Stress-induced martensitic transformation in (Ni47Ti44)100-xNbx shape memory alloys with wide hysteresis

HE Xiang-ming(何向明)1, ZHAO Long-zhi(赵龙志)2, DUO Shu-wang(多树旺)1,

ZHANG Rong-fa(张荣发)1, RONG Li-jian(戎利建)3

1. Jiangxi Key Laboratory of Surface Engineering, Jiangxi Science and Technology Normal University,Nanchang 330013, China;

2. School of Mechanical and Electrical Engineering, East China Jiaotong University, Nanchang 330013, China;

3. Institute of Metal Research, Chinese Academy of Science, Shenyang 110016, China

Received 10 April 2006; accepted 25 May 2006

Abstract:

The effect of deformation via stress-induced martensitic transformation on the reverse transformation behavior of the (Ni47Ti44)100-xNbx (x=3, 9, 15, 20, 30, mole fraction, %) shape memory alloys was investigated in detail by differential scanning calorimetry (DSC) after performing cryogenic tensile tests at a temperature of Ms+30 ℃. The results show that Nb-content has obvious effect on the process of stress-induced martensitic transformation. It is also observed that the stress-induced martensite is stabilized relative to the thermally-induced martensite (TIM) formed on cooling, and Nb-content in Ni-Ti-Nb alloy has great influence on the reverse transformation start temperature and transformation temperature hysteresis of stress-induced martensite(SIM). The mechanism of wide transformation temperature hysteresis was fully explained based on the microscopic structure and the distribution of the elastic strain energy of (Ni47Ti44)100-xNbx alloys.

Key words:

Ni-Ti-Nb alloy; shape memory alloy; martensitic phase transformation; wide hysteresis; differential scanning calorimetry;

1 Introduction

Ni-Ti-Nb alloy can exhibit a wide transformation temperature hysteresis compared to Ni-Ti binary alloys (about 150 ℃ versus 30 ℃). Thus, this wide hysteresis has important engineering utility, as parts made of this alloy can avoid storing and installing at cryogenic temperature. Due to this unique property, this alloy is now being used or expected to be used in the applications for coupling and sealing [1-7].

The stabilization effect in Ni-Ti-Nb alloy was observed to die out after the occurrence of the first reverse martensitic transformation, and transformation temperatures were depressed by retained dislocations in the subsequent thermal cycles. ZHANG et al [8] proposed that the elastic strain energy of martensite interfaces was relaxed by the plastic deformation of the adjacent β-Nb particles. PIAO et al [2] suggested that the elastic strain energy stored upon the forward trans- formation was relaxed by plastic deformation. The loss of the elastic strain energy as a driving force for the reverse transformation results in the stabilization effect. However, little experimental evidence of calorimetric measurements has been reported to support these hypotheses. Moreover, most of the works have been done only for the typical alloy with Ni47Ti44Nb9 (mole fraction, %, the same below) composition and there are only limited reports about the effect of composition [9, 10]. Systematic investigations have been made on the effect of Nb-content on the microstructure in the Ni-Ti-Nb alloys [9, 10]. It was found [10] that the microstructural change followed such trend as: the solid solution microstructure (x(Nb)≤3%)?the hypoeutectic micro- structure (3%

2 Experimental

The nominal compositions of the alloys were (Ni47Ti44)100-xNbx (x=3, 9, 15, 20, 30) in this study which were prepared by vacuum induction melting in a lime crucible. The as-melted ingots with a mass of 10 kg were homogenized at 880 ℃ for 28.8 ks and cooled in furnace, then hot swaged and rolled to rods with a diameter of 8.5 mm. Specimens for cryogenic tensile tests were all cut from the rods. All the specimens were solution treated at 860 ℃ for 2.4 ks, followed by quenching into water.

Round bar specimens of 30mm in gauge length were used for cryogenic tensile deformation. The deformation was carried out on a Schimadzu Autograph DCS-10T type machine at a strain rate of 2.8×10-4 s-1. The specimens were deformed in pure austenite state at a temperature of Ms+30 ℃ with an accuracy of ±1 ℃. Differential scanning calorimetry (DSC) measurements were made to measure the reverse transformation temperatures and the heat of transformation of specimens after deformation by using a PerkinElmer Pyris Diamond DSC at the heating rate of 0.17 ℃/s. Samples for DSC measurement were carefully cut from the gauge length of each deformed specimens using a low speed diamond saw cooled by water to avoid extra deformation.

