分类号:TG146.2 文献标志码:A

Microstructure and mechanical properties of ultra-fine grain ZK60 magnesium alloy processed by equal channel angular pressing

HE Yun-bin1, PAN Qing-lin1, QIN Yin-jiang1, LIU Xiao-yan1, LI Wen-bin1, Yu-lung CHIU2, John J J CHEN2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

(2. Department of Chemical and Materials Engineering, University of Auckland, Auckland 1102, New Zealand)

Abstract: Ultra-fine grain ZK60 magnesium alloys were fabricated separately by conventional single-step equal channel angular pressing (ECAP) processing and two-step ECAP processing. The microstructures and mechanical properties of the ZK60 magnesium alloys were investigated by optical microscopy, scanning electron microscopy, transmission electron microscopy and tensile test, and the texture was measured by XRD. The results show that, two-step ECAP is more effective in grain refinement than single-step ECAP process due to the lower deformation temperature. The grain size is refined to 0.8 μm after being processed with treatment of (240 ℃, 4 passes)+(180 ℃, 4 passes). Compared with the as-received ZK60 alloy, the single-step ECAP processed alloy has lower strength but higher elongation to failure. The decrease in strength is mainly ascribed to texture softening. However, after two-step ECAP process, the strength is improved due to the enhancement of fine grain strengthening and substructure strengthening.

Key words: ZK60 magnesium alloy; equal channel angular pressing; microstructure; mechanical properties; dynamic recovery; recrystallization; texture

镁合金作为目前工业应用中最轻的金属结构材料,在汽车、航空航天和3C电子等工业领域都有广阔的应用前景,尤其是变形镁合金的应用和研究备受关注。然而,由于镁为密排六方结构,滑移系比较少,在常温下变形能力有限,因此,这在很大程度上阻碍了镁合金的发展。改善镁合金的力学性能一个比较有效的方法就是细化晶粒[1-4]。一般而言,细晶材料具有更高的强度和更好的塑性。而等通道角挤压(ECAP)作为一种强变形的加工方法,已成功用于制备超细晶铜合金、铝合金、镁合金、钛合金以及低碳钢等块体材料[5-14]。MIYAHARA等[2],FIGUEIREDO 和LANGDON[15-18] 等研究了ECAP制度对镁合金超塑性的影响,发现经ECAP变形后的镁合金具备很好的超塑性能。ECAP的晶粒细化效果不仅与ECAP模具的结构有关,更主要取决于ECAP的温度和挤压路 径[19]。研究[20-24]表明,随着ECAP挤压温度的升高,材料的最终晶粒尺寸也变大。这主要是因为在高温下,合金的回复和再结晶加速,合金晶粒的长大速度也加快,导致晶粒粗化。 因此,为了获得良好的细化效果,宜尽量采用较低的温度。然而对于镁合金,由于低温加工性能较差,低温变形很容易造成试样开裂。因此,如何在低温变形开裂与晶粒细化之间找到一个平衡温度至关重要。

WATANABE等[25]用原始晶粒小于5 μm的ZK60镁合金,在150 ℃时利用ECAP法成功制备出晶粒尺寸为1.4 μm的超细晶ZK60合金,且该合金具有良好的低温超塑性。这说明采用细晶材料可以大大降低镁合金的ECAP变形温度。MATSUBARA等[26]采用传统挤压技术与ECAP相结合,在ECAP变形之前,利用传统挤压方法进行开坯,获得晶粒尺寸为12 μm的材料后再在200 ℃下进行ECAP变形,最终获得晶粒尺寸为0.7 μm的超细晶粒。 JIN等[27]也采用两步ECAP变形的方法,即先在较高温度下进行ECAP变形,使合金的晶粒获得一定程度细化,然后再在较低温度进行ECAP变形,使AZ31合金晶粒尺寸获得最终细化。与传统挤压相比,高温ECAP变形具有更好的晶粒细化效果。因此,本文作者采用两步ECAP法对ZK60合金进行变形,旨在得到具有超细晶粒的ZK60合金;并对不同ECAP变形工艺的组织演变、力学性能以及织构变化进行分析。

1 实验

本实验材料为工业ZK60镁合金(成分为5.6% Zn, 0.6% Zr,质量分数)挤压棒材。合金棒材经465 ℃、10 h固溶处理后,采用电火花切割成d 20 mm×100 mm的ECAP试样。

