DOI: 10.11817/j.ysxb.1004.0609.2021-36540

轧制单层和少层晶铜箔塑性各向异性的晶体塑性有限元模拟

陈守东1, 2,卢日环2,孙 建1,李 杰1

(1. 铜陵学院 机械工程学院,铜陵 244061;

2. 东北大学 轧制技术及连轧自动化国家重点实验室,沈阳 110819)

摘 要:

采用具有拉拔-压缩-剪切复合成形功能的微型异步轧机,对厚度方向具有单层和少层晶结构的铜极薄带开展箔轧实验。基于晶体塑性有限元理论,模拟分析复合轧制单层和少层晶铜极薄带的塑性各向异性行为。将单层和少层晶铜极薄带的初始织构和晶粒形貌输入晶体塑性有限元模型,分析极薄带轧制成形中晶粒层次的滑移启动、定量应变演化以及变形局部化现象。同时,模拟分析单/多滑移系启动、滑移局部化以及与微观组织相关的变形演化。结果表明:轧制单层晶铜极薄带的滑移区域和局部化趋势主要依赖于晶粒形貌结构,晶体塑性有限元模型准确获得滑移启动及其滑移区域的演化。轧制少层晶铜极薄带的滑移和塑性变形具有明显的各向异性,且随晶粒层数的减少而增强。同一晶粒内部和相邻晶粒的晶界局部区域存在显著的滑移与变形差异,这为裂纹的萌生和缺陷的形成提供了有利的位置。

关键词:

文章编号:1004-0609(2021)-02-0353-12 中图分类号:TG335.5 文献标志码:A

引文格式:陈守东, 卢日环, 孙 建, 等. 轧制单层和少层晶铜箔塑性各向异性的晶体塑性有限元模拟[J]. 中国有色金属学报, 2021, 31(2): 353-364. DOI: 10.11817/j.ysxb.1004.0609.2021-36540

CHEN Shou-dong, LU Ri-huan, SUN Jian, et al. Crystal plasticity finite element simulations for plastic anisotropy in single layer and oligo-crystal copper under foil rolling[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 353-364. DOI: 10.11817/j.ysxb.1004.0609.2021-36540

微机械/微机构所使用的各种微零部件是由很多形状、尺寸和取向各异的单晶体组合而成,这些性能差异的单晶体决定其多晶体微构件成形和使用的性能,如晶粒尺寸、取向和织构的差异会导致应力流动和塑性变形的各向异性。即使在单相组织的金属材料中,各晶粒具有相同的晶体结构,但是由于初始晶粒取向、滑移系启动以及位错密度差异,各晶粒在变形和热处理过程中会表现出不同的性能[1-4]。多晶体金属材料经过热处理、轧制、拉拔、锻压等塑性成形工艺,制备出满足使用性能、结构和尺寸精度的各种零部件。塑性变形程度在单个晶粒内部或相邻晶粒之间是极不均匀的,这将导致应力-应变的局部化和微观组织的各向异性演化,这是由各晶粒的弹-塑性异向性和相邻晶粒协调变形造成的。经过热处理和塑性变形,材料内会形成择优取向或变形各向异性,准确获得这些信息对精确控制成形精度与预防缺陷产生具有重要作用。特别对于厚度只有0.1 mm的金属极薄带材而言,在其厚度方向只分布一层或几层晶粒,单个晶粒的特性对极薄带材成形性能影响更大,其中表层晶粒相对心部晶粒具有不同的微观变形特性[5-8]。

基于位错滑移导致塑性变形的晶体塑性有限元模型(CPFEM)被广泛的应用于单/多晶体材料宏微观变形不均匀性以及微观组织-性能之间关系的分析,其直接将各晶粒的结构、形貌、取向以及各滑移系的启动信息输入到模型,可分析微观组织特性对成形性能的影响。晶体塑性有限元模型已成功用于铝带轧制变形和轧制铜带的微压缩-微冲裁等微塑性成形的模拟分析,其基于微观结构建模的特点,可分析极薄带变形过程中的尺寸效应现象[9-13]。本文采用基于微观结构建模的晶体塑性有限元模型,模拟分析拉-压-剪复合轧制单层和少层晶铜箔的塑性各向异性行为。采用自编程晶粒形貌生成和取向赋予程序,根据实验提供的晶粒尺寸和形貌,构建了轧制单层和少层晶铜箔的晶体塑性有限元模型,重点分析单层和少层晶铜极薄带轧制成形中晶粒层次的滑移系启动、变形演化以及变形局部化现象,对比模拟和实验的轧制力结果。同时,模拟分析单/多滑移系启动、滑移局部化以及与微观组织相关的变形演化。

