网络首发时间: 2020-01-21 14:23

新型超高强铝锂合金厚板厚度方向组织及性能的不均匀性

中南大学材料科学与工程学院

北京宇航系统工程研究所

航空材料及工艺研究所

摘 要:

以一种40 mm厚度新型超高强铝锂合金(Al-3. 76Cu-1. 3Li-0. 11Zr-0. 42Mg-0. 44Ag-0. 38Zn-0. 28Mn-0. 05Ti)板材为对象,研究了其T8时效态(压缩预变形6%,温度150℃)厚度方向上室温纵向拉伸力学性能和组织的不均匀性。结果表明:时效初期(5 h),厚板表层强度(抗拉强度为499 MPa)略高于T/2层(抗拉强度为461 MPa)。而时效16~96 h后,厚板T/2层的屈服强度和抗拉强度均高于表层,并且强度差保持在55MPa左右。峰时效时T/2层抗拉强度为668 MPa,表层抗拉强度为611 MPa。厚板表层和T/2层纵截面固溶态的晶粒组织呈长条状,沿轧制方向被拉长。表层织构总体积分数为48. 9%,主要由变形织构(Brass{011}<211>织构、S{123}<634>织构和Cu{112}<111>织构,总体积分数达45. 6%)组成;而T/2层织构总体积分数较表层高(73. 1%),主要由变形织构(39. 6%)和较多的再结晶织构(Goss{011}<100>织构和Cube{001}<100>织构,总体积分数为33. 5%)组成。合金厚板T8时效析出相包括T1相(Al2CuLi),θ′相(Al2Cu)和δ′相(Al3Li)。与表层相比,时效24 h时厚板T/2层析出的T1相数量较多,而θ′相数量较少。

关键词:

中图分类号: TG146.21

作者简介:刘添乐(1995-),男,湖南长沙人,硕士研究生,研究方向:铝锂合金,E-mail:18351938656@163.com;;*李劲风,教授,电话:13278861206,E-mail:lijinfeng@csu.edu.cn;

收稿日期:2019-10-21

基金:国家科技部863项目(2013AA032401)资助;

Through-Thickness Inhomogeneity of Structures and Tensile Property in a Novel Super-High Strength Al-Li Alloy Thick Plate

Liu Tianle Ma Yunlong Huang Jialei Li Jinfeng Chen Yonglai Zhang Xuhu

School of Materials Science and Engineering,Central South University

Beijing Institute of Aerospace System Engineering

Aerospace Research Institute of Materials and Processing Technology

Abstract:

The through-thickness inhomogeneity of tensile property and structures in a 40 mm novel super-high strength Al-Li alloy(Al-3.76 Cu-1.3 Li-0.11 Zr-0.42 Mg-0.44 Ag-0.38 Zn-0.28 Mn-0.05 Ti)thick plate after T8 aging(6% pre-deformation followed by aging at150°C)were investigated. The results showed that the surface strength(tensile strength,499 MPa)of the alloy thick plate was slightly higher than that of the T/2 layer(tensile strength,461 MPa)in the early stage of aging(5 h). However,both yield strength and tensile strength of the T/2 layer of the alloy thick plate were higher than that of the surface after 16~96 h T8 aging,and their strength differences were maintained at 55 MPa approximately. The peak tensile strength of the T/2 layer was 668 MPa,and the peak tensile strength of the surface was 611 MPa. In the solution condition,the grain structures of the surface and T/2 layer remain strip-liked and both were elongated along the rolling direction. The total volume fraction of the textures in surface was 48.9%,which was mainly composed of deformed textures(Brass{011}<211>,S{123}<634> and Cu{112}<111>,45.6%). The total volume fraction of the textures in T/2 layer was higher(73.1%),composed of deformed textures(39.6%)and recrystallized textures(Goss{011}<100> and Cube{001}<100>,33.5%). The T8 aging precipitates included T1 phase(Al2 CuLi),θ′phase(Al2 Cu)and δ′phase(Al3 Li)of the novel super-high strength Al-Li alloy thick plate. After 24 h T8 aging,the T1 phase of the alloy T/2 layer was finer and denser than that of the surface,while the amount of θ′phase was less.