ECAP变形采用的模具为圆形通道。两通道夹角![]() 为90?,外弧圆角

为90?,外弧圆角![]() 为20?。等效应变

为20?。等效应变![]() 可根据Iwahashi的理论计算公式计算,即

可根据Iwahashi的理论计算公式计算,即

![]() (1)

(1)

由式(1)可以得出,每道次的等效应变约为1。对于单步ECAP变形,合金在240 ℃分别挤压4道次和8道次。对于两步ECAP变形,合金预先在240 ℃挤压4道次后,再于180 ℃分别挤压2道次和4道次。合金ECAP变形采用的路径为Bc,即每相邻道次之间顺时针旋转90?,ECAP过程中润滑剂采用石墨油剂。

合金室温力学性能测试在MTS材料试验机上进行,拉伸试样的标距部分尺寸为2 mm×3 mm×5 mm。标距长度方向平行于ECAP加工出口方向。拉伸应变速率为 1×10-3 s-1。

微观组织观察取样垂直于ECAP变形方向,金相组织观察样品经机械抛光后,用金相腐蚀剂1 g草酸+1 g醋酸+1 mL浓硫酸+100 mL蒸馏水进行腐蚀,然后在 Sunny 金相显微镜下观察晶粒大小和形态。晶粒大小采用线截距法进行测量。 TEM观察样品经机械减薄至0.8 μm后冲成3 mm的圆片,最后进行离子减薄。TEM观察在Tecnai G2 20 上进行,加速电压为200 kV。合金XRD分析样品取样平行于ECAP变形方向,经机械抛光后用D/MAX 2550VB+ X射线衍射仪上进行扫描,扫描速度为2 (?)/min。

2 实验结果

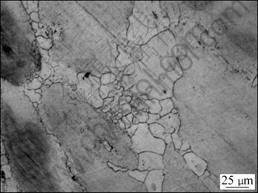

图1所示为ZK60合金原始挤压态的晶粒组织。从图1可以看出,挤压态合金组织非常不均匀,合金晶粒由粗大的未变形晶粒(100~200 μm)以及细小的再结晶晶粒(10~20 μm)组成。图2所示为合金在240 ℃经ECAP变形不同道次后的晶粒组织。从图2可以看出,经过240 ℃ECAP变形4道次后,合金晶粒得到明显细化,合金晶粒主要是等轴的再结晶晶粒,平均

图1 挤压态ZK60合金晶粒的组织

Fig.1 Grain structure of as-extruded ZK60 alloy

图2 经240 ℃ECAP变形不同道次后合金的晶粒组织

Fig.2 Grain structures of studied alloys after ECAP at 240 ℃: (a) 240 ℃, 4 passes; (b) 240 ℃, 8 passes

晶粒大小约为2.0 μm,继续增加挤压道次合金晶粒没有得到明显的进一步细化,挤压8道次后,合金的平均晶粒大小约为1.6 μm。在240 ℃ ECAP变形的合金中,除了细小的晶粒外,还存在少量大于10 μm的晶粒,说明在ECAP过程中,部分再结晶晶粒已经开始长大。张郑等[28]的研究表明,ECAP的晶粒细化效果随道次变化存在一个极限值,即当晶粒细化到一定程度以后,继续增加挤压道次,合金晶粒大小基本保持不变,且变形温度越低,极限晶粒尺寸越小。因此,为进一步细化合金晶粒,宜采用较低的变形温度。但对于晶粒较大的ZK60镁合金,当变形温度低于200 ℃时,很容易造成试样的开裂。因此,采用两步ECAP变形工艺,即在经过240 ℃ ECAP变形合金的基础上再进行低温ECAP变形,使合金晶粒得到最终的细化。两步ECAP变形后合金的晶粒组织如图3所示。经(240 ℃,4 道次)+(180 ℃,2道次)变形后,合金的晶粒细化到约1 μm,经(240 ℃,4 道次)+(180 ℃,4道次)挤压后,晶粒进一步细化至0.8 μm左右。这说明经两步ECAP变形能有效地进一步细化合金晶粒。