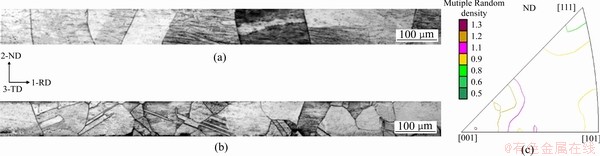

1 实验

采用课题组自主设计研制的具有拉拔-压缩-剪切复合成形功能的微型异步轧机,开展单层/少层晶铜极薄带的箔轧实验。将0.5 mm厚度的T2纯铜带经过5道次极薄轧制,将其厚度减薄至0.1 mm,对一系列0.1 mm厚度的铜箔进行氩气保护的真空退火处理,退火温度分别为920 ℃和850 ℃,保温时间分别为7h和6 h,退火后铜箔试样的显微组织如图1(a)和(b)所示,可见在箔材厚度方向上分别只有1层和3层晶粒存在,其中厚度方向上只有1层晶粒存在时,各晶粒的晶界平直且与轧制方向呈一定夹角。图1(c)所示为厚度方向上只有1层晶粒存在的单层晶铜箔沿其法向的织构分布,经过高温长时间真空退火后,箔材各晶粒取向随机分布不具有特定织构,因此,在建立相应晶体塑性有限元模型时,赋予单层/少层晶铜极薄带轧制模型随机取向。采用微型轧机对单层/少层晶铜极薄带进行轧制实验,测定单位宽度轧制力并与模拟结果对比。

2 晶体塑性有限元建模

图1 退火后单层和少层晶铜箔轧制试样的显微组织和单层晶铜箔沿法向的织构分布

Fig. 1 Microstructures of Cu single layer-crystal (a) and oligo-crystal (b) rolling specimen after annealing and initial texture of single layer crystal experimental foil along normal direction with 100 grains (c)

本文采用适用于面心立方(FCC)金属而开发的晶体塑性有限元模型(CP-FEM),模拟复合轧制单 层/少层晶铜极薄带的塑性各向异性行为。该模型是基于变形梯度分解理论和率相关晶体塑性准则建立的,可准确用于模拟分析晶粒尺度的微观-介观行为[14-16]。采用指数形式表示各滑移系的滑移率:

(1)

(1)

式中: 为第α滑移系的参考剪切率;n为率敏感系数;

为第α滑移系的参考剪切率;n为率敏感系数; 为第α滑移系的分剪切应力;

为第α滑移系的分剪切应力; 为第α滑移系的滑移阻力。本文研究的对象为T2铜箔,其滑移运动发生在12个{111}

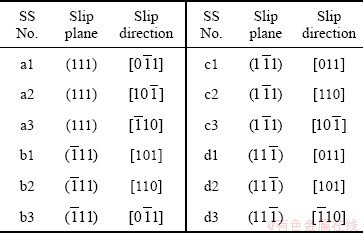

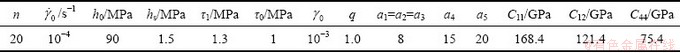

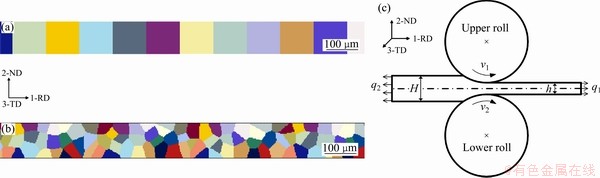

为第α滑移系的滑移阻力。本文研究的对象为T2铜箔,其滑移运动发生在12个{111} 滑移系上,模拟中各滑移系定义如表1所列。本构模型和材料硬化模型中的各参数可通过拟合模拟和实验的应力-应变曲线获得,本文的晶体塑性有限元模拟所用材料硬化参数和滑移系参数如表2所列。采用自编程序,依据实验测得的晶粒平均尺寸、取向、晶粒形貌等信息,建立单层/少层晶极薄带的晶体塑性有限元轧制模型,如图2(a)和(b)所示,其中单层晶模型的晶界垂直于轧制方向,少层晶模型的厚度方向分布3层晶粒,各模型分别赋予3种随机晶粒取向,为分析晶粒内部的变形特性,保证每个晶粒平均包含100个CPE4R单元。图2(c)所示为极薄带轧制示意图,模拟中同时考虑轧辊和轧件为变形体,用于分析弹性变形,轧制工艺参数采用上下工作轧辊直径为30 mm,前后张力均设置为q1=q2=100 MPa,上轧辊转速为1.04 rad/s,上下轧辊异速比为1.1,轧辊与轧件之间接触采用库仑摩擦,摩擦因数为0.1,道次压下率为40%。

滑移系上,模拟中各滑移系定义如表1所列。本构模型和材料硬化模型中的各参数可通过拟合模拟和实验的应力-应变曲线获得,本文的晶体塑性有限元模拟所用材料硬化参数和滑移系参数如表2所列。采用自编程序,依据实验测得的晶粒平均尺寸、取向、晶粒形貌等信息,建立单层/少层晶极薄带的晶体塑性有限元轧制模型,如图2(a)和(b)所示,其中单层晶模型的晶界垂直于轧制方向,少层晶模型的厚度方向分布3层晶粒,各模型分别赋予3种随机晶粒取向,为分析晶粒内部的变形特性,保证每个晶粒平均包含100个CPE4R单元。图2(c)所示为极薄带轧制示意图,模拟中同时考虑轧辊和轧件为变形体,用于分析弹性变形,轧制工艺参数采用上下工作轧辊直径为30 mm,前后张力均设置为q1=q2=100 MPa,上轧辊转速为1.04 rad/s,上下轧辊异速比为1.1,轧辊与轧件之间接触采用库仑摩擦,摩擦因数为0.1,道次压下率为40%。

