DOI:10.19476/j.ysxb.1004.0609.2018.02.06

低于β相相变温度时TC4钛合金搅拌摩擦焊接头的成形及拉伸性能

王 月1,姬书得1,李政玮1,柴 鹏2

(1. 沈阳航空航天大学 航空航天工程学部,沈阳 110136;

2. 北京航空航天大学 机械工程与自动化学院,北京 100191)

摘 要:

摘 要:利用轴肩直径为15 mm的钨铼合金搅拌头对2.5 mm厚TC4钛合金进行搅拌摩擦焊,重点分析接头成形、显微组织与拉伸性能。结果表明:焊核区的横截面形貌呈现典型的“碗形”;当转速小于200 r/min时,焊接过程中的温度峰值低于β相相变温度。组成焊核的搅拌针作用区常出现“撕裂”型缺陷,其主要与焊接过程中的焊接拉应力有关;降低搅拌头的旋转速度有利于减小、甚至消除“撕裂”型缺陷。低于相变温度下获得的无缺陷焊接接头的抗拉强度几乎与母材的等同,拉伸测试后的断口由大量韧窝组成,为典型的韧性断裂。

关键词:

文章编号:1004-0609(2018)-02-0260-07 中图分类号:TG453 文献标志码:A

钛及钛合金因高的比强度、比刚度和良好的抗腐蚀性能,被广泛用于航空航天、汽车及医疗器械等行业[1-2]。而如何实现钛合金高质量的连接一直是研究者所追求的目标。在传统熔化焊连接钛合金过程中,焊缝温度峰值超过母材(Base material, BM)熔点,易产生热裂纹、大变形及粗大组织等缺陷[3-4]。英国焊接研究所于1991年发明的搅拌摩擦焊(Friction stir welding, FSW)是一种固相连接技术,其焊接温度峰值低于材料熔点,目前FSW已被广泛用于焊接铝、镁等低熔点合金[5-8],且在钛合金连接方面亦有着巨大潜力[9-14]。

与熔化焊相同,在FSW过程中温度场是决定焊缝组织的关键因素,其相关报道较多。姬书得等[9]利用Abaqus有限元软件研究FSW过程的温度场,指出TC4钛合金沿板厚方向的温度梯度是造成焊核区(Nugget zone, NZ)组织不均匀的主要因素,这与YOON等[11]的报导类似。SONG等[15]利用Deform软件建立了FSW的3D有限元模型,研究温度对动态再结晶晶粒大小及位错密度的影响。目前,研究较多的TC4(Ti-6Al-4V)合金是一种双相合金,温度峰值是决定焊接过程中是否发生相变的主要因素,进而影响到力学性能。FALL等[3]、LIU等[13]及ZHOU等[12, 14]研究了焊接温度峰值低于β相相变点时TC4钛合金的FSW过程,得出NZ由双态或完全等轴的动态再结晶晶粒组成。SANDERS等[16]及ZHANG等[17]的研究中指出,温度峰值高于β相相变点时NZ由完全片层状组织构成。KITAMURA等[18]研究了FSW过程中温度峰值对于NZ试样拉伸性能的影响,当温度峰值高于β相变点时,NZ强度随热输入增加而减小;温度峰值低于β相相变点时NZ的强度高于母材的。综上所述可知,温度峰值对于双相TC4钛合金的显微组织及力学性能至关重要,而低于相变温度时易获得更优力学性能的FSW接头;已报道文献重点研究在低于相变点下的织构、典型区域的组织及力学性能[3, 12-13]。

因此,本文作者以应用较广泛的α+β型TC4钛合金为研究对象,在低于相变点下分析焊接工艺参数对FSW接头的成形、显微组织与拉伸性能的影响,重点分析焊缝内部缺陷的形成与转速的关系。

