![]()

Trans. Nonferrous Met. Soc. China 22(2012) 104-110

Mechanical properties of hydroxyapatite-zirconia coatings prepared by magnetron sputtering

KONG De-jun, LONG Dan, WU Yong-zhong, ZHOU Chao-zheng

College of Mechanical Engineering, Changzhou University, Changzhou 213016, China

Received 22 December 2010; accepted 7 September 2011

Abstract:

Hydroxyapatite (HA)-zirconium (ZrO2) composite coating was produced by magnetic sputtering on Ti6Al4V titanium alloy substrate, the coatings of 50HA-50ZrO2 and 75HA-25ZrO2 (mass fraction, %) were characterized by scanning electron microscopy, energy disperse spectroscopy, X-ray diffraction and scratch test, respectively, and the effects of HA contents in the coating on residual stress were analyzed. The experimental results show that the phases of HA-ZrO2 composite coatings are HA, ZrO2 and Y2O3, and the HA has a certain decomposition in the combination process, producing TCP and CaO impurity phases. The porous surface of coating is conducive to the growth of bone tissue, and the surface roughness values of 50HA-50ZrO2 and 75HA-25ZrO2 are 1.61 μm and 2.92 μm, respectively. The coating interface is of mechanical integration, the bonding strength values of 50HA-50ZrO2 and 75HA-25ZrO2 are 30 N and 17.5 N, respectively, showing a downward trend with the HA contents increasing. The residual stress values in the coating of 50HA-50ZrO2 and 75HA-25ZrO2 are (-399.1±3.0) MPa, (-343.2±20.3) MPa, respectively, as a result, the appropriate increase of HA contents in the coating will reduce its residual stress.

Key words:

magnetron sputtering; zirconia; hydroxyapatite; surface morphology; bonding strength;

1 Introduction

Hydroxyapatite (HA) is a biological active material, composed of the essential elements of human tissues such as calcium and phosphorus, and has been widely used in bone implants. Due to the hierarchical porous structures, HA is more suitable to repairing bone defect [1]. HA has higher fracture toughness, but low strength which is the bottlenecks of its wide application [2]. So, it is unable to meet the requirements of people physical site [3, 4]. Therefore, to improve the mechanical properties of HA has thus attracted wide attention [5]. Clinical titanium alloy has excellent properties such as low density, low elastic modulus, good corrosion resistance, as bio-inert materials to form bone tissue regeneration with bone tissues [6]. Zirconia (ZrO2) is ceramic bioinert, and shows good wear resistance, corrosion resistance and biocompatibility [7]. In order to enhance the binding strength between the HA coating and titanium alloy substrate, the ZrO2 coating was prepared on titanium alloy surface. The merits of ceramic and metal could be used, which not only had good biocompatibility, biological activity [8], and the ability to achieve a direct chemical bonding of bone tissues, but also can be used as load-bearing parts of the body to meet the long-term growth needs. It is very significant for the development of human hard tissue replacement implants and clinical applications [9, 10]. In recent years, the researches of magnetron sputtering were mainly concentrated on the preparation of HA coating at home and abroad. However, HA-ZrO2 coating fabricated by traditional electrochemical deposition has several major drawbacks which limit the application potential of this coating technique [11]. In order to reduce residual stress and improve HA-ZrO2 composite coating, the composite coatings of 50HA-50ZrO2 and 75HA-25ZrO2 (mass fraction, %) were prepared by magnetron sputtering on Ti6Al4V substrate in this work, and the surface-interface structures, chemical elements and phases were analyzed by SEM, EDS and XRD, respectively, and the residual stress and bonding strength were measured.

2 Experimental

The commercial ZrO2 powder and self-made sub-micron HA powder were used to deposit the HA-ZrO2 composite coating by ANELVA-SPC2350 multi magnetron sputtering instrument. The technological parameters are as follows: the base pressure of 2×10-3 Pa, working gas of argon with purity of 99.99%, working pressure of 0.1 MPa, sputtering power of 200 W, time of 3 h. After magnetron sputtering, the coating was tempered at 600 °C for 2 h, and then was cooled in the furnace. The structures of HA-ZrO2 composite coatings were observed on a JSM-6360LA-type scanning electron microscope, the compositions of the coatings were measured by electron dispersive spectrometer, the coating phases were analyzed by D/max2500PC type X-ray diffraction (XRD) instrument, and the surface morphologies of the coating were observed with WYKONT1100 type surface tester. Residual stresses of the coating were analyzed with X-350A type X-ray stress analyzer, and the bonding strength of coating was tested with WS-2005 type thin film adhesion automatic scratch tester.

