(FeCo)73.5Cu1Nb3Si13.5B9的晶化处理及微结构

李丽娅,易健宏,葛毅成,彭元东

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:

摘 要:采用熔体快淬+晶化处理方法制备宽度为4 mm、厚度为30 μm的Fe73.5Cu1Nb3Si13.5B9纳米晶软磁合金,并用XRD和TEM对其微结构进行表征。研究结果表明:(FeCo)73.5Cu1Nb3Si13.5B9于600 ℃晶化处理15 min后具有较高的饱和磁化强度(1.30 T)和较小的矫顽力(4.61 A/m);提高晶化温度至700 ℃,合金的软磁性能迅速降低,饱和磁化强度为1.02 T,矫顽力增大至1.95 kA/m;于600 ℃晶化处理5 min时,合金主要由非晶构成,同时有少量α-Fe(Si)相;于600 ℃晶化处理15 min后合金由α-Fe(Si)主相和少量残余非晶相构成,α-Fe(Si)相的晶粒粒径约为15 nm;于700 ℃晶化处理15 min后,合金由α-Fe(Si)相、残余非晶相和少量Fe3B相构成,α-Fe(Si)相的晶粒粒径约为27.9 nm。Fe3B相的形成、α-Fe(Si)相晶粒粒径的长大和晶格常数的增大直接导致合金软磁性能下降。

关键词:

(FeCo)73.5Cu1Nb3Si13.5B9;非晶;α-Fe(Si);晶化;

中图分类号:TM271.2;TG132.271 文献标识码:A 文章编号:1672-7207(2008)03-0522-05

Nanocrystallization and microstructure of (FeCo)73.5Cu1Nb3Si13.5B9

LI Li-ya, YI Jian-hong, GE Yi-cheng, PENG Yuan-dong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Amorphous ribbons with 4 mm in width, 30 μm in thickness were obtained by the melt spinning technique with nominal compositions (FeCo)73.5Cu1Nb3Si13.5B9, and the microstructure features were investigated by using TEM and XRD. The magnet annealed at 600 ℃ for 15 min shows the highest saturation magnetization of 1.30 T and low coercivity of 4.61 A/m. The soft magnetic properties of the alloy are deteriorated by increasing the annealing temperature to 700 ℃, saturation magnetization decreases to 1.02 T and coercivity increases to 1.95 kA/m. After annealing at 600 ℃ for 5 min, amorphous structure is kept with little α-Fe(Si) nanocrystallites embedded in it. The alloy annealed at 600 ℃ for 15 min is characterized mainly by the precipitation of randomly oriented α-Fe(Si) nanocrystals embedded in a residual amorphous matrix, and the grain size of α-Fe(Si) phase is about 15 nm. When amorphous alloy is annealed at 700 ℃ for 15 min, this nanocrystalline material consists of α-Fe(Si) phase, amorphous structure, and little Fe3B phase. The grain size of α-Fe(Si) phase increases to about 27.9 nm. The formation of Fe3B phase, the grain coarsening of α-Fe(Si) phase and the increase of crystal lattice constant decrease the soft magnetic properties of the magnets.

Key words: (FeCo)73.5Cu1Nb3Si13.5B9; amorphous; α-Fe(Si); crystallization

由Y. Yoshizawa等[1]发现并命名为Finemet的Fe基纳米晶合金以其优异的软磁特性引起了人们广泛的研究兴趣,这种合金通过适当的纳米晶化退火后显示出很好的软磁特性,初始磁导率可达105数量级。Finemet的软磁特性主要是由于纳米晶化后在非晶的基体上形成了细小的α-Fe(Si)纳米晶粒[2-4],纳米晶粒通过晶粒间的非晶相发生强的交换耦合作用,使合金的有效磁各向异性

1 实验方法

(FeCo)73.5Cu1Nb3Si13.5B9纳米晶软磁合金按化学计量比配比,Fe和Co的摩尔比为1?1。采用中频感应熔炼炉熔炼,在熔炼过程中使用高纯氩气作保护气体。为了保证合金成分的均匀性,在合金熔炼过程中重熔2次。熔炼后的合金锭用单辊急冷法制备非晶薄带。制得的非晶带厚度约为30 μm,宽度为4 mm。将所得非晶薄带在1×10-5 Pa的真空中进行退火晶化,以获得理想的纳米晶组织。用HH-20型振动样品磁强计测量样品的磁滞回线;用日本理学Rigadu X射线衍射仪测量相结构,测试条件如下:Cu Kα单色光辐射,管电压为35 kV,管电流为20 mA;透射电镜试样采用常规双喷方法制备,显微组织观察与分析在JEM- 2000EX电子显微镜上进行,加速电压为160 kV。