Keyword:

super-high strength Al-Li alloy; tensile property; aging precipitates; texture; inhomogeneity;

Received: 2019-10-21

作为21世纪最具发展潜力的航空航天材料之一,铝锂合金具有高强度、高韧性、耐损伤性、热稳定性和易加工成形性等特点,广泛地应用于机身框架、桁条、燃料贮箱等航空航天重要构件

科研工作者们在合金化及微合金化的基础上,开发了一种新型超高强铝锂合金。作者所在课题组对此种新型超高强铝锂合金薄板的微观组织及性能做了大量的研究

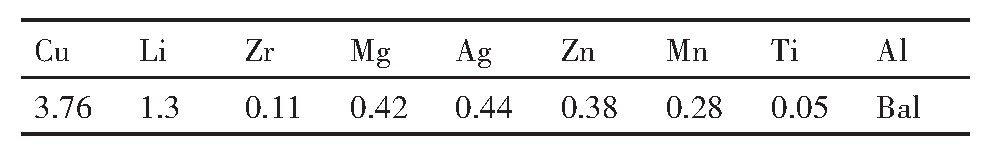

1 实验

实验使用的材料为西南铝业集团有限公司提供的40 mm厚度新型超高强铝锂合金热轧板材,其化学成分如表1所示。热轧板材试样先在510℃的盐浴炉中保温2.5 h,之后进行冷水淬火和T8时效处理。T8时效处理制度为:6%压缩预变形+150℃人工时效。压缩预变形在YA32-315型液压机上进行,具体示意图如图1所示。

分别于时效后试样的表层和T/2层沿板材轧制方向取棒状拉伸样。根据ASTM-E8M标准制备室温拉伸力学性能试验样品,试样平行段长度为25mm,直径为5 mm。室温拉伸在MTS-858万能力学试验机上进行,拉伸速率为2 mm?min-1。

表1 新型超高强铝锂合金化学成分 下载原图

Table 1 Chemical composition of novel super-high strength Al-Li alloy(%,mass fraction)

图1 压缩预变形示意图

Fig.1 Diagram of compression pre-deformation

采用Leica DMILM光学显微镜(OM)对固溶态样品进行金相观察,样品观察前经打磨、抛光和阳极覆膜处理。采用BruckerD8 Discovery型X射线衍射仪(XRD)测定固溶处理后合金厚板表层和T/2层的织构组分,分别测得{111},{200}和{220}3个方向的不完全极图后,利用Bunge函数级数展开法计算取向分布函数(ODF)。采用粒子群算法对织构进行定量分析,角度偏差在15°以内视为同种织构。采用TecnaiG2 20型透射电镜(TEM)进行厚板表层及T/2层时效态样品的时效析出相观察,测试时加速电压为200 kV。TEM试样首先机械减薄至80~100μm左右,之后采用双喷电解减薄仪制取。