3 Results and analysis

3.1 Surface morphology

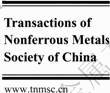

The surface morphologies of HA-ZrO2 composite coatings are shown in Fig. 1. The partial ZrO2 substrate can be seen clearly and the ZrO2 substrate is almost continuously covered on the HA surface layer; the particles on the surface of HA turn into coarse particles of uneven shape, showing a network and porous structure, with some different diameter holes, which increases the surface area of the coating microstructures, makes the contact area increase at the bonding interface combined with the new bone tissues after it is implanted into human body to provide the conditions for the nucleating of the new bone tissues [12]. As a result, the bone bonding of the composite coating is improved in human body. There are no micro-cracks in 50HA-50ZrO2 and 75HA-25ZrO2, showing that the HA-ZrO2 coating prepared by magnetron sputtering does not produce stress concentration, which will be beneficial to improving bonding strength of the coatings.

Fig. 1 Surface morphologies of composite coatings: (a) 50HA-50ZrO2; (b) 75HA-25ZrO2

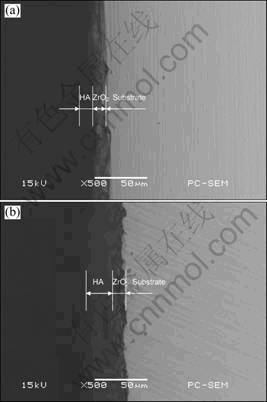

From Fig. 2, it can be seen that the HA-ZrO2 coating surface is rough, with ZrO2 particles and some obvious holes. For the biological coating, the small amount of the holes make the coating have a greater surface area, which is beneficial to combining with the surrounding tissues in the organism, providing a stent and channel for the new bone tissue growth, and improving the good biocompatibility [13]. In Fig. 2(a), the coating surface is relatively gentle undulating, and the surface ravines are less. In Fig. 2(b), the coating has larger ravines, showing a reticular structure, and the large pores are obvious, indicating that the HA content has affected the surface morphologies of the composite coatings, and the increase of HA content is helpful to improving the surface morphologies, and increasing the contact area of the coating surfaces.

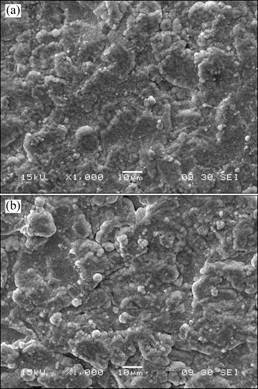

The interface morphologies of HA-ZrO2 composite coating are shown in Fig. 3. The thickness of the 50HA-50ZrO2 coating is about 40 μm, whereas that of 75HA-25ZrO2 is about 45 μm. The coating bottom is tightly combined with the uneven substrate and the bonding interfaces of the coating combined with the substrate are well. There are no cracks in the interfaces, and the bonding way is mainly mechanical bonding. The section structures from the substrate to the coating are changed from compact to loose, and the interface between the coating and substrate is a uniformly transited bonding.

Fig. 2 Surface grains of composite coatings: (a) 50HA-50ZrO2; (b) 75HA-25ZrO2

Fig. 3 Interface morphologies of HA-ZrO2 composite coatings: (a) 50HA-50ZrO2 ; (b) 75HA-25ZrO2

3.2 EDS analysis

Energy spectrum analyses of the composite coating surfaces are shown in Fig. 4. There are mainly the characteristic X-ray peaks of Ca, P and O, indicating the surface layer of HA. The contents of chemical elements of 50HA-50ZrO2 are as follows (mass fraction, %): C 10.36, O 15.34, Na 0.21, Mg 0.05, Al 0.06, Si 0.68, P 6.21, Ca 29.01, Ti 1.24, V 0.01, Cr 0.47, Fe 2.04, Zr 34.32; whereas those of 75HA-25ZrO2 are as follows (mass fraction, %): C 8.35, O 16.85, Na 0.24, Mg 0.07, Al 0.13, Si 0.80, P 6.47, Ca 28.66, Ti 1.66, Cr 0.35, Fe 1.76, Zr 34.70. The major chemical element contents such as Ca, P and O in the 50HA-50ZrO2 are basically the same as those in the 75HA-25ZrO2 coating, indicating that the coating surface is mainly the chemical elements of HA, and the other trace elements are slightly changed, which does not affect the mechanical properties of the coatings.

Fig. 4 Energy spectrum analyses of composite coatings: (a) 50HA-50ZrO2; (b) 75HA-25ZrO2

3.3 XRD analysis

As shown in Fig. 5, there is a better crystallization degree of HA-ZrO2 composite coating after heat treatment at 600 °C, its main crystal component phases are HA, ZrO2 and Y2O3, and the pyrolysis products of HA such as TCP, CaO appear at the same time, showing that the composite coating does not change the phase composition of the original powder after magnetron sputtering. The diffraction peak shape is more clear and the HA diffraction peaks become more acute, showing that the crystallinity has a further increase after heat treatment, and the prepared HA-ZrO2 has good crystallinity and high purity.

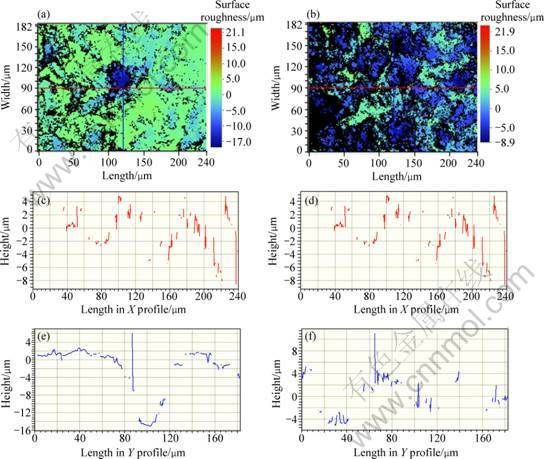

3.4 Surface roughness

When the coating began to grow on the substrate surface, the surface was an island-like, the grains were smaller, the surface undulating was greater, and the granularity distribution was uneven. The average granularity of the coatings was larger, but the granularity distribution was uneven. The measured results are shown in Fig. 6 with VEECO-WYKONT 1100 type non-contact optical profiler. The results show that the surface roughness of 50HA-50ZrO2 composite coating is 1.61 μm, and that of 75HA-25ZrO2 was about 2.92 μm. In Refs. [2, 14], the change of surface roughness in 10 nm-10 μm has little effects on the mechanical properties of the interface, but has a conspicuous effect on the biocompatibility, because the dimension range is in the same magnitude grade as the cell size and the biological macromolecules size. With the surface roughness increasing, the osteoblasts adhesion and proliferation ability increase, which is beneficial to attaching and proliferating of the oseosteoblasts when the surface roughness is large (Ra>1.5 μm).

Fig. 5 XRD patterns of composite coatings: (a) 50HA-50ZrO2; (b) 75HA-25ZrO2

Fig. 6 Analysis of surface roughness: (a1), (a2) 50HA-50ZrO2; (b1), (b2) 75HA-25ZrO2

The surface roughness of HA-ZrO2 composite coatings is shown in Fig. 7, and the measured results of roughness are shown in Table 1. The surface roughness parameters of arithmetic average deviation of the outline Ra, mean square root of the roughness Rq, total height of the outline Rt, the maximal valley Rv and the depth of defect Rp, have the same trend basically, showing that the content of HA has no effects on the roughness of the composite coating surface.

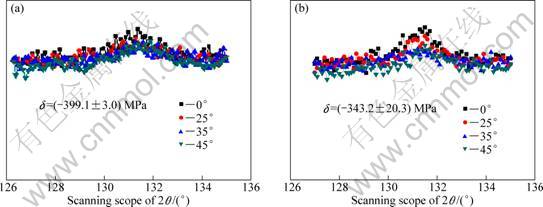

3.5 Residual stress

The residual stresses of the HA-ZrO2 composite coatings were analyzed with X-350A type X-ray stress analyzer. The measuring method was a roll fixation, and the fixed peak method was a peak cross-correlation function. The experimental parameters are as follows: tube voltage of 22 kV, tube current of 6 mA, Cr target Kα radiation, collimator diameter of 2 mm, scan step angle of 0.1°, time constant of 2 s, starting angle of 135° and ending scan angle of 127°, and roll angle Ψ of 0°, 25°, 35° and 45°, the stress constant of -605 MPa/(°). The measured results of residual stress of the HA-ZrO2 composite coatings are shown in Fig. 8, showing compressive stress. The residual stress of 50HA-50ZrO2 coating is (-399.1±3) MPa, whereas that of 75HA- 25ZrO2 coating is (-343.2±20.3) MPa, depending on the deposition temperature of HA coating [15]. As a result, it is indicated that the appropriate increase of HA content could reduce residual stress of the composite coatings and change the stress distribution of HA-ZrO2 coatings.

Fig. 7 2D analyses of surface roughness of HA-ZrO2 coatings: (a), (c), (e) 50HA-50ZrO2; (b), (d), (f) 75HA-25ZrO2

Table 1 2D analysis results of HA-ZrO2 surface roughness

Fig. 8 Measured residual stress in HA-ZrO2 composite coatings: (a) 50HA-50ZrO2; (b) 75HA-25ZrO2

There are two types of residual stresses in the coating: one is intrinsic stress and the other is thermal stress. Thermal stress is residual stress caused by the different expansion coefficients between the coating and the substrate. The linear expansion coefficients of HA, ZrO2 and Ti6Al4V are about 15×10-6 K-1, 7.33×10-6 K-1, 8.8×10-6 K-1, respectively. In the deposition process of magnetic sputtering, the growth and coalescence of the grain stress produce intrinsic stress, the nearby crystal is in compressed state as the interaction between the grain boundaries. The residual stress of coating surface was measured by XRD, to show compressive stress, indicating that the intrinsic stress has the maximum contribution to residual stress of the coatings.

3.6 Bonding strength

The bonding strength of the composite coating was tested with the WS-2005 type thin film adhesion automatic scratch tester. The test parameters are as follows: load of 40 N, loading rate of 40 N/min, scratch length of 4 mm, and scratch speed of 4 mm/s. The measuring method was acoustic emission and friction force. At the beginning of the scratch, there are no obvious traces on the coating surface, when the load increases to a certain extent, the coating has not ruptured.

Fig. 9 Measured bonding strength of HA-ZrO2 coating: (a) 50HA-50ZrO2; (b) 75HA-25ZrO2

Figure 9 shows that there are no mutation of acoustic emission waves. As the contrast of friction coefficients between the coating and the substrate is larger, the inflexion of friction curve is observed in the way of friction force, when the needle pierces the surface to the substrate, the friction has a major change, and the inflexion appears, at this time, the bonding strength between the coating and the substrate is represented with the load. Figure 9 shows that the bonding strength of 50HA-50ZrO2 composite coating is 30 N, whereas that of 75HA-25ZrO2 composite coating is 17.5 N.

In order to improve residual stress and bonding strength of the HA-ZrO2 coatings, the HA-ZrO2 compounds with different ratios were prepared on ZrO2 substrate surface. In the recombining process, due to the mismatch of thermal expansion coefficients, the coating interface combined with the substrate produces thermal stress concentration, and the larger residual stress is generated between the HA coating and the substrate, leading to a poor integration. The composite coating graded by different proportions would relax the mismatches of thermal expansion coefficients between the coating and the substrate.

4 Conclusions

1) The HA-50ZrO2 composite coating is deposited on the Ti6Al4V substrate by magnetron sputtering. After tempering at 600 °C, the crystalline coating is obtained. The coating surface is porous, of which the crystalline phases are mainly HA, ZrO2 and Y2O3, and the surface roughness of the HA-ZrO2 coatings is 1.61 μm-2.92 μm. This is beneficial to forming of bone tissue.

2) The residual stress of 50HA-50ZrO2 coating is (-399.1±3.0) MPa, whereas that of 75HA-25ZrO2 coating is (-343.2±20.3) MPa, showing that the appropriate increase of HA content can reduce the residual stress of the composite coatings.

3) The binding mode of the composite coating and substrate is mainly mechanical bonding, and the bonding strength values of 50HA-50ZrO2 and 75HA-25ZrO2 coatings measured by scratch test are about 30 N and 17.5 N, respectively. The bonding strength will be improved with the appropriate HA content in the composite coatings.

References

[1] MA Li, ZHOU Ke-chao, LI Zhi-you, HUANG Shu-ping. Porous bioglass reinforced hydroxyapatite materials produced with carbon particles [J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1885-1892. (in Chinese)

[2] LIU Ji-jin, RUAN Jian-ming, ZOU Jian-peng. Densification and mechanical properties of hydroxyapatite-zirconia composite materials [J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 952-957. (in Chinese)

[3] ZHANG Fu-qiang, LI Jing, HUANG Hui, XU Chun, JIN Xi-hai, GAO Lian. Nano-hydroxyapatite-zirconia ceramics sintered by spark plasma sintering [J]. Journal of Shanghai Jiao Tong University: Medical Science, 2006, 26(10): 1085-1088. (in Chinese)

[4] YU Xue-liang, TANG Yue-jun, CAO Mei-yu, TANG Yue-feng, ZHOU Zhong-hua, L? Chun-tang. Biocompatibility for nano-zirconium dioxide-toughened hydroxyapatite [J]. Journal of Clinical Rehabilitative Tissue Engineering Research, 2010, 14(16): 2895-2898. (in Chinese)

[5] CHIU C Y, HSU H C, TUAN W G. Effect of zirconia addition on the microstructural evolution of porous hydroxyapatite [J]. Ceramics International, 2007, 33(5): 715-718.

[6] ZHANG Min, WANG Hong-bin, QUAN Ren-fu, WU Xiao-chun. Preparation and biocompatibility of hydroxylapatite-zirconia biocomposite [J]. Acta Materiae Compositae Sinica, 2006, 23(2): 115-122. (in Chinese)

[7] QIU De-liang, WANG Ai-ping, YIN Yan-sheng. Characterization and corrosion behavior of hydroxyapatite/zirconia composite coating on NiTi fabricated by electrochemical deposition [J]. Applied Surface Science, 2010, 257(5): 1774-1778.

[8] LI Chao, TAO Shu-qing, ZHOU Chang-lin, LU Dai-feng, RONG Jie-sheng. Histocompatibility evaluation of nano hydroxyapatite-40% zirconia composite bioceramic [J]. Orthopedic Journal of China, 2009, 17(23): 1815-1818. (in Chinese)

[9] SHI Qiu-ping, ZHAO Yu-tao, DAI Qi-xun, LIN Dong-yang, LUO Ping-hui. HA/YSZ composite coatings on Ti-alloy substrate fabricated by magnetron sputtering [J]. Materials for Mechanical Engineering, 2006, 30(10): 52-56. (in Chinese)

[10] TANG Yue-jun, TANG Yue-feng, WANG Xin-ling, LU Chun-tang. Preparation and performance of zirconium oxide-toughened hydroxyapatite nano-composite porous bioceramic [J]. Journal of Clinical Rehabilitative Tissue Engineering Research, 2009, 13(29): 5723-5726. (in Chinese)

[11] WANG Jian, HUANG Chun-peng, WAN Qian-bing, CHEN Yi-fan, CHAO Yong-lie. Characterization of fluoridated hydroxyapatite/ zirconia nano-composite coating deposited by a modified electrocodeposition technique [J]. Surface and Coatings Technology, 2010, 204(16-17): 2576-2582.

