Fabrication of nano Rhizama Chuanxiong particles and determination of tetramethylpyrazine

SU Yan-li(苏艳丽), FU Zheng-yi(傅正义), QUAN Cong-juan(全从娟), WANG Wei-ming(王为民)

State Key Laboratory of Advanced Technology for Materials Synthesis and Processing,

Wuhan University of Technology, Wuhan 430070, China

Received 10 April 2006; accepted 25 April 2006

Abstract:

Rhizama Chuanxiong is a kind of traditional medicinal herb used to promote blood circulation and eliminate wind to relieve pain. In this work, nano Rhizoma Chuanxiong particles were successfully prepared by high speed centrifugal sheering (HSCS) pulverizer. The influence of processing parameters on the size of Rhizama Chuanxiong particles and the different properties between nano Rhizoma Chuanxiong particles and original fine powder were systematically studied by ZetaPALS light scattering granulometric analyzer and optical microscope. The content of effective ingredient tetramethylpyrazine (TMP) was determined by high-performance liquid chromatography (HPLC). The results illustrate that general Rhizama Chuanxiong powder can be ultrafinely ground to nanometer within 50 min, and the cellular tissues of Rhizoma Chuanxiong are broken into pieces and dispersed stably and homogeneously after being ultrafinely ground. In addition, the active ingredients can dissolve out directly and fully, and the extraction ratio of TMP is increased 32.2% by HSCS processing.

Key words:

Rhizoma Chuanxiong; nanoparticles; microscopic structure; HPLC;

1 Introduction

Rhizoma Chuanxiong, derived from the rhizome of Ligusticum chuanxiong hort (Umbelliferae), is a well-known traditional Chinese medicine (TCM) with haemodynamic and analgesic effects. In the TCM practice, this herb is commonly prescribed for the treatment of migraine and various cardiovascular diseases, such as angina pectoris and ischemic stroke [1, 2].

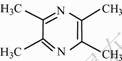

Chuanxiongzine, also called tetramethylpyrazine (TMP), has been reported to be an effective component of Ligusticum Chuanxiong affecting heart, brain and vessel diseases [3-5]. It was purified from Ligusticum Chuanxiong by high-speed counter-current chromatography [6]. Some of organic acids, including ferulic acid, sedanonic acid, folic acid, vanillic acid and caffeic acid, were isolated and identified from Ligusticum Chuanxiong by comprehensive two dimensional liquid chromatography coupled to mass spectrometry [7]. In addition, butylidenephthalide and ligustilide in volatile oil from Ligusticum Chuanxiong showed a long-term effect on pentobarbital sleep in mice, and was suggested the role involved in central noradrenergic and/or GABAA system [8]. The chemical structure of TMP is shown in Fig.1.

Fig.1 Chemical structure of TMP

However, original medicines are hard to be absorbed effectively, in order to improve the value in use, nano Rhizoma Chuanxiong particles was prepared by high speed centrifugal sheering technology in this work. The reason is that pharmacological effect of TCM is not only due to the special chemical components, but also closely connected with the physical state. Pharmacological effect may well change paroxysmal when the TCM size is decreased to nanometer [9]. It is critical of combining nanotechnology and TCM to improve the utilization ratio and rapid releasing.

The main purpose of this piece of research is to prepare and characterize nano Rhizoma Chuanxiong particles and to study the impact of nano Rhizoma Chuanxiong particles on TMP dissolving-out ratio comparing with the raw powder.

2 Experimental

Rhizoma Chuanxiong was purchased from Wuhan Chinese Drug Store, and identified by Hubei College of Traditional Chinese Medicine as umbelliferous vegetable, which is growing in Sichuan, China. Reference standard sample of tetramethylpyrazine (TMP) was purchased from the National Institute for the Control of Pharmaceutical and Biological Products (Beijing, China). Methanol and acetic acid are of HPLC grade, and all other reagents are of analytical grade.

After dryness, Rhizoma Chuanxiong was ground into micro powder using common grinding method. Original powder of Rhizoma Chuanxiong was weighted accurately and mixed with a quantity of distilled water and moved into the vessel of high speed centrifugal sheering pulverizer. After being ultrafinely ground at different rotating speed for some time, nano-sized Rhizoma Chuanxiong suspension was obtained. The temperature of the whole grinding process was kept at below 30 ℃ to prevent the active ingredients of Rhizoma Chuanxiong from volatilizing.

The average particle size after being ground was measured by laser scattering light granularity analyzer (BROOKHAVEN Co., USA), which allows sample measurement in the range of 0.002-3 μm. Each sample was measured in triplicate. The mass fraction, rotating speed and grinding time that have significant influence on the average particle sizes were studied. The microstructure of Chuanxiong before and after being ultrafinely ground was observed by optical microscope. The powder was dyed with hydration chloroaldehyde and sampled using laboratory slides. The magnifying multiple was 800×.

TMP extracted from Rhizama Chuanxiong before and after being ultrafinely ground at 1 400 r/min for 40 min were studied respectfully by using absolute alcohol back flow extracting for 3 h. Temperature was maintai-

ned at 60 ℃ by water bath. Then the filtrate filtered with common filter paper and filtered again using 0.45 ?m micropore membrane. The last filtrate was collected respectively. Experiments were conducted in triplicate for each condition.