2 结果与讨论

2.1 力学性能

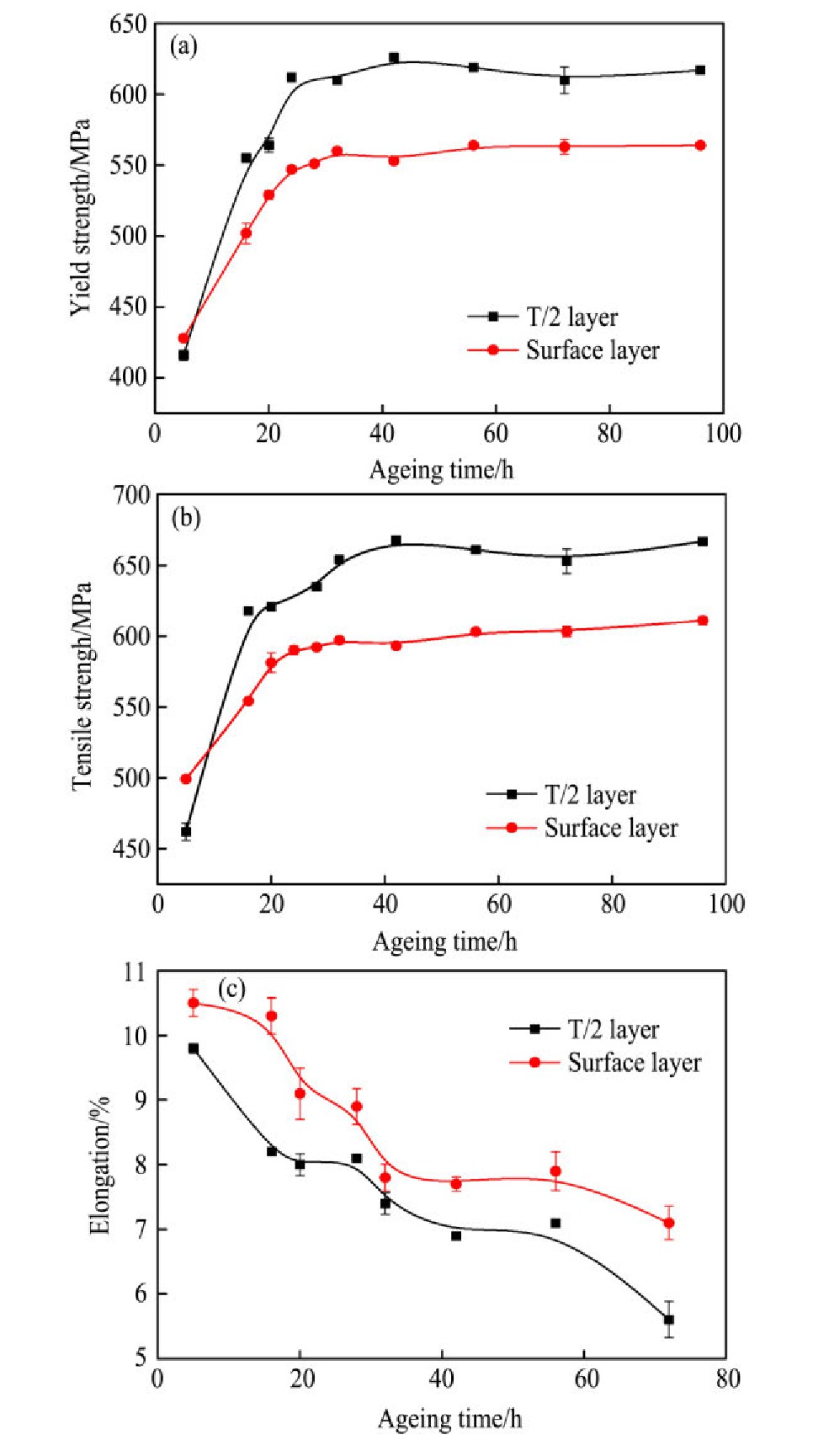

图2为合金厚板表层及T/2层T8时效态的室温纵向拉伸力学性能曲线。由图2可知,时效早期,合金强度水平较低。时效5 h时,厚板T/2层屈服强度和抗拉强度分别为416和461 MPa;而表层屈服强度和抗拉强度分别为428和499 MPa,略高于T/2层。

图2 厚板表层及T/2层T8时效态室温纵向拉伸力学性能曲线

Fig.2 Tensile properties of surface and T/2 layer of T8 aged al-loy thick plate as a function of aging time

(a)Yield Strength;(b)Tensile Strength;(c)Elongation

延长时效时间,合金强度逐渐提升。厚板T/2层时效响应速率较快,强度快速提升,在40 h左右达到峰值,峰值屈服强度及抗拉强度分别为625和668 MPa。达到峰时效之后,厚板T/2层强度趋于稳定,保持在一个较高的强度平台。厚板表层时效响应速率略慢于T/2层,时效至24 h后强度上升幅度减小。时效96 h时表层取得屈服强度和抗拉强度的最大值,最大值分别为563和611 MPa。从图中可以看出,在后续整个时效区间内(16~96 h)厚板T/2层的屈服强度和抗拉强度均高于表层,且表层与T/2层的屈服强度差和抗拉强度差基本保持不变,差值在55 MPa左右。在本文实验所取的时效时间区间内,厚板表层及T/2层均未达到真正意义上的过时效状态。由图2(c)可知,厚板表层和T/2层的延伸率均随时效时间的延长而逐渐降低,并且表层延伸率高于T/2层。