2 结果与讨论

2.1 (FeCo)73.5Cu1Nb3Si13.5B9的磁性能

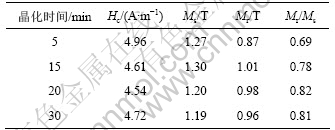

表1所示为(FeCo)73.5Cu1Nb3Si13.5B9于500 ℃晶化处理不同时间后的磁化强度与矫顽力。可见, 合金于500 ℃晶化处理15 min后具有最高的饱和磁感应强度Ms=1.28 T,而晶化处理20 min后的试样具有较高的剩余磁感应强度Mr=0.96 T和较高的剩磁比Mr/Ms=0.80。矫顽力Hc在晶化处理过程中变化不大,平均约为5.4 A/m。

表1 (FeCo)73.5Cu1Nb3Si13.5B9于500 ℃晶化处理不同时间的磁性能

Table 1 Magnetic properties of (FeCo)73.5Cu1Nb3Si13.5B9 annealed at 500 ℃ for different time

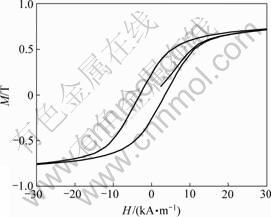

表2所示为(FeCo)73.5Cu1Nb3Si13.5B9于600 ℃晶化处理不同时间后的磁性能。可见,合金的Ms先随 600 ℃晶化处理时间的延长而增大,当晶化处理时间为15 min时,Ms和Mr均达最大值,分别为1.30 T和1.01 T,随着时间的进一步延长,Ms和Mr均降低。Hc随晶化处理时间的延长变化不大,而且比500 ℃晶化处理后的稍低。由此可见,提高合金的晶化处理温度至600 ℃时,试样具有更高的Mr和Ms和更小的Hc。但继续升高晶化处理温度至700 ℃并保温15 min后(图1),合金的软磁性能迅速降低,Ms降至1.02 T,矫顽力增大至1.95 kA/m。

表2 (FeCo)73.5Cu1Nb3Si13.5B9于600 ℃晶化处理不同时间的磁性能

Table 2 Magnetic properties of (FeCo)73.5Cu1Nb3Si13.5B9 annealed at 600 ℃ for different time

图1 (FeCo)73.5Cu1Nb3Si13.5B9在700 ℃晶化处理15 min后的M-H曲线

Fig.1 Magnetic hysteresis loop for (FeCo)73.5Cu1Nb3Si13.5B9 annealed at 700 ℃ for 15 min

2.2 晶化处理对相结构的影响

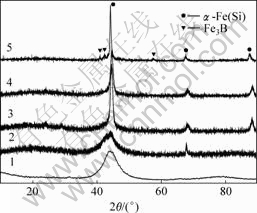

图2所示为(FeCo)73.5Cu1Nb3Si13.5B9晶化处理后的XRD图。可见,快淬后合金为非晶结构,于600 ℃晶化处理5 min时就出现少量的晶化相α-Fe(Si)相。延长晶化处理时间至15 min时,α-Fe(Si)相的体积分数增大,但还有少量的残余非晶。再延长晶化处理时间至30 min时,合金仍然由α-Fe(Si)主相和少量的残余非晶相构成。但在700 ℃晶化处理15 min后,合金内存在3种相结构:α-Fe(Si)相、残余非晶相和少量的Fe3B相。

