La/CeO2稀土对熔敷金属拉伸断口形貌与力学性能的影响

江苏师范大学机电工程学院

徐州鸿源自动化技术有限公司

摘 要:

钛铁矿型焊条成本低, 焊接时电弧稳定, 焊缝成形美观、熔渣覆盖度好, 熔敷效率较高, 对焊缝中的锈、油污等不敏感, 但抗裂性能差, 影响焊接质量。针对钛铁矿型焊条熔敷金属抗裂性差的问题, 将12种不同含量的稀土镧 (La) 及氧化铈 (CeO2) 过渡到钛铁矿型焊条药皮中, 在螺旋式压涂机上将其压涂成钛铁矿型电焊条。按照国家标准制取试板并截取冲击及拉伸样坯, 对12种熔敷金属进行了冲击试验和拉伸试验。采用扫描电镜 (SEM) 对含La/CeO2稀土的拉伸断口形貌进行观察, 用能谱仪 (EDS) 分析断口夹杂物化学成分组成。结合熔敷金属的宏观力学性能, 分析熔敷金属断裂的相关信息。结果表明:不含稀土的熔敷金属拉伸断口韧窝较浅, 尺寸小些, 熔敷金属抗拉强度、延伸率和-20℃下的冲击功分别是467.9 MPa, 27%和27 J。其他加入稀土的断口可见韧窝变大变深, 夹杂物尺寸变小。但La和CeO2加入的量要适当, 不是越多越好, 当La, CeO2在药皮中的含量分别是0.5%和0.1%时, 和不加入稀土的配方相比, 熔敷金属的抗拉强度提高了6.36%, 延伸率提高了25.1%, 冲击功提高了54.4%, 成本仅提高了6.3%, 具有较大的推广价值。

关键词:

中图分类号: TG422.1

作者简介:范希营 (1965-) , 男, 黑龙江嫩江人, 硕士, 副教授;研究方向:焊接材料、工艺装备;郭永环 (E-mail:gyh8421@126.com) ;

收稿日期:2013-04-30

基金:国家自然科学基金项目 (50974107);徐州市科技计划项目 (XC12A013) 资助;

Influence of La/CeO2 on Tensile Fracture Morphology and Mechanical Properties of Deposited Metal

Fan Xiying Guo Yonghuan Zhang Liang Li Shuncai Xu Yijun

College of Mechanical and Electrical Engineering;Jiangsu Normal University

Hongyuan Automation Technology Co. , Ltd

Abstract:

The ilmenite type welding electrode had low cost, stable electric arc during welding, beautiful weld, good slag coverage, higher deposition efficiency, low sensitivity to rust and oil in welding, but it had disadvantage in crack resistance, which could influence the quality of welding. Considering the poor crack resistance of deposited metal in ilmenite type welding electrode, 12 different content types of rare earth La / CeO2were transferred into electrode coating, then pressured to the type of ilmenite welding electrode on the spiral pressure machine. Test plates were made according to national standards and the specimens of impact and tensile were intercepted, 12 types of the deposited metal were used to the test of impact and tensile. Tensile fracture morphology with La / CeO2was observed through scanning electron microscope ( SEM) ; the chemical components of the inclusion on the fractures were analyzed by energy-dispersive spectroscopy ( EDS) . Relevant information about the fracture of deposited metal was analyzed, combined with the macromechanical properties of the deposited metal. The results showed that the deposited metal tensile fracture without rare earth had smaller and shallow dimples. The tensile strength, elongation and impact energy under- 20 ℃ of the deposited metal were 467. 9 MPa, 27%and 27 J, respectively. Other dimples on the fracture were bigger and deeper while the size of the inclusion was reduced, compared with the formula without rare earth addition. But, the amount of La and CeO2must be appropriate; it did not mean the more the better. When the amount of La / CeO2in coating was 0. 5% /0. 1%, compared with the formula without rare earths, the tensile strength of deposited metal improved 6. 36%, elongation 25. 1%, impact energy 54. 4%, but cost only 6. 3%, so it possessed great promotional value.