The extractive ratio of tetramethylpyrazine from Chuanxiong was performed by high performance liquid chromatography (HPLC) (Agilent 1110, USA). It was separated on an Agileng SB C18 column (150 mm×4.6 mm i.d., 5 μm). The mobile phase was composed of 1% acetic acid and methanol at the volume ratio of 60∶40. Flow rate was 0.8 mL/min. TMP in sample was detected at 313 nm. The column temperature is 25 ℃. An amount of 20 ?L of each sample was injected. The samples were determined in triplicate.

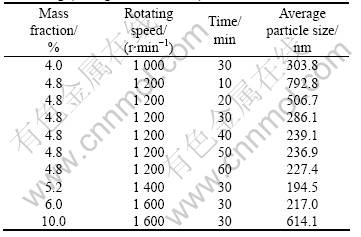

3 Results and discussionTable 1 indicates that the mass fraction, rotating speed and grinding time all have significant influence on the average particle sizes. The results show that the average particle size decreases gradually with the increasing of rotating speed (rotating speed limit: ≤1 600 r/min), but there was a limit to the magnitude of the mass fraction. If the mass fraction is too high, the viscosity of the solution will increase accordingly, which will prevent Rhizoma chuanxiong particles from being ultrafinely ground and affect the homogeneous of the particle size distribution. It is better to control the mass fraction within the limit of 6.0%. But if the mass fraction is too dilute or rotating speed is too high, the machine will be worn quickly under the powerful compressing force and cutting force. So in order to get smaller particle size, grinding time can be prolonged accordingly. As seen from Table 1, the particle size becomes smaller with the prolonging of grinding time when the mass fraction and rotating speed are fixed. When grinding time is exceeding 30 min, the particle size decreases unconspi-cuous. It is better to control the grinding time within the limit of 30-40 min.

Table 1 Influence of processing parameters on particle size of Chuanxiong (average of three times)

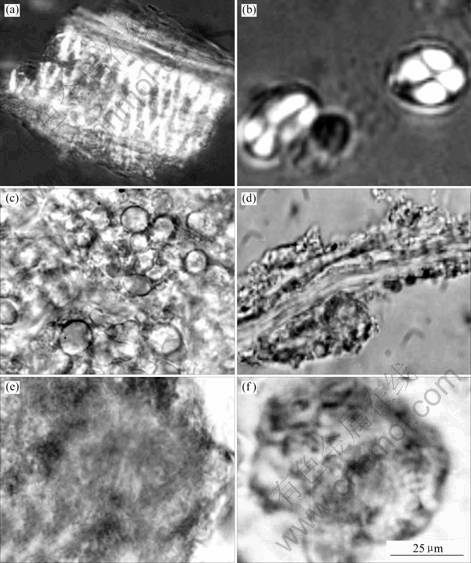

The optical microstructure of original Chuanxiong powder is shown in Fig.2. In the original powder, trachea, starch grain, grease chamber, xylogen, phellem cell and calcium oxalate crystal are all observed clearly. The tissues sizes change from 10 ?m to 50 ?m. The trachea, which mainly delivers water, is reticular. Some starch grains are circle and some are elliptical shape. It appears black “+” shape under orthogonal polarization.

Fig.3 shows the optical microscope of nano

Fig.2 Optical microstructures of original Chuanxiong powder: (a) Trachea; (b) Starch grain; (c) Grease chamber; (d) Xylogen; (e) Phellem cell; (f) Calcium oxalate crystal

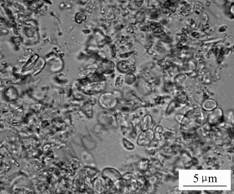

Fig.3 Optical microstructure of nano Chuanxiong particles

Chuanxiong particles. It demonstrates that cell walls are mostly broken into pieces except some minute quantity of small sized starch grain, and the integrated cellular tissues can not be seen any more. The reason is that the medicinal material is subjected to fierce forward compressing force and tangential cutting force during the grinding, cell walls are fallen to pieces and inclusions in the cellular tissues can be dissolved out directly. Fig.3 also illustrates that the broken tissues are dispersed stably and homogeneously. Comparing with common pulverized powder, high speed centrifugal sheering pulverizer can grind cells up to nearly nano-size, cellular active components can contact dissolvent even can enter into dissolvent completely [10]. It also can minimize the loss of active components.

