J. Cent. South Univ. (2016) 23: 2336-2345

DOI: 10.1007/s11771-016-3292-9

Effects of thermal treatment on physical and mechanical characteristics of coal rock

YIN Tu-bing(尹土兵)1, WANG Pin(王品)1, LI Xi-bing(李夕兵)1, SHU Rong-hua(舒荣华)1, YE Zhou-yuan(叶洲元) 2

1. School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2. School of Energy and Safety Engineering, Hunan University of Science and Technology, Xiangtan 411201, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Abstract:

To study the physical and mechanical properties of coal rock after treatment at different temperatures under impact loading, dynamic compression experiments were conducted by using a split Hopkinson pressure bar (SHPB). The stress–strain curves of specimens under impact loading were obtained, and then four indexes affected by temperature were analyzed in the experiment: the longitudinal wave velocity, elastic modulus, peak stress and peak strain. Among these indexes, the elastic modulus was utilized to express the specimens’ damage characteristics. The results show that the stress–strain curves under impact loading lack the stage of micro-fissure closure and the slope of the elastic deformation stage is higher than that under static loading. Due to the dynamic loading effect, the peak stress increases while peak strain decreases. The dynamic mechanical properties of coal rock show obvious temperature effects. The longitudinal wave velocity, elastic modulus and peak stress all decrease to different extents with increasing temperature, while the peak strain increases continuously. During the whole heating process, the thermal damage value continues to increase linearly, which indicates that the internal structure of coal rock is gradually damaged by high temperature.

Key words:

1 Introduction

In recent years, with the increased depth of coal mining and the constant innovation of mining technology, some mining methods with strong drilling and strong disturbance have become widely extended and used; the local stress concentration will be more obvious in coal rock, caused by the effect of large-scale and high strength mining. The coal rock will suffer a violent impact loading as a result of the excavation blasting and uncovering of cross-cut coal rock in mining process, and the dynamic loading produced by the fracture of seam roof is likely to trigger the rock burst [1]. In addition, deep mining presents a series of difficulties, such as high temperature, high depth and high ground pressure [2-4]. Coal rock in deep mining not only suffers from dynamic impact loading but also is affected by the high temperature. The physical and mechanical properties of coal rock will exhibit significant changes under the coupled effects of extreme temperature and impact loading [5-6]. Therefore, it is of great importance for reliably ensuring the safety of deep coal mining to study the mechanical behaviours of coal rock treated by different temperatures.

Up to now, scholars have conducted various researches on the dynamic mechanical properties of rock after treatment at high temperatures. For example, LIU and XU [7] investigated the effects of temperature and impact loading on the mechanical properties of marble by using split Hopkinson pressure bar (SHPB) equipment. They concluded that the transformation of mineral components and the change of mineral particles are the two main reasons for the variation of the dynamic mechanical properties of marble after heating. RAO et al [8] studied the mechanical properties of sandstone at high temperature by developing the Brazilian disc test, axial compressive test and three-point bending test. The experimental results obtained a critical temperature of 200 °C or 250 °C; on either side of the critical temperature, the mechanical properties show an opposite variation. Their results also show that the mineral composition and microstructure of natural rock material have a great influence on its mechanical properties at high temperature, and the dominance of drying or micro cracking will lead to the improvement or degradation of the mechanical properties of the rock. DEMIRDAG et al [9] carried out a study of the effects of porosity, unit volume weight and Schmidt hardness on the quasi-static and dynamic compressive behaviours of some carbonate rocks using a classical servo-hydraulic testing machine and SHPB testing system, respectively. The results show that the porosity, unit volume weight and Schmidt hardness have significant effects on the compressive stress–strain behaviour of the rock samples under dynamic loading, and also beige limestone samples have significantly higher dynamic compressive strength than other carbonate rock samples. CHEN et al [10] conducted a study on the dynamic mechanical properties of post-high-temperature sandstone. The sandstone samples were impacted by the different-velocity which was driven by a SHPB system, and the stress–strain curves of the sandstone samples subjected to impact loading as well as their failure modes were obtained. They concluded that the dynamic failure modes of sandstone are affected by the temperature and impact loading, the break degree increases with the increase of impact loading and the damage develops from the outer of sandstone to the core. XIE et al [11] studied the dynamic mechanical properties of cement and asphalt mortar by using the split Hopkinson pressure bar. The experimental results show that the peak strength of CA mortar increases with increasing strain rate, and the growth rate decreases gradually. The elastic modulus and specific energy absorption with strain rates were further analyzed. Finally, a constitutive model of CA mortar based on statistical damage theory was established. And also, the authors in this work evaluated the mechanical properties of sandstone after high temperature under static and dynamic loading by using the SHT4206 electro-hydraulic servo-controlled testing machine and SHPB equipment, respectively [12]. The differences of rock failure modes, peak stress and peak strain at high temperatures under static and dynamic loading were analyzed and compared systematically. The effects of temperature on rock mechanical properties were investigated from the microscopic view.