3 Results and discussion

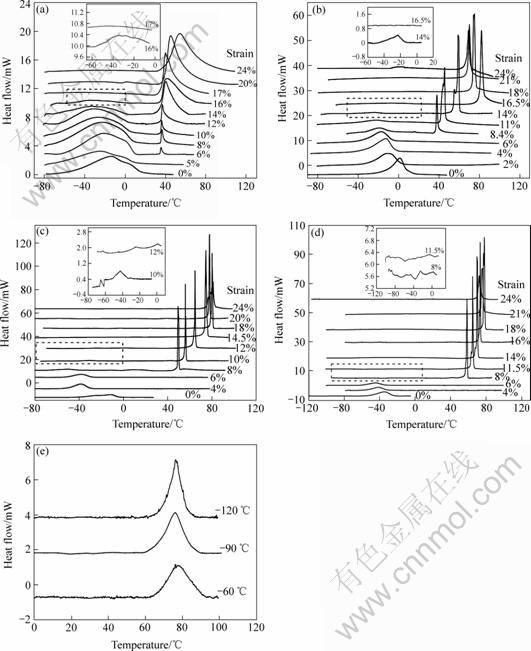

ZHANG et al [8] found that Ni47Ti44Nb9 alloy existed a characteristic deformation temperature Ms+30 ℃, at which deformation could effectively increase the transformation temperature hysteresis, while the alloy retained a better shape memory effect. Cryogenic tensile tests at Ms+30 ℃ were made on the (Ni47Ti44)100-xNbx alloy with various deformation levels. For 30% Nb alloy, the Ms can not be determined in the test temperature range, so this alloy was only deformed to 16% at -60, -90 and -120 ℃ in this experiment for comparison. For the other four alloys, the Ms temperatures are -61, -69, -83 and -120 ℃, respectively. Prior to the measurement all the DSC samples were cooled to -160 ℃ so that the residual NiTi phase would transform to martensite thermally, then heated from -100 ℃ to 100 ℃ at the heating rate of 0.17 ℃/s. It can be seen from Fig.1(a) that as the total strain is less than 6%, the curves only show the reverse transformation of TIM. When the strain is in the range of 6% to 16%, the DSC curves exhibit two transformation peaks: the peak at lower temperature is due to the reverse transformation of TIM and the another one at higher temperature corresponds to the reverse transformation of SIM. With the increase of deformation, the transformation peaks of SIM become more clear, and the transformation proceeds in a wider temperature range while those of TIM become diffuse. When the specimen is deformed to16%, the DSC curves in the dotted line in Fig.1(a) are almost flat in the same scale, and no endothermic reaction due to the reverse transformation is observed. However, the endothermic reaction is actually presented. The reverse transformation (due to TIM) is observed, as indicated by the enlarged figure in the upper inset. This means that only little amount of residual parent phase is transited to TIM. When the total strain is above 16%, DSC curves only exhibit the reverse transformation peak of SIM. This means that the process of stress-induced martensitic transformation is completed as the sample is deformed in tension to above 16% of strain. The DSC curves for the 9% Nb alloy and 15% Nb alloy have the similar trend as that of 3% Nb alloy, as shown in Fig.1(b) and Fig.1(c). For these two alloys, the process of stress-induced martensitic transformation is completed as the samples are deformed to about 14% and 10%, respectively. For 20% Nb alloy, it can be seen in Fig.1(d) that the specimens deformed to strains above 8% only exhibit a single-step reverse transformation peak for SIM whereas the rest shows a single-step reverse transformation peak for TIM. For 30% Nb alloy, it can be seen that the curves all show the reverse transformation peak due to the SIM in this alloy after deformed to 16% at three different temperatures, as shown in Fig.1(e).

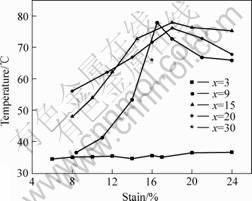

Fig.2 shows the effect of deformation on reverse transformation start temperature ![]() of SIM. It can be seen that

of SIM. It can be seen that ![]() rises to about 37 ℃ with the increase of strain and there is no obvious change of As temperature for 3% Nb alloy. However, for the 9% Nb alloy, the

rises to about 37 ℃ with the increase of strain and there is no obvious change of As temperature for 3% Nb alloy. However, for the 9% Nb alloy, the ![]() is observed to increase progressively at first with increasing strain. But,

is observed to increase progressively at first with increasing strain. But, ![]() increases remarkably in the strain range of 14%-16.5%. As the total strain is 16.5%,

increases remarkably in the strain range of 14%-16.5%. As the total strain is 16.5%, ![]() has the maximum value, and then decreases slightly with further deformation. The variation of

has the maximum value, and then decreases slightly with further deformation. The variation of ![]() of 15% Nb and 20% Nb alloy follows the same trend as that of 9% Nb alloy. For the 30% Nb alloy, although no obvious transformation peak is observed for the undeformed specimens, the deformed specimens occur the obvious

of 15% Nb and 20% Nb alloy follows the same trend as that of 9% Nb alloy. For the 30% Nb alloy, although no obvious transformation peak is observed for the undeformed specimens, the deformed specimens occur the obvious

Fig.1 Effect of deformation on reverse transformation behavior of (Ni47Ti44)100-xNbx alloys during heating: (a) x=3; (b) x=9[4]; (c) x=15; (d) x=20; (e) x=30 (The upper inset show enlarged DSC curves from dotted area.)

Fig.2 Effect of deformation on reverse transformation start temperature ![]() of (Ni47Ti44)100-xNbx alloys during heating

of (Ni47Ti44)100-xNbx alloys during heating

reverse transformation (due to SIM) during the heating, and the ![]() for specimens deformed at three different temperatures reaches about 65 ℃.

for specimens deformed at three different temperatures reaches about 65 ℃.

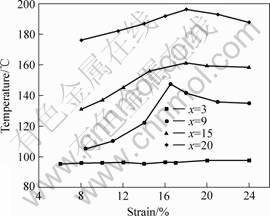

Fig.3 shows the effect of deformation on transformation temperature hysteresis (|![]() – Ms|) of (Ni47Ti44)100-xNbx alloys. The behavior follows the same trend as the effect of deformation on the

– Ms|) of (Ni47Ti44)100-xNbx alloys. The behavior follows the same trend as the effect of deformation on the![]() temperature. As the Ms temperature of the 20% Nb alloy is the lowest among the experimental alloys, it has the widest transformation temperature hysteresis. This indicates that for the same deformation, a wider transformation temperature hysteresis can be attained in higher Nb content alloys.

temperature. As the Ms temperature of the 20% Nb alloy is the lowest among the experimental alloys, it has the widest transformation temperature hysteresis. This indicates that for the same deformation, a wider transformation temperature hysteresis can be attained in higher Nb content alloys.

The cause for the widening of the transformation

Fig.3 Effect of deformation on transformation temperature hysteresis (|![]() – Ms|) of (Ni47Ti44)100-xNbx alloys during heating

– Ms|) of (Ni47Ti44)100-xNbx alloys during heating

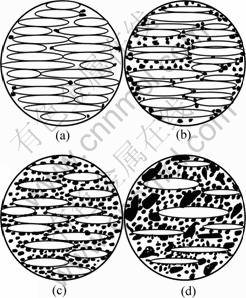

temperature hysteresis is believed to be due to the presence of β-Nb particles. So the distribution of β-Nb particles will greatly influence the stabilization effect. To analyze easily, we simplified the microstructure of the Ni-Ti-Nb alloy during the deformation as the following model: the Nb-rich phase was distributed around the SIM. The effect of β-Nb particles on the transformation hysteresis is schematically illustrated in Fig.4. Fig.4(a) shows the solution microstructure, Fig.4(b) shows the hypoeutectic microstructure, Fig.4(c) shows the eutectic microstructure and Fig.4(d) shows the hypereutectic microstructure. In these presentations the black block particle represents the β-Nb particle, and the ellipse represents the SIM.