1—未晶化处理;2—600 ℃×5 min;3—600 ℃×15 min;4—600 ℃×30 min;5—700 ℃×15 min

图2 (FeCo)73.5Cu1Nb3Si13.5B9的XRD图谱

Fig.2 XRD patterns of (FeCo)73.5Cu1Nb3Si13.5B9

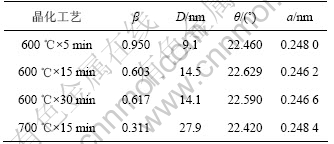

一般而言,由于晶粒粒径的减少,衍射峰会变宽。为了估算晶粒平均粒径,晶粒粒径D采用Scherrer公式[9]计算,结果见表3。其中:β为半高宽的弧度;D为晶晶直径;θ为衍射角;a为晶格常数。由表3可见,在600 ℃晶化处理5 min时,α-Fe(Si)相的晶粒粒径约为9.1 nm;延长晶化时间至15 min时,晶粒粒径迅速长大至14.5 nm;继续延长时间至30 min时,晶粒粒径稍减小,为14.1 nm。但是合金于700 ℃晶化处理15 min后,α-Fe(Si)相的晶粒粒径增大至27.9 nm。(FeCo)73.5Cu1Nb3Si13.5B9初始晶化时,Si原子向临近的Fe原子周围扩散,形成α-Fe(Si)固溶相核心;随着晶化的进行,成核饱和,α-Fe(Si)固溶相在二维方向长大;二次晶化时,由于初始晶化为其产生足够的晶核 (即α-Fe(Si)固溶相),晶化主要为B原子与α-Fe(Si)固溶相发生界面反应,产生Fe3B晶粒,并伴随着Fe3B晶粒向三维方向生长[10]。Fe3B相的析出会造成α-Fe(Si)相晶粒粗化,由于硼化铁具有较大的磁晶各向异性常数(K1=430 kJ/m3),所以,即使Fe3B的体积分数非常少,仍可使矫顽力大大增加。同时,α-Fe(Si)相开始析出时的温度较Fe3B相开始析出的温度低,所以,最先析出的α-Fe(Si)相晶粒已经长大,而较晚析出的α-Fe(Si)相晶粒与第二步晶化析出的Fe3B相晶粒都还很小,由此还会造成晶粒粒径不均匀。

表3 α-Fe(Si)的晶粒粒径D与晶格常数a

Table 3 Grain size D and crystal lattice constant of α-Fe(Si)

由表3还可见,α-Fe(Si)相的晶格常数小于体心立方结构的α-Fe的晶格常数(0.289 2 nm)。这主要是因为硅原子固溶于铁原子团中,使其变小[11]。当合金在600 ℃晶化处理时间小于15 min时,a随退火时间的延长而变小,说明晶相中固溶的Si含量增多;当退火时间多于15 min时,a随退火时间的延长而增大,这是由于合金中Si含量有限,当退火时间继续延长时,导致α-Fe(Si)从非晶基体中继续析出的过程没有过多的Si原子溶入,降低了α-Fe(Si)固溶体中的平均Si含量,并导致α-Fe(Si)晶格常数增大。同样,当晶化温度升高至700 ℃时,也会使α-Fe(Si)固溶体中的平均Si含量降低,导致α-Fe(Si)晶格常数增大至0.248 4 nm。

