DOI: 10.11817/j.ysxb.1004.0609.2021-36524

Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�����֯����ѧ����

������1, 2, 3, 4����־ΰ1, 2, 3, 4��������5���� ��1, 2, 3, 4����С��1, 2, 4��������5���� �1, 2, 3, 4��������1, 2, 4���� ��1, 2, 4��Ԭ��ΰ5��ʯ����5

(1. ���пƼ���������˾������ɫ���������Ӳ��Ϸ����������ģ����� 100088��

2. ����ͨ�ò���������֤�ɷݹ�˾������ 101407��

3. ������ɫ�����о���Ժ������ 100088��

4. ����(����)������֤����˾������ 101407��

5. ���й��̼����о�Ժ����˾ ��ɫ���������Ʊ��ӹ������ص�ʵ���ң����� 101407)

ժ Ҫ��

����ɨ��������������ӱ�ɢ�����䡢������������߽ǶȻ��ΰ���-ɨ���䣬������Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2, ����������%)��ѹ̬�Ͻ�����֯�ṹ����ѧ���ܣ�ּ��̽��Zn���ںϽ�����Ӