Trans. Nonferrous Met. Soc. China 23(2013) 478-483

Creep experiment and rheological model of deep saturated rock

Lang LIU, Ge-ming WANG, Jian-hong CHEN, Shan YANG

School of Resources and Safety Engineering, Central South University, Changsha 410083, China

Received 20 September 2011; accepted 10 April 2012

Abstract:

By the methods of uniaxial single-stage loading and graded incremental cyclic loading, the creep experiments were performed on the deep saturated rock from Dongguashan Mine, and the creep curves of saturated rock under different loading stresses were obtained. By comparing with the creep rule of dry rock in the same location, the creep rule of deep saturated rock was analyzed. Based on the united rheological mechanical model, the rheological model of deep saturated rock was recognized, and the parameters of the model were determined. The results show that the creep curves are very smooth under low stress, but the phenomena of wave and catastrophe turn up under high stress, and the bearing capacity of rock is weakening over time. The rheological properties of saturated and dry rocks are very different under the condition of deep high stress, especially when unloading, degradation and damage of rock quality is more serious, and the effect of water cannot be neglected. The H—H|N—N|S model (Schofield-Scott-Blair model) was selected to represent the rheology rule of deep saturated rock, and the fitting curves of model agree well with the experiment data, so the selected model is reasonable.

Key words:

deep saturated rock; creep; united rheological model; rheology rule;

1 Introduction

Mining engineering is one of the most important rock engineering. With the increasingly serious problems of depletion of mineral resources in shallow mines and crisis mines, the mineral exploitation gradually extends to deep level. There are over 80 metal mines with more than 1000 m depth level of exploitation in China [1]. The Hongtoushan Mine, Dongguashan Mine, Gaofeng Mine, Xiangxi Mine, Jinchuan Mine and so on in China have been in the condition of deep mining. Deep mining is a rock engineering problem in special environment, which is manifested as the mutagenicity of the dynamic response of deep rock mass, the complexity of rock mass stress field, the brittle-ductile transition, large deformation and rheology of deep rock deformation mechanism, and the instantaneity of karst water bursting [2]. It can be seen that the shallow rock mechanic theory could not provide guidance and support for deep mining due to those characteristics. Therefore, the rock mechanics of deep mining has become a focus for researchers.

The rheological property of rock and rock mass is one of the important causes of rock engineering failure, especially in deep rock mass engineering [3]. The domestic and foreign scholars carried out a lot of researches on the rheological properties of rock and its rheological model, and obtained many meaningful results. GASC-BARBIER and CHANCHOLE [4] made rheological tests on clay rock, and established the corresponding constitutive equations.

FUJII et al [5] studied the axial and lateral rock creep deformation using the triaxial creep tests with constant confining pressure and increasing axial pressure. They considered that the lateral deformation shows stronger regularity, which could be used as an important indicator for rock damage. FU et al [6] found that the lateral creep shows apparent anisotropy when carrying out lateral creep tests on oil shale. YAN et al [7] analyzed the shear rheological characteristics of jointed marble, and proposed the jointed rock shear rheological constitutive model which can consider the effect of normal stress. SUN [8,9] studied the nonlinear characteristics of viscosity coefficient based on the Bingham rheological model. He considered the coefficient as the function of load and loading time. XU et al [10-12] established the nonlinear and viscoelastic-plastic rheological model of rock by connecting the nonlinear viscoplastic body and five-component viscoplastic model. And the model was applied to the rock engineering of Jinping Hydropower Station Project.

However, the research object is mainly shallow rock, while the research on the rheological properties of saturated rock in deep and high stress conditions is relatively scare. The authors carried out tests on the rheological properties of the saturated rock from Dongguashan deep copper mine, and compared the rheological properties of dry rock in the mine field. The rheology regularity of deep saturated rock was analyzed, and the corresponding rheological mode was established based on the uniform rheological model.

2 Experimental

Dongguashan Copper Mine is difficult to mine due to high stress and poor rock mass stability. The depth from the current operating field to ground reaches 1100 m. The engineering disasters of deep mining such as serious underground pressure and rock burst are serious. The destruction of deep roadways of the copper mine has time characteristics. Therefore, it is necessary to carry out creep tests to study the rheological creep law in the deep roadways.

The amphibolite cores from deep roadways of the mine were made as standard rock samples with size of d50 mm×100 mm. The samples were divided into two groups. One was placed in natural circumstance, and the other was soaked in groundwater (pH=7.1) collected from the mine site. The specimens were soaked for 7 d at room temperature.

2.1 Experimental equipment

The equipment for the rock creep test was the RYL-600 computer controlling rock shear rheometer. The rheometer has the ac-servo high speed system, which is mainly used for the rheological test of rock and rock weak plane, direct shear, uniaxial compression and bi-directional compression tests. The host composite portal frame structure consists of axial loading framework, horizontal loading framework, control cabinet, cranes and other components.

The axial loading framework is composed of motor base, ball screw, moving beams, fixed beams and axial lifting device.

2.2 Experiment designing

The methods of uniaxial compression loading and single-stage incremental cyclic loading and unloading were used to ensure the test to take into account rock bombs, instantaneous plastic, viscoelastic and viscoplastic properties, according to the test requirement and the actual sampling conditions. There were 12 samples in each group for the test. The specific test programs are as follows.

1) Each one of the dry rock and saturated rock was chosen for the uniaxial compression test, and the load threshold values of the instantaneous compressive strength and instantaneous plastic deformation of rock were obtained.

2) Each one of the dry rock and saturated rock was chosen for the uniaxial compression single-stage loading stable creep test. The initial condition that was slightly higher than the threshold value causing instantaneous plastic deformation was used for the constant loading of the test. The loading rate was 0.3 kN/s. The pressure was unloaded completely when the deformation was stable, to observe the viscoelastic hysteretic recovery.

3) Each one of the dry rock and saturated rock was chosen for the constant strain rate test with uniaxial compression loading and single-stage incremental cyclic loading and unloading. The initial load was slightly lower than the threshold value of the load causing instantaneous plastic deformation. The loading rate was 0.3 kN/s, and the loading increment was 10 kN. The pressure was unloaded completely when the deformation was stable, to observe the viscoelastic hysteretic recovery. When there was no hysteretic recovery, the next cyclic loading was carried out. The progressive loading was made step by step, until the constant strain rate phenomena appeared. And then the pressure was unloaded completely when the deformation was stable, to observe the viscoelastic hysteretic recovery.

4) Each one of the dry rock and saturated rock was chosen for uniaxial compression single-stage incremental loading full test. The process was similar to the procedure 3, while the loading was continued until the sample was damaged.

5) Every two of the dry rock and saturated rock were chosen for uniaxial compression single-stage loading creep full test. The loading value higher than the long-term strength and below the uniaxial compressive strength was applied as single-stage constant pressure, until the sample was damaged. The loading rate was 0.3 kN/s.

3 Results and analysis

3.1 Results of dry rock samples

Figure 1 shows the loading and unloading curves of dry rock creep. It can be seen that in dry conditions, the rock is in fracture compaction and elastic deformation stage when the loading stress is small (6.3 MPa for the test, due to the obvious difference between the strain and the loading stress, in order to get more clear curves, the creep curve is not shown). The fractures, pores, joints, and dislocation structure contained in the rock material are compacted and have closure adjustment in initial creep pressure. And the rock almost shows no new microscopic damage with time extending. When the stress reaches 26.5 MPa, the constant rock material compaction and local contracture closure adjustment show that the samples will be soon in stable creep state. Then the samples are in stable creep state when the stress increases to 46.8 MPa. There will be micro cracks as the stress increases to 67.2 MPa. However, the internal loading capacity of samples is not weakened, and the continuous flow curve is in fine integrity. The reason is that the amphibolite rock is in good structure, and the flow load has little effect on the deformation characteristics. There are no abrupt curves with increasing stress until the specimen is damaged, illustrating that the sample structure is of good integrity.

3.2 Results of water-saturated rock samples

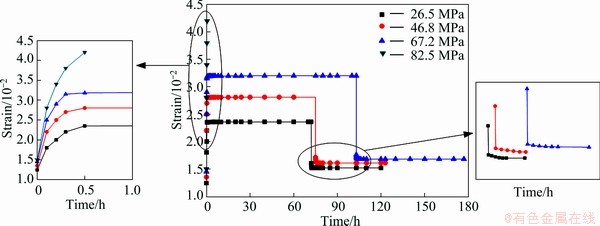

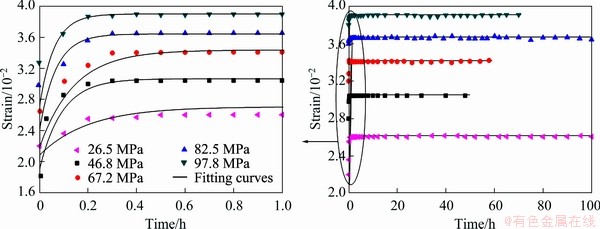

Figure 2 shows the creep curves of saturated amphibolite. The creep curve is very smooth (not plotted in Fig. 2) under the load stress of 6.3 MPa. When the loading stress increases to 26.5 MPa, the rock still shows no new microscopic damage with time prolonging and soon reaches stable state, despite of the obvious rock material heterogeneity and the compaction and closure adjustment of the initial damage of fractures, pores, joints, and dislocation structure contained in the rock material. When the stress is 46.8 or 67.2 MPa, the samples are in stable creep state, and the fractures are continuously compacted and have elastic deformation. The axial plastic deformation is nearly 0. And the increasing stress only extends the stable scope of creep. The curves show mutation when the stress increases to 82.5 MPa. The reason for the axial strain mutation may be the failure of the lower strength area in rock materials which can not bear long-term cumulative effects of micro-damage caused by the heterogeneity of rock and local non-uniform damage. The phenomenon is more significant when the loading stress is 97.8 MPa. The fluctuation of flow curves (as shown in the two figures in right of Fig. 2) shows the weakening and failure adjustment of the rock internal loading capacity with time growth.

Fig. 1 Loading and unloading curves of dry rock creep

Fig. 2 Loading and unloading curves of saturated rock creep

3.3 Discussion

It can be seen from Figs. 1 and 2 that the amphibolite loading and unloading creep curves are smooth at all time without obvious viscoplastic strain in dry circumstance. However, the influence of water can not be neglected under the effect of saturated water, especially when there is mutation under high stress unloading. The reason for the phenomenon is the re-adjustment of compacted fractures, pores, joints, and dislocation structure contained in rock material under the effect of water due to rock heterogeneity. Meanwhile, a large number of cracks caused by the combined effect of unloading and water make the rock quality deteriorated and the damage is intensified. It should be noted that the non-uniform deformation of rock may also lead to local stress release. Under the combined effects of the above factors, the rock deformation has the phenomenon of mutation with time prolonging.

4 Unified rheological model

4.1 Unified rheological model

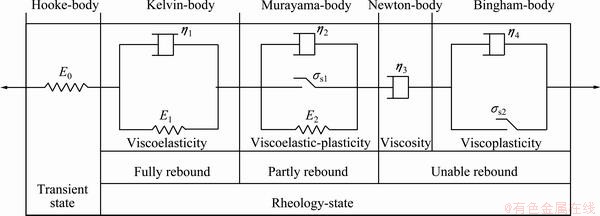

Unified rheological model is a rheological model including the viscoelasticity, viscoplasticity, viscosity and sticky plasticity, which actually contains four fundamental rheological models and eleven composite rheological models. The unified rheological model of the 14 special cases can be identified effectively based on the loading and unloading characteristics of the creep test curves of rocks under different stress levels [12,13]. The unified rheological model is shown in Fig. 3.

In the previous study, the rheological models were usually determined according to the results of creep tests [14,15], which are circumscribed and theoretically imprecise because of the limited number of models which can be used to compare to each other [9]. The proposed unified rheological model is to overcome this problem, so that researchers can conduct a comprehensive and systematic identification of rheological models [12].

Based on the foregoing creep test, the deep saturated rock rheological mechanical model was identified according to a unified rheological model, and the corresponding rheological model parameters were determined.

4.2 Model identification

According to the method proposed in Ref. [12], the deep saturated rock rheological model was identified, the core of which is to study the loading-unloading creep curve on different stress levels.

Sample producing instantaneous elastic strain immediately after the instantaneous force should be described by the elastic element. The strain rate decreases rapidly in the early creep stage, and then gradually becomes stable. When the stress is less than the long-term strength, the creep value is infinitely close to a constant value; when the stress is equal to or greater than the long-term strength, the strain increases with time, indicating that there must be viscous material characteristics, so it should contain adhesive components. After quick unloading at each grade, there is residual deformation except the fast recovery elastic strain. Among the residual deformations there is unrecoverable permanent deformation besides the viscoelastic deformation that can be fully restored, so the model should contain plastic components.