G. Herzer[12]用无规各向异性模型从理论上解释了纳米晶合金优异的软磁性能与晶粒粒径之间的关系。当晶粒粒径D远小于铁磁交换长度时,平均各向异性常数<>1>可表示为[12]:

显然,很小的晶粒粒径将导致很小的磁晶各向异性,使纳米晶合金获得优异软磁性能。

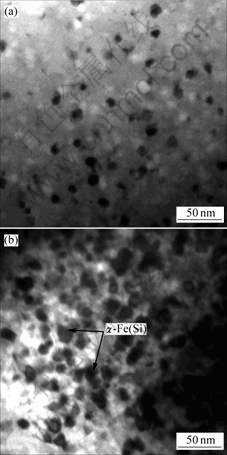

2.3 晶化过程的TEM显微结构分析

图3所示为(FeCo)73.5Cu1Nb3Si13.5B9于600 ℃晶化处理5 min和15 min时的TEM显微结构。图中黑色粒子为α-Fe(Si)相,其余为残余非晶相。晶化处理5 min后磁体主要由非晶相和少量的α-Fe(Si)相构成,α-Fe(Si)相的晶粒粒径为9~10 nm;当晶化处理时间延长至15 min时,有大量的α-Fe(Si)相生成,其晶粒粒径长大为15 nm左右,但是,在α-Fe(Si)相的周围仍有少量的非晶相存在,α-Fe(Si)相所占的体积分数为60%~80%。Cu和Nb对晶化形成纳米晶起了关键的作用,Cu促进α-Fe(Si)固溶体晶粒在非晶基体上成核,而Nb在晶界上的偏聚对晶粒长大起一定阻碍作用,使得晶粒粒径在一个很大的退火温度范围内保持纳米晶尺寸[13-14]。纳米晶+非晶的双相组织为优良的复合交换耦合软磁性能创造了必要的组织条件,即α-Fe(Si)晶粒能通过晶间铁磁非晶相发生强烈的磁耦合,加上纳米尺度bcc结构的形成,两者共同作用能有效降低有效磁晶各向异性和磁致伸缩系数[15]。具有高居里温度和热稳定性的富固溶元素非晶相也是通过上述两者共同作用成为1个使合金获得优异软磁性能的重要因素。

晶化处理时间/min:(a) 5;(b) 15

图3 (FeCo)73.5Cu1Nb3Si13.5B9于600 ℃晶化处理5 min和15 min后的TEM显微结构

Fig.3 TEM morphologies of (FeCo)73.5Cu1Nb3Si13.5B9 heat treated at 600 ℃ for 5 min and 15 min, respectively

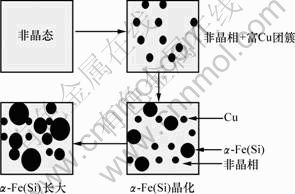

图4所示为(FeCo)73.5Cu1Nb3Si13.5B9晶化过程中的微结构演变示意图。快淬态合金在结构上和化学上都是均匀的非晶态固溶体。由于Cu和Fe不互溶,在退火的开始阶段,它们互相分离,这样,Cu的浓度会发生变化。通过调幅分解或成核机理,形成直径为几纳米的Cu团簇。与此同时,Fe的浓度也会发生变化。因此,体心立方晶态相的晶核密度明显增大,并形成α-Fe(Si)固溶体,而Nb和B则因为不溶于α-Fe(Si)相中而在残余非晶相中富集,使残余非晶相稳定,且α-Fe(Si)相的晶粒长大被抑制。当晶化继续时,团簇中Cu的浓度也会继续增大,直径可达5 nm左右。然而,因为富Cu颗粒的粒径远小于畴壁宽度,它的析出对软磁性能影响不大,但是,目前尚不能确定这种颗粒是晶态相还是非晶相[16]。

图4 (FeCo)73.5Cu1Nb3Si13.5B9晶化过程中的微结构演变示意图

Fig.4 Microstructure transformation of (FeCo)73.5Cu1Nb3Si13.5B9 during crystallization process

3 结 论

a. 采用熔体快淬方法,并于600 ℃晶化处理15 min制备了(FeCo)73.5Cu1Nb3Si13.5B9纳米晶软磁合金,饱和磁化强度为1.30 T,矫顽力为4.61 A/m。提高晶化温度至700 ℃时,合金的软磁性能迅速降低,Ms为1.02 T,Hc增大至1.95 kA/m。

b. 于600 ℃晶化处理不同时间后合金由非晶相逐渐转变为α-Fe(Si)主相和少量残余非晶相,晶化处理15 min后α-Fe(Si)相的晶粒粒径约为15 nm,晶格常数约为0.246 2 nm。

c. 于700 ℃晶化处理15 min后,合金由α-Fe(Si)相、残余非晶相和少量Fe3B相构成,α-Fe(Si)相的晶粒粒径约为27.9 nm。Fe3B相的形成、α-Fe(Si)相晶粒粒径的长大和晶格常数的增大直接导致合金软磁性能下降。

参考文献:

[1] Yoshizawa Y, Oguma S, Yamauchi K. New Fe-based soft magnetic composed of ultrafine grain structure[J]. Journal of Applied Physics, 1988, 64(10): 6044-6046.

[2] Ramanujana R V, Zhang Y R. Solid state dendrite formation in an amorphous magnetic Fe77.5Si13.5B9 alloy observed by in situ hot stage transmission electron microscopy[J]. Applied Physics Letters, 2006, 88(18): 182506.

[3] Iturriza N, García C, Fernández L, et al. Structural, magnetic, and magnetostriction behaviors during the nanocrystallization of the amorphous Ni5Fe68.5Si13.5B9Nb3Cu1 alloy[J]. Journal of Applied Physics, 2006, 99(8): 08F104.