1 实验

实验选用2.5 mm厚轧制退火态TC4钛合金进行平板对接焊,试板尺寸为200 mm×100 mm,BM的力学性能见表1。FSW实验在由北京赛福斯特技术有限公司制造的型号为FSW-3LM-4012设备上进行。实验所用搅拌头由高温钨铼合金(75%钨、25%铼,质量分数)制造而成,其形状参数如下:轴肩直径为15 mm、锥形搅拌针的根部与尖端直径分别为7.2 mm与5.0 mm、搅拌针长度为2.14 mm。项目组前期对比了常规工艺与背部加热下的TC4钛合金FSW,指出背部加热利于扩宽焊接工艺参数范围,但研究重点在于NZ内部的完全片层状组织[19],而不是本研究中提及的低于β相相变点的焊接。由焊接速度与搅拌头受力间的关系可知[20],搅拌头受作用力随焊速的增加而增加。因此,根据本课题组前期的研究成果,本文作者采用30 mm/min的焊接速度以减少搅拌头的磨损与避免其折断。同时,为了实现低于β相相变点的焊接,基于文献及项目组前期研究结果[21],本研究中采用的旋转速度为200、150、120与100 r/min。同时,本实验中采用轴肩下压量与主轴倾角分别为0.2 mm与2.5°。

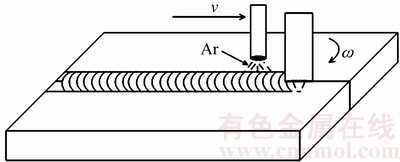

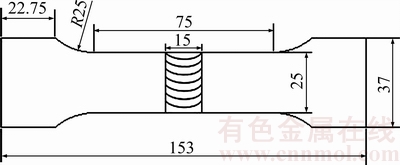

在焊接过程中,钛合金在250 ℃吸氢、400 ℃吸氧、600 ℃吸氮,这会降低其塑性与韧性[22],因此,在焊接过程中采用气管中通氩气对焊接位置进行随焊保护(见图1)。实验前将焊接区域用酒精擦去表面油污等杂质。焊后,金相试样与拉伸试样用线切割机沿垂直于焊缝方向制备,拉伸试样的尺寸按《GB/T 2651-2008焊接接头拉伸试验方法》制定(见图2)。经打磨、抛光、腐蚀后,横截面形貌、显微组织分别采用光学显微镜(OM,Olympus-GX71)与扫描电镜(SEM,SU3500)进行观察,腐蚀液为Kroll 试剂(13 mL HF+26 mL HNO3+100 mL H2O)。室温拉伸实验在Instron 8801型试验机上以恒定速度5 mm/min进行,断口形貌用SEM观察。拉伸实验之前剔除焊缝表面飞边,不再机加工消除其表面弧纹。

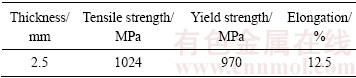

表1 TC4钛合金母材的力学性能

Table 1 Mechanical Properties of TC4 titanium alloy

图1 焊接过程示意图

Fig. 1 Schematic diagram of welding process

图2 拉伸试样示意图

Fig. 2 Schematic diagram of tensile specimen (Unit: mm)

2 结果与讨论

2.1 横截面形貌与显微组织

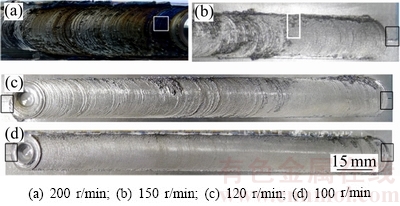

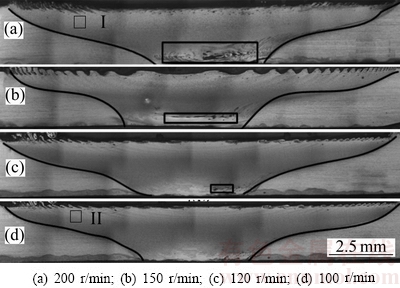

图3所示为不同旋转速度下的接头表面成形。本研究中焊接速度为定值,因此焊接温度峰值主要受旋转速度的影响,其随旋转速度的增加而提高。在焊接过程中,搅拌头后方的材料仍处于高温状态,且此高温区域范围及经历的时间会随着NZ温度峰值的提高而增加。因此,在有限范围的氩气保护下,当旋转速度为200 r/min时,过高的温度仍使焊缝表面有轻微污染(见图3(a))。