[12] LI Zhuo-xin, WU Yong-zhi, HE Ding-yong, ZHAO Qiu-ying. Micro-plasma sprayed zirconia reinforced hydroxyapatite composite coatings [J]. Transactions of the China Welding Institution, 2008, 29(6): 1-4. (in Chinese)

[13] ZHAO Yu-tao, CHENG Xiao-nong, DAI Qi-xun, LIN Dong-yang, LI Su-min. HA (+ZrO2+Y2O3)/Ti6Al4V bioactive composite coating fabricated by RF magnetron sputtering [J]. Journal of Inorganic Materials, 2006, 21(5): 1237-1243. (in Chinese)

[14] LIANG Fang-hui, WANG Ke-guang, ZHOU Lian. Scratch testing of adhesion of biomimetic apatite coatings to titanium substrates [J]. Journal of Materials Science & Engineering, 2004, 22(1): 38-40. (in Chinese)

[15] YANG Yung-chin, CHANG Edward. Measurements of residual stress in plasma-sprayed hydroxyapatite coatings on titanium alloy [J]. Surface and Coatings Technology, 2005, 190(1): 122-131.

磁控溅射法制备的羟基磷灰石-氧化锆涂层的力学性能

孔德军,龙 丹,吴永忠,周朝政

常州大学 机械工程学院,常州 213016

摘 要:采用磁控溅射法在Ti6Al4V钛合金基体上制备羟基磷灰石(HA)-氧化锆(ZrO2)复合涂层,通过SEM、EDS、XRD和划痕法对50HA-50ZrO2和75HA-25ZrO2(质量分数,%)涂层进行表征,分析HA含量对涂层残余应力的影响。实验结果表明,HA-ZrO2复合涂层的物相为HA、ZrO2和Y2O3,在复合过程中HA部分发生分解,产生TCP和CaO等杂质相;涂层表面呈多孔状,有利于类骨组织的生长,50HA-50ZrO2和75HA-25ZrO2深层的表面粗糙度分别为1.61 μm和2.92 μm;涂层结合界面为机械结合方式,划痕法测量的50HA-50ZrO2和75HA-25ZrO2深层界面结合强度分别为30 N和17.5 N,随着HA含量的增加,涂层结合强度呈现下降的趋势;50HA-50ZrO2和75HA-25ZrO2涂层的残余应力分别为(-399.1±3) MPa和(-343.2±20.3) MPa,适当增加HA可以减小涂层的残余应力。

关键词:磁控溅射法;氧化锆;羟基磷灰石;表面形貌;结合强度

(Edited by YANG Hua)

Foundation item: Project (08KJB430002) supported by the Natural Science Foundation of the Higher Education Institutions of Jiangsu Province, China; Project (CJ20110019) supported by the Applied Basic Research Programs of Changzhou City, China

Corresponding author: KONG De-jun; Tel: +86-519-83290205; E-mail: kong-dejun@163.com

DOI: 10.1016/S1003-6326(11)61147-3

Abstract: Hydroxyapatite (HA)-zirconium (ZrO2) composite coating was produced by magnetic sputtering on Ti6Al4V titanium alloy substrate, the coatings of 50HA-50ZrO2 and 75HA-25ZrO2 (mass fraction, %) were characterized by scanning electron microscopy, energy disperse spectroscopy, X-ray diffraction and scratch test, respectively, and the effects of HA contents in the coating on residual stress were analyzed. The experimental results show that the phases of HA-ZrO2 composite coatings are HA, ZrO2 and Y2O3, and the HA has a certain decomposition in the combination process, producing TCP and CaO impurity phases. The porous surface of coating is conducive to the growth of bone tissue, and the surface roughness values of 50HA-50ZrO2 and 75HA-25ZrO2 are 1.61 μm and 2.92 μm, respectively. The coating interface is of mechanical integration, the bonding strength values of 50HA-50ZrO2 and 75HA-25ZrO2 are 30 N and 17.5 N, respectively, showing a downward trend with the HA contents increasing. The residual stress values in the coating of 50HA-50ZrO2 and 75HA-25ZrO2 are (-399.1±3.0) MPa, (-343.2±20.3) MPa, respectively, as a result, the appropriate increase of HA contents in the coating will reduce its residual stress.