Keyword:

La/CeO2; tensile fracture; morphology; mechanical properties;

Received: 2013-04-30

零件断裂后的自然表面称为断口。断口是断裂失效中两个断裂分离面的简称, 断口真实地记录了裂纹由萌生, 扩展直至失稳断裂全过程的各种与断裂有关的信息[1]。传统的金属断口分析研究的对象大多采用冲击断口, 随着研究的不断深入, 人们不断地对拉伸试样的微观断裂过程进行观察和分析[2,3,4,5,6,7,8,9], 并与宏观的力学性能指标结合起来, 同样能获得对金属强韧化机制的本质认识。钛虽然是稀有金属, 但含量并不稀少, 我国钛材的产量已进入世界排名的前三位[10], 且制取容易, 因此其价格较低。钛材作为母材不断地被应用到焊接中[11,12], 含钛合金的熔敷金属组织和力学性能不断地被探索[13,14,15]。作为钛的氧化物———二氧化钛无毒、具有良好的物理化学稳定性, 广泛应用于涂料、化纤、橡胶、陶瓷、环保等工业[16], 是焊条药皮中不可缺少的原料。

本文将使用天然矿石金红石 (二氧化钛) 和还原钛制成钛铁矿型焊条, 钛铁矿型焊条成本低, 焊接时电弧稳定, 焊缝成形美观、熔渣覆盖度好, 熔敷效率较高, 对焊缝中的锈、油污等不敏感, 但抗裂性能差, 影响焊接质量。为提高此类焊条的抗裂性能, 将作为“工业味精”的稀土镧 (La) 及氧化铈 (Ce O2) 过渡到焊条药皮中, 通过拉伸断口形貌与宏观力学性能相结合的方法分析熔敷金属断裂的相关信息, 为研制高性价比的焊条提供理论数据。

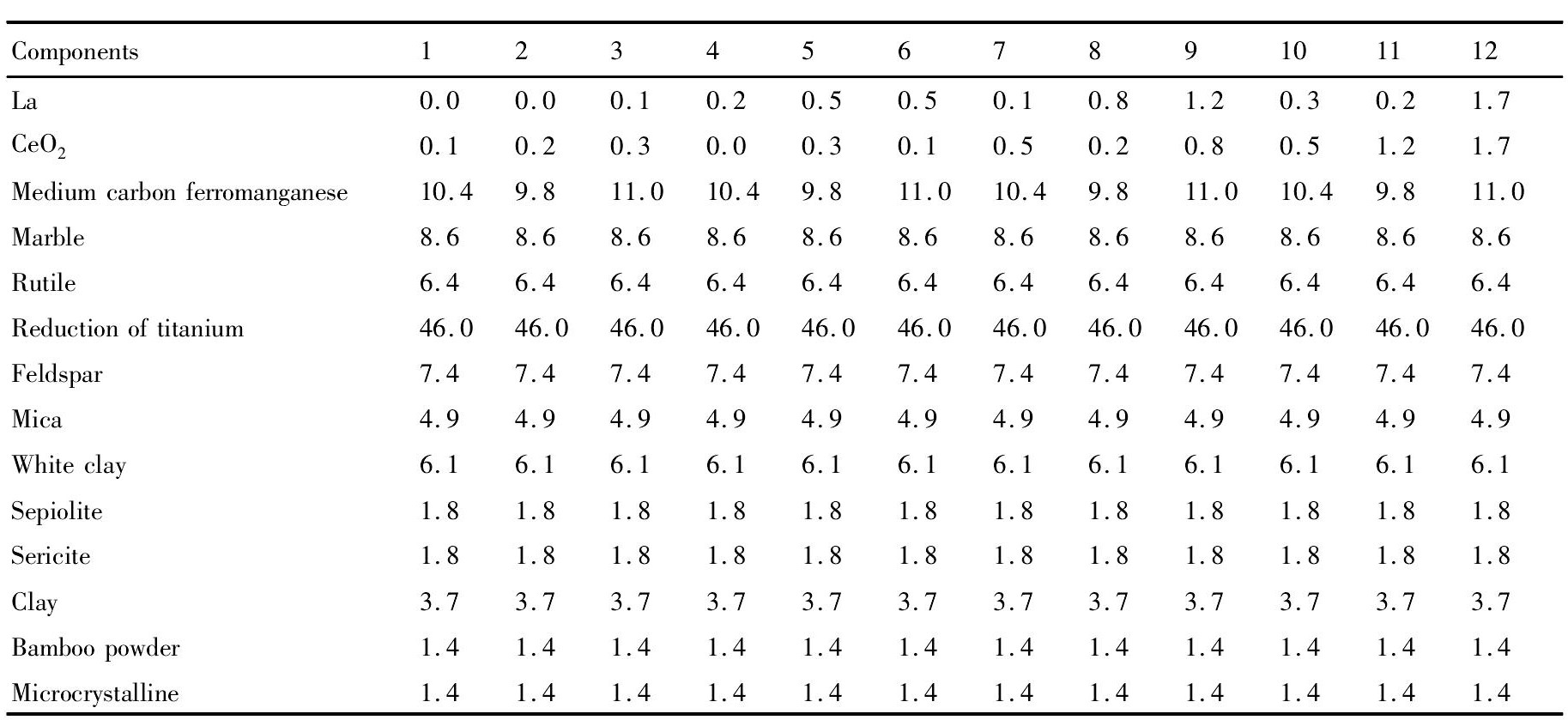

1 实验

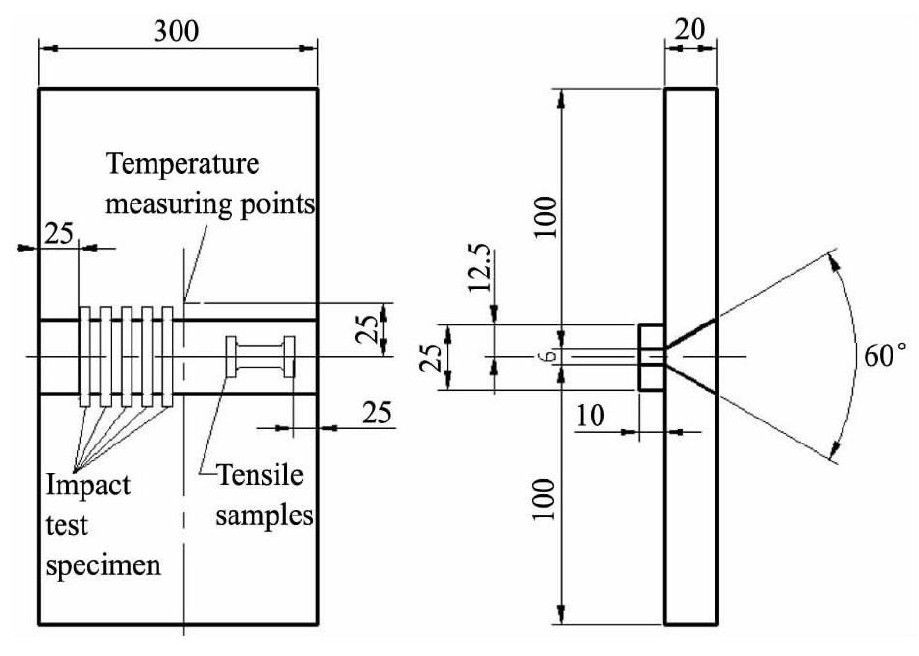

试验所用的母材为Q345B, 试板尺寸为300mm×100 mm×20 mm, 共24块, 按GB/T5117-1995要求制备12组钢板, 以备截取冲击试样以及拉伸试样, 如图1所示。选用的焊芯是H08A, 试验经正交试验设计以及曲线拟合优选12种药皮配方, 如表1所示, 其中1号焊条为试验对照例药皮配方, 不加任何稀土。将表1各组分的药粉材料混合均匀后用模数为2.9, 浓度为37B'e的钾钠水玻璃做粘结剂, 在螺旋式压涂机上将其压涂在直径为4 mm的H08A焊芯上做成钛铁矿型电焊条, 其制造工艺与普通钛铁矿型电焊条制造工艺相同。