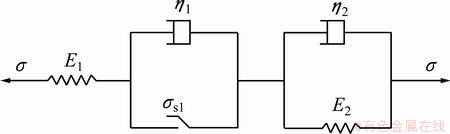

After the above analysis and checking the table of unified rheological models [12], it is known that H-H|N-N|S model or Schofield-Scott-Blair Model can describe the deep water-saturated rock rheological model for mechanical properties well, as shown in Fig. 4.

The constitutive relationship of H-H|N-N|S rheological model is shown as

σ=σ1=σ2=σ3 (1)

ε=ε1=ε2=ε3 (2)

When it is one-dimensional, the constitutive equation is

(3)

(3)

Fig. 3 Unified rheological mechanical model

Fig. 4 H-H|N-N|S model

When σ=σ0=constant, and the initial conditions are t=0, ξ=0,

(4)

(4)

Then, we can see

(5)

(5)

It is thus clear that when σ<σf, the creep equation has instantaneous elastic deformation and steady creep, when t→∞, ε(∞)→σ0/E0; when σ≥σf, the creep equation has the features of elasticity and the strain adds over time.

The unloading effect of the model is divided into two cases as the same as the loading progress, the elastic aftereffect of which is

(6)

(6)

Clearly, when σ<σf, there is an instantaneous elastic recovery at the time t1, when t→∞, ε→0; when σ≥σf, t→∞, ε→(σ0-σf)t1/η2.

4.3 Modeling parameters

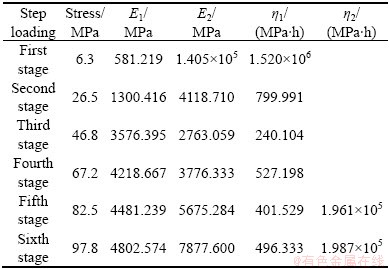

Based on the method provided in Ref. [13], the creep test data were fitted according to Eqs. (5) and (6), and the model parameters of deep saturated plagioclase amphibolite-grade stress can be obtained (as shown in Table 1). According to the fitted curve in Fig. 5, except the loading curve of the initial strain is slightly less than the measured data when the loading stress is 67.2 MPa, the other curves fit well with the experimental data, which proves that the deep saturated rock rheological model based on the unified rheological model is feasible and effective.

Table 1 Parameters of H-H|N-N|S model

Fig. 5 Fitting curves of H-H|N-N|S model

5 Conclusions

1) The single-stage uniaxial compression loading and cyclic loading incremental classification methods were used on deep water-saturated rock creep tests. And the rheological test curves under different stress states of saturated rock were obtained, as well as the rheological laws of the water-saturated deep rocks in the whole stage were analyzed.

2) Due to the impact of the water, the rheological properties of the saturated rocks and dry rocks are very different, especially under high stress unloading situation, the rock damage aggravates, indicating that water cannot be neglected when analyzing the reliability and safety of deep rock engineering.

3) The deep saturated rheological model was identified based on a unified rheological mechanical model, and the H-H|N-N|S model was chosen to describe the rheological laws of deep saturated rocks, which fits very well with the experimental data, proving that the selected model is reasonable.

References

[1] XIE He-ping, PENG Su-ping, HE Man-chao. Basic theory and engineering practice of deep mining [M]. Beijing: Science Press, 2006: 14-18. (in Chinese)

[2] HE Man-chao, XIE He-ping, PENG Su-ping, JIANG Yao-dong. Study on rock mechanics in deep mining engineering [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(16): 2803-2813. (in Chinese)

[3] ZHAO Yan-lin, CAO Ping, WEN You-dao, WANG Yi-xiao, CHAI Hong-bao. Elastovisco-plastic rheological experiment and nonlinear rheological model of rocks [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(3): 477-486. (in Chinese)

[4] GASC-BARBIER M, CHANCHOLE S. Creep behavior of burse clayey rock [J]. Applied Clay Science, 2004, 26(1-4): 449-458.

[5] FUJII Y, KIYAMA T, 1SHIJIMA Y, KODAMA J. Circumferential main behavior during creep tests of brittle rocks [J]. Int J Rock Mech Min Sci, 1999, 36(3): 323-337.