表1 滑移系定义

Table 1 Definition of slip systems

3 结果与讨论

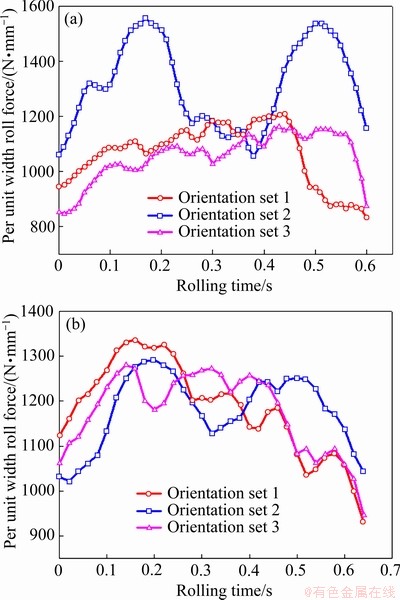

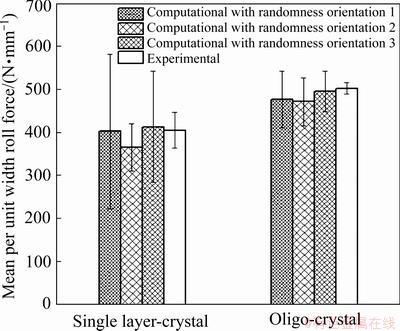

采用建立的轧制单层和少层晶铜极薄带的晶体塑性有限元模型,模拟得到的轧制单层和少层晶铜极薄带的单位宽度轧制力与轧制时间的关系如图3所示。每种模型被赋予三种随机晶粒取向,并将三种轧制力曲线进行对比,由图3可知,单层和少层晶模型的轧制力随时间变化都具有波动性,晶粒取向不同,轧制力相应具有差别。在单层晶模型中,其中一种取向对应的轧制力曲线显著区别于另外两种,整个轧制过程出现明显的跳跃,在轧制开始和结束阶段出现两个轧制力峰值,其他两种取向所对应的轧制力变化趋势基本一致,轧制力随时间逐渐增加,在轧制终了时迅速下降。三种取向所对应的轧制力曲线在少层晶模型中的变化趋势基本一致,都随轧制时间快速达到最高值而后逐渐降低。通过对比可发现,轧制单层晶极薄带的各轧制力曲线波动程度以及相互之间的差异性都明显大于少层晶模型。相应的模拟结果与箔轧实验结果的对比如图4所示,模拟结果与实验结果吻合较好,各模型模拟结果的波动程度大于实验结果,结果的波动程度随极薄带厚度方向上晶粒层数的增加而减弱。轧制极薄带厚度方向上晶粒层数的增多,轧制力变化及变形对晶粒取向分布的依赖性降低,轧制单层晶极薄带的轧制力变化及变形主要受其层状晶粒结构影响。

表2 晶体塑性有限元模拟参数

Table 2 Material parameters used in CP-FEM simulations

图2 轧制单层和少层晶铜箔的晶体塑性有限元模型及极薄带轧制示意图

Fig. 2 Crystal plasticity finite element models of single layer-crystal (a) and oligo-crystal (b) Cu foil and schematic illustration of foil rolling process (c)

图3 晶粒取向分布对轧制单层和少层晶铜箔单位宽度轧制力的影响

Fig. 3 Influence of grain orientation distribution on per unit width roll force during cold rolling single layer (a) and oligo-crystal (b) Cu foil

图4 轧制单层和少层晶铜箔单位宽度轧制力模拟计算与实验结果的对比

Fig. 4 Comparison of computational and experimental results of mean per unit width roll force during cold rolling single layer and oligo-crystal Cu foil (Error bars represent one standard deviation, with three crystallographic orientations simulated)