2.2 晶粒组织

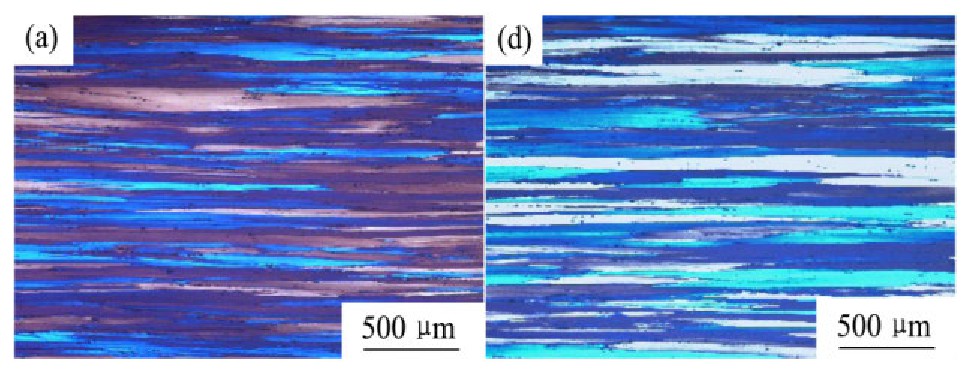

图3为合金厚板经固溶处理后表层及T/2层纵截面的金相照片。如图3所示,厚板表层及T/2层纵截面晶粒组织沿轧向呈长条状,具有很大的长厚比。

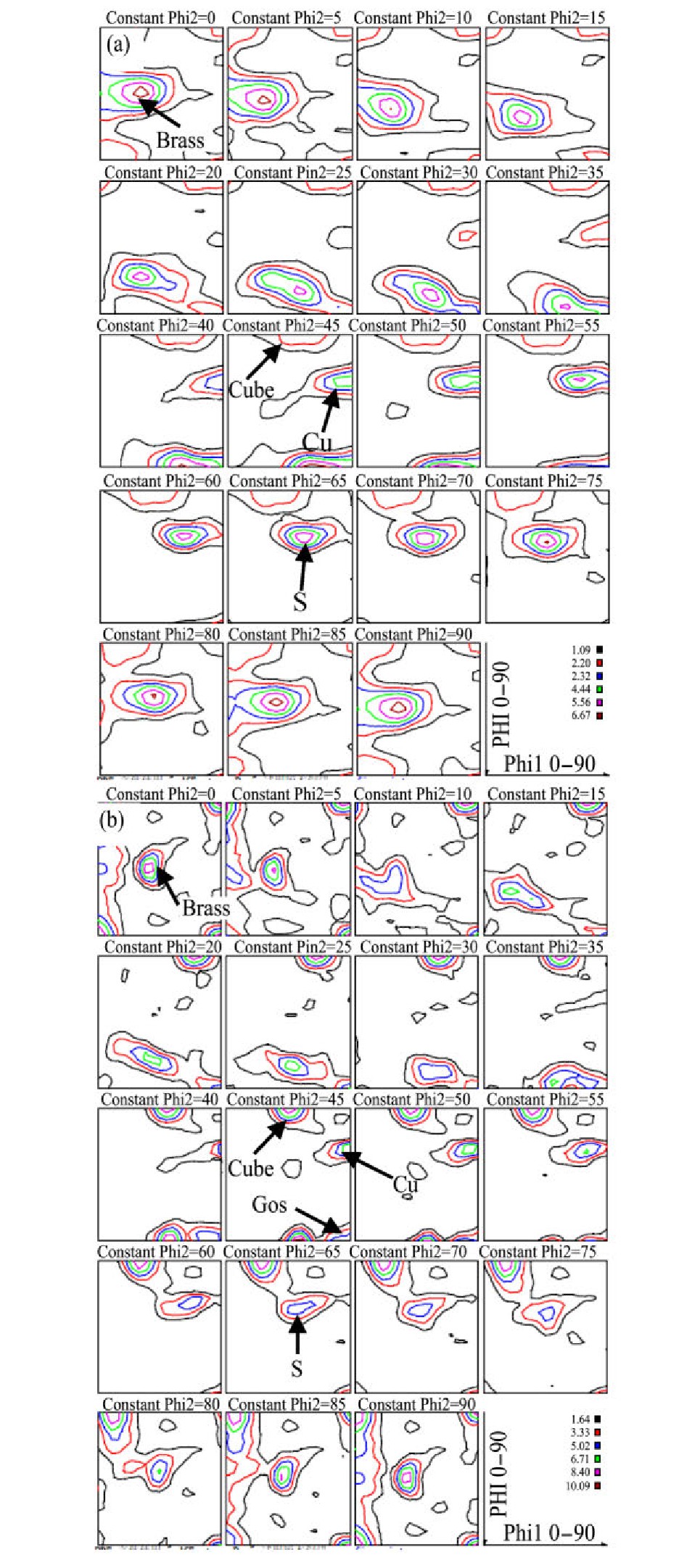

图4为固溶态厚板表层及T/2层的ODF图。由图4可知,经固溶处理后厚板表层内含有大量的β取向纤维变形织构,包括Brass{011}<211>织构、S{123}<634>织构和Cu{112}<111>织构。此外,还有少量的再结晶织构Cube{001}<100>。T/2层同样出现了包括Brass{011}<211>织构、S{123}<634>织构和Cu{112}<111>织构在内的β取向纤维变形织构,且织构强度更高。同时再结晶织构的种类增加,包括有较多的Goss{011}<100>织构和Cube{001}<100>织构。