[6] FU Zhi-liang, GAO Yan-fa, NING Wei, XU Jin-peng. Creep of anisotropic oil shale [J]. Journal of Mining and Safety Engineering, 2007, 24(3): 353-356. (in Chinese)

[7] YAN Zi-jian, XIA Cai-chu, WANG Xiao-dong, ZHANG Chun-sheng. Shear rheological properties and model for rock joints [J]. Journal of Tongji University: Natural Science, 2009, 37(5): 601-606. (in Chinese)

[8] SUN Jun. Rheological behaviors of geomaterials and their engineering applications [M]. Beijing: China Architecture and Building Press, 1999. (in Chinese)

[9] SUN Jun. Rock rheological mechanics and its advance in engineering applications [J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(6): 1082-1106. (in Chinese)

[10] XU Wei-ya, YANG Sheng-qi, CHU Wei-jiang. Nonlinear viscoelasto-plastic theological model (Hohai model) of rock and its engineering application [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(3): 433-447. (in Chinese)

[11] MARANINI E, BRIGNOLI M. Creep behaviour of a weak rock: Experimental characterization [J]. Int J Rock Mech Min Sci, 1999, 36(1): 127-138.

[12] XU Wei-ya, ZHOU Jia-wen, YANG Sheng-qi, SHI Chong. Study on creep damage constitutive relation of greenschist specimen [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(S1): 3093-3097. (in Chinese)

[13] XIA Cai-chun, WANG Xiao-dong, XU Chong-bang, ZHANG Chun-sheng. Method to identify rheological models by unified rheological model theory and case study [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(8): 1594-1600. (in Chinese)

[14] XIA Cai-chun, XU Chong-bang, WANG Xiao-dong, ZHANG Chun-sheng. Method for parameters determination with unified rheological mechanical model [J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(2): 425-432. (in Chinese)

[15] LU Ai-zhong, DING Zhi-kun, JIAO Chun-man, LI Jin-lan. Identification of non-stationary creep constitutive models of rock [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(1): 16-21. (in Chinese).

深部饱水岩石蠕变试验及其流变模型

刘 浪, 王革民, 陈建宏, 杨 珊

中南大学 资源与安全工程学院,长沙 410083

摘 要:选取冬瓜山铜矿的深部饱水岩石试样,以单轴压缩单级加载和分级增量循环加卸载两种方式进行蠕变试验,得到不同应力状态下饱水岩石的流变试验曲线。以同一地点的干燥岩石的蠕变规律为对比,分析深部岩石在饱水情况下的流变规律,并基于统一流变力学模型,对深部饱水岩石的流变模型进行辨识,确定流变模型的相关参数。结果表明:在低应力条件下,饱水岩石的蠕变曲线非常平稳,但在高应力时,蠕变曲线出现波动,有突变现象产生,岩样内部承载能力随着时间的延长而不断弱化;在深部高应力条件下,饱水岩石的流变特性与干燥情况下的差别很大,尤其是在高应力卸载时,岩石质量劣化、损伤加剧,水的影响不可忽略。选定H-H|N-N|S模型(Schofield-Scott-Blair模型)描述深部饱水岩石的流变规律,模型的拟合曲线与试验数据符合得很好,表明所选的模型是合理的。

关键词:深部饱水岩石;蠕变;统一流变模型;流变规律

(Edited by Sai-qian YUAN)

Foundation item: Project (50774095) supported by the National Natural Science Foundation of China; Project (200449) supported by China National Outstanding Doctoral Dissertations Special Funds

Corresponding author: Lang LIU; Tel/Fax: +86-731-88877859; E-mail: csuliulang@163.com

DOI: 10.1016/S1003-6326(13)62488-7

Abstract: By the methods of uniaxial single-stage loading and graded incremental cyclic loading, the creep experiments were performed on the deep saturated rock from Dongguashan Mine, and the creep curves of saturated rock under different loading stresses were obtained. By comparing with the creep rule of dry rock in the same location, the creep rule of deep saturated rock was analyzed. Based on the united rheological mechanical model, the rheological model of deep saturated rock was recognized, and the parameters of the model were determined. The results show that the creep curves are very smooth under low stress, but the phenomena of wave and catastrophe turn up under high stress, and the bearing capacity of rock is weakening over time. The rheological properties of saturated and dry rocks are very different under the condition of deep high stress, especially when unloading, degradation and damage of rock quality is more serious, and the effect of water cannot be neglected. The H—H|N—N|S model (Schofield-Scott-Blair model) was selected to represent the rheology rule of deep saturated rock, and the fitting curves of model agree well with the experiment data, so the selected model is reasonable.