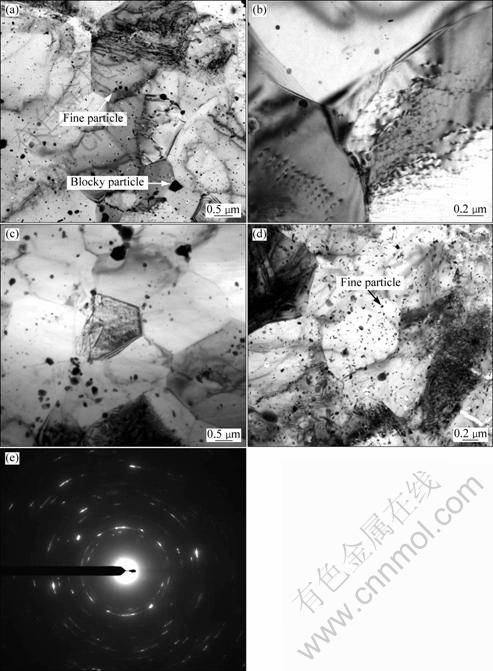

图4所示为ZK60合金经240 ℃ ECAP变形4道

图3 经两步ECAP挤压后合金的晶粒组织

Fig.3 Grain structures of studied alloy after two-step ECAP process: (a) (240 ℃, 4 passes)+(180 ℃, 2 passes); (b) (240 ℃, 4 passes)+(180 ℃, 4 passes)

次和8道次后的TEM像。从图4可以看出,经240 ℃ECAP变形4道次后,合金的微观组织主要由细小的亚晶结构组成(见图4(a));而且还可以看出,合金中存在大量的由位错塞积形成的位错界面,这些不稳定的位错结构逐渐形成亚晶界(见图4(b))。经过8道次变形后,合金中的非平衡位错结构通过动态回复和再结晶转变成稳定的再结晶晶粒组织。从相应的选区衍射可以看出衍射斑点趋于形成衍射环,说明合金中大部分晶界为大角度晶界。由于变形温度较高,合金的ECAP变形过程也伴随着时效析出过程。从TEM像中可以发现,合金中主要存在两种析出相。根据文献[29-30]报道:一种为粗大的块状MgZn2相,该相主要是在凝固过程中形成,并具有较好的稳定性;另一种为细小的粒状MgZn相,为ZK60合金中的主要析出相。这些析出相的存在能够阻碍合金中的位错运动和晶界迁移,稳定亚结构,有利于形成细小的再结晶晶粒。

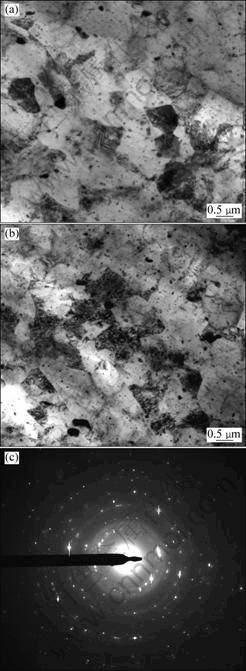

经过两步ECAP变形后,合金的晶粒得到进一步细化(见图5),平均晶粒尺寸约为1 μm左右。但从图5可以看出,合金组织存在严重畸变,合金的晶粒边界比较模糊,说明经两步ECAP变形后,合金中存在较大的内应力,形成了非平衡的晶粒组织。从选区衍射图可以看出,合金的衍射斑点趋于形成衍射环,说明经过两步ECAP挤压后,合金中大部分晶界由大角度晶界构成。

图4 ZK60合金经240 ℃ ECAP变形4道次和8道次后的TEM像

Fig.4 TEM images of ZK60 alloys after ECAP processing at 240 ℃ for different passes: (a), (b) 240 ℃, 4 passes; (c), (d) 240 ℃, 8 passes; (e) EDS pattern of Fig.4(d)

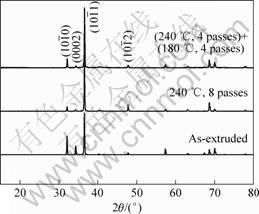

在ECAP变形过程中,ZK60合金受到强烈剪切力的作用,其晶粒取向将发生改变。图6所示为ZK60原始挤压态和ECAP变形后的XRD谱。从图6可以看出,对于原始挤压态合金,(10![]() 0)晶面的X射线衍射峰的强度很高。经ECAP多道次挤压后,ZK60合金(10

0)晶面的X射线衍射峰的强度很高。经ECAP多道次挤压后,ZK60合金(10![]() 0)晶面的衍射峰强度降低,而(10

0)晶面的衍射峰强度降低,而(10![]() 1)方向的衍射强度则明显增高。为了进一步分析合金经ECAP挤压后的晶粒取向变化,对合金的X射线衍射峰进行归一化处理。定义X射线衍射峰的相对强度(J)如下:

1)方向的衍射强度则明显增高。为了进一步分析合金经ECAP挤压后的晶粒取向变化,对合金的X射线衍射峰进行归一化处理。定义X射线衍射峰的相对强度(J)如下:

![]() (2)

(2)

式中:Ii为扣除背底后的衍射强度;i=(10![]() 0),(0002),(10

0),(0002),(10![]() 1),(10

1),(10![]() 2)。为了评价晶粒取向的大小,定义取

2)。为了评价晶粒取向的大小,定义取

图5 ZK60合金经两步ECAP变形后的TEM像

Fig.5 TEM images of ZK60 alloys after two-step ECAP process: (a) (240 ℃, 4 passes)+(180 ℃, 2 passes); (b) (240 ℃, 4 passes)+(180 ℃, 4 passes) (c), (b) EDS pattern of Fig.5(b)

向参数K的计算公式如下:

![]() (3)

(3)

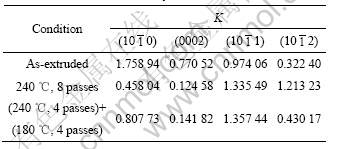

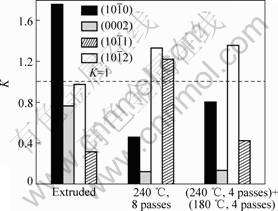

式中:Jexp为实验测得的相对强度;Jran为具有随机织构取向的相对强度。如K趋向于1,则表明晶粒取向趋向于随机分布;K大于1,表明有明显的取向;K小于1则表明无明显取向。ECAP变形后合金各晶面的相对衍射强度如表1所列,各晶面的K值如图7所示。

从表1和图7可以看出,对于原始挤压态合金,(10![]() 0)晶面的K值达到1.7,表明合金在(10

0)晶面的K值达到1.7,表明合金在(10![]() 0)方向上具有明显的取向;而(0002)和(10

0)方向上具有明显的取向;而(0002)和(10![]() 1)晶面的K值接

1)晶面的K值接

图6 ZK60合金不同状态下的XRD谱

Fig.6 XRD patterns of ZK60 alloys under different conditions

表1 ZK60合金不同状态的K值

Table 1 K value of ZK60 alloys under different conditions

图7 不同状态下合金各界面的K值

Fig.7 K values of planes for ZK60 alloy under different conditions

近1,说明在该晶面上晶粒趋向于随机分布;而经过240 ℃ ECAP挤压8道次后,(10![]() 0)晶面的相对强度明显降低,而(10

0)晶面的相对强度明显降低,而(10![]() 1)和(10

1)和(10![]() 2)晶面的相对强度则明显提高,表明经过ECAP挤压后,合金中的晶粒取向发生了明显变化,由ECAP挤前的强(10

2)晶面的相对强度则明显提高,表明经过ECAP挤压后,合金中的晶粒取向发生了明显变化,由ECAP挤前的强(10![]() 0)取向转变成(10

0)取向转变成(10![]() 1)和(10

1)和(10![]() 2)取向。经过两步ECAP变形后,(10

2)取向。经过两步ECAP变形后,(10![]() 2)取向逐渐弱化,合金只存在明显的(10

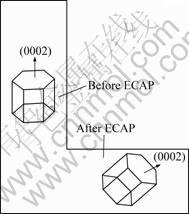

2)取向逐渐弱化,合金只存在明显的(10![]() 1)取向。合金ECAP过程中的晶粒取向示意图如图8所示。

1)取向。合金ECAP过程中的晶粒取向示意图如图8所示。

图8 ECAP 前、后合金晶粒取向变化图

Fig.8 Variation of crystal orientation before and after ECAP

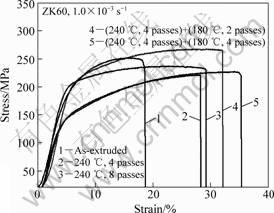

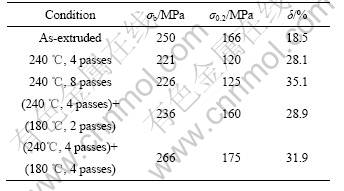

图9所示为ZK60合金经不同ECAP变形后的应力—应变曲线,其抗拉强度,屈服强度和伸长率如表2所列。从以上结果可以看出,与原始挤压态合金相比,经240 ℃ ECAP变形4道次和8道次后,合金的抗拉强度和屈服强度都明显降低,但是其伸长率明显增大; 对比不同ECAP变形道次的拉伸曲线可以发现,增加ECAP变形道次对合金强度的提高并不明显,