图3 不同转速下的接头表面形貌

Fig. 3 Surface morphologies of joints under different rotating speeds

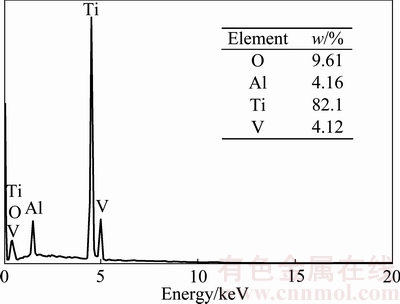

为进一步确定蓝色污染物,对图3(a)中标示的区域进行成分分析。如图4所示,蓝色物质中含有氧元素,未发现氮元素,因此可确定蓝色物质为氧化物。同时,随转速降低,焊缝表面呈现银亮色,无氧化现象出现(见图3(c)~(d))。不同转速下接头表面成形的对比说明,低热输入焊接更有利于避免钛合金表面氧化现象的出现。

钛合金FSW接头的横截面可分为NZ、热影响区(Heat affected zone, HAZ)和BM,NZ又可分为轴肩作用区(Shoulder affected zone, SAZ)和搅拌针作用区(Pin affected zone, PAZ)。图5中所有试样的横截面均呈碗型,这与搅拌头特定的形状有关,而碗型的大小与产热密切相关。图5(d)所示为转速为100 r/min时的横截面,PAZ相比于其他试样的横截面减小。观察图5(a)和(b)可知,在高转速(200 r/min)下,焊缝底部出现了较大的不连续的缺陷,此缺陷平行于焊缝表面,且几乎贯穿于整个PAZ。当转速在120~200 r/min之间时,缺陷随转速的减小而减小。当转速进一步减小到100 r/min时,缺陷消失,得到NZ内部无缺陷的TC4钛合金FSW接头。

图4 在图3(a)中标示的蓝色物质的EDS谱

Fig. 4 EDS spectrum of blue materials marked in Fig. 3(a)

尽管FSW的焊接温度低,但受热膨胀的NZ材料在冷却时收缩,易产生焊接拉应力。TC4钛合金较小的热导率系数(约为铝合金的1/6),使焊缝沿板厚方向产生较大的温度梯度,导致焊接拉应力进一步增 加。当冷却过程中的焊接拉应力大于材料的抗拉强度时,焊缝材料发生断裂,进而在NZ内部产生体积型缺陷[23]。对于铝合金的FSW来说,由于热输入不足而导致的孔洞或隧道缺陷一般出现在NZ的前进侧,且缺陷尺寸往往随转速的增加而减小。这与图5涉及的缺陷尺寸与转速间的关系相反。同时,铝合金FSW接头的孔洞或隧道形态与图5中的缺陷亦存在明显不同。因此,本研究与已报道的文献[19, 24]将由焊接拉应力引起的缺陷称之为“撕裂型”缺陷。

图5 不同转速下的横截面形貌

Fig. 5 Morphologies of cross sections at different rotating speeds

众所周知,焊接热输入与焊接工艺参数密切相关。当焊速一定时,焊接热输入随搅拌头旋转速度的降低而减小,使焊接温度峰值也降低,利于减小焊接拉应力。同时,项目组的前期研究结果表明,低转速可降低在焊接过程中沿板厚方向的温度梯度,亦利于减小焊接拉应力[24]。综上所述可知,由焊接拉应力导致的NZ内部撕裂型缺陷尺寸随转速降低而减小(见图5(a)、(b)与(c))。当转速为100 r/min时,可获得无内部缺陷的接头(见图5(d))。另外,焊后FSW接头的NZ因搅拌头下压导致厚度有轻微减小,实际的NZ厚度约为2.3 mm,略小于BM值(2.5 mm)。

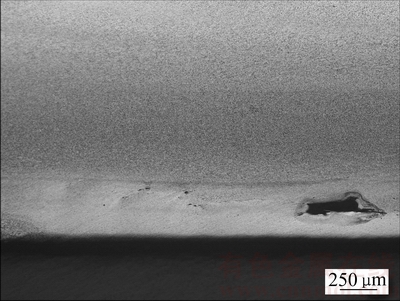

在FSW过程中,高速旋转的搅拌头带动与其接触的金属流动;高速流动的材料也会带动其附近材料流动,从而形成间接作用区。因此,为避免与垫板直接接触,搅拌针尖端通常到焊件背面间存在0.1~0.2 mm的距离;尽管如此,根部未焊透陷在合理的工艺参数下仍可避免。图6给出了图5(c)焊件背面的局部放大图,分析可知未见根部未焊透缺陷。

图6 120 r/min时NZ底部的放大图

Fig. 6 Enlarged image of NZ bottom at 120 r/min

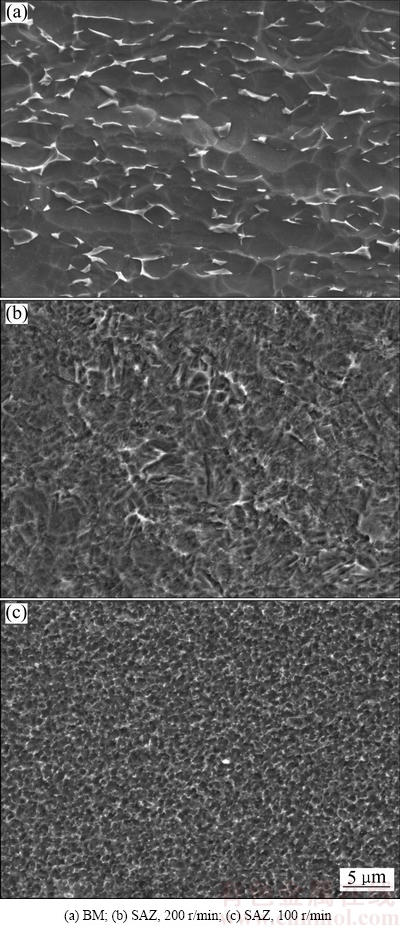

图7所示为母材及焊缝不同区域的显微组织。如图7(a)所示的TC4钛合金,BM由初级α相和细长β相组成,二者在SEM下分别呈现灰色和白色;β相均匀的包围在α相周围,使α相呈现等轴状。

图7 母材及不同转速下BM和SAZ的显微组织

Fig. 7 Microstructures of BM and SAZ at different rotating speeds

图7(b)及 (c)均取自近轴肩边缘处,即图5(a)及(d)中的区域Ⅰ和区域Ⅱ。在焊接过程中,轴肩边缘处经历了较大的线速度且钛合金较低的热导率,这导致了此区域的温度最高。因此,轴肩边缘附近区域的显微组织形态可说明整个焊核区的温度峰值是否超过相变温度。

由已报道的文献可知[3, 12-13],当焊核区温度低于相变点,焊核区有等轴的初生α相存在。在高转速(200 r/min)时产热最多,而图5(a)的区域Ⅰ(见图7(b))由少量片层状和等轴组织构成,说明此处的焊接温度峰值低于β相相变温度。由于SAZ的温度峰值较PAZ高,因此,整个NZ的焊接温度峰值低于β相相变温度。本研究中其他低转速下NZ温度峰值亦低于β相相变温度。图7(c)所示为转速100 r/min时所得接头SAZ的组织。通过分析可知,图5(d)中区域Ⅱ的微观组织因产生动态再结晶形成细小的等轴晶,尺寸明显小于母材的。

2.2 力学性能

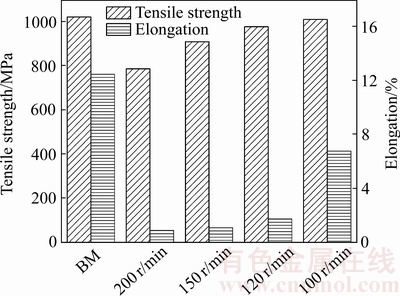

图8所示为TC4钛合金FSW接头不同焊接参数下的拉伸性能。通过分析可知,有缺陷试样的抗拉强度均低于无缺陷试样。对于FSW接头来说,NZ内的缺陷会造成结构的不连续,在受拉伸载荷时会形成应力集中,最终导致拉伸性能的降低[25]。对于带有几乎贯穿于整个NZ底部的撕裂型缺陷的FSW试样来说,其抗拉强度仅为母材的71%。随着缺陷尺寸的减小,试件的强度逐渐由89.5%提高到95.6%。对于100 r/min下得到的无缺陷试样,其抗拉强度为母材的98.9%,几乎与母材等强。

图8 不同转速下FSW接头的拉伸性能

Fig. 8 Tensile properties of FSW joints at different rotating speeds

另外,FSW接头的伸长率均低于母材的;随着旋转速度的降低,伸长率呈增加趋势(见图8)。拉伸过程中,焊缝所承受的应力随载荷的不断增加也逐渐增加,当应力达到焊缝的抗拉强度时,焊缝发生断裂;而焊接接头伸长率的大小与母材是否屈服有关。有缺陷试样抗拉强度均小于母材屈服强度,因此,焊缝断裂时母材区未发生屈服,实验测得的伸长率主要来源于相对较小的焊缝区,其值较低。当焊缝中不存在缺陷时,FSW接头抗拉强度(1012.76 MPa)超过母材的屈服强度(970 MPa),在拉伸过程中母材将发生屈服,因此伸长率较高,其值为母材的54.4%。

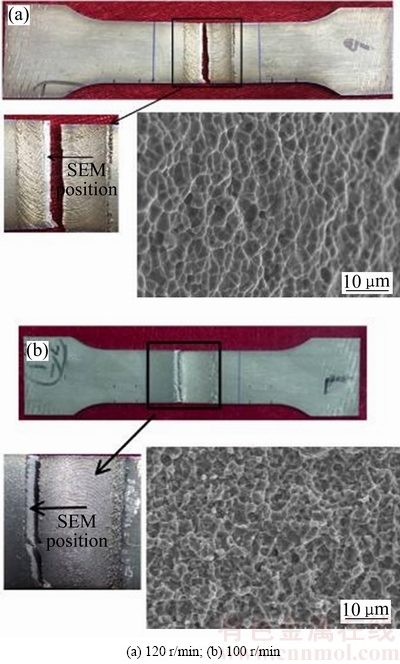

2.3 断口形貌分析

为进一步揭示断裂性能,对断裂位置进行SEM观察。图9所示为不同转速下的断裂位置及断口形貌。有缺陷的拉伸试样(120 r/min)断裂于NZ,组成断口表面的韧窝较浅。对于转速为100 r/min的无缺陷试样,其断裂位置是SAZ边缘。对于FSW接头来说,NZ细小组织对焊缝起到了强化作用;由于表面下凹引起的几何应力集中,SAZ边缘处的材料承受较母材更大的应力。这使拉伸试样最终断裂于轴肩边缘,而不是母材。断口表面均匀细小的韧窝表明TC4钛合金FSW接头呈现典型的韧性断裂。

图9 不同转速下接头的断裂位置及断口形貌

Fig. 9 Fracture locations and morphologies of FSW joints under different rotating speeds

3 结论

1) 当转速为200与100 r/min时,SAZ分别由细小的双态组织与等轴晶组成,说明实验是在低于相变温度下进行的。在NZ内平行于焊件表面的撕裂型缺陷随搅拌头旋转速度的降低而减小。当转速为100 r/min时,接头NZ内的撕裂型缺陷消失。

2) 对于2.5 mm厚的TC4钛合金,当旋转速度为100 r/min且焊接速度为30 mm/min时,FSW接头的拉伸强度与伸长率分别达到母材的98.9%与54.4%。由韧窝组成的断口形貌说明拉伸试件呈现典型的韧性断裂。

REFERENCES

[1] 陈玉华, 董春林, 倪 泉, 柯黎明. 钛合金/铝合金搅拌摩擦焊接头的显微组织[J]. 中国有色金属学报, 2010, 20(S1): s211-s214.

CHEN Yu-hua, DONG Chun-lin, NI Quan, KE Li-ming. Microstructures of friction stir welding joint between titanium and aluminum alloy dissimilar alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s211-s214.

[2] 王玉晓, 岳玉梅, 姬书得, 吕 赞, 温 泉. 钛合金搅拌摩擦焊研究进展[J]. 精密成形工程, 2015, 7(5): 40-45.

WANG Yu-xiao, YUE Yu-mei, JI Shu-de, Lü Zan, WEN Quan. Recent advances in friction stir welding of titanium alloys[J]. Journal of Netshape Forming Engineering, 2015, 7(5): 40-45.

[3] FALL A, JAHAZIA M, KHODABANDEHB A R, FESHARAKIB M H. Effect of process parameters on microstructure and mechanical properties of friction stir-welded Ti-6Al-4V joints[J]. International Journal of Advanced Manufacturing Technology, 2017, 91(5): 1-13.

[4] 姚俊歌, 贺地求, 赖瑞林, 李 然, 王海军. 采用FSW与MIG工艺补焊6005A-T6铝合金的接头力学性能[J]. 中国有色金属学报, 2015, 25(3): 589-594.

YAO Jun-ge, HE Di-qiu, LAI Rui-lin, LI Ran, WANG Hai-jun. Mechanical properties of repairing welding joints of 6005A-T6 aluminum alloy prepared by FSW and MIG processes[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 589-594.

[5] 贺地求, 叶绍勇, 汪 建. 20 mm厚6063铝合金搅拌摩擦焊焊缝S曲线控制[J]. 焊接学报, 2013, 34(12): 21-24.

HE Di-qiu, YE Shao-yong, WANG Jian. Elimination of lazy S defect in friction stir welded joint of 20 mm-6063 alumimum alloy[J]. Transactions of the China Welding Institution, 2013, 34(12): 21-24.

[6] 邢 丽, 宋 骁, 柯黎明. 2198和C24S异种铝锂合金搅拌摩擦焊接头的显微组织和力学性能[J]. 中国有色金属学报, 2014, 24(7): 1714-1720.

XING Li, SONG Xiao, KE Li-ming. Microstructures and mechanical properties of friction stir welding dissimilar 2198 and C24S Al-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(7): 1714-1720.

[7] 张 华, 林三宝, 吴 林, 冯吉才, 郭和平. 镁合金AZ31 搅拌摩擦焊接头的微观组织[J]. 中国有色金属学报, 2003, 13(6): 1510-1513.

ZHANG Hua, LIN San-bao, WU Lin, FENG Ji-cai, GUO He-ping. Microstructure of friction stir welds in AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1510-1513.

[8] 孙景峰, 郑子樵, 林 毅, 贺地求, 李红萍, 吴秋萍. 2060合金FSW接头微观组织与力学性能[J]. 中国有色金属学报, 2014, 24(2): 364-370.

SUN Jing-feng, ZHENG Zi-qiao, LIN Yi, HE Di-qiu, LI Hong-ping, WU Qiu-ping. Microstructures and mechanical properties of 2060 alloy FSW joint[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(2): 364-370.

[9] 姬书得, 温 泉, 马 琳, 李继忠, 张 利. 钛合金搅拌摩擦焊厚度方向的显微组织[J]. 金属学报, 2015, 51(11): 1391-1399.

JI Shu-de, WEN Quan, MA Lin, LI Ji-zhong, ZHANG Li. Microstructure along thickness direction of friction stir welded TC4 titanium alloy joint[J]. Acta Metallurgica Sinica, 2015, 51(11): 1391-1399.

[10] MUZVIDZIWA M, OKAZAKI M, SUZUKI K, HIRANO S. Role of microstructure on the fatigue crack propagation behavior of a friction stir welded Ti-6Al-4V[J]. Materials Science and Engineering A, 2015, 652(2): 59-68.

[11] YOON S, UEJI R, FUJII H. Effect of rotation rate on microstructure and texture evolution during friction stir welding of Ti-6Al-4V plates[J]. Materials Characterization, 2015, 106: 352-358.