[4] 卢 斌, 易丹青, 刘 岩, 等. Fe73.5Cu1Nb3Si13.5B9机械合金化纳米晶粉末的特种烧结及磁性能[J]. 中国有色金属学报, 2005, 15(5): 739-745.

LU Bin, YI Dan-qing, LIU Yan, et al. Sintering and magnetic properties of mechanical alloying Fe73.5Cu1Nb3Si13.5B9 nano- crystalline powder[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 739-745.

[5] Chrissafis K, Maragakis M I, Efthimiadis K G, et al. Detailed study of the crystallization behaviour of the metallic glass Fe75Si9B16[J]. Journal of Alloys and Compounds, 2005, 386(1/2) :165-173.

[6] 李成栋, 田学雷, 陈熙琛, 等. FINEMET合金Fe73.5Si13.5B9- Cu1Nb3不同状态微观结构研究进展[J]. 稀有金属, 2003, 27(3): 371-375.

LI Cheng-dong, TIAN Xue-lei, CHEN Xi-chen, et al. Development of investigations on microstructure of FINEMET alloy Fe73.5Si13.5B9Cu1Nb3 in different states[J]. Rare Metals, 2003, 27(3): 371-375.

[7] Principi G, Maddalena A, Meyer M, et al. Structural evolution of the amorphous grain boundary phase during nanocrystallisation of Fe72Cu1Nb4.5Si13.5B9[J]. Journal of Magnetism and Magnetic Materials, 2004, 272/276: 1441-1442.

[8] 王 玉, 张文礼, 孙冬柏, 等. 非晶纳米晶复合材料的性能与制备[J]. 材料科学与工程学报, 2006, 24(2): 292-296.

WANG Yu, ZHANG Wen-li, SUN Dong-bai, et al. Properties and fabrication of amorphous nanocrystalline composites[J]. Journal of Materials Science & Engineering, 2006, 24(2): 292-296.

[9] Miguel C, Zhukov A P, Val J J, et al. Effect of stress and/or field annealing on the magnetic behavior of the (Co77Si13.5B9.5)90- Fe7Nb3 amorphous alloy[J]. Journal of Applied Physics, 2005, 97(3): 034911.

[10] 黎 阳, 陆 伟, 严 彪. FINEMET合金晶化行为的DSC研究[J]. 材料科学与工程学报, 2006, 24(1): 132-134.

LI Yang, LU Wei, YAN Biao. Crystallization behavior of FINEMET amorphous alloy[J]. Journal of Materials Science & Engineering, 2006, 24(1): 132-134.

[11] Varga L K, Slawska-Waniewska A, Roig A, et al. Microstructure and magnetic properties of Fe81P13Si2Nb3Cu1 nanocrystalline alloy[J]. Journal of Magnetism and Magnetic Materials, 2004, 272/276: 1360-1361.

[12] Herzer G. Nanocrystalline soft magnetic materials[J]. Journal of Magnetics and Magnetic Materials, 1992, 112(1/3): 258-262.

[13] Zhang Y R, Ramanujan R V. Characterization of the effect of alloying additions on the crystallization of an amorphous Fe73.5Si13.5B9Nb3Cu1 alloy[J]. Intermetallics, 2006, 14(6): 710- 714.

[14] Ohnuma M, Ping D H, Abe T, et al. Optimization of the microstructure and properties of Co-substituted Fe-Si-B-Nb-Cu nanocrystalline soft magnetic alloys[J]. Journal of Applied Physics, 2003, 93(11): 9186-9194.

[15] Bitoh T, Makino A, Inoue A. Origin of low coercivity of (Fe0.75B0.15Si0.10)100-xNbx (x=1-4) glassy alloys[J]. Journal of Applied Physics, 2006, 99(8): 08F102.

[16] Hono K, Hiraga K, Wang Q, et al. The microstructure evolution of a Fe73.5Si13.5B9Nb3Cu1 nanocrystalline soft magnetic material[J].Acta Metallurgica et Materialia, 1992, 40(9): 2137- 2147.

收稿日期:2007-08-03;修回日期:2007-10-06

基金项目:湖南省自然科学基金资助项目(04JJ6029)

通信作者:李丽娅(1973-),女,湖南郴州人,博士,讲师,从事磁性材料和粉末冶金材料研究;电话:0731-8877328;E-mail: llylucky@163.com