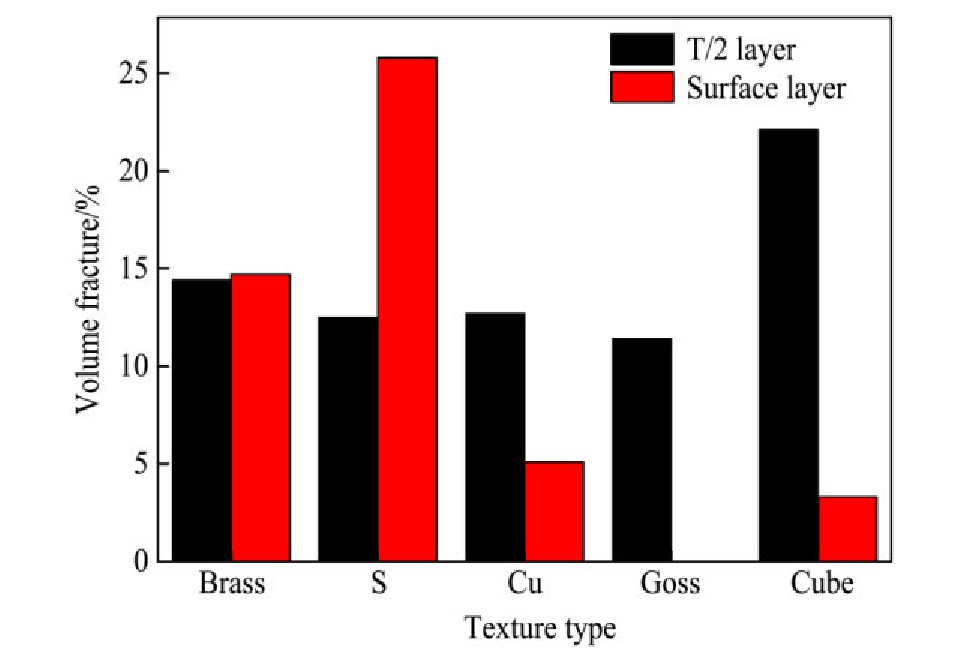

图5为固溶态厚板表层和T/2层各类织构的体积分数柱状图。由图5可知,固溶处理后厚板T/2层织构含量较多,总体积分数达73.1%。其中Brass{011}<211>织构、S{123}<634>织构和Cu{112}<111>织构等变形织构总体积分数为39.6%,Goss{011}<100>织构和Cube{001}<100>织构等再结晶织构的体积分数为33.5%。与T/2层不同,厚板表层织构含量明显较少,总体积分数为48.9%。其中Brass{011}<211>织构、S{123}<634>织构和Cu{112}<111>织构等变形织构体积分数为45.6%,较T/2层略高,而再结晶织构Cube{001}<100>体积分数仅有3.3%,明显少于T/2层。