However, research on coal rock mechanical properties is still confined to static tests. Although some scholars have studied the effect of impact loading on coal rock, they did not consider the coupled effect of temperature and impact loading [13-17]. Coal rock has some different features in physical and mechanical properties, such as small consistent coefficient, high porosity and low compressive strength; in particular, these differences will be greater when the coal rock is exposed to high temperature. In this work, a uniaxial dynamic compressive experiment on coal rock is carried out by using a split Hopkinson pressure bar (SHPB) and the stress–strain curves under impact loading are obtained after different temperatures (from 25 °C to 500 °C). Combining the transformation of mineral components and the damage to the internal microstructure at high temperatures, the relationships of the four indexes with temperature variation were analyzed and verified. Thus, the causes of rock failure are explored and the influence of high temperature and impact loading on the mechanical properties of coal rock are obtained.

2 Rock samples

2.1 Specimen preparation

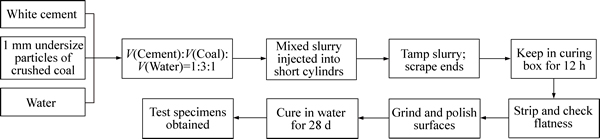

Because there are several types of weak planes in raw coal, such as cracks and holes, the mechanical properties obtained from experiments on raw coal samples will show a large variation directly. Therefore, a material made of white cement, coal particles and water, with similar rock properties (brittleness and dilatancy) is used for the test samples. The volume ratio of cement, coal particles and water is 1:3:1, and the coal particles screened from the crushed raw coal have a diameter of 1 mm. In order to reduce the inertia effect of the test samples, this experiment adopts the optimum aspect ratio (L/D=1) recommended by DAVIES and HUNTER [18]. A 50 mm diameter plastic long tube is cut into 50 mm long cylinders and the mixed ingredients are injected into the cylinders with some grease on its inner wall. Then, the mixtures are compacted and the two end surfaces are flattened; when the specimens have been maintained for about 12 h, they are taken out and the surfaces and ends are then polished to meet the test requirements. After stripping, specimens are cured in tap water for 28 d to produce the water-saturated specimens required, where the influence of water should be considered. The process of making the specimens is illustrated in Fig. 1.

Fig. 1 Sample preparation process

2.2 Longitudinal wave velocity of coal rock

The longitudinal wave velocities of the unheated and heated specimens are measured, respectively, by using the rock and soil engineering quality detection instrument CE9201. The working principle of the detecting instrument is as follows. The detector is equipped with two ultrasonic transducers used respectively for receiving and transmitting; the transducers are respectively arranged on the two end faces of the specimen. The ultrasonic signals are obtained by the technology of a programmable amplifier and attenuation, and the initial entry point of the waveform is the point used to data selection. The longitudinal wave velocity is computed according to the acoustic transmission time in the sample.

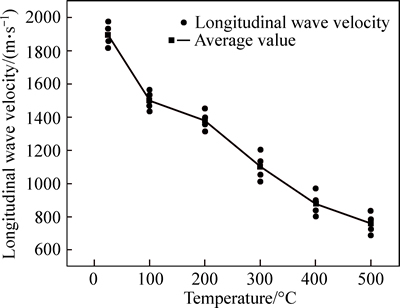

As shown in Fig. 2, the longitudinal wave velocity at 100 °C is 1499 m/s while it is 1895.5 m/s at 25 °C, showing a sharp increase of 21%. When the temperature is in the range of 100-200 °C, the rate of decrease of the longitudinal wave velocity obviously slows down with increasing temperature, and the decrease ratio is only 8%; then it continues to be a linear decrease when the temperature is above 200 °C and below 400 °C. The wave velocities are respectively 1379, 1101 and 876.5 m/s, and in this period, the decrease rate is about 20%. When the temperature reaches 500 °C, the velocity is only 757m/s, a decrease of 60% compared with that of 25 °C.

Fig. 2 Relationship between longitudinal wave velocity and temperature

2.3 Uniaxial compression strength at room temperature

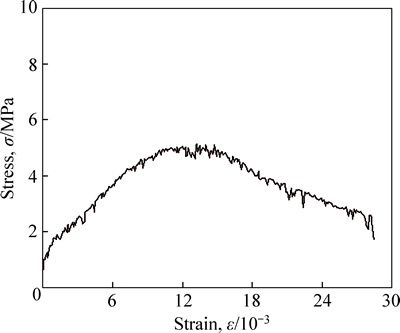

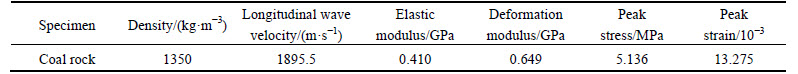

Uniaxial compressive experiments on the coal rock samples are carried out by using the MTS810 testing system, and this experiment adopts the optimum aspectratio (L/D=2:1) recommended by ISRM. The stress– strain curves under static loading and normal temperature (25 °C) are obtained, and a typical one is shown in Fig. 3. The density of the coal rock specimens is determined using the volume method commonly used in engineering. Their basic physical and mechanical properties under static loading and normal temperature are given in Table 1.

