- Abstract:

- 1 Introduction▲

- 2 Principle of LSSVM▲

- 3 Experiments▲

- 4 Conclusions▲

- References

- Figure

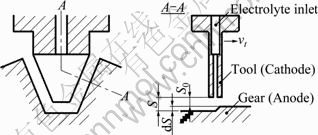

- Fig.1 Scheme of SBG tooth surface finishing by PECF

- Fig.2 Experimental setup of SBG tooth surface finishing

- Fig.3 Tooth surface roughness predictive model of SBG PECF based on LSSVM

- Fig.4 Comparison between predicted values and experimental values of surface roughness

- Fig.5 Comparison between predicted values and experimental values of applied voltage

J. Cent. South Univ. Technol. (2011) 18: 685-689

DOI: 10.1007/s11771-011-0748-9![]()

Prediction method for surface finishing of spiral bevel gear tooth based on least square support vector machine

MA Ning(马宁)1, 2, XU Wen-ji(徐文骥)1, WANG Xu-yue(王续跃)1,

WEI Ze-fei(魏泽飞)1, PANG Gui-bing(庞桂兵)3

1. School of Mechanical Engineering, Dalian University of Technology, Dalian 116024, China;

2. School of Electromechanical Engineering, Shenyang Aerospace University, Shenyang 110136, China;

3. School of Mechanical Engineering and Automation, Dalian Polytechnic University, Dalian 116034, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2011

Abstract:

The predictive model of surface roughness of the spiral bevel gear (SBG) tooth based on the least square support vector machine (LSSVM) was proposed. A nonlinear LSSVM model with radial basis function (RBF) kernel was presented and then the experimental setup of PECF system was established. The Taguchi method was introduced to assess the effect of finishing parameters on the gear tooth surface roughness, and the training data was also obtained through experiments. The comparison between the predicted values and the experimental values under the same conditions was carried out. The results show that the predicted values are found to be approximately consistent with the experimental values. The mean absolute percent error (MAPE) is 2.43% for the surface roughness and 2.61% for the applied voltage.

Key words:

1 Introduction

Spiral bevel gear (SBG) has been widely applied in the transmission systems of helicopters, automobiles and many machines. The increasing requirements for low noise and high strength lead to higher quality in manufacturing spiral bevel and hypoid gears. Due to heat treatment distortions, machine tolerances, variation of cutting forces, and other unpredictable factors, the real tooth flank form geometry may deviate from the theoretical or master target geometry. This causes unfavorable displacement of tooth contact and increased transmission errors that result in noisy operation and premature failure due to the edge contact and highly concentrated stresses [1]. Gear noise becomes a common problem in all spiral bevel and hypoid gear drives. The improvement of surface quality can increase the gear lifespan largely and reduce its noise effectively [2]. At present, gears with a complex curve tooth, such as spiral bevel and hypoid gears, lack an expected technique for the final finishing process. The present techniques are limited to grinding and lapping. Because the gear grinding is low in efficiency and high in product cost, the conventional lapping is poor in material removal rate and shows low precision in modifying tooth shape [3]. Many studies have shown that the pulse electrochemical finishing (PECF) is an effective method for surface roughness improving of workpiece [4-6].

In PECF, the surface irregularities are removed by electrochemical anodic dissolution rather than by cutting force. There is no residual stress and thermal effect on the workpiece surface due to non-contact nature of the PECF process [7]. But, the PECF system is a complicated and nonlinear system. The surface quality is influenced by all processing factors and the interaction of different factors is complicated in PECF. Thus, it is difficult to establish an exact mathematical model by theoretical analysis. Many studies on the models of pulse electrochemical machining (PECM) have been published. A mathematical model for the PECM process was proposed where the non-steady physicochemical phenomena were taken into account in the interelectrode gap [8]. However, this model was too complicated to control. A PECM monitoring system was proposed which used a high speed data acquisition system to acquire current pulse signals [9]. The current signal control was only mentioned but control strategy was not discussed. A mathematical model was proposed for accurately estimating the thickness of the workpiece layer under different working conditions [10]. But there existed more assumptions in the model. Consequently, an exact mathematical model is necessary for controlling the surface quality effectively in the PECF.

Least square support vector machine (LSSVM) has been successfully applied in pattern recognition and function estimation problems [11-13]. It was developed from the standard support vector machine (SVM) [14-15]. The LSSVM is computationally more efficient than the standard SVM method, since the LSSVM training only requires the solution of a set of linear equations instead of the long and computationally hard quadratic programming problem involved in the standard SVM [16].

As a complicated and nonlinear process, the results of PECF are difficult to control. Usually, the trial-and- error method is used to select the finishing parameters. However, it is difficult for this method to obtain the desired surface roughness. In this work, the LSSVM method with a radial basis function (RBF) kernel is employed to develop an offline model which can predict the surface roughness and select the finishing parameters in PECF.

2 Principle of LSSVM

Considering a given training set {xi, yi} (i=1, 2, …, N), where xi∈Rn represents a n-dimensional input vector and yi∈R, which is a scalar measured data, represents the system output. The form of this function is defined as [17]

![]() (1)

(1)

where w is the weight vector, b is the bias term and φ(·) is a nonlinear function that maps the input space into a higher dimension feature space.

The regression model (Eq.(1)) can be constructed with a nonlinear mapping function φ(·). By mapping the original input data into a high-dimensional space, the nonlinear separable problem becomes linearly separable in space. Now, the objective is to find the optimal parameters that minimize the prediction error of the regression model. Hence, consider the following optimization problem with equality constraints:

(2)

(2)

where ei is the random error and γ∈R+ is a regularization parameter in determining the trade-off between minimizing the training errors and minimizing the model complexity.

To solve the above optimization problem, the following Lagrange function is constructed:

![]() (3)

(3)

where α is the Lagrange multiplier. The solution of Eq.(3) can be obtained by partially differentiating with respect to w, b, ei and αi:

(4)

(4)

In the form of matrix, the above equations can be expressed as

![]() (5)

(5)

where y=[y1, …, yN]T, Θ=[1, …, 1]T, α=[α1, …, αN]T, Ω is a square matrix, and I is an identity matrix. The elements Ωij=φ(xi)Tφ(xj)=κ(xi, xj), i, j=1, …, N. Finally, the estimated values of α and b can be obtained by solving the linear system of Eq.(5), and the resulting LSSVM model can be expressed as

![]() (6)

(6)

where κ(x, xi) is the kernel function. In comparison with some other feasible kernel functions, the radial basis function (RBF) is a more compact supported kernel and is able to reduce the computational complexity of the training process and improve the generalization performance of LSSVM. As a result, the RBF kernel is selected as the kernel function:

![]() (7)

(7)

where σ is the kernel width parameter.

Note that the parameters γ and the value of σ from the kernel function have to be turned. Using the above LSSVM model with RBF kernel, the offline nonlinear model of the controlled system can be expressed as

![]() (8)

(8)

3 Experiments

3.1 Fundamental of SBG tooth surface finishing by PECF

The scheme of SBG tooth surface finishing by PECF is illustrated in Fig.1. Two electrodes were connected to a pulse power supply. The tool was the cathode and the gear was the anode. The electrolyte was pumped at high velocities through the interelectrode gap in order to remove the reaction products and to dissipate the heat generated.

Fig.1 Scheme of SBG tooth surface finishing by PECF

According to the Faraday’s law and Ohm’s law, the interelectrode gap thickness can be calculated as [18]

![]() (9)

(9)

where S0 is the initial interelectrode gap, ? is the current efficiency of anodic dissolution, κe is the electrolyte conductivity, kv is the volumetric electrochemical equivalent, U is the applied voltage, ΔU is the over potential value, δ is the pulse duty factor, and t is the finishing time.

3.2 Experimental setup

Figure 2 shows the sketch of the PECF system for finishing the SBG surface. The gear and the tool were securely held by a universal dividing head and a clamp, respectively. Both the gear and the tool were insulated from the main body in order to only focus an electrochemical reaction between them. As the tool scanned over the tooth surface, the whole surface was finished.

Fig.2 Experimental setup of SBG tooth surface finishing

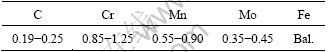

The pulse DC power supply was adopted in this system. The main ingredient of electrolyte was NaNO3. The experimental and workpiece parameters are listed in Table 1 and Table 2. The workpiece chemical compositions are listed in Table 3.

Table 1 Experimental parameters of SBG PECF

Table 2 SBG parameters

Table 3 Chemical composition of SBG (mass fraction, %)

3.3 Experimental design

According to the principle of PECF, the finishing process is influenced by tool rotating speed (nt), applied voltage (U), initial interelectrode gap (S0), pulse duty factor (δ) and finishing time (t). In order to assess the effect of finishing parameters, the Taguchi method L16(45) was introduced and the interaction effect of parameters was estimated by carrying out 16 experiments. The main effect shows the contribution of individual parameter to the surface roughness in the experimental results. For generating the training data, all parameters were set by four levels, as listed in Table 4.

3.4 Prediction of surface roughness

The input data {xi, yi} of LSSVM consist of five experimental parameters, including the tool rotating speed (nt), applied voltage (U), initial interelectrode gap (S0), pulse duty factor (δ) and finishing time (t). The output data yi is the result of experiments, that is, the surface roughness Ra. Table 4 lists the experimental results of PECF. The sixteen groups of experimental data selected from Table 4 were used to perform the training. The values of α and b could be obtained from Eq.(5). Toolbox of MATLAB was adopted for the algorithm of LSSVM. The nonlinear radial basis function (RBF) kernel was chosen, and variables γ=15, σ=2.45 were fixed. Consequently, the predictive LSSVM model can be constructed, as shown in Fig.3.

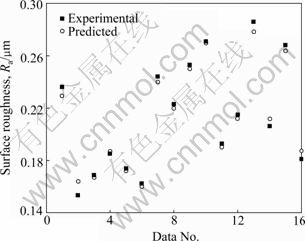

The other four groups of experimental results in Table 4 were used for verifying the availability of the predictive model. From Fig.4, the errors between the predicted values and the experimental values can be acquired. It can be concluded that the model can predict the surface roughness with reasonable accuracy.

Table 4 Experimental data of SBG PECF

Fig.3 Tooth surface roughness predictive model of SBG PECF based on LSSVM

Fig.4 Comparison between predicted values and experimental values of surface roughness

The mean absolute percent error (MAPE) is a very common criterion for evaluating the performance of a forecasting system since it gives the mean of the absolute. The MAPE is computed as

![]() (10)

(10)

where y is the experimental value, yi is the LSSVM predicted value and l is the number of validation data. It can be seen form Fig.4 that the model provides good prediction performance with MAPE of 2.43% for the surface roughness of SBG in PECF.

3.5 Determination of finishing parameters

The actual manufacturing process was constrained by the desired surface roughness and the machining cost. Usually, the trial-and-error method was used to select the finishing parameters. However, it is difficult for this method to obtain the desired surface roughness with a higher machining efficiency. Therefore, the prediction of the finishing parameters is also necessary.

Table 5 lists the factorial analysis results of the orthogonal experiments of the PECF. It can be seen that the applied voltage has more effect on the surface roughness than the other finishing parameters.

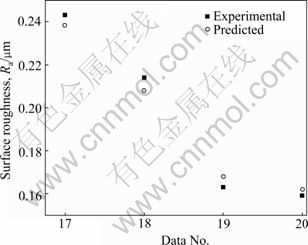

Therefore, the applied voltage (U) was chosen as the output data, and the surface roughness and the other four parameters were regarded as the input data. By applying the above procedure, a new LSSVM model was constructed to obtain the optimum applied voltage matching the desired value of surface roughness. By adjusting the variables γ=35 and σ=2.24, the predictive results of the applied voltage are shown in Fig.5. The MAPE between the experimental values and the predicted values of the applied voltage is 2.61%.

Table 5 Factorial analysis results of orthogonal experiments of PECF

Fig.5 Comparison between predicted values and experimental values of applied voltage

4 Conclusions

1) A predictive model based on the LSSVM is developed. The gear tooth surface finishing system is also established for obtaining the training data.

2) In the PECF, the surface roughness of the tooth surface is mainly influenced by the applied voltage, initial interelectrode gap, pulse duty factor and finishing time. The factorial analysis of the orthogonal experiments of the PECF shows that the applied voltage is the most important parameter.

