Trans. Nonferrous Met. Soc. China 23(2013) 1936-1941

Effect of Ce addition on microstructure of Mg-9Li alloy

Heng-mei YIN1,2, Bin JIANG1,2, Xiao-yong HUANG1,2, Ying ZENG1,2, Qing-shan YANG1,2, Ming-xing ZHANG3, Fu-sheng PAN1,2

1. National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing 400044, China;

2. College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China;

3. School of Mechanical and Mining Engineering, University of Queensland, St Lucia 4072, Australia

Received 15 April 2011; accepted 25 December 2012

Abstract:

The as-cast and as-extruded Mg-9Li, Mg-9Li-0.3Ce alloys were respectively prepared through a simple alloying process and hot extrusion. The microstructures of these alloys were investigated by optical microscope (OM), scanning electron microscope (SEM), X-ray diffractometer (XRD) and energy dispersive spectrometer (EDS). The results indicate that Ce addition produces a strong grain refining effect in Mg-9Li alloy. The grain size of the as-extruded alloy reduces abruptly from 88.2 μm to 10.5 μm when the addition of Ce is 0.36%. Mg12Ce is verified and exists inside the grains or at the grain boundaries, thus possibly pins up grain boundaries and restrains the grain growth.

Key words:

magnesium-lithium alloys; microstructure; grain refinement; intermetallic compound;

1 Introduction

Mg-Li alloys are the lightest magnesium alloys [1] and have much better plasticity than the general Mg-Al or Mg-Zn alloys [2,3]. According to the Mg-Li phase diagram, with Li content between 5% and 11%, BCC- structured β phase of Li solid solution will co-exist with the HCP-structured α phase of Mg solid solution [4]. The α phase exhibits moderate strength [5-7]. The β phase is well known to exhibit good formability [8-10] but possesses relatively low strength and work hardening capacity [11,12]. Therefore, the strength of Mg-Li binary alloys is relatively low. Grain refinement can strengthen the alloy with the increase of strength and plasticity. Minor element addition [13], which is particularly suitable for mass production, is a simple and economical method to refine the microstructure. Compared with the addition of Nd, Ag [6,14] or Y [15] into Mg-Li alloys, Ce is a cheaper RE element and has shown strong potential to refine and strengthen Mg alloys [16-18]. Moreover, many researches [19-23] have indicated that Ce addition could not only refine the grains of Mg-Li alloys, but also strengthen both α phase and β phase of Mg-Li alloys through the formation of Mg-Ce or Al-Ce intermetallic compounds. Hence, in this work, Mg-9Li-0.3Ce alloy was prepared to examine the effect of Ce on the microstructure of as-cast and extruded Mg-9Li alloys.

2 Experimental

The materials used in this work were pure commercial magnesium and pure commercial lithium. Mg-20Ce master alloy was added into the alloys. In a typical procedure, pure magnesium and pure lithium blocks with or without addition of the master alloy were placed in steel crucibles (90 mm in diameter, 250 mm in height), respectively. Then, the crucibles were placed into an induction furnace, followed by pumping the furnace chamber to a vacuum state and inputting pure argon as a protective gas. Subsequently, the crucibles were heated to 700 °C until the charge was completely molten and then isothermally held for 10 min, followed by solidification and cooling of the melts with argon protection to minimize the oxidation. Finally, cast ingots (85 mm in diameter and 150 mm in height) were obtained. The compositions of the as-cast alloys were measured by inductively coupled plasma atomic emission spectroscopy (ICP-AES). The designed compositions and measured results of all the alloys prepared in the experiment are shown in Table 1.

Table 1 Chemical composition of experimental alloys (mass fraction, %)

The extrusion was carried out at 250 °C and the extrusion ratio was 27. Before extrusion, the cast ingot was heat treated at 250 °C for 3 h. The Mg-9Li-0.3Ce bars with a diameter of 16 mm were obtained. Here, Mg-9Li alloy, as a reference sample, was prepared and extruded using the same procedure.

The samples used for microstructure observation were cut from the cast ingot or the as-extruded bar at the same position. Microstructure was observed by optical microscopy and scanning electron microscopy (SEM, TESCAN VEGA). Before observation, the specimens were polished and etched with an 4.0% etchant (volume fraction). The grain size was measured by the linear intercept method at the centre of transverse sections. The phase in the alloys was identified by Rigaku D/max 2500PC using Cu Kα radiation (λ=1.5418  ) operating at 4 (°)/min and 10°-90° of 2θ.

) operating at 4 (°)/min and 10°-90° of 2θ.

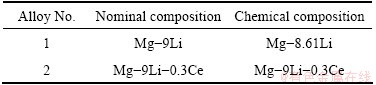

Fig. 1 Optical microstructures of alloys

3 Results and discussion

3.1 Grain size of Mg-9Li-0.3Ce alloy

Figures 1(a) and (b) show the optical microstructures of as-cast Mg-9Li alloys without or with Ce addition. The gray β phase and white α phase is observed in all samples. Notable grain refinement occurs with the addition of 0.36%Ce, which reduces the size of the α phase greatly so that it could not be distinguished from Fig. 1(b). The microstructures of the as-extruded Mg-9Li alloys without or with Ce addition are presented in Figs. 1(c) and (d). Equiaxed grains are observed. The grain size was abruptly reduced from 88.2 to 10.5 μm when the addition of Ce was 0.36%. It can be concluded that the addition of Ce in Mg-9Li alloy has a great refinement effect on the microstructure of both as-cast and as-extruded Mg-9Li alloys.

3.2 Characteristics of intermetallic compounds in Mg-9Li alloys

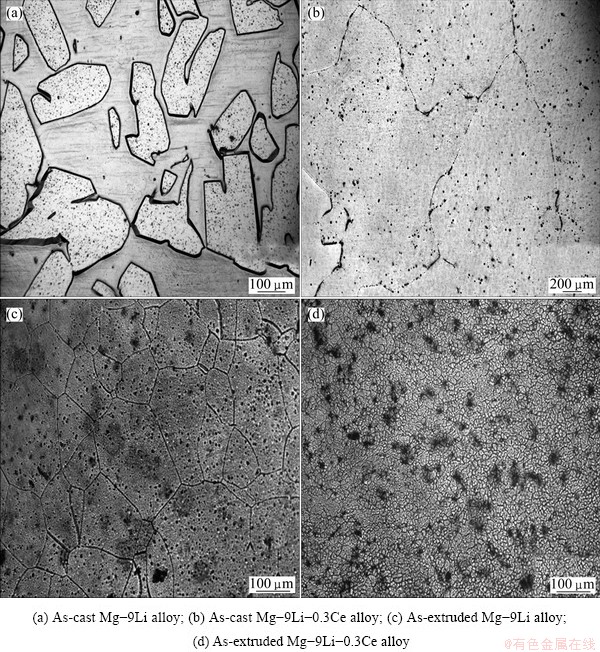

The XRD patterns of the Mg-9Li and Mg-9Li- 0.3Ce alloys are demonstrated in Fig. 2. It reveals that Mg-9Li alloy contains both α-Mg and β-Li. Meanwhile, CeMg12 appears in the as-cast Mg-9Li-0.3Ce alloys.

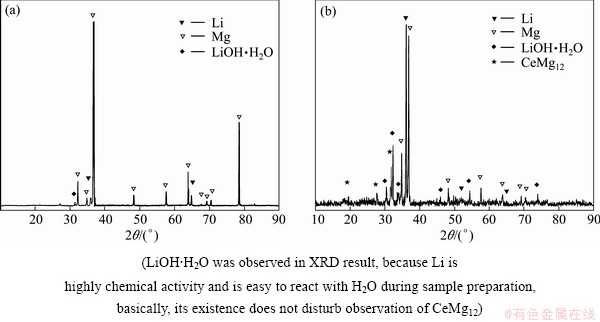

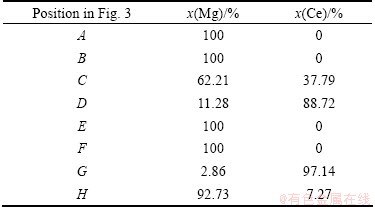

SEM images and micro-area chemical composition analysis results of the as-cast and as-extruded alloys are shown in Fig. 3 and Table 2, respectively. As can be observed, the second phases locate within the grain or at grain boundary. According to the EDS and XRD results, the intermetallic compound in the as-cast or as-extruded Mg-9Li-0.3Ce alloy is CeMg12. Some of CeMg12 intermetallic compounds in the as-cast Mg-9Li-0.3Ce look like granular, and most of CeMg12 intermetallic compounds look coarse plate-like and locate at the grain boundaries. After the extrusion, the CeMg12 compound changes to fine granular and distributes evenly in the as-extruded alloy due to the extrusion stress and dynamic recrystallization. Firstly, the extrusion stress can break the CeMg12 compounds into the smaller particles. Secondly, the extrusion temperature is 250 °C, which is much higher than the recrystallization temperatures of the Mg-9Li-0.3Ce alloy and CeMg12 (about 70 °C and 84 °C, respectively).

Fig. 2 XRD patterns of as-cast Mg-9Li alloy (a) and Mg-9Li-0.3Ce alloy (b)

Fig. 3 SEM images of alloys

Table 2 EDS results at different positions in Fig. 3

3.3 Mechanism of grain refinement of Mg-9Li-0.3Ce alloy

The addition of alloying elements to metallic materials can refine the microstructure of the matrix, through the growth restriction of the grains due to the segregation power of solute elements in the matrix [24,25] and/or through heterogeneous nucleation [26] of the intermetallic compound on the matrix alloys. According to Mg-Li binary phase diagram [27], the solidification and cooling procedure of Mg-9Li alloy is liquid→β-Li→β-Li+α-Mg. The β-Li phase is crystallized from Mg-9Li alloy melt at 591 °C, then the α-Mg phase is precipitated from the β-Li phase at 580 °C. The melt point of CeMg12 is about 621 °C according to the Mg-Ce binary phase diagram [27], and the casting temperature is 700 °C, thus CeMg12 cannot act as the heterogeneous nucleation site of the β-Li phase during solidification. As shown in Fig. 3 and Table 2, there is almost no Ce to be dissolved into the β-Li, thus the growth restriction of the grain is very limited. But, the as-cast CeMg12 compound at the boundaries can refine the microstructure through pinning up the boundaries although this role is limited. On the other hand, during the process of the precipitation of the α-Mg phase from the β-Li phase, the CeMg12 compound is possible to be the heterogeneous nucleation site of the α-Mg phase. As shown in Fig. 3, after the extrusion, the morphology of the CeMg12 compound evolves from coarse plate-like to fine granular and the CeMg12 compounds can act as the nucleation sites of both the α-Mg phase and the β-Li phase during the dynamic recrystallization. Therefore, the grain refinement of the as-cast or as-extruded Mg-9Li-0.3Ce alloy is attributed to the CeMg12 compound.

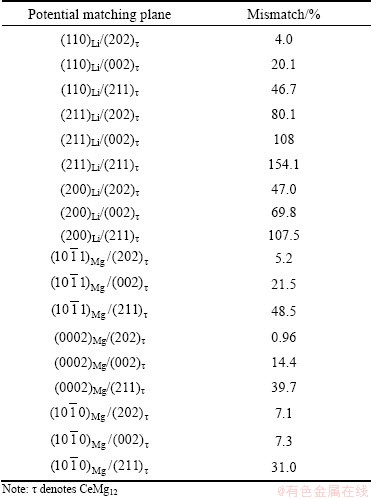

The grain refinement effect of CeMg12 on the as-cast or as-extruded Mg-9Li-0.3Ce alloy needs to identify the crystallography orientation relationships [26,28] between CeMg12 and α-Mg or β-Li. The edge-to-edge match model developed by ZHANG et al [29,30] is a simple and effective method to predict and examine the orientation relationships between an intermetallic compound and a metal matrix. As for this model, when the crystallography mismatch of the close or near close packed planes between the compound and the metal matrix is less than 10%, some orientation relationships exist. According to the crystallographic database and X-ray powder diffraction data [31,32], three close packed CeMg12 planes are defined as (202), (002) and (211), those of Mg as  , (0002) and

, (0002) and  , those of Li as (110), (211) and (200). Therefore, there are nine pairs of potential matching planes between Mg and CeMg12, or between Li and CeMg12. All the mismatch values are listed in Table 3. There are one matching plane pair between Li and CeMg12, and three pairs between Mg and CeMg12 with less than 10% mismatch, which shows that a crystallography orientation relationship exists between Mg and CeMg12, or between Li and CeMg12.

, those of Li as (110), (211) and (200). Therefore, there are nine pairs of potential matching planes between Mg and CeMg12, or between Li and CeMg12. All the mismatch values are listed in Table 3. There are one matching plane pair between Li and CeMg12, and three pairs between Mg and CeMg12 with less than 10% mismatch, which shows that a crystallography orientation relationship exists between Mg and CeMg12, or between Li and CeMg12.

Table 3 Mismatches of potential matching planes for β-Li and CeMg12, α-Mg and CeMg12

4 Conclusions

1) The microstructures of both as-cast and extruded alloys are fined significantly. The size of the α phase reduces greatly in the as-cast alloy and the grain size of the as-extruded alloy is reduced from 88.2 μm to 10.5 μm when the addition of Ce is 0.36%.

2) As for the Mg-9Li-0.3Ce alloy, β-Li, α-Mg and CeMg12 are identified as the three primary components. The morphology of CeMg12 in the as-extruded Mg-9Li-0.3Ce alloy evolves from coarse plate-like to fine granular due to the extrusion stress and dynamic recrystallization. CeMg12 can refine the microstructure of the alloy by the heterogeneous nucleation due to the crystallography orientation relationship.

References

[1] LI J F, ZHENG Z Q, TAO G Y. Ultra-light Mg-Li alloy [J]. Light Alloy Fabrication Technology, 2004, 10: 32-35.

[2] JIANG B, QIU D, ZHANG M X, DING P D, GAO L. A new approach to grain refinement of a Mg-Li-Al cast alloy [J]. Journal of Alloys and Compounds, 2010, 492: 95-98.

[3] MA C J, ZHANG D, ZHANG G D, QIN J N. Mg-Li matrix composites [J]. Rare Metal Materials and Engineering, 1998, 27(3): 125-129.

[4] JENSEN J A, CHUMBLEY L S. Processing and mechanical properties of magnesium-lithium composites containing steel fibers [J]. Metallurgical and Materials Transactions A, 1998, 29: 863-873.

[5] LI J Q, QU Z K, WU R Z. Microstructure, mechanical properties and aging behaviors of as-extruded Mg-5Li-3Al-2Zn-1.5Cu alloy [J]. Materials Science and Engineering A, 2011, 528: 3915-3920.

[6] WU R Z, ZHANG M L. Microstructure, mechanical properties and aging behavior of Mg-5Li-3Al-2Zn-xAg [J]. Materials Science and Engineering A, 2009, 520: 36-39.

[7] XIANG Q, WU R Z, ZHANG M L. Influence of Sn on microstructure and mechanical properties of Mg-5Li-3Al-2Zn alloys [J]. Journal of Alloys and Compounds, 2009, 477: 832-835.

[8] SAHOO M, ATKINSON J. Magnesium-lithium-alloys constitution and fabrication for use in batteries [J]. Journal of Materials Science, 1982, 17: 3564-3574.

[9] JACKSON J H, FROST P D, LOONAM A C, EASTWOOD L W, LORING C H. Magnesium-lithium base alloys-preparation, fabrication, and general characteristics [J]. Transactions of the Institution of Mining and Metallurgy Section A, 1949, 185: 149-168.

[10] BUSK R S, LEMAN D L, CASEY J J. The properties of some magnesium-lithium alloys containing aluminum and zinc [J]. Transactions of the Institution of Mining and Metallurgy Section A, 1950, 188: 949-951.

[11] LEE R E, JONES W J D. Micro-plasticity and fatigue of some magnesium-lithium alloys [J]. Journal of Materials Science, 1974, 9: 469-475.

[12] MCDONALD J C. Age hardening of magnesium alloy LA141A (Mg+14wt.%Li+1wt.%Al) [J]. Transactions of the American Society for Metals, 1968, 61: 505-518.

[13] GUANG S S, STAIGER M, KRAL M. Some new characteristics of the strengthening phase in β-phase magnesium-lithium alloys containing aluminum and beryllium [J]. Materials Science and Engineering A, 2004, 371: 371-376.

[14] OHUCHI K, IWASAWA S, KAMADO S, KOJIMA Y, NINOMIYA R. Effects of neodymium and silver additions on the microstructures and mechanical properties of Mg-8 mass% Li alloys [J]. Journal of Japan Institute of Light Metals, 1992, 42: 446-452.

[15] DONG H W, WANG L D, WU Y M, WANG L M. Effect of Y on microstructure and mechanical properties of duplex Mg-7Li alloys [J]. Journal of Alloys and Compounds, 2010, 506: 468-474.

[16] LI W P, ZHOU H, LIN P Y, ZHAO S Z. Microstructure and rolling capability of modified AZ31-Ce-Gd alloys [J]. Materials Characterization, 2009, 60: 1298-1304.

[17] WANG J L, LIAO R L, WANG L D, WU Y M, CAO Z Y, WANG L M. Investigations of the properties of Mg-5Al-0.3Mn-xCe (x=0-3, wt.%) alloys [J]. Journal of Alloys and Compounds, 2009, 477: 341-345.

[18] LIU S F, LI B, WANG X H, SU W, HAN H. Refinement effect of cerium, calcium and strontium in AZ91 magnesium alloy [J]. Journal of Materials Processing Technology, 2009, 209: 3999-4004.

[19] TANNO O, OHUCHI K, MATUZAWA K, KAMADO S, KOJIMA Y. Effect of rare-earth elements on the structures and mechanical properties of Mg-8%Li alloys [J]. Journal of Japan Institute of Light Metals, 1992, 42: 3-9.

[20] WANG T, ZHANG M L, WU R Z. Microstructure and properties of Mg-8Li-1Al-1Ce alloy [J]. Materials Letters, 2008, 62: 1846-1848.

[21] ZHANG M L, WU R Z, WANG T. Microstructure and mechanical properties of Mg-8Li-(0-3)Ce alloys [J]. J Materials Science, 2009, 44: 1237-1240.

[22] YAN H, CHEN R S, HAN E H. Microstructures and mechanical properties of cold rolled Mg-8Li and Mg-8Li-2Al-2RE alloys [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: s550-s554.

[23] LIU B, ZHANG M L, WU R Z. Influence of Ce on microstructure and mechanical properties of LA141 alloys [J]. Transactions of Nonferrous Metals Society of China, 2007, 17: s376-s380.

[24] EASTON M, STJOHN D. Grain refinement of aluminum alloys: Part I. The nucleant and solute paradigms-a review of the literature [J]. Metallurgical and Materials Transactions A, 1999, 30: 1613-1623.