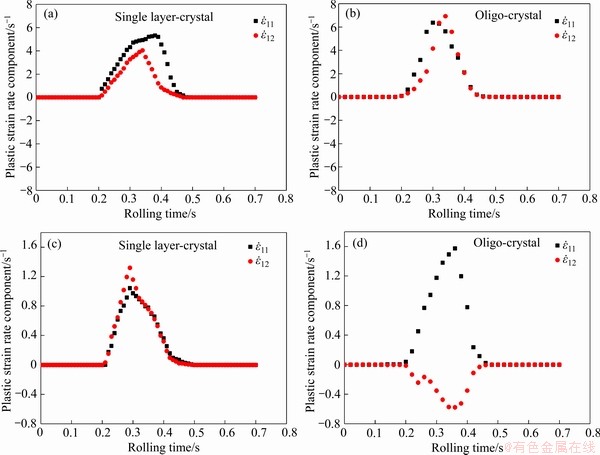

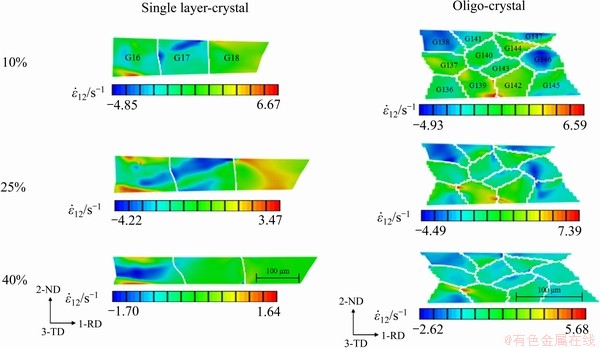

轧制力变化反映了极薄带轧制变形的宏观规律,需要分析其微观滑移机制。图5所示为轧制单层和少层晶铜箔变形区累积塑性滑移的分布,累积滑移在两种模型中的分布都是不均匀的,其中在单层晶模型中更加明显,在同一晶粒内部不同区域和相邻晶粒晶界两侧都出现了累积滑移的局部化现象,存在易滑移区域和非滑移区,如在单层晶模型中晶粒的上下表层处出现对应的高-低滑移区,这可导致轧制力曲线的显著波动,随箔材厚度方向上晶粒层数的增加,累积滑移的局域化趋势有所减弱。对比分析了两种模型高-低滑移区的应变速率演化过程,其结果如图6所示。两种模型在高滑移区的应变速率演化趋势基本一致,但轧制少层晶模型的演化更加平稳,且两个方向的应变速率分布差异更小。两种模型在低滑移区的应变速率演化趋势则表现出明显的差异性,存在平面应变速率方向相反,两个方向的应变速率演化趋势基本一致在轧制单层晶模型中,随轧制时间迅速达到峰值,而后迅速下降,而在轧制单层晶模型中,两个方向的应变速率演化呈正负对称,出现变形速度方向相反的情况。正是这种微观的累积滑移特性导致了宏观变形的各向异性。

图5 冷轧单层和少层晶铜箔变形区累积塑性滑移的分布

Fig. 5 Distribution of accumulated plastic slip in deformation zones (roll bite) during cold rolling of single layer (a) and oligo-crystal (b) Cu foil

图6 轧制单层和少层晶铜箔高低累积滑移区塑性应变率随变形时间的变化

Fig. 6 Change of plastic strain rates with deformation time at high ((a), (b))-low ((c), (d)) accumulated plastic slip sites during cold rolling of single layer((a), (c)) and oligo-crystal((b), (d)) Cu foil