3) The predicted values based on the predictive model are found to be in reasonable agreement with the experimental values. The results show that the mean absolute percent error (MAPE) is 2.43% for the surface roughness and 2.61% for the applied voltage.

References

[1] FAN Q, DAFOE R S, SWANGER J W. Higher-order tooth flank form error correction for face-milled spiral bevel and hypoid gears [J]. Journal of Mechanical Design, 2008, 130(7): 072601.

[2] NAKATSUJIN T, MORI A. Pitting durability of electrolytically polished medium carbon steel gears-succeeding report [J]. Tribology Transactions, 1999, 42(2): 393-400.

[3] WEI Bing-yang, DENG Xiao-zhong, FANG Zong-de. Study on ultrasonic-assisted lapping of gears [J]. International Journal of Machine Tools and Manufacture, 2007, 47(12/13): 2051-2056.

[4] MAHDAVINEJAD R, HATAMI M. On the application of electrochemical machining for inner surface polishing of gun barrel chamber [J]. Journal of Materials Processing Technology, 2008, 202: 307-315.

[5] RAMASAWMY H, BLUNT L. Investigation of the effect of electrochemical polishing on EDM surfaces [J]. The International Journal of Advanced Manufacturing Technology, 2007, 31: 1135-1147.

[6] ZHOU Jin-jin, PANG Gui-bing, WANG Hui, XU Wen-ji. Research on pulse electrochemical finishing using a moving cathode [J]. International Journal of Manufacturing Technology and Management, 2005, 7: 352-365.

[7] MCGEOUGH J A. Principles of electrochemical machining [M]. London: Chapman and Hall, 1974: 1-10.

[8] KOZAK J, RAJUKAR K P. WEI B. Modelling and analysis of pulse electrochemical machining [J]. Journal of Engineering for Industry, 1994, 116(3): 316-323.

[9] RAJURKAR K P, WEI, B, KOZAK, J, MCGEOUGH J A. Modelling and monitoring interelectrode gap in pulse electrochemical machining [J]. Annals of CIRP, 1995, 44(1): 177-180.

[10] HEWIDY M S. Controlling of metal removal thickness in ECM process [J]. Journal of Materials Processing Technology, 2005, 160: 348-353.

[11] LI Xi, CAO Guang-yi, ZHU Xin-jian. Modeling and control of PEMFC based on least squares support vector machines [J]. Energy Conversion and Management, 2006, 47: 1032-1050.

[12] SHI, D F, GINDY N N. Tool wear predictive model based on least squares support vector machines [J]. Mechanical Systems and Signal Processing, 2007, 21(4): 1799-1814.

[13] LI Yan-bin, ZHANG Ning, LI Cun-bin. Support vector machine forecasting method improved by chaotic particle swarm optimization and its application [J]. Journal of Central South University of Technology, 2009, 16(3): 478-481. (in Chinese)

[14] VAPNIK V N. The nature of statistical learning theory [M]. New York: Springer, 1995: 181-218.

[15] SUYKENS J A K, GESTEL T V, BRABANTER J D, MOOR B D, VANDEWALLE J. Least squares support vector machines [M]. Singapore: World Scientific, 2002: 29-70.

[16] SUYKENS J A K, VANDEWALLE J, MOOR B D. Optimal control by least squares support vector machines [J]. Neural Networks, 2001, 14(1): 23-35.

[17] SUYKENS J A K, VANDEWALLE J. Least squares support vector machine classifiers [J]. Neural Processing Letters, 1999, 9(3): 293-300.

[18] RUSZAJ A, ZYBURA-SKRABALAK M. The mathematical modelling of electrochemical machining with flat ended universal electrodes [J]. Journal of Materials Processing Technology, 2001, 109: 333-338.

(Edited by YANG Bing)

Foundation item: Project(90923022) supported by the National Natural Science Foundation of China; Project(2009220022) supported by Liaoning Science and Technology Foundation, China

Received date: 2010-01-21; Accepted date: 2010-10-14

Corresponding author: XU Wen-ji, Professor, PhD; Tel: +86-411-84708422; E-mail: wenjixu@dlut.edu.cn

- Prediction method for surface finishing ofspiral bevel gear tooth based on least square support vector machine