[25] EASTON M, STJOHN D. Grain refinement of aluminum alloys: Part II. Confirmation of, and a mechanism for, the solute paradigm [J]. Metallurgical and Materials Transactions A, 1999, 30: 1625-1633.

[26] FU H M, QIU D, ZHANG M X, WANG H, KELLY P M, TAYLOR J A. The development of a new grain refiner for magnesium alloys using the edge-to-edge model [J]. Journal of Alloys and Compounds, 2008, 456: 390-394.

[27] MASSASKI T B. Binary alloy phase diagrams [M]. OH, Materials Park: TMS, 1990.

[28] DOHERTY R D, HUGHES D A, HUMPHREYS F J, JONAS J J, JENSON D J, KASSNER M E, KING W E, MCNELLEY T R, MCQUEEN H J, ROLLETT A D. Current issues in recrystallization: A review [J]. Materials Science and Engineering A, 1997, 238: 219-274.

[29] ZHANG M X, KELLY P M, EASTON M A, TAYLOR J A. Crystallographic study of grain refinement in aluminum alloys using the edge-to-edge matching model [J]. Acta Materialia, 2005, 53: 1427-1438.

[30] ZHANG M X, KELLY P M, QIAN M, TAYLOR J A. Crystallography of grain refinement in Mg-Al based alloys [J]. Acta Materialia, 2005, 53: 3261-3271.

[31] VILLARS P, CALVERT L D. Pearson’s handbook of crystallographic data for intermetallic phases: vol. 1 [M]. Materials Park, OH: ASM International, 1991.

[32] 2002 JCPDS–International Center for Diffraction Data, PCPDF-WIN v. 2.3.

Ce元素对Mg-9Li合金显微组织的影响

殷恒梅1, 2,蒋 斌1, 2,黄小勇1, 2,曾 迎1, 2,杨青山1, 2,Ming-xing ZHANG3,潘复生1, 2

1. 重庆大学 国家镁合金材料工程技术研究中心,重庆 400044;

2. 重庆大学 材料科学与工程学院,重庆 400044;

3. 昆士兰大学 机械与采矿学院,圣卢西亚 4072,澳大利亚

摘 要:通过合金化和热挤压制备铸态及挤压态的Mg-9Li和Mg-9Li-0.3Ce合金,通过光学显微镜和扫描电镜观察结合能谱分析以及XRD分析对这一系列合金的微观组织进行研究。结果表明:Ce的添加对Mg-9Li合金有很好的晶粒细化效果,当Ce的添加量达到0.36%时,挤压态合金的尺寸从未添加的88.2 μm减小至10.5 μm, Mg12Ce存在于晶粒内或晶界处,因此认为Mg12Ce可能聚集在晶界处从而阻碍晶粒的长大。

关键词:镁锂合金;显微组织;晶粒细化;金属间化合物

(Edited by Xiang-qun LI)

Foundation item: Project (2007CB613706) supported by the National Basic Research Program of China; Project (2009AA03Z507) supported by the National High-tech Program of China; Projects (2010CSTC-HDLS, CSTC2010AA4048) supported by Chongqing Science and Technology Commission, China

Corresponding author: Heng-mei YIN; Tel: +86-18012680862; E-mail: yinhengmei1986@gmail.com

DOI: 10.1016/S1003-6326(13)62680-1

Abstract: The as-cast and as-extruded Mg-9Li, Mg-9Li-0.3Ce alloys were respectively prepared through a simple alloying process and hot extrusion. The microstructures of these alloys were investigated by optical microscope (OM), scanning electron microscope (SEM), X-ray diffractometer (XRD) and energy dispersive spectrometer (EDS). The results indicate that Ce addition produces a strong grain refining effect in Mg-9Li alloy. The grain size of the as-extruded alloy reduces abruptly from 88.2 μm to 10.5 μm when the addition of Ce is 0.36%. Mg12Ce is verified and exists inside the grains or at the grain boundaries, thus possibly pins up grain boundaries and restrains the grain growth.