Fig. 3 Stress–strain curve of coal rock under static loading and ambient temperature (25 °C)

3 Experimental equipment and programme

3.1 Experimental setup

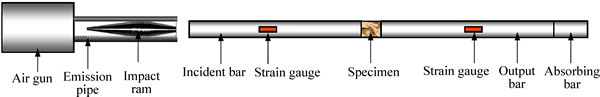

For impact loading on the specimens, the improved split Hopkinson pressure bar (SHPB) with a spindle impact ram is used for testing. It is composed of an air gun, emission pipe, spindle impact ram, incident bar, output bar and absorbing bar (as shown in Figs. 4 and 5). This testing system has the advantage of being adapted for high strain rate loading on heterogeneous brittle materials, and the spindle impact ram can realize the half sine stress wave loading with a constant strain rate [19]. The rate of impact loading can be controlled by controlling the inflation pressure of the air gun. The strain gauges are fixed to the incident bar and output bar, and the mechanical properties of the specimens can be calculated through analysis of the voltage in the strain gauges. The formula is given as follows [20]:

(1)

(1)

(2)

(2)

Table 1 Static mechanical properties of coal rock at ambient temperature (25 °C)

Fig. 4 Functional diagram of SHPB

Fig. 5 SHPB test device and test system

(3)

(3)

where A0 and AS respectively stand for the cross- sectional areas of the specimen and the bar;E is the elastic modulus of the bar; C0 and LS respectively stand for the longitudinal wave velocity and the length of the bar; εI, εR and εT, respectively, represent the incident, reflection and transmission strains of the bar.

The high temperature heating box used in the experiment is made by the Great Wall Electric Furnace Factory located in the Tian-xin district of Changsha city, China (as shown in Fig. 6). The device is composed of a high temperature furnace and a temperature controller. The model is SX-4-10, which has a 4 kW rated power and 1050 °C peak heating temperature.

Fig. 6 Heating box

3.2 Heat treatment on samples

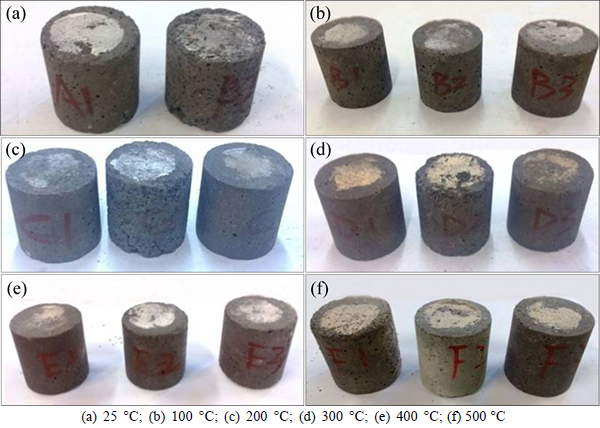

Before the test, all of the specimens are numbered and grouped according to different temperature grades; six different temperature levels (25 °C, 100 °C, 200 °C, 300 °C, 400 °C and 500 °C) are designed. The six letters A–F are used to mark the six temperature grades. Six samples are used for each temperature grade, with the temperature as the single variable. In order to ensure that the specimens are heated uniformly, the heating rate is set at 3 °C/min; the temperature remains constant for 3 h after reaching the intended value, and then it is cooled down to room temperature at a lower rate in order to avoid thermal shock during cooling. Some of the samples after treatment at different temperatures are shown in Fig. 7.