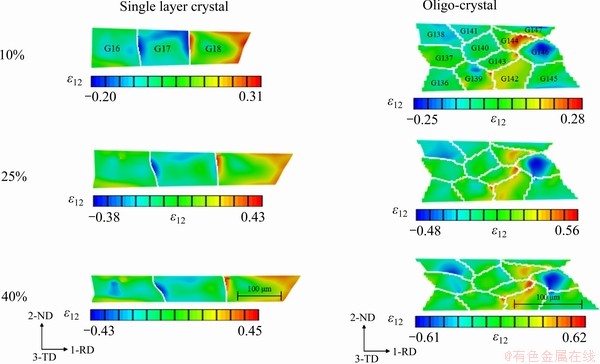

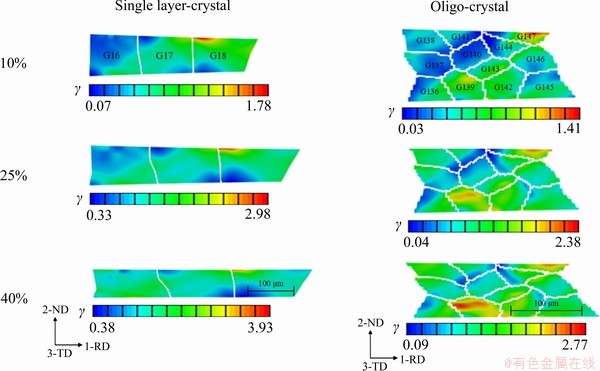

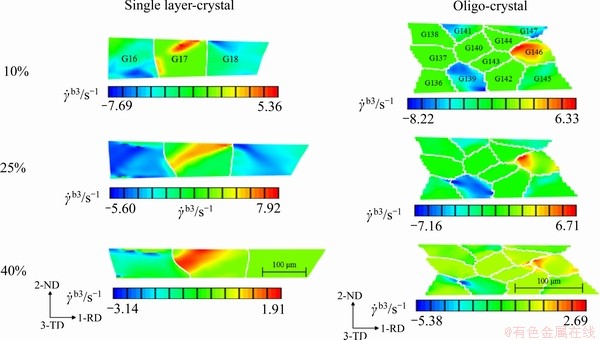

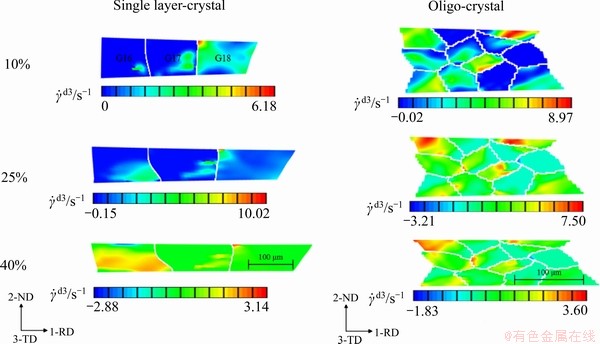

为进一步阐明轧制单层-少层晶极薄带塑性变形异向性的微观机制,模拟分析了轧制变形区内局部晶粒的变形和滑移演化过程。图7所示为轧制单层和少层晶铜箔变形区局部晶粒在x-y平面内塑性分应变的演化过程。由图7可看出,在两种模型中都存在变形局部化现象,在单层晶模型中,优先在晶界处产生应变,而后随变形向晶粒内部扩展,在晶界两侧区域存在方向相反的变形,在少层晶模型中,变形先在晶内和晶界产生,随变形再逐渐扩展,相邻晶粒的协调变形增强,变形差异减弱。图8所示为轧制单层和少层晶铜箔变形区局部晶粒在x-y平面内塑性分应变速率的演化过程。由图8可看出,在层晶模型中,剪切变形优先在晶界和晶粒边界产生,而后随变形逐渐形成了与轧制方向呈一定角度的贯穿相邻晶粒的剪切变形带,剪切带之间存在非变形区,同时,在同一晶粒内部形成多条方向相反的剪切带,在少层晶模型中,由于晶粒变形的协调,剪切变形带的局部化趋势减弱,在晶粒内部和相邻晶粒间形成一些小的剪切变形带。图9所示为轧制单层和少层晶铜箔变形区局部晶粒累积塑性滑移的演化过程。由图9可看出,两种模型的累积滑移在变形中的演化是非均匀局部化的,存在易滑移区和非滑移区,随着变形的进行,在晶粒内部和相邻晶粒间形成了与轧制方向呈一定角度的滑移带,随箔材厚度方向上晶粒层数的增加,累积滑移局部化减弱。可见轧制单层晶极薄带的变形异向性主要由其晶粒结构决定,轧制单层-少层晶极薄带塑性变形各向异性随箔材厚度方向上晶粒层数的增加而减弱。

图7 轧制单层和少层晶铜箔变形区局部晶粒塑性应变的演化

Fig. 7 Evolution of plastic strains of local grains in deformation zones during cold rolling single layer and oligo-crystal Cu foil

图8 轧制单层和少层晶铜箔变形区局部晶粒塑性应变率的演化

Fig. 8 Evolution of plastic strain rates of local grains in deformation zones during cold rolling single layer and oligo-crystal Cu

图9 轧制单层和少层晶铜箔变形区局部晶粒累积塑性滑移的演化

Fig. 9 Evolution of accumulated plastic slip of local grains in deformation zones during cold rolling single layer and oligo-crystal Cu foil

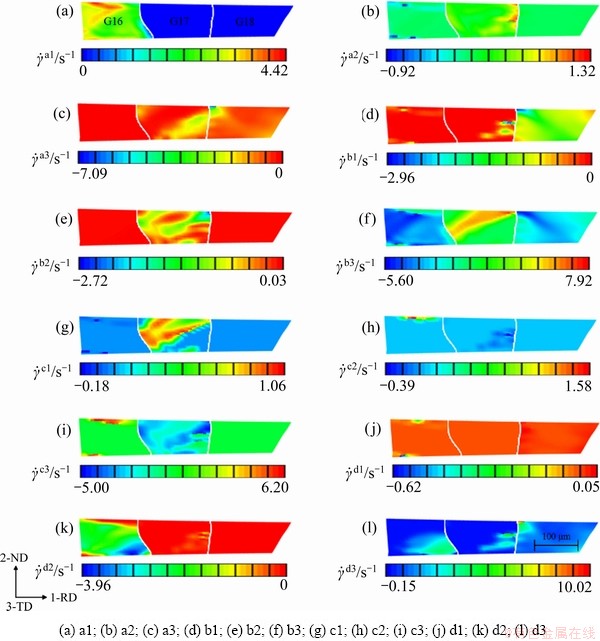

图10 轧制单层晶铜箔变形区局部晶粒启动滑移系的分布

Fig. 10 Distribution of activated slip systems of local grains in deformation zones during cold rolling single layer-crystal Cu foil