For 3% Nb alloy, a little amount of the β-Nb particle only appears at the leading ends of the SIM during deformation, and its plastic deformation will relax the elastic stress field of leading ends of the SIM. The loss of the stored elastic strain energy results in the rise of the reverse transformation start temperature ![]() . For this alloy, the elastic strain energy of the martensite interfaces is little affected by the deformation of the β-Nb particles. On the other hand, the small quantity of β-Nb particles may produce plastic deformation as the specimen deforms to above 6%, with further increase of deformation, no more plastic deformation will be induced in β-Nb particles. These factors will result in the

. For this alloy, the elastic strain energy of the martensite interfaces is little affected by the deformation of the β-Nb particles. On the other hand, the small quantity of β-Nb particles may produce plastic deformation as the specimen deforms to above 6%, with further increase of deformation, no more plastic deformation will be induced in β-Nb particles. These factors will result in the ![]() having no obvious change with increase of deformation, as shown in Fig.2.

having no obvious change with increase of deformation, as shown in Fig.2.

However, for the 9% Nb and 15% Nb hypoeutectic alloys, large amount of the β-Nb particles appear at the leading ends of the SIM, so the elastic stress field of leading ends of the SIM could be relaxed sufficiently by the plastic deformation of the β-Nb particles with increase of deformation. In addition, some fine dispersive β-Nb particles also distribute around the interfaces of the SIM besides, therefore, the elastic strain energy of martensite interfaces can be relaxed by the plastic deformation the β-Nb particles during deformation. Compared to the 3% Nb alloy, the elastic energy is relaxed more in the hypoeutectic alloys, which results in the occurrence of a much higher ![]() temperature and a much wider transformation hysteresis.

temperature and a much wider transformation hysteresis.

For the 20% Nb eutectic alloy, the SIM is surrounded fully by large amount of the β-Nb particles due to the stress-induced martensitic transformation experiences in the eutectic microstructure. Apparently, the elastic strain energy can be relaxed fully by the deformation of the β-Nb particles. It can be found that the ![]() temperature of the 20% Nb alloy among the four alloys has the maximum at the critical strain (in which the

temperature of the 20% Nb alloy among the four alloys has the maximum at the critical strain (in which the ![]() temperature occurs at above ambient temperature), as shown in Fig.2. For the 30% Nb hypereutectic alloy, many large block β-Nb particles occur. The martensite adjacent the large block β-Nb particles are more easily intersected by the β-Nb particles. This means that the more plastic deformation near the martensite is induced, so that the elastic strain energy of the martensite is easily relaxed.

temperature occurs at above ambient temperature), as shown in Fig.2. For the 30% Nb hypereutectic alloy, many large block β-Nb particles occur. The martensite adjacent the large block β-Nb particles are more easily intersected by the β-Nb particles. This means that the more plastic deformation near the martensite is induced, so that the elastic strain energy of the martensite is easily relaxed.

Fig.4 Schematic illustration of effect of β-Nb particles on transformation hysteresis: (a) x(Nb)≤3%; (b) 3%

Since the relaxation of elastic strain energy by the deformation of β-Nb particles is related to the process of SIM during deformation, so the reverse transformation start temperature ![]() should not keep on increasing with further deformation. However, as shown in Fig.1 and Fig.2, the

should not keep on increasing with further deformation. However, as shown in Fig.1 and Fig.2, the ![]() still increases as the process of SIM has completed during deformation. We supposed that except the relaxation of elastic strain energy by the plastic deformation of β-Nb particles, the plastic deformation of SIM itself could also relax the part of elastic strain energy, in addition, the plastic deformation of NiTi phase due to the stress concentration of local area will create an internal elastic stress field to oppose the reversion of the SIM [10, 11]. The reverse transformation start temperature

still increases as the process of SIM has completed during deformation. We supposed that except the relaxation of elastic strain energy by the plastic deformation of β-Nb particles, the plastic deformation of SIM itself could also relax the part of elastic strain energy, in addition, the plastic deformation of NiTi phase due to the stress concentration of local area will create an internal elastic stress field to oppose the reversion of the SIM [10, 11]. The reverse transformation start temperature ![]() of the 3% Nb alloy is smaller than that of the high Nb content alloys after the same deformation at Ms+30 ℃ and does not increase obviously with increasing deformation. This can be attributed to the plastic deformation induced by β-Nb particles that are more effective for the stabilization of martensite and can widen the transformation temperature hysteresis than that of the deformation of the NiTi phase and the SIM itself.