[12] ZHOU L, LIU H J, WU L Z. Texture of friction stir welded Ti-6Al-4V alloy[J] Transactions of Nonferrous Metals Society of China, 2014, 24(2): 368-372.

[13] LIU H J, ZHOU L, LIU Q W. Microstructural characteristics and mechanical properties of friction stir welded joints of Ti-6Al-4V titanium alloy[J]. Materials and Design, 2010, 31: 1650-1655.

[14] ZHOU L, LIU H J, LIU Q W. Effect of rotation speed on microstructure and mechanical properties of Ti-6Al-4V friction stir welded joints[J]. Materials and Design, 2010, 31: 2631-2636.

[15] SONG K J, DONG Z B, FANG K, ZHAN X H, WEI Y H. Cellular automaton modelling of dynamic recrystallisation microstructure evolution during friction stir welding of titanium alloy[J]. Materials Science and Technology, 2014, 30(6): 700-711.

[16] SANDERS D G, EDWARDS P, CANTRELL A M, GANGWAR K, RAMULU M. Friction stir-welded titanium alloy Ti-6Al-4V: Microstructure, mechanical and fracture properties[J]. The Minerals, Metals & Materials Society, 2015, 67(5): 1054-1063.

[17] ZHANG Y, SATO Y S, KOKAWA H, PARK S H C, HIRANO S. Microstructural characteristics and mechanical properties of Ti-6Al-4V friction stir welds[J]. Materials Science and Engineering A, 2008, 485: 448-455.

[18] KITAMURA K, FUJII H, IWATA Y, SUN Y S, MORISADA Y. Flexible control of the microstructure and mechanical properties of friction stir welded Ti-6Al-4V joints[J]. Materials and Design, 2013, 46: 348-354.

[19] JI S D, LI Z W, LV Z, MA L. Joint formation and mechanical properties of back heating assisted friction stir welded Ti-6Al-4V alloy[J]. Materials and Design, 2016, 113: 37-46.

[20] 吴 奇, 张 昭, 张洪武. 搅拌摩擦焊接中焊接速度与搅拌头受力关系研究[C]// 中国计算力学大会. 长沙: 湖南大学出版社, 2014.

WU Qi, ZHANG Zhao, ZHANG Hong-wu. Force analysis of welding tool during friction stir welding process of different welding speeds based on CFD model[C]// China Congress on Computational Mechanics. Changsha: Hunan University Press, 2014.

[21] JI S, WANG Y, LI Z W, MA L, ZHANG L G, YUE Y M. Effect of plate thickness on tensile property of Ti-6Al-4V alloy joint friction stir welded below β-transus temperature[J]. High Temperature Materials & Processes, 2017, 36(6): 693-699.

[22] 王快社, 张小龙, 沈 洋, 徐可为. TC4 钛合金搅拌摩擦焊连接组织形貌研究[J]. 稀有金属材料与工程, 2008, 31(11): 2045-2048.

WANG Kuai-She, ZHANG Xiao-Long, SHEN Yang, XU Ke-wei. Microstructure of friction stir weld for TC4 titanium alloy[J]. Rare Metal Materials and Engineering, 2008, 31(11): 2045-2048.

[23] JI S D, LI Z W, ZHANG L G, WANG Y. Eliminating the tearing defect in Ti-6Al-4V alloy joint by back heating assisted friction stir welding[J]. Materials Letters, 2017, 188: 21-24.

[24] YUE Y, WEN Q, JI S, MA L, LV Z. Effect of temperature field on formation of friction stir welding joints of Ti-6Al-4V titanium alloy[J]. High Temperature Materials & Processes, 2017, 36(7): 733-739.

[25] FUJII H, SUN Y F, KATO H, NAKATA K. Investigation of welding parameter dependent microstructure and mechanical properties in friction stir welded pure Ti joints[J]. Materials Science and Engineering A, 2010, 527: 3386-3391.