2 结果与讨论

2.1 冲击试验结果

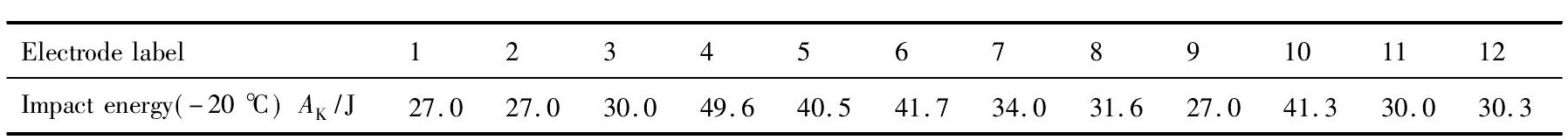

按GB/T5117-1995要求截取焊接接头冲击样坯, 按GB2650-89金属夏比V型缺口冲击试验方法, 在-20℃进行冲击试验。实验设备为冲击试验缺口双刀拉床、摆式冲击试验机及半导体制冷电源。冲击试验结果如表2所示。

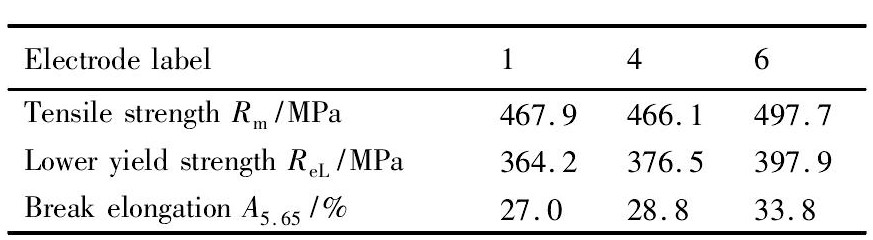

2.2 拉伸试验结果

从表2可知, 加入稀土后除了2号配方的冲击功没有提高外, 4, 6号焊条熔敷金属的冲击功较高。按GB/T5117-1995要求, 对1, 4, 6号焊条熔敷金属进行拉伸试验, 其结果如表3所示。从表3中可知, 3种熔敷金属的断后伸长率都大于5%, 初步判断为韧性断裂。结合表2, 3可知, 4号焊条冲击功最高, 但抗拉强度略有下降。从综合力学性能看6号的性能最好。

图1 焊条试板Fig.1Test plate of electrode preparation

表1 12种药皮配方 (%, 质量分数) Table 1Coating formula of 12 electrodes (%, mass fraction) 下载原图

表1 12种药皮配方 (%, 质量分数) Table 1Coating formula of 12 electrodes (%, mass fraction)

表2 冲击试验结果Table 2Results of impact test 下载原图

表2 冲击试验结果Table 2Results of impact test

表3 拉伸试验结果Table 3Results of tensile test 下载原图

表3 拉伸试验结果Table 3Results of tensile test

2.3 拉伸断口形貌

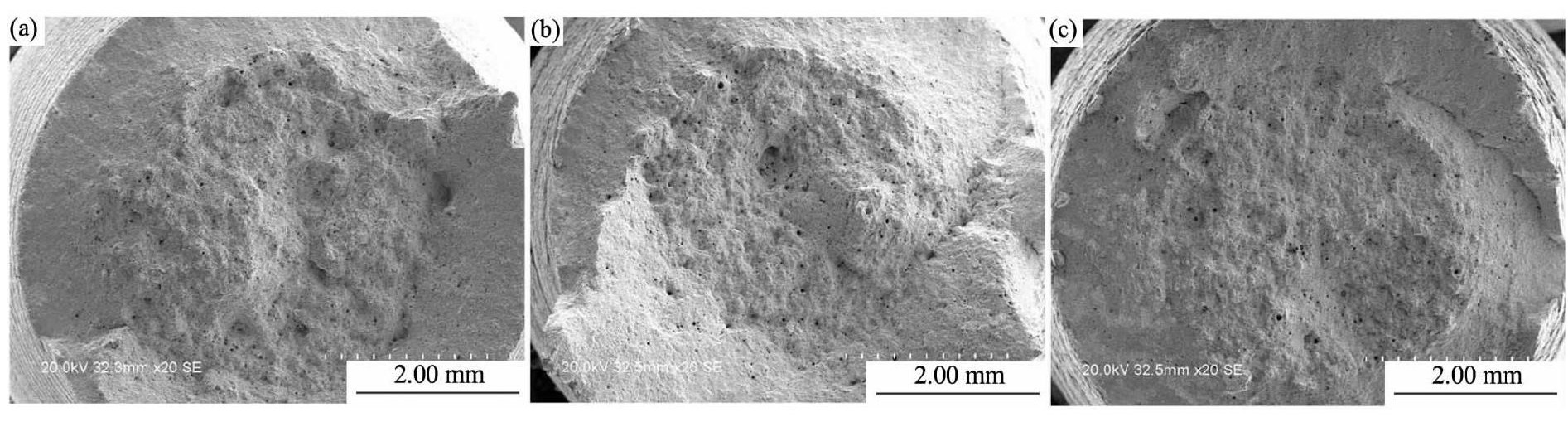

试验采用S-3400N型扫描电子显微镜 (SEM) 。图2为1号、4号和6号拉伸断口宏观形貌。

3种拉伸试样断口的外形呈现杯锥状, 都呈灰色且没有光泽的纤维状。从图2可以看出, 断口从中心到外边缘依次为纤维区和剪唇区 (属韧性断裂) , 没有放射区。裂纹起源于中心的纤维区, 但裂纹源不明显, 并随着拉伸的不断进行, 裂纹源扩展到表面形成剪唇区, 以至于形成杯锥状断口。沿着拉应力方向断口有大量的小坑。和1号断口比较, 4号与6号断口的小坑较多, 尺寸也较大些。

图2 拉伸断口宏观形貌Fig.2 Macro morphologies of tensile fracture

(a) No.1 fracture morphology; (b) No.4 fracture morphology; (c) No.6 fracture morphology

2.4 拉伸断口的扫描电镜分析

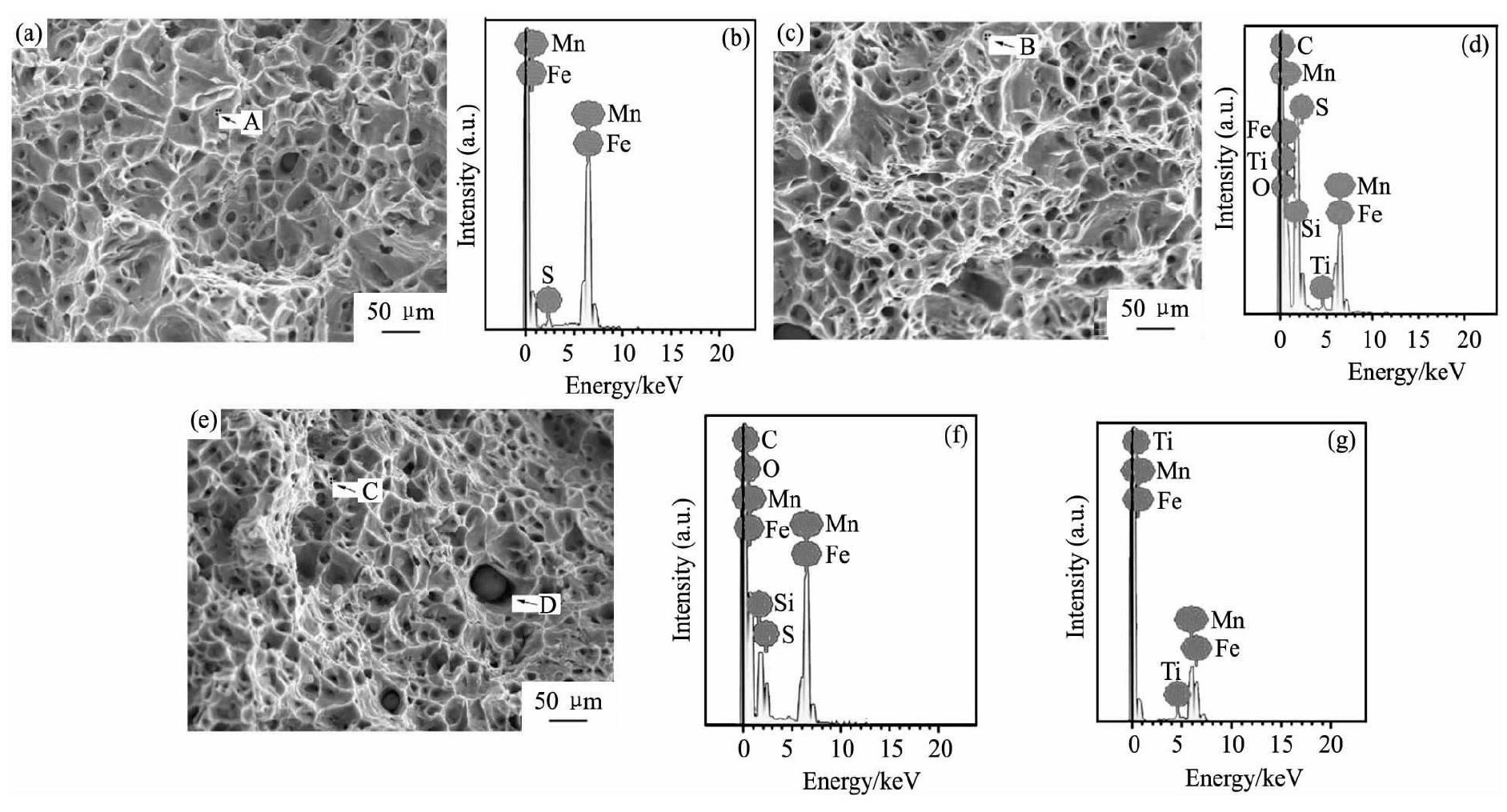

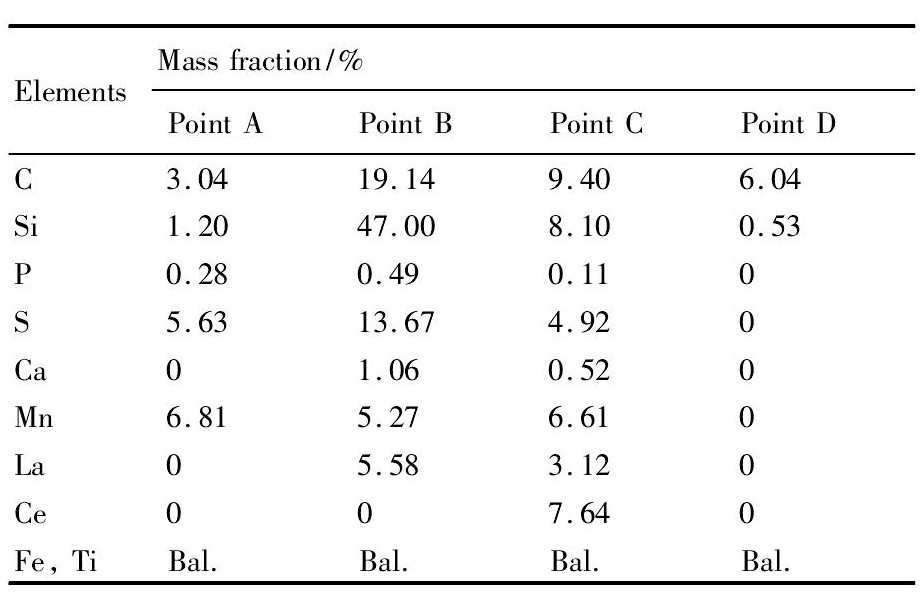

纤维区是断裂源的发祥地。因此, 在SEM上将拉伸断口的纤维区放大比例观察, 发现这些断口微观上呈微孔洞汇聚断裂模式。这些微孔洞是呈圆形、椭圆形和多边形的韧窝, 许多韧窝中还有呈球状的夹杂物颗粒 (图3) , 图3中, 图3 (b) 为1号断口中A点能谱;图3 (d) 为4号断口中B点能谱;图3 (f) , (g) 为6号断口中C, D点能谱。采用EDS能谱分析法对A, B, C和D点断口的夹杂物的化学成分组成进行测试分析, 成分组成见表4。

表4 能谱分析数据Table 4EDS data 下载原图

表4 能谱分析数据Table 4EDS data

从图3可以看出, 3种配方的熔敷金属都有韧窝, 这是金属具有良好塑性的断口微观特征, 都属于韧性 (延性) 断口, 韧窝的大小不一, 具有分散性。韧窝是由空穴长大和分离而成的微坑, 夹杂物和第二相质点为显微空穴的成核点, 所以韧窝底部能观察到这种质点。大多数韧窝内有球状夹杂物存在。

结合图3, 表3与表4分析, 1号断口韧窝中的球状夹杂物不含有镧铈稀土, 韧窝较浅, 尺寸小些。与之相比, 4号焊条药皮含镧0.2%, 6号焊条药皮含镧0.5%, 氧化铈0.1%, 4号与6号的韧窝较深, 尺寸大些, 而且4号与6号的夹杂物在数量上明显比1号的少, 夹杂物的尺寸明显比1号的小, 因此其冲击功明显比1号的大。