4 Experimental results

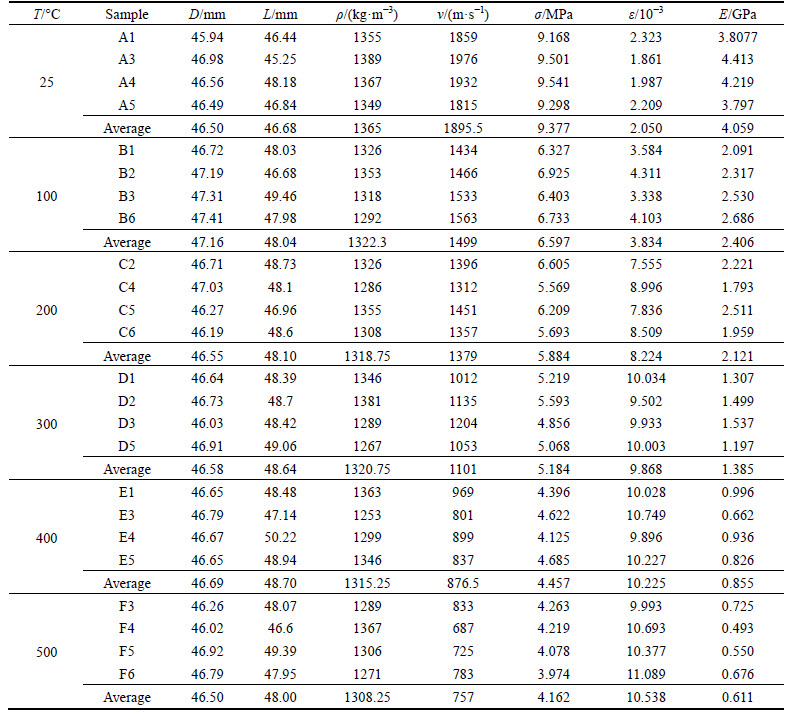

After a series of preparation, the results of the dynamic compression test on the coal rock after high temperatures are obtained. In order to reduce experimental error, two data with larger discrete values are eliminated from their group. Then, the average value of the four mechanical indexes can be obtained, as seen in Table 2.

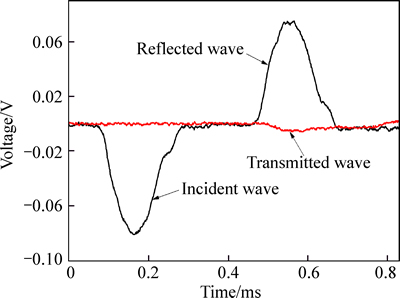

4.1 Dynamic equilibrium

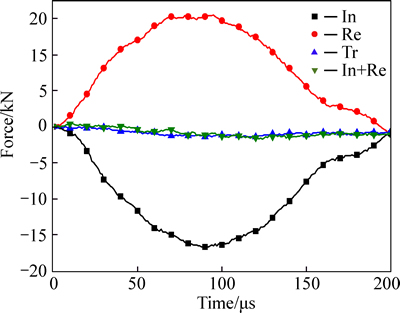

A sample was sandwiched between the incident bar and the output bar, and after the preparation work was all completed, the impact ram was launched by a high-speed emission pipe and the incident bar is subjected to a longitudinal impact pressure. A series of voltage signal curve of specimens are obtained after high temperature through the SHPB test system; a typical one at temperature of 100 °C is shown in Fig. 8.

In order to guarantee that the stress inside the specimen can be evenly distributed, the dynamic equilibrium verification is needed; the loading forces on the two ends of the sample can be obtained by the following formula [21]:

(4)

(4)

where ε is the strain; E and A are the elastic modulus and the cross-sectional area of the bar, respectively.

A dynamic force balance check for a typical test at 100 °C is shown in Fig. 9, which is calculated using Eq. (4). It can be seen that the dynamic forces on both sides of the specimen are in a state of balance, as the sum of the incident (In) and reflected (Re) stress waves is absolutely equal to the dynamic force transmitted (Tr) on the other side [22]. In this work, the dynamic force balance of all tests has been proven.

Fig. 7 Appearance of coal rock specimens after high temperatures:

Table 2 Results of dynamic compression test on coal rock after high temperatures

Fig. 8 Typical voltage signal curve at 100 °C

Fig. 9 Dynamic force balance check for a typical dynamic test at 100 °C

4.2 Stress–strain curves of coal rock

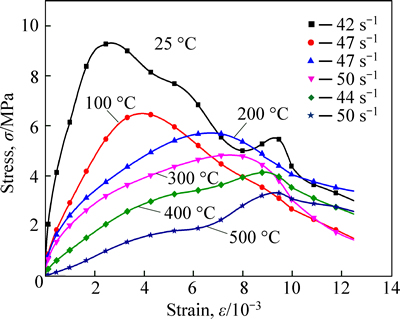

The stress–strain curves of coal rock treated under different temperatures are calculated using Eqs. (1), (2) and (3), as shown in Fig. 10. The stress–strain relation forms a nonlinear variation with increasing temperature compared with the static loading test. In addition, the stress–strain curves under impact loading lack the micro-fissure closure stage and the slope of elastic deformation stage is higher than that of static loading, mainly owing to the dynamic loading and the inherent inertia of internal crystals. With the increase of temperature, the peak stress decreases while peak strain increases; in particular, the slope of the elastic deformation stage decreases substantially. And after the peak stress, although the structure of the specimen is damaged and a larger deformation is generated, it still has a certain bearing capacity while the strength is not reduced to zero.