图3 厚板表层及T/2层纵截面固溶态金相照片

Fig.3 Longitudinal sectional OM images of surface and T/2layer of solution-treated alloy thick plat

e(a)Surface;(b)T/2 layer

图4 固溶处理后合金厚板表层及T/2层ODF图

Fig.4 ODF images of surface and T/2 layer of solution-treated alloy thick plate

(a)Surface;(b)T/2 layer

2.3 时效析出相

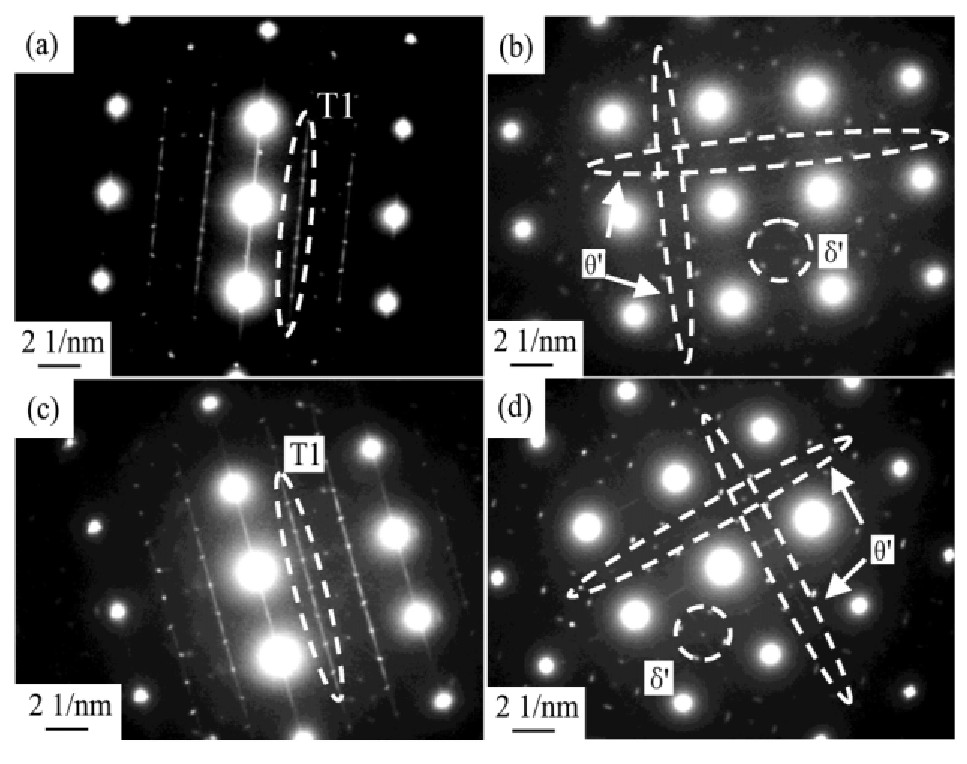

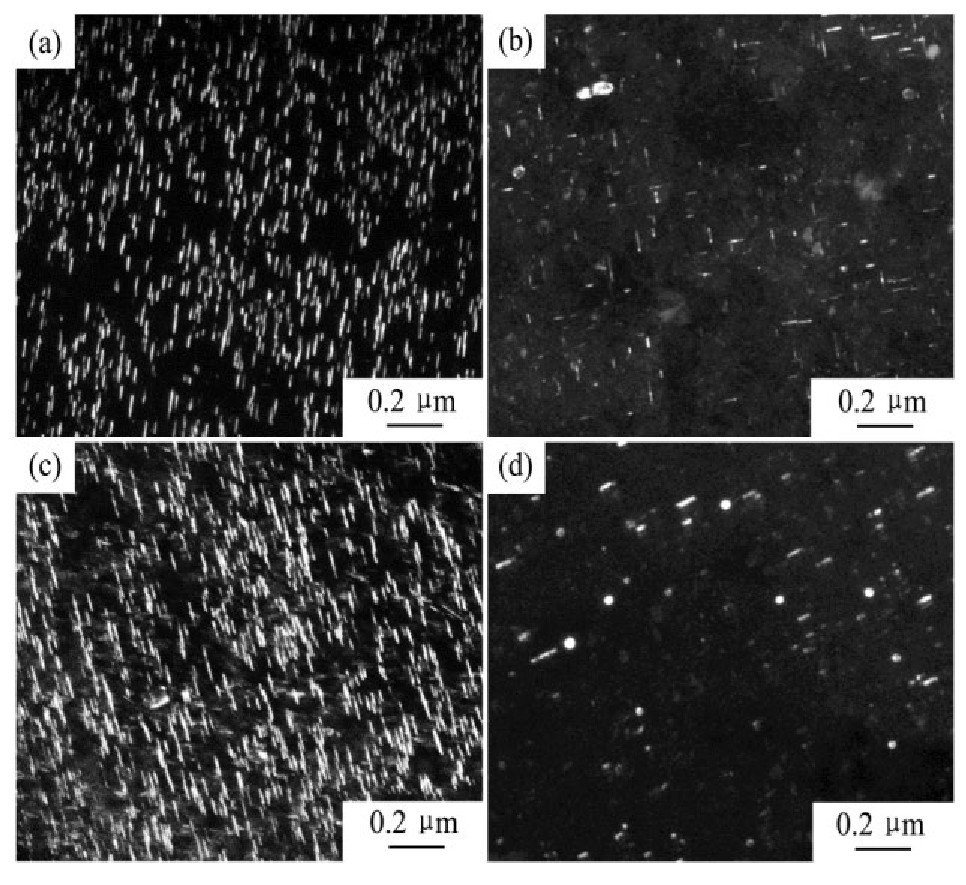

图6和7分别为厚板表层及T/2层T8时效24 h时的选区电子衍射(SAED)谱和TEM暗场像照片。从图6(a,c)所示的[112]Al晶带轴SAED谱中可以观察到非常明显的T1相斑点,且图6(c)中的T1相斑点相对较明亮,斑点强度更高。相应地在图7(a,c)所示的TEM暗场像中可以观察到大量的T1相析出,并且图7(a)中T1相析出较不均匀,数量密度较低。此外,如图6(b,d)所示,合金厚板表层和T/2层[100]Al晶带轴SAED谱中均可观察到θ′相芒线和δ′相斑点,在相应的暗场像(图7(b,d))中可以观察到相互垂直的θ′相和球状δ′相。上述微观组织观察表明,T8时效24 h时,厚板表层和T/2层中均析出大量的T1相,以及一定量的θ′相和δ′相。相较于表层,厚板T/2层析出的T1相更为均匀密集,析出数量密度较高。θ′相的析出情况则相反,厚板表层析出的θ′相较多,而T/2层几乎没有θ′相析出。表层和T/2层析出的δ′相数量则相差不大。

图5 固溶处理后厚板表层及T/2层各类织构体积分数

Fig.5 Textures volume fracture of surface and T/2 layer of so-lution-treated alloy thick plate

图6 厚板表层及T/2层T8时效24 h的SAED斑点图

Fig.6 SAED patterns of surface and T/2 layer of T8 aged(24h)alloy thick plate

(a)Surface,T1 phase;(b)Surface,θ?phase andδ?phase;(c)T/2 layer,T1 phase;(d)T/2 layer,θ?phase andδ?phase

图7 厚板表层及T/2层T8时效24 h的TEM暗场像照片

Fig.7 TEM dark field images of surface and T/2 layer of T8aged(24 h)alloy thick plate

(a)Surface,T1 phase;(b)Surface,θ?phase;(c)T/2 layer,T1 phase;(d)T/2 layer,θ?phase