4号与6号的夹杂物相比, 尺寸更均匀些, 也更小些, 从表4中可以看出, 4号熔敷金属中B点的夹杂物含硫、磷很高, 这是因为稀土极易和氧、硫、磷结合[17,18], 焊条药皮加入稀土后, 在熔滴内部, 熔池内部各反映生成的稀土氧化物、稀土硫化物及稀土硫氧化物大部分进入残渣, 少部分残留在焊缝中成为夹杂物。稀土硫化物的生成, 减少了基体金属中的Mn S, 这也是4号熔敷金属的冲击功最高的原因。

图3 拉伸断口韧窝形貌及能谱Fig.3Morphologies and energy spectra of dimples on tensile fracture

(a) No.1 fracture morphology; (b) Energy spectrum at point A; (c) No.4 fracture morphology; (d) Energy spectrum at point B; (e) No.6 fracture morphology; (f) Energy spectrum at point C; (g) Energy spectrum at point D

3 结论

1.加入适量的稀土La/Ce O2后, 能够提高熔敷金属的冲击功, 但提高的幅度不同。当加入镧0.5%, 氧化铈0.1%时, 拉伸断口呈微孔洞汇聚断裂模式, 韧窝较深较大, 夹杂物较少较小。熔敷金属-20℃下的冲击功为41.7 J, 抗拉强度497.7MPa, 和不加入稀土的配方相比, 冲击功提高了54.4%, 抗拉强度提高了6.36%。成本仅提高了6.3%, 性价比高, 具有较大的推广价值。

2.稀土硫化物、稀土硫氧化物的生成及大部分进入残渣, 减少了基体金属中的Mn S, 使熔敷金属的冲击功提高。

参考文献