图9 不同状态下ZK60合金的室温应力—应变曲线

Fig.9 Stress—strain curves of ZK60 magnesium alloys under different conditions

表2 不同状态下合金的室温拉伸力学性能

Table 2 Mechanical properties of studied alloys under different conditions

但可使合金的伸长率明显提高。经两步ECAP变形后,合金的强度与单步ECAP变形相比得到明显提高,但仍然低于原始挤压态合金时;合金的伸长率与单步ECAP变形相比有所降低,但与原始挤压态相比,也得到明显提高。

3 讨论

从以上实验结果可以看出,ECAP变形能有效地细化ZK60合金的晶粒。而相比而言,两步ECAP变形比单步ECAP变形的晶粒细化效果更明显。实际上,两步ECAP变形与单步ECAP变形相比,主要是降低了变形温度,说明变形温度对ECAP过程的晶粒细化起着至关重要的作用。

张郑等[28]对于7475铝合金的研究表明,7475铝合金在250 ℃ ECAP变形8道次以后,合金的微观组织趋于稳定,合金晶粒很难再进一步细化。这说明在一定温度下,ECAP的晶粒细化效果存在一个极限,而该极限值与变形温度密切相关。细化极限晶粒大小与ECAP变形温度之间的关系可以表示为

![]() (4)

(4)

式中:α,β为常数。从式(4)可以看出,ECAP变形后的极限晶粒尺寸的倒数与温度的倒数成正比,即变形温度越低,极限晶粒尺寸越细。从本实验结果来看,对于两步ECAP加工,挤压温度从240 ℃降低到180 ℃后,合金晶粒也由约1.6 μm减小到约0.8 μm,基本符合该规律。 从微观组织上来看,当挤压温度较高时,镁合金的基面滑移和非基面滑移被激活,在ECAP变形初期是多滑移系一起开动,形成分布杂乱的位错缠结。部分位错缠结逐渐形成位错界面、亚结构及进一步形成小角度亚晶界(见图2(b))。随着变形量的增加,位错胞的数量逐渐增加,尺寸减小,胞内位错逐渐减少,而胞壁位错逐渐增加,小角度亚晶界逐渐转变成大角度晶界,晶粒被新形成的界面重新分割,从而得到明显细化。从图2可以看出,经过4道次ECAP变形后,合金组织主要由细小、等轴的再结晶晶粒组成。继续增加挤压道次,在晶内产生的位错密度减小,同时由于晶粒尺寸较小,位错运动的平均自由程减小,晶内位错很容易被已形成的大角度晶界吸收,因而不会再在晶粒内部重新形成新的界面,相当于在位错的产生和大角度晶界吸收位错这两者之间达到一个平衡。因此,晶粒不能得到进一步细化,只是大角度晶界吸收晶内位错后,晶粒间的取向差进一步增大。

SU等[31]的研究表明,动态再结晶过程可以认为是一个热激活过程,即原子越过势垒从一个晶粒穿过晶界迁移到另一个晶粒。晶界的迁移速率随温度呈指数增长,即温度越低,迁移速率越慢。 因此,低温可以降低原子的迁移速率,从而延缓小角度晶界向大角度晶界的转变,使晶内的位错密度急剧增大。根据低能位错理论[32],这些位错很容易形成小角度的亚晶界,这些亚晶界把原始晶粒分割成小的亚晶,从而使晶粒得到进一步细化。在本试验中,两步ECAP变形采用的挤压温度为180 ℃,远远低于单步ECAP变形的温度。在此温度下,合金的晶界迁移受到抑制,回复速率减慢,因此,晶粒细化效果要比单步ECAP变形要好。

通常情况下,材料的强度与晶粒大小的关系符合Hall-Petch公式,即随着晶粒尺寸的减小,合金的强度提高:

![]() (5)

(5)

其中:σ0.2为屈服强度;σ0和k均为材料常数;d为晶粒大小。然而式(5)只适用于不存在织构或者织构较弱的材料。对于具有强织构的材料,Hall-Petch公式将不再适用,因为织构的变化将强烈影响Schmid因子的变化:

![]() (6)

(6)

式中:μ为Schmid因子,![]() (λ和

(λ和![]() 分别为拉力与滑移面法线的夹角和拉力与滑移方向的夹角)。从式(6)可知,作用在材料上的分切应力与Schmid因子密切相关。而对于具有强织构的材料而言,晶粒具有明显的取向,因此,织构的类型和强弱将强烈影响Schmid因子。当织构处于硬取向时,能大大提高材料的强度,而织构处于软取向时,则降低材料的强度。 在本实验中,对于原始挤压态合金,从X射线分析可以看出,合金晶粒具有强烈的(10

分别为拉力与滑移面法线的夹角和拉力与滑移方向的夹角)。从式(6)可知,作用在材料上的分切应力与Schmid因子密切相关。而对于具有强织构的材料而言,晶粒具有明显的取向,因此,织构的类型和强弱将强烈影响Schmid因子。当织构处于硬取向时,能大大提高材料的强度,而织构处于软取向时,则降低材料的强度。 在本实验中,对于原始挤压态合金,从X射线分析可以看出,合金晶粒具有强烈的(10![]() 0)取向,即大部分晶粒的(10

0)取向,即大部分晶粒的(10![]() 0)面平行于拉伸方向,而滑移面(0002)则垂直于拉伸方向而处于硬取向(见图8),因此合金得到织构的强化。而对于ECAP变形后的合金,大部分晶粒具有á10

0)面平行于拉伸方向,而滑移面(0002)则垂直于拉伸方向而处于硬取向(见图8),因此合金得到织构的强化。而对于ECAP变形后的合金,大部分晶粒具有á10![]() 1?和á10

1?和á10![]() 2?取向,这些晶粒处于软取向,因此使合金的强度降低。而对于两步ECAP加工的合金,á10

2?取向,这些晶粒处于软取向,因此使合金的强度降低。而对于两步ECAP加工的合金,á10![]() 2?取向稍有减弱,使织构的弱化效果有所减弱。另外,由于两步ECAP变形合金的挤压温度较低,合金中的位错密度比单步ECAP变形合金中的高,一定程度上也使合金的强度提高。因此,两步ECAP变形后虽然存在织构软化效应,但是由于细晶强化和亚结构强化的作用,合金的强度整体上还是有所提高。

2?取向稍有减弱,使织构的弱化效果有所减弱。另外,由于两步ECAP变形合金的挤压温度较低,合金中的位错密度比单步ECAP变形合金中的高,一定程度上也使合金的强度提高。因此,两步ECAP变形后虽然存在织构软化效应,但是由于细晶强化和亚结构强化的作用,合金的强度整体上还是有所提高。

4 结论

1) 两步ECAP变形与单步ECAP变形相比,由于降低了变形温度,具有更好的晶粒细化效果,经(240 ℃,4道次)+(180 ℃,4道次)ECAP变形后,合金晶粒细化至 0.8 μm。

2) 与原始挤压态相比,合金经单步ECAP变形后强度有所降低,但伸长率明显增加,强度的降低主要是织构软化所致;而经两步ECAP变形后,由于细晶强化和亚结构强化作用增强,合金的强度有所提高。

REFERENCES

[1] HAN B Q, LANGDON T G. Improving the high-temperature mechanical properties of a magnesium alloy by equal-channel angular pressing[J]. Materials Science and Engineering A, 2005, 410: 435-438.

[2] MIYAHARA Y, MATSUBARA K, HORITA Z, LANGDON T. Grain refinement and superplasticity in a magnesium alloy processed by equal-channel angular pressing[J]. Metallurgical and Materials Transactions A, 2005, 36(7): 1705-1711.

[3] SU C W, CHUA B W, LU L, LAI M O. Properties of severe plastically deformed Mg alloys[J]. Materials Science and Engineering A, 2005, 402(1/2): 163-169.

[4] KAI M, HORITA Z, LANGDON T G. Developing grain refinement and superplasticity in a magnesium alloy processed by high-pressure torsion[J]. Materials Science and Engineering A, 2008, 488(1/2): 117-124.

[5] 路 君, 靳 丽, 董 杰, 曾小勤, 丁文江, 姚真裔. 等通道角挤压变形AZ31镁合金的变形行为[J]. 中国有色金属学报, 2009, 19(3): 424-432.