2.4 分析与讨论

时效初期(5 h),厚板表层强度略高于T/2层,这应该与固溶处理后表层及T/2层的织构差异有关。研究表明

延长时效时间,合金内时效析出相数量逐渐增多。在中高Cu/Li比含量的铝锂合金中(本文研究合金Cu/Li比为2.9),经时效前预变形处理引入大量位错后,其时效过程中的主要析出强化相为T1相和θ′相。又由于Mg、Ag和Zn等微合金化元素的添加,提高了T1相的析出动力,使其优先于θ′相在位错处析出

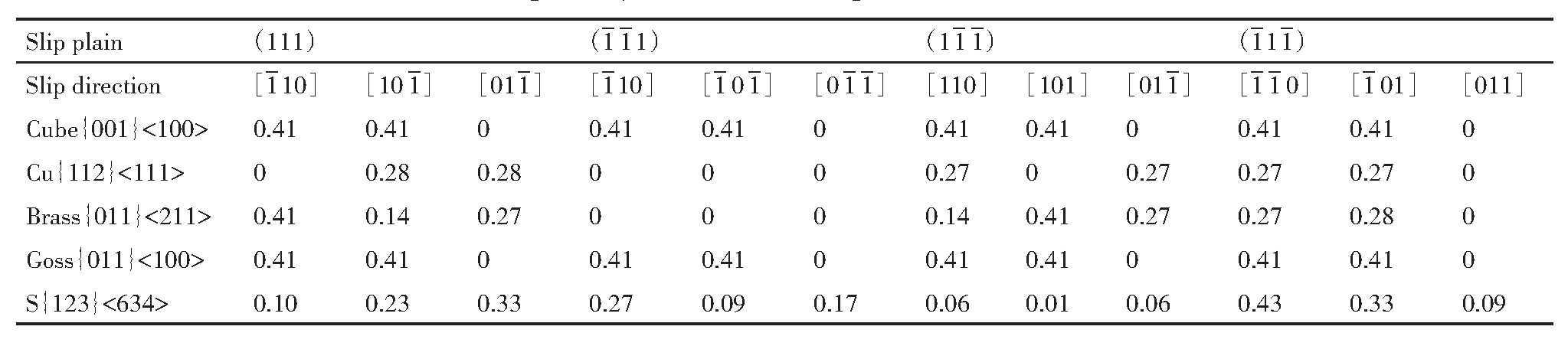

T1相的惯析面为{111}Al,与基体的晶体学位向关系为{0001}T1//{111}Al和<1010>T1//<110>Al,位错运动时引起的临界分切应力增量比在{100}Al晶面簇上析出的θ′相的大,所以在铝锂合金中T1相强化效果远大于θ′相,起主要强化作用

表2 铝合金中常见织构对应{111}<110>滑移系的施密特因子 下载原图

Table 2 Schmid factor of textures corresponding to{111}<110>slip system in Al alloy

3 结论

1.新型超高强铝锂合金厚板厚度方向上T8时效态室温纵向拉伸力学性能、织构组分和时效析出相存在不均匀性。T8时效初期(5 h)厚板表层强度略高于T/2层;之后继续延长时效时间(16~96h),厚板T/2层强度始终高于表层,且强度差基本稳定在55 MPa左右。在实验所取的时效时间区间内厚板T/2层最高屈服强度达625 MPa,最高抗拉强度为668 MPa;表层最高屈服强度为563 MPa,最高抗拉强度为611 MPa。

2.固溶处理后,厚板T/2层织构总体积分数较大(73.1%),由变形织构(Brass{011}<211>织构、S{123}<634>织构和Cu{112}<111>织构,总体积分数达39.6%)和再结晶织构(Goss{011}<100>织构和Cube{001}<100>织构,总体积分数为33.5%)组成,同时其加权施密特因子较大(0.374)。而表层织构含量相对较低(48.9%),主要含有大量的变形织构(45.6%),加权施密特因子也较小(0.368)。

3.合金厚板T8时效主要析出相为T1相、θ′相和δ′相。与表层相比,时效24 h时厚板T/2层析出的T1相数量密度较高,而θ′相数量则相对较少。表层和T/2层中析出的δ′相数量相差不大。

参考文献