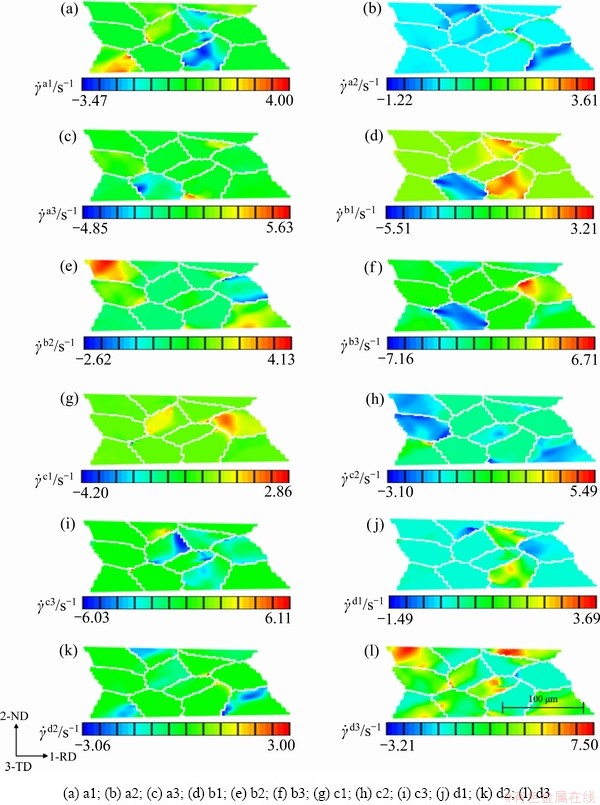

累积塑性滑移反映了在极薄带轧制变形中12个滑移系中可动滑移系的滑移总和,为分析轧制单层-少层晶极薄带塑性变形各向异性的微观滑移机制,模拟分析了轧制变形区内局部晶粒的滑移系启动及滑移演化。图10所示为轧制单层晶铜箔变形区局部晶粒启动滑移系的分布。由图10可知,各滑移系在同一晶粒和相邻晶粒内的滑移状态差异很大,在当前变形程度下有些滑移系在晶粒内就没有被启动滑移,如a3和d3在晶粒17中没有被激活,而a3、b2、b3、c1、c3和d3则在晶粒17内形成明显的滑移带,在滑移带之间存在非滑移区,随着先启动滑移系的滑移运动,引起晶粒转动,激发滑移系在相邻晶粒内被激活滑移,如a3、b1、b3和d3在晶粒17和18中的滑移状态,存在明显的易滑移晶粒和区域,形成贯穿晶粒和相邻晶粒的滑移带。图11所示为轧制少层晶铜箔变形区局部晶粒启动滑移系的分布。由图11可知,各滑移系的滑移运动主要集中发生在个别晶粒,由于箔材厚度晶粒层数的增多,当前的变形程度不足以激活更多的滑移系进行滑移,为保持各晶粒变形的协调性,在相邻晶粒易形成集中滑移区域,在少层晶模型中产生滑移局部化的趋势减弱,存在明显的易滑移晶粒和滑移方向。在同一变形条件下,各滑移系在不同晶粒内的滑移状态有差异,随厚度上晶粒层数的减少,易形成贯穿晶粒的滑移带和滑移局部化程度增强,异向性显著。

图11 轧制少层晶铜箔变形区局部晶粒启动滑移系的分布

Fig. 11 Distribution of activated slip systems of local grains in deformation zones during cold rolling oligo-crystal Cu foil

上述分析了轧制单层-少层晶极薄带各滑移系在塑性变形区内局部晶粒的滑移状态,反映了当前变形程度下各滑移系在晶粒内的启动与运动形式, 为分析滑移系在轧制变形过程中的演化过程,模拟了特定滑移系在整个变形过程的滑移演化。图12所示为b3滑移系在轧制单层-少层晶极薄带变形区局部晶粒内的滑移演化。由图12可看出,b3滑移系在单层晶模型晶粒17的晶界和上边界被激活启动,而后随变形进行逐渐向晶内扩展并扩大滑移区域,形成与轧制方向呈45°的滑移带,而在晶粒16和18的下上边界处被激活滑移,向晶内扩大滑移区域,分布在晶粒16和18中形成与轧制方向平行和呈-45°的滑移带,b3在晶粒17和18中形成对称分布的滑移带(滑移方向相反),存在明显的非滑移区域。b3滑移系只在少层晶模型中少数个别晶粒内被激活滑移,先在表层晶粒139、141和心部晶粒146中被激活,在表层晶粒内沿负方向进行滑移,而在心部晶粒沿正方向进行滑移,为保持变形的协调性,在三角晶界处形成了集中滑移区域,出现易变形晶粒和易滑移方向。滑移系b3易在单层晶模型中形成较大的滑移带,而在少层晶模型中形成小滑移带。

图13所示为d3滑移系在轧制单层-少层晶极薄带变形区局部晶粒内的滑移演化。由图13可看出,滑移系d3在单层-少层晶模型中的滑移状态完全不同于b3,d3先在晶粒18的左右晶界处被激活,而后迅速向晶内滑移,随晶粒18的变形,引起d3在晶粒17的右侧晶界处被激活,并逐渐向晶内滑移扩展,形成与轧制方向平行的滑移带,晶粒17的进一步变形导致d3在晶粒16的右侧晶界处被激活启动滑 移,最终也形成与轧制方向平行的滑移带,d3滑移系在单层晶模型的晶粒16、17和18中都形成了多条小的滑移带,滑移带之间存在非滑移区。相比b3,只在少层晶模型中少数个别晶粒内被激活滑移,而d3则在少层晶模型中大部分晶粒内被激活,且都沿正方向进行滑移,在表层晶粒138和147内形成局部高滑移区,d3滑移状态体现的晶粒协调变形的特性更加明显。单个滑移系的滑移状态随箔材厚度上晶粒层数的减少,其滑移局部化趋势增强。