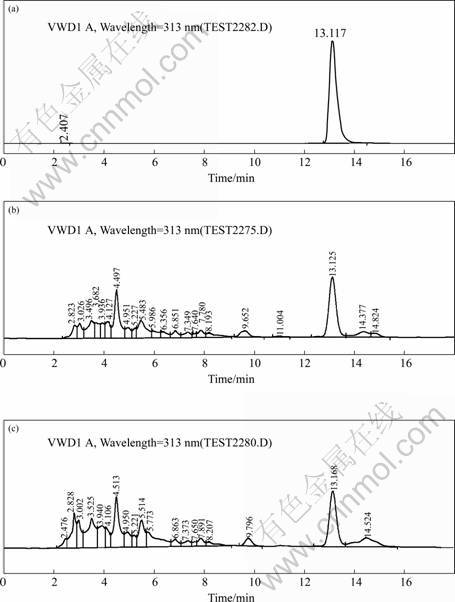

Fig.4 shows the HPLC chromatograms of TMP at different samples respectively. From the HPLC patterns, it can be seen that the retention time of reference standard sample of TMP is 13.117 min, which the purity of TMP is 99.08%. The peak of TMP at different

Fig.4 HPLC chromatograms of TMP: (a) Standard sample TMP; (b) TMP in nanoparticles; (c) TMP in original powder

samples is identified by comparing its retention time. The retention time of TMP from Chuanxiong nanoparticles is 13.125 min, which is approach to the standard sample TMP; the mass fraction of TMP is 22.409%. The retention time of TMP from Chuanxiong original powder is 13.168 min, which is also approximately approach to the standard sample TMP; however, the mass fraction is 17.664%.

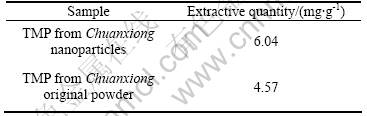

The extraction quantities of TMP before and after being ultrafinely ground at the same complex external condition are calculated by external reference method. The result is listed in Table 2. The quantity of TMP from Chuanxiong nanoparticles is increased by 32.2% higher than that from original powder.

Within so smaller size, herbs’ cell tissues will be broken into pieces, most of effective ingredients existing

Table 2 Extractive quantities of TMP (average of three times)

in the inner of cytoplasm can be exposed directly while not being released from cell-walls, thus could make effective ingredients dissolve-out rapidly and fully.

4 Conclusions

High speed centrifugal sheering technology is a new and important processing method to prepare nano TCM particles. The cellular tissues of Rhizoma Chuanxiong were broken into pieces and dispersed stably and homogeneously after processing, and the extracting quantities of TMP were increased by 32.2% compared with original powder. High speed centrifugal sheering technology can be regarded as a new method to extract the effective ingredients of TCM in a sense.

References[1] YAN R, LI S L, CHUNG H S, TAM Y K, LIN G. Simultaneous quantification of 12 bioactive components of Ligusticum chuanxiong Hort by high-performance liquid chromatography [J]. J Pharm Biomed Anal, 2005(37): 87-95.

[2] HOU Y Z, ZHAO G R, YUAN Y J, ZHU G G, HILTUNEN R. Inhibition of rat vascular smooth muscle cell proliferation by extract of Ligusticum chuangxiong and Angelica sinensis [J]. J Ethnopharmacol, 2005(100): 140-144.

[3] CUI R X, CHEN Y G, GU Y. Influence of acupuncture on brain taxis of tetramethylpyrazine in acute cerebral infarction rats [J]. World Journal of Acupuncture-Moxibustion, 2003(13): 36- 40.

[4] HUANG R J, LIAO C X, CHEN, D Z, CHEN W M, WENG Q Y. Effects of tetramethylpyrazine on TXA2 and PGI2 in congenital heart diseases with pulmonary hypertension patients during cardio-pulmonary bypass [J]. Chinese Journal of Integrated Traditional and Western Medicine, 1998(4): 263-266.

[5] LI L M, SUN Z Q, ZHAO H X. Cardiac protective effects of tetramethylpyrazine in patients performed open heart operation with cardiopulmonary bypass [J]. Chinese Journal of Integrated Traditional and Western Medicine, 2000(6): 119- 121.

[6] LI H B, CHEN F. Preparative isolation and purification of chuanxiongzine from the medicinal plant Ligusticum Chuanxiong by high-speed counter current chromatography[J]. J Chromatogr A, 2004(1047): 249- 253.

[7] CHEN X G, KONG L, SU X Y, FU H G, NI J Y, ZHAO R H, ZOU H F. Separation and identification of compounds in Ligusticum Chuanxiong by comprehensive two-dimensional liquid chromatography coupled to mass spectrometry[J]. J Chromatogr A, 2004(1040): 169-178.

[8] MATSUMOTO K, KOHNO S, OJIMA K, TEZUKA Y, KADOTA S, WATANABE H. Effects of methylenechloride-soluble fraction of Japanese angelica root extract, ligustilide and butylidenephthalide, on pentobarbital sleep in group-housed and socially isolated mice [J]. Life Sciences Including Pharmacology Letters, 1998(62): 2073-2082.

[9] XU H B, YANG X L, XIE C S. Application of nanotechnology in the TCM field [J]. J Chin Pharm Univ. 2001, 32 (3): 161-165.

[10] YUAN Y J, LIU M Y, DONG J A. Critical Technology in Modern Production of Chinese Traditional Medicine [M]. Beijing: Chemical Industry Press, 2002.(in Chinese)

Foundation item:Project(50272047)supported by the National Natural Science Foundation of China

Corresponding author: SU Yan-li: Tel:+86-27-87865484;Fax:+86-27-87215421;E-mail:susiay@sohu.com