Formation and tensile properties of friction stir welded TC4 titanium alloy joint below β-phase transus temperature

WANG Yue1, JI Shu-de1, LI Zheng-wei1, CHAI Peng2

(1. Faculty of Aerospace Engineering, Shenyang Aerospace University, Shenyang 110136, China;

2. School of Mechanical Engineering and Automation, Beihang University, Beijing 100191, China)

Abstract: TC4 titanium alloy with thickness of 2.5 mm was friction stir welded using W-Re rotational tool with shoulder diameter of 15 mm. The formation, microstructure and tensile property of FSW joint were mainly discussed. The results show that nugget zone (NZ) of cross section presents typical bowl-like shape. When rotating speed is lower than 200 r/min, the peak temperature during welding is below β-phase transus temperature. The tearing defect often appears in pin affected zone of NZ, which results from the welding tensile stress during welding. Decreasing the rotating speed is beneficial to reduce and even eliminate the tearing defect. The defect-free FSW joint attained below β-phase transus temperature owns high tensile strength, which is almost equal to that of base metal. The fracture surface is composed of plenty dimples, presenting the typical ductile fracture.

Key words: TC4 titanium alloy; friction stir welding; tensile strength; tearing defect; phase transus temperature

Foundation item: Project(51204111) supported by the National Natural Science Foundation; Project(2014024008) supported by the Natural Science Foundation of Liaoning Province, China; Project(LJQ2015084) supported by Liaoning Province Outstanding Young Scholars Growth Plans, China

Received date: 2016-11-02; Accepted date: 2017-07-10

Corresponding author: JI Shu-de; Tel: +86-24-89723472; E-mail: superjsd@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51204111);辽宁省自然科学基金资助项目(2014024008);辽宁省高等学校杰出青年学者成长计划资助(LJQ2015084)

收稿日期:2016-11-02;修订日期:2017-07-10

通信作者:姬书得,教授,博士;电话:024-89723472;E-mail: superjsd@163.com

[1] 陈玉华, 董春林, 倪 泉, 柯黎明. 钛合金/铝合金搅拌摩擦焊接头的显微组织[J]. 中国有色金属学报, 2010, 20(S1): s211-s214.

[2] 王玉晓, 岳玉梅, 姬书得, 吕 赞, 温 泉. 钛合金搅拌摩擦焊研究进展[J]. 精密成形工程, 2015, 7(5): 40-45.

[4] 姚俊歌, 贺地求, 赖瑞林, 李 然, 王海军. 采用FSW与MIG工艺补焊6005A-T6铝合金的接头力学性能[J]. 中国有色金属学报, 2015, 25(3): 589-594.

[5] 贺地求, 叶绍勇, 汪 建. 20 mm厚6063铝合金搅拌摩擦焊焊缝S曲线控制[J]. 焊接学报, 2013, 34(12): 21-24.

[6] 邢 丽, 宋 骁, 柯黎明. 2198和C24S异种铝锂合金搅拌摩擦焊接头的显微组织和力学性能[J]. 中国有色金属学报, 2014, 24(7): 1714-1720.

[7] 张 华, 林三宝, 吴 林, 冯吉才, 郭和平. 镁合金AZ31 搅拌摩擦焊接头的微观组织[J]. 中国有色金属学报, 2003, 13(6): 1510-1513.

[8] 孙景峰, 郑子樵, 林 毅, 贺地求, 李红萍, 吴秋萍. 2060合金FSW接头微观组织与力学性能[J]. 中国有色金属学报, 2014, 24(2): 364-370.

[9] 姬书得, 温 泉, 马 琳, 李继忠, 张 利. 钛合金搅拌摩擦焊厚度方向的显微组织[J]. 金属学报, 2015, 51(11): 1391-1399.

[20] 吴 奇, 张 昭, 张洪武. 搅拌摩擦焊接中焊接速度与搅拌头受力关系研究[C]// 中国计算力学大会. 长沙: 湖南大学出版社, 2014.

[22] 王快社, 张小龙, 沈 洋, 徐可为. TC4 钛合金搅拌摩擦焊连接组织形貌研究[J]. 稀有金属材料与工程, 2008, 31(11): 2045-2048.