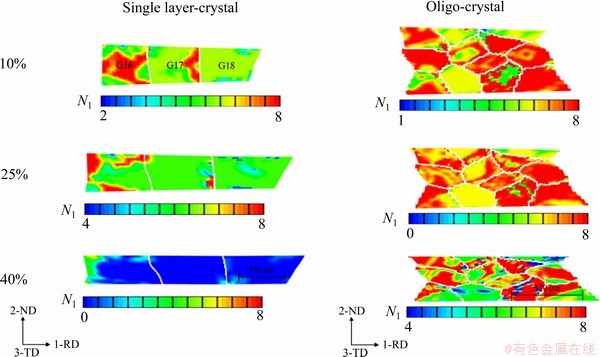

针对上述轧制单层-少层晶极薄带变形区局部晶粒变形和滑移的各向异性模拟分析,其塑性变形的异向性与微观各滑移系的运动状态密切相关。图14显示了轧制单层-少层晶极薄带变形区局部晶粒内的启动滑移系个数N1的演化。由图14可见,启动滑移系数目在变形区晶粒内的分布情况与上述变形和滑移分析是一致的,启动滑移系数目在晶粒内的分布是不均匀的,存在滑移系启动集中区域,这在轧制单层晶模型中更加明显。随箔材厚度上晶粒层数的增加,启动滑移系的局部化趋势减弱,晶粒变形协调性增强,塑性各向异性降低。

图12 轧制单层和少层晶铜箔变形区局部晶粒b3滑移系的演化

Fig. 12 Evolution of b3 slip system of local grains in deformation zones during cold rolling single layer and oligo-crystal Cu foil

图13 轧制单层和少层晶铜箔变形区局部晶粒d3滑移系的演化

Fig. 13 Evolution of d3 slip system of local grains in deformation zones during cold rolling single layer and oligo-crystal Cu foil

图14 轧制单层和少层晶铜箔变形区局部晶粒启动滑移系数目的演化

Fig. 14 Evolution of activated slip systems number of local grains in deformation zones during cold rolling single layer and oligo-crystal Cu foil

4 结论

1) 晶体塑性有限元模型中的材料硬化和滑移参数通过拟合应力-应变曲线获得,在相同变形条件下模拟和实验获得的单位宽度轧制力具有很好的吻合,晶体塑性有限元模型准确地获得了极薄带轧制的塑性异向性行为。

2) 模拟分析了轧制变形区内局部晶粒的变形和滑移特性,单层-少层晶铜极薄带在复合轧制变形条件下存在变形和滑移的局部化趋势,随极薄带厚度方向上晶粒层数的减少,局部化程度增强,各向异性显著。

3) 采用晶体塑性有限元模拟可以准确获得极薄带轧制变形的塑性各向异性行为,而无需再做大量的箔轧实验,这对降低材料消耗和提高效率具有重要作用。

4) 晶体塑性有限元模型直接嵌入材料的微观结构信息,这为研究材料微观结构特性和调控微观组织与性能提供了必要的条件。

REFERENCES

[1] MARTI N, FAVIER V, GREGORI F, et al. Correlation of the low and high frequency fatigue responses of pure polycrystalline copper with mechanisms of slip band formation[J]. Materials Science and Engineering A, 2020, 772: 138619.

[2] XUE S X,WANG C J, CHEN P Y, et al. Investigation of electrically-assisted rolling process of corrugated surface microstructure with T2 copper foil[J]. Materials, 2019, 12(24): 4144.

[3] ZHAO H L, CHEN W B, WU M W, et al. Influence of low oxygen content on the recrystallization behavior of rolled copper foil[J]. Oxidation of Metals, 2018, 90(1/2): 203-215.

[4] LIM H, JONG BONG H, CHEN S R, et al. Developing anisotropic yield models of polycrystalline tantalum using crystal plasticity finite element simulations[J]. Materials Science and Engineering A, 2018, 730: 50-56.

[5] LIU Y, WANG C J, HAN H B, et al. Investigation on effect of ultrasonic vibration on micro-blanking process of copper foil[J]. The International Journal of Advanced Manufacturing Technology, 2017, 93(1/8): 2243-2249.

[6] PASOODEH B, PARVIZI A, AKBARI H. Investigation of microstructure and mechanical properties in asymmetrically rolled copper wire[J]. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2017, 39(12): 5109-5116.

[7] ZHANG Q, ZHANG T T, DAI M Q, et al. Numerical simulation and experimental research on water jet forming of copper foil[J]. The International Journal of Advanced Manufacturing Technology, 2016, 85(9/12): 2265-2276.

[8] XU ZT, PENG LF, FU M W, et al. Size effect affected formability of sheet metals in micro/meso scale plastic deformation: Experiment and modeling[J]. International Journal of Plasticity, 2015, 68: 34-54.

[9] LIM H, CARROLL J D, BATTAILE C C, et al. Quantitative comparison between experimental measurements and CP-FEM predictions of plastic deformation in a tantalum oligocrystal[J]. International Journal of Mechanical Sciences,2015, 92: 98-108.