of the 3% Nb alloy is smaller than that of the high Nb content alloys after the same deformation at Ms+30 ℃ and does not increase obviously with increasing deformation. This can be attributed to the plastic deformation induced by β-Nb particles that are more effective for the stabilization of martensite and can widen the transformation temperature hysteresis than that of the deformation of the NiTi phase and the SIM itself.

4 Conclusions

Nb-content has effect on the process of stress-induced martensitic transformation. The DSC measurements show that the process of stress-induced martensitic transformation completes as the specimens are deformed in tension to about 16%, 14%, 10%, 8% for the 3%, 9%, 15%, 20% Nb alloys, respectively. This confirms that the As can be raised by deformation via SIM. The stabilization effect of SIM in Ni-Ti-Nb alloy is mainly due to the relaxation of elastic strain energy by the plastic deformation of β-Nb particles, which results in the loss of the energy as a driving force for the reverse transformation. The SIM itself relaxes the part of elastic strain energy and the plastic deformation of parent phase will increate an internal elastic stress field to oppose the reversion of the SIM also have contribution to the stabilization effect of SIM more or less.

References[1] ZHAO L C. Study of Ti-Ni-Nb shape memory alloys with wide hysteresis [J]. Materials Science Forum, 2000, 327-328:23-30.

[2] PIAO M, MIYAZAKI S, OTSUKA K. Characteristics of deformation and transformation in Ti44Ni47Nb9 shape memory alloy [J]. Mater Trans JIM, 1992, 33: 346-353.

[3] ZHANG C S, WANG Y Q, CAI W, ZHAO L C. The study of constitutional phases in a Ni47Ti44Nb9 shape memory alloy [J]. Materials Chemistry and Physics, 1991, 28: 43-50.

[4] HE X M, RONG L J, YAN D S, LI Y Y. Temperature memory effect of Ni47Ti44Nb9 wide hysteresis shape memory alloy [J]. Scripta Materialia, 2005, 53: 1411-1415.

[5] HE X M, YAN D S, JIANG Z M, RONG L J. Effect of Nb-content on mechanical properties in (Ni47Ti44)100-xNbx shape memory alloys[J]. Materials Science Forum, 2005, 475-479: 1945-1948.

[6] HE X M, RONG L J. DSC analysis of reverse martensitic transformation in deformed Ti-Ni-Nb shape memory alloy [J]. Scripta Materialia, 2004, 51: 7-11.

[7] JIN W, CAO M.Z., YANG R, HU ZQ. Effect of pre-strain on the transformation and recovery behaviours of a Ti44Ni47Nb9 shape memory alloy [J]. J Mater Sci Technol, 2001, 17: 318-320.

[8] ZHANG C S, ZHAO L C, DUERIG T W, WAYMAN C M. Effect of deformation on the transformation hysteresis and shape memory effect in a Ni47Ti44Nb9 alloy [J]. Scripta Metall Mater, 1990, 24: 1807-1812.

[9] PIAO M, MIYAZAKI S, OTSUKA K, NISHIDA N. Effects of Nb addition on the microstructure of Ti-Ni alloys [J]. Mater Trans JIM, 1992, 33: 337-345.

[10] HE X M, YAN D S, RONG L J, LI Y Y. Effect of Niobium content on shape memory characteristics of (Ni47Ti44)100-xNbx alloys [J]. Advances in Cryogenics Engineering (Materials), 2004, 50A: 18-25.

[11] LIU Y N, TAN G S. Effect of deformation by stress-induced martensitic transformation on the transformation behaviour of NiTi [J]. Intermetallics, 2000, 8: 67-75.

Corresponding author: HE Xiang-ming; Tel: +86-791-3160103; Fax: +86-791-3801423; E-mail: hexiangming@gmail.com