[6] LU Jun, JIN Li, DONG Jie, ZENG Xiao-qin, DING We-jiang, YAO Zhen-yi. Deformation behaviors of AZ31 magnesium alloy by equal channel angular extrusion[J]. The Chinese Journal Nonferrous Metals, 2009, 19(3): 424-432.

[7] AMOUYAL Y, DIVINSKI S V, KLINGER L, RABKIN E. Grain boundary diffusion and recrystallization in ultrafine grain copper produced by equal channel angular pressing[J]. Acta Materialia, 2008, 56(19): 5500-5513.

[8] EI-DANAF E A. Mechanical properties and microstructure evolution of 1050 aluminum severely deformed by ECAP to 16 passes[J]. Materials Science and Engineering A, 2008, 487(1/2): 189-200.

[9] QU S, HUANG C X, GAO Y L, YANG G, WU S D, ZANG Q S, ZHANG Z F. Tensile and compressive properties of AISI 304L stainless steel subjected to equal channel angular pressing[J]. Materials Science and Engineering A, 2008, 475(1/2): 207-216.

[10] MATHIS K, RAUCH E F. Microstructural characterization of a fine-grained ultra low carbon steel[J]. Materials Science and Engineering A, 2007, 462(1/2): 248-252.

[11] ZHAO X C, FU W J, YANG X R, LANGDON T G. Microstructure and properties of pure titanium processed by equal-channel angular pressing at room temperature[J]. Scripta Materialia, 2008, 59(5): 542-545.

[12] 郑立静, 陈昌麒, 周铁涛, 刘培英, 曾梅光. ECAP细晶机制及对纯铝显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2004, 33(12): 1325-1328.

[13] ZHENG Li-jing, CHEN Chang-qi, ZHOU Tie-tao, LIU Pei-ying, ZENG Mei-guang. Grain-refining mechanism of ECAP and its effect on microstructures and mechanical properties of pure Al[J]. Rare Metal Materials and Engineering, 2004, 33(12): 1325-1328.

[14] 孙有平, 严红革, 陈振华, 陈 刚. Bc路径等径角挤压7090/SiCp的显微组织及性能[J]. 中国有色金属学报, 2008, 18(11): 1964-1970.

[15] SUN You-ping, YAN Hong-ge, CHEN Zhen-hua, CHEN Gang. Microstructure and properties of Bc route ECAP of 7090/SiCp composite[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(11): 1964-1970.

[16] SONG Dan, MA Ai-bin, JIANG Jing-hua, LIN Pin-hua, YANG Dong-hui. Corrosion behavior of ultra-fine grained industrial pure Al fabricated by ECAP[J]. Transactions of Nonferrous Metals Society of China, 2009, 19: 1065-1070.

[17] 李 萍, 黄科帅, 薛克敏, 周明智, 韩国民. 纯铝粉末多孔烧结材料等通道转角挤压[J]. 中国有色金属学报, 2009, 19(5): 881-886.

[18] LI Ping, HUANG Ke-shuai, XUE Ke-min, ZHOU Ming-zhi, HAN Guo-min. Equal channel angular pressing of pure Al powder sintered material[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 881-886.

[19] FIGUEIREDO R B, LANGDON T G. Strategies for achieving high strain rate superplasticity in magnesium alloys processed by equal-channel angular pressing[J]. Scripta Materialia, 2009, 61(1): 84-87.

[20] LOPOVOK R, ESTRIN Y, POPOV M V, LANGDON T G. Enhanced superplasticity in a magnesium alloy processed by equal-channel angular pressing with a back-pressure[J]. Advanced Engineering Materials, 2008, 10(5): 429-433.

[21] FIGUEIREDO R B, LANGDON T G. Developing superplasticity in a magnesium AZ31 alloy by ECAP[J]. Journal of Materials Science, 2008, 43(23/24): 7366-7371.

[22] MIYAHARA Y, HORITA Z, LANGDON T G. Exceptional superplasticity in an AZ61 magnesium alloy processed by extrusion and ECAP[J]. Materials Science and Engineering A, 2006, 420(1/2): 240-244.

[23] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51(7): 881-981.

[24] GUTIERREZ-URRUTIA I, MUNOZ-MORRIS M A, PUERTAS I, LUIS C, MORRIS D G. Influence of processing temperature and die angle on the grain microstructure produced by severe deformation of an Al-7%Si alloy[J]. Materials Science and Engineering A, 2008, 475(1/2): 268-278.