Fig. 10 Stress–strain curves of coal rock under impact loading after high temperatures

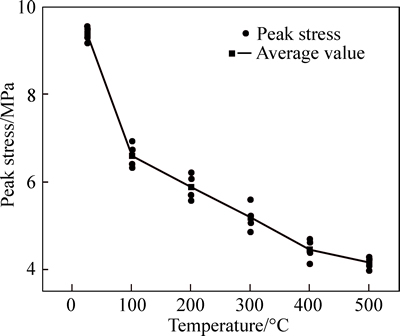

4.3 Temperature effect on peak stress

The variation of the peak stress of coal rock under the coupled effects of high temperature and impact loading can be observed in Fig. 11. Compared to the ambient temperature and static loading conditions, the peak stress of impact loading shows an upward trend from 5.136 MPa to 9.377 MPa. When the temperature reaches 100 °C, the peak stress is 6.597 MPa, a decrease of 30% compared with 25 °C; in the temperature range from 100 °C to 400 °C, the peak stress is respectively 6.597 MPa, 5.884 MPa, 5.184 MPa and 4.457 MPa, a linear decrease of 11%. When the temperature exceeds 400 °C, the rate of decrease slows down slightly. At the temperature of 500 °C, the peak stress is only 4.162 MPa, a decrease of 56% compared to that of 25 °C.

Fig. 11 Relationship between peak stress and temperature

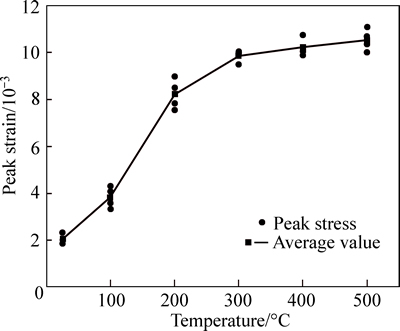

4.4 Temperature effect on peak strain

The relationship between the peak strain and temperature can be seen in Fig. 12. At the temperature of 25 °C, the peak strain of coal rock under impact loading is 2.05, only 15% compared with that under static loading conditions. When the temperature reaches 100 °C, the peak strain is 3.834, an increase of 87% compared with 25 °C. In the temperature range from 100 °C to 200 °C, the peak strain shows an abrupt increase from 3.834 to 8.224, that is an increase of 115%. When the temperature is 200-500 °C, the increase rate of peak strain is at a level of 20%, and then it keeps a lower increase by 3.6% or 3.1%.

Fig. 12 Relationship between peak strain and temperature

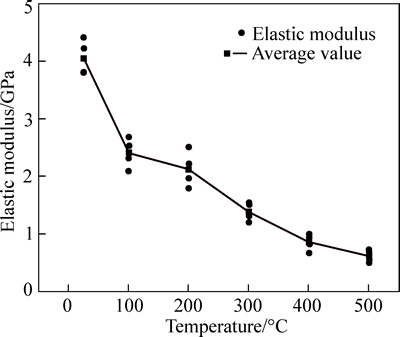

4.5 Temperature effect of elastic modulus

The elastic modulus is an important index to measure the resistance capacity of the elastic deformation. And the initial elastic modulus, tangent elastic modulus and secant elastic modulus are always used to express the deformation characteristics of rocks in practical work. The variation of stress–strain curves is fluctuant and nonlinear because of the low compressive strength of the specimens, and the slope of the curves decreases with the stress increasing, so the value of the elastic modulus is closely related to the choice of the reference point.

In this work, the elastic modulus means the slope corresponding to 40% and 60% of the compressive strength during the rising phase of the stress–strain curve [23]. The computation formula is as follows:

(5)

(5)

where subscripts 1 and 2 respectively correspond to the two points 0.4σ0 and 0.6σ0 of the above stress–strain curve, S stands for axial stress, and ε stands for axial strain. The elastic modulus EC is calculated from the stress–strain curve. The relationship of the elastic modulus and temperature can be observed in Fig. 13.

Compared with the ambient temperature and static loading conditions, the dynamic elastic modulus shows an obviously upward trend from 0.410 GPa to 4.059 GPa. Compared with 25 °C, the elastic modulus is 2.406 GPa at the temperature of 100 °C, a decrease of 40.7%. At the temperature range from 100 °C to 200 °C, the decrease rate obviously slows down, only decreasing by 11.88%. When the temperature is 200-400 °C, the elastic modulus is respectively 2.121 GPa, 1.385 GPa and 0.855 GPa, a linear decrease of 35%. When the temperature exceeds 400 °C, the rate of decrease slows down again. At the temperature of 500 °C, the elastic modulus is only 0.611 GPa, a decrease of 85% compared to 25 °C.

Fig. 13 Relationship between elastic modulus and temperature

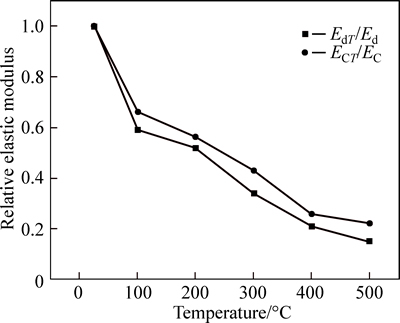

According to the elastic mechanics theory, the dynamic elastic modulus of coal rock has a direct relationship with its density, longitudinal wave velocity and Poisson ratio, and the computation formula is as follows [24-25]:

(6)

(6)

where Ed stands for the dynamic elastic modulus obtained by theoretical calculation, ρ stands for density, vp stands for longitudinal wave velocity and μ stands for Poisson ratio. In this work, Poisson ratio is 0.25, according to the mineral composition and production process of coal rock mass.

The relative elastic modulus can be obtained in two ways, theoretical calculation and calculation from the stress–strain curve, respectively. In Fig. 14, two calculation results are compared, and the relativechange rate under the temperature change is explored.

Fig. 14 Relationship between relative elastic modulus and temperature

The dynamic elastic modulus obtained in two different ways decreases continuously as the temperature increases, but the rate of decrease of the relative elastic modulus obtained by theoretical calculation is higher than that calculated from the stress–strain curve, which indicates that the physical and mechanical properties of the coal rock have a large change after high temperature treatment; in particular, the variation of physical properties is more extreme. In addition, some errors compared with actual reality may be another reason for the difference between the two results, because the elastic modulus obtained by theoretical calculation is under ideal conditions.

5 Discussion

Combining the structural characteristics, mineral compositions and the change of microstructure with each test curve of mechanical properties obtained from the experiment, the dynamic mechanical characteristics are analyzed and the essence of coal rock fracture after exposure to high temperature is explored.

Under impact loading, the specimens are unable to have a timely deformation and the crystal particles preserve their inertia, with the pores compacted compared with the static condition. At this time, the peak stress increases while the peak strain decreases, as the lateral strain is severely restricted if there is a confining pressure, and the higher the impact velocity the greater the restriction. In addition, because of the rapid progress of the impact loading, the stress–strain curves will lack the stage of micro-fissure closure and the slope of the elastic deformation stage will be higher than that under static loading.

Coal rock is a material with high porosity and poor density. When it is heated from 25 °C to 100 °C, the density of the specimen shows an obvious decrease, as seen in Table 2. This is because a large amount of free water existing in the pores evaporates into water vapor and the original cracks expand. Owing to the increase of porosity and destruction of integrity, the peak stress of the coal rock decreases abruptly with increasing temperature in this period. In the meantime, the longitudinal wave velocity and elastic modulus also show a decreasing trend with temperature increase, as the ultrasonic wave velocity in the air is far slower than in a solid or liquid medium.

When the temperature reaches 100-200 °C, the free water is completely lost and the mineral particles expand. At the same time, some pyrolysis gas is produced by the deformation of the coal particles. The production of pyrolysis gas makes the quality of coal rock reduced, and the number of cracks is obviously increased, which may speed up the decrease rate of the longitudinal wave velocity and elastic modulus slightly. As the coefficient of thermal expansion is different, there will be a binding force between the mineral particles; some particles with large deformation are compressed, others with little deformation are stretched, and this generates a thermal stress between them. Under the interaction of these factors, the longitudinal wave velocity and elastic modulus maintain a slow decrease, the peak stress continues to rise and the peak strain increases significantly.

At high temperature (exceeding 200 °C), the gap of the thermal expansion increases and the structure’s thermal stress plays a dominant role, showing that temperature has the effect of weakening the rock [26]. But, this failure process of the specimen is gradual, so the longitudinal wave velocity, elastic modulus and the peak stress maintain a linear decrease. With the coal rock mass producing a deformation, the internal structure is gradually destroyed and the peak strain still increases slowly with temperature increasing, as the strength is not reduced to zero.

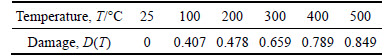

The thermal damage to coal rock under the coupled effects of high temperature and impact loading can be defined by its elastic modulus. The computation formula is as follows [27]:

(7)

(7)

where E stands for the elastic modulus, and the subscripts T and 0, respectively, correspond to the two temperatures T and 25 °C.

The thermal damage to coal rock under different temperatures is obtained by putting the elastic modulus’ values into Eq. (7), as shown in Table 3.

Table 3 Thermal damage to coal rock after different temperature treatments

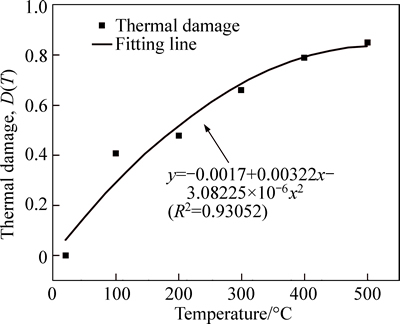

As shown in Table 3, the thermal damage continuously increases with increasing temperature, and the range equation of coal rock with temperature variation can be obtained by fitting the scatter diagram of the thermal damage values:

(8)

(8)

where T stands for the heating temperatures, b1, b2 and b3 stand for the material parameters of coal rock.

The integrity, porosity and water saturation coefficient of coal rock can be represented by the damage variable. This can be seen from the fitted Eq. (8) and Fig. 15. Thermal damage increases linearly with the increase of temperature, which indicates that the internal structure of the coal rock is gradually damaged by high temperature. At low temperature, the increase rate of damage is higher than that under high temperatures, mainly because the internal structure of the specimens has already been seriously damaged.

Fig. 15 Relationship between thermal damage and temperature

6 Conclusions

1) Compared with the static loading condition, there is no stage of micro-fissure closure of the stress–strain curves and the slope of the elastic deformation stage is higher, mainly caused by the dynamic loading and the internal crystals preserving their inertia. With increasing temperature, the stage of elastic deformation is extended and the peak stress decreases quickly while peak strain increases.

2) Due to the evaporation of free water and the increase of pore volume after high temperature treatment, the longitudinal wave velocity, elastic modulus and the peak stress decrease rapidly with the increase of temperature up to 100 °C. When the temperature reaches 100-200 °C, some pyrolysis gas is generated from the decomposition of the organic material of the coal granules, which speeds up the rate of decrease of the longitudinal wave velocity and elastic modulus slightly. However, because the free water is completely lost and the mineral particles expand, the longitudinal wave velocity and elastic modulus maintain a slower decrease compared with that of 100 °C.

3) The peak strain increases continuously with increasing temperature, especially at the temperature stage of 100-200 °C, where the increase is 115%. The abrupt increase of peak strain is due to the volume increase and density decrease caused by the thermal expansion of coal rock. Meanwhile, high porosity of samples makes the dynamic loading effect no longer obvious, which results in a large deformation under the impact loading.

4) When the temperature exceeds 200 °C, the longitudinal wave velocity, peak stress and elastic modulus all decline almost linearly with the increase of temperature. The thermal damage increases linearly with the increase of temperature, which indicates that the effect of high temperature gradually damages the internal structure of the coal rock. Although the structure of the specimen is damaged and a larger deformation is generated, it still has a certain bearing capacity while the strength is not reduced to zero, and at the high temperature stage, the peak strain increases slowly.

5) Overall, the water loss, thermal expansion and deformation, the pyrolysis gas produced by decomposition of organic material and the structure thermal stress caused by high temperatures are important reasons leading to changes in the coal rock’s dynamic mechanical characteristics, and at different temperature levels, the leading factors are different. Therefore, the mechanical behaviours of coal rock show different variations in different temperature ranges.

References

[1] WU Xing-rong, DOU Lin-ming. Mechanism of rock burst under the combined conditions of hard coal and hard rock [J]. Coal Mining Technology, 2006, 11(4): 70-72.

[2] HE Man-chao, XIE He-ping, PENG Su-ping, JIANG Yao-dong. Study on rock mechanics in deep mining engineering [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(16): 2803-2813.

[3] GURTUNCA R G, KEYNOTE L. Mining below 3000 m and challenges for the South African gold mining industry [C] //Proc Mech of Jointed and Fractured Rock. Rotterdam: A. A. Balkema, 1998: 3-10.

[4] LI Xi-bing, YAO Jin-rui, GONG Feng-qiang. Dynamic problems in deep exploitation of hard rock metal mines [J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2551-2563.

[5] KANG Jian. Research on thermal cracking of rocks and its application [M]. Dalian: Dalian University of Technology Press, 2008: 97-159. (in Chinese)

[6] XIE He-ping, PENG Su-ping, HE Man-chao. Engineering catastrophes induced by underground coal mining at great depth and the scopes for future researches [C]// The Fifth National Congress of China Coal Society. China Coal Society. 2001: 57-62.

[7] LIU Shi, XU Jin-yu. Study on dynamic characteristics of marble under impact loading and high temperature [J]. International Journal of Rock Mechanics and Mining Sciences, 2013, 62: 51-58.

[8] RAO Qiu-hua, WANG Zhi, XIE Hai-feng, XIE Qiang. Experimental study of mechanical properties of sandstone at high temperature [J]. Journal of Central South University of Technology, 2007, 14: 478-483.

[9] DEMIRDAG S, TUFEKCIK K, KAYACAN R, YAVUZ H, ALTINDAG R. Dynamic mechanical behavior of some carbonate rocks [J]. International Journal of Rock Mechanics & Mining Sciences, 2010, 47: 307-312.

[10] CHEN Teng-fei, XU Jin-yu, LIU Shi, WANG Peng, FANG Xin-yu. Experimental study on dynamic mechanical properties of post-high- temperature sandstone [J]. Explosion and Shock Waves, 2014, 34(2): 195-201.

[11] XIE You-jun, FU Qiang, ZHENG Ke-ren, YUAN Qiang, SONG Hao. Dynamic mechanical properties of cement and asphalt mortar based on SHPB test [J]. Construction and Building Materials, 2014, 70: 217-225.

[12] YIN Tu-bing, LI Xi-bing, YIN Zhi-qiang, ZHOU Zi-long, LIU Xi-ling. Study and comparison of mechanical properties of sandstone under static and dynamic loadings after high temperature [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(2): 273-279.

[13] WAN Zhi-jun, FENG Zhi-jun, ZHAO Yang-sheng, ZHANG Yuan, LI Gen-wei, ZHOU Chang-bing. Elastic modulus’s evolution law of coal under high temperature and triaxial stress [J]. Journal of China Coal Society, 2011, 36(10): 1736-1740.

[14] MENG Zhao-ping, LIU Chang-qing, HE Xiao-hei, ZHANG Ning. Experimental research on acoustic wave velocity of coal measures rocks and its influencing factors [J]. Journal of Mining and Safety Engineering, 2008, 25(4): 389-393.

[15] BUSTIN R M, ROSS J V, MOFFAT I. Vitrinite anisotropy under differential stress and high confining pressure and temperature: Preliminary observation [J]. International Journal of Coal Geology, 1986, 6(4): 343-351.

[16] LIU Xiao-hui, ZHANG Ru, LIU Jian-feng. Dynamic test study of coal rock under different strain rates [J]. Journal of China Coal Society, 2012, 37(9): 1528-1534.

[17] MA Zhan-guo, MAO Xian-biao, LI Yu-shou, CHEN Zhan-qing, ZHU Peng. The experimental study on the effect of temperature on the mechanical properties of coal [J]. Mining Pressure and Strata Control, 2005, 3: 46-48.

[18] DAVIES E D H, HUNTER S C. The dynamic compression testing of solids by the method of the split Hopkins on pressure bar [J]. Journal of the Mechanics and Physics of Solids, 1963(11): 155-179.

[19] LI X B, LOK T S, ZHAO J, ZHAO P J. Oscillation elimination in the Hopkinson bar apparatus and resultant complete dynamic stress- strain curves for rocks [J]. International Journal of Rock Mechanics and Mining Sciences, 2000, 37(7): 1055-1060.

[20] LI Xi-bing, GU De-sheng. Rock impact dynamics [M]. Changsha: Central South University of Technology Press, 1994: 10-14. (in Chinese)

[21] YIN Tu-bing, LIXi-bing, CAO Wen-zhuo. Effects of thermal treatment on tensile strength of Laurentian Granite using Brazilian test [J]. Rock Mechanics and Rock Engineering, 2015, 48(6): 2213-2223.

[22] MAHABADI O K, COTTRELL B E, GRASSELLI G. An example of realistic modelling of rock dynamics problems: FEM/DEM simulation of dynamic Brazilian test on barre granite [J]. Rock Mechanics and Rock Engineering, 43(6): 707-716.

[23] XU Jin-yu, LIU Shi. Analysis of energy dissipation rule during deformation and fracture process of rock under high temperatures in SHPB test [J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(S2): 3109-3115.

[24] DU Shou-ji, MA Ming, CHEN Hao-hua, QIU Yi-ping. The study on longitudinal wave characteristics of granite after high temperature [J]. Chinese Journal of Rock Mechanics and Engineering, 2003, 22(11): 1803-1806.

[25] LIU Shi, XU Jin-yu, ZHI Le-peng, CHEN Teng-fei. Experimental research on mechanical behaviors of marble after high temperatures subjected to impact loading [J]. Chinese Journal of Rock Mechanics and Engineering, 2013, 32(2): 273-280.

[26] LIU Quan-sheng, XU Xi-chang. Damage analysis of brittle rock at high temperature [J]. Chinese Journal of Rock Mechanics and Engineering, 2000, 19(4): 408-411.

[27] LIU Shi, XU Jin-yu. An experimental study on the physic- mechanical properties of two post-high-temperature rocks [J]. Engineering Geology, 2015(185): 63-70.

(Edited by YANG Bing)

Foundation item: Projects(41272304, 51304241, 51204068) supported by the National Natural Science Foundation of China; Project(2014M552164) supported by the Postdoctoral Science Foundation of China; Project(20130162120015) supported by the PhD Programs Foundation of Ministry of Education of China

Received date: 2015-05-07; Accepted date: 2015-06-05

Corresponding author: YIN Tu-bing, Lecturer; Tel: +86-18684770361; E-mail: tubing_yin@ csu.edu.cn

Abstract: To study the physical and mechanical properties of coal rock after treatment at different temperatures under impact loading, dynamic compression experiments were conducted by using a split Hopkinson pressure bar (SHPB). The stress–strain curves of specimens under impact loading were obtained, and then four indexes affected by temperature were analyzed in the experiment: the longitudinal wave velocity, elastic modulus, peak stress and peak strain. Among these indexes, the elastic modulus was utilized to express the specimens’ damage characteristics. The results show that the stress–strain curves under impact loading lack the stage of micro-fissure closure and the slope of the elastic deformation stage is higher than that under static loading. Due to the dynamic loading effect, the peak stress increases while peak strain decreases. The dynamic mechanical properties of coal rock show obvious temperature effects. The longitudinal wave velocity, elastic modulus and peak stress all decrease to different extents with increasing temperature, while the peak strain increases continuously. During the whole heating process, the thermal damage value continues to increase linearly, which indicates that the internal structure of coal rock is gradually damaged by high temperature.