[10] PHAM C H, THUILLIER S, MANACH P Y. Prediction of flow stress and surface roughness of stainless steel sheets considering an inhomogeneous microstructure[J]. Materials Science and Engineering A, 2016, 678: 377-388.

[11] GUAN Y J, CHEN B, ZOU J W, et al. Crystal plasticity modelling and HR-DIC measurement of slip activation and strain localization in single and oligo-crystal Ni alloys under fatigue[J]. International Journal of Plasticity, 2017, 88: 70-88.

[12] BISHOP J E, EMERY J M, FIELD R V, et al. Direct numerical simulations in solid mechanics for understanding the macroscale effects of microscale material variability[J]. ComputerMethodsinAppliedMechanics and Engineering, 2015, 287: 262-289.

[13] LIM H, DINGREVILLE R, DEIBLER L A, et al. Investigation of grain-scale microstructural variability in tantalum using crystal plasticity-finite element simulations[J]. Computational Materials Science, 2016, 117: 437-444.

[14] BASSANI J L, WU T Y. Latent hardening in single crystals Ⅱ. Analytical characterization and predictions[J]. Proceedings of the Royal Society A, 1991, 435(1893): 21-41.

[15] LIM H, CARROLL J D, BATTAILE C C, et al. Grain-scale experimental validation of crystal plasticity finite element simulations of tantalum oligocrystals[J]. International Journal of Plasticity, 2014, 60: 1-18.

[16] CHEN S D, LIU X H, LIU L Z. Effects of grain size and heterogeneity on the mechanical behavior of foil rolling[J]. International Journal of Mechanical Sciences, 2015, 100: 226-236.

Crystal plasticity finite element simulations for plastic anisotropy in single layer and oligo-crystal copper under foil rolling

CHEN Shou-dong1, 2, LU Ri-huan2, SUN Jian1, LI Jie1

(1. School of Mechanical Engineering, Tongling University, Tongling 244061, China;

2. State Key Laboratory of Rolling and Automation, Northeastern University, Shenyang 110819, China)

Abstract: The single layer and oligo-crystal copper were studied using foil rolling under the compound forming with tension, compression and shearing. The plastic anisotropy of single layer and oligo-crystal copper under foil rolling was characterized by meso-scale crystal plasticity-finite element (CPFE) simulations. The single layer and oligo-crystal copper initial texture, grain morphology (microstructures) were incorporated into crystal plasticity finite element models. The grain-by-grain comparisons of slip activation, quantify the developing strain fields and the deformation localization can be carried out to analyze the foil rolling forming process. The single and multiple slip activation, slip localization and microstructure-sensitive deformation evolution were examined. The slip fields and localization of single layer-crystal copper under foil rolling depending on crystallographic structure. Modelling correctly captures slip activation and the developing slip fields. The slip and plastic deformation of oligo-crystal copper under foil rolling are markedly anisotropy, with the grain layer decreases driving strong variations, also reasonably captured by the model. The remarkable variations occur in grain and between locations either side of grain boundaries, providing appropriate opportunities for crack nucleation.

Key words: single layer-crystal; oligo-crystal; foil rolling; crystal plasticity; anisotropy

Foundation item: Project(51804219) supported by the National Natural Science Foundation of China; Project (1808085QE161) supported by the Provincial Natural Science Foundation of Anhui Province, China; Project(2016tlxyrc05) supported by the Scientific Research Foundation for Advanced Talents of Tongling University, China

Received date: 2020-02-25; Accepted date: 2020-06-25

Corresponding author: CHEN Shou-dong; Tel: +86-15056817605; E-mail: csdong0910@sina.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51804219);安徽省自然科学基金资助项目(1808085QE161);铜陵学院人才科研启动基金资助项目(2016tlxyrc05)

收稿日期:2020-02-25;修订日期:2020-06-25

通信作者:陈守东,副教授,博士;电话:15056817605;E-mail:csdong0910@sina.com

摘 要:采用具有拉拔-压缩-剪切复合成形功能的微型异步轧机,对厚度方向具有单层和少层晶结构的铜极薄带开展箔轧实验。基于晶体塑性有限元理论,模拟分析复合轧制单层和少层晶铜极薄带的塑性各向异性行为。将单层和少层晶铜极薄带的初始织构和晶粒形貌输入晶体塑性有限元模型,分析极薄带轧制成形中晶粒层次的滑移启动、定量应变演化以及变形局部化现象。同时,模拟分析单/多滑移系启动、滑移局部化以及与微观组织相关的变形演化。结果表明:轧制单层晶铜极薄带的滑移区域和局部化趋势主要依赖于晶粒形貌结构,晶体塑性有限元模型准确获得滑移启动及其滑移区域的演化。轧制少层晶铜极薄带的滑移和塑性变形具有明显的各向异性,且随晶粒层数的减少而增强。同一晶粒内部和相邻晶粒的晶界局部区域存在显著的滑移与变形差异,这为裂纹的萌生和缺陷的形成提供了有利的位置。