[25] GOLOBORODKO A, SITDIKOV O, KAIBYSHEV R, MIURA H, SAKAI T. Effect of pressing temperature on fine-grained structure formation in 7475 aluminum alloy during ECAP[J]. Materials Science and Engineering A, 2004, 381(1/2): 121-128.

[26] YAMASHITA A, YAMAGUCHI D, HORITA Z, LANGDON T G. Influence of pressing temperature on microstructural development in equal-channel angular pressing[J]. Materials Science and Engineering A, 2000, 287(1):100-106.

[27] SHIN D H, PAK J J, KIM Y K, PARK K T, KIM Y S. Effect of pressing temperature on microstructure and tensile behavior of low carbon steels processed by equal channel angular pressing[J]. Materials Science and Engineering A, 2002, 325(1/2):31-37.

[28] RAAB G I, SOSHNIKOVA E P, VALIEV R Z. Influence of temperature and hydrostatic pressure during equal-channel angular pressing on the microstructure of commercial-purity Ti[J]. Materials Science and Engineering A, 2004, 387/389: 674-677.

[29] WATANABE H, MUKAI T, ISHIKAWA K, HIGASHI K. Low temperature superplasticity of a fine-grained ZK60 magnesium alloy processed by equal-channel-angular extrusion[J]. Scripta Materialia, 2002, 46(12): 851-856.

[30] MATSUBARA K, MIYAHARA Y, HORITA Z, LANGDON T G. Developing superplasticity in a magnesium alloy through a combination of extrusion and ECAP[J]. Acta Materialia, 2003, 51(11): 3073-3084.

[31] JIN L, LIN D L, MAO D L, ZENG X Q, DING W J. Mechanical properties and microstructure of AZ31 Mg alloy processed by two-step equal channel angular extrusion[J]. Materials Letters, 2005, 59(18): 2267-2270.

[32] 张 郑, 王经涛, 赵西成. 7475铝合金ECAP的晶粒细化极限[J]. 中国有色金属学报, 2004, 14(5): 741-745.

[33] ZHANG Zhen, WANG Jing-tao, ZHAO Xi-cheng. Microstructure and grain refinement limit of 7475 aluminum alloy after equal channel angular pressing[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 741-745.

[34] MA Y L, PAN F S, ZUO R L, ZHANG J, YANG M B. Effects of heat-treatment on microstructure of wrought magnesium alloy ZK60[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 1888-1891.

[35] PAN F S, WANG W M, MA Y L, ZUO R L, TANG A T, ZHANG J. Investigation on the alloy phases in as-aged ZK60 magnesium alloy[J]. Materials Science Forum, 2005, 488/489: 181-184.

[36] SU C W, LU L, LAI M O. Recrystallization and grain growth of deformed magnesium alloy[J]. Phiosophical Magazine, 2008, 88(2): 181-200.

[37] KUHLMANN-WILSDORF D. LEDS: Properties and effects of low energy dislocation structures[J]. Materials Science and Engineering A, 1987, 86: 53-66.

(编辑 龙怀中)

基金项目:新西兰奥克兰大学国际合作资助项目(9271/3609563)

收稿日期:2009-12-07;修订日期:2010-03-08

通信作者:潘清林,教授,博士;电话:0731-88830933;E-mail:mcdonlean@gmail.com

[5] 路 君, 靳 丽, 董 杰, 曾小勤, 丁文江, 姚真裔. 等通道角挤压变形AZ31镁合金的变形行为[J]. 中国有色金属学报, 2009, 19(3): 424-432.

[12] 郑立静, 陈昌麒, 周铁涛, 刘培英, 曾梅光. ECAP细晶机制及对纯铝显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2004, 33(12): 1325-1328.

[14] 孙有平, 严红革, 陈振华, 陈 刚. Bc路径等径角挤压7090/SiCp的显微组织及性能[J]. 中国有色金属学报, 2008, 18(11): 1964-1970.

[17] 李 萍, 黄科帅, 薛克敏, 周明智, 韩国民. 纯铝粉末多孔烧结材料等通道转角挤压[J]. 中国有色金属学报, 2009, 19(5): 881-886.

[32] 张 郑, 王经涛, 赵西成. 7475铝合金ECAP的晶粒细化极限[J]. 中国有色金属学报, 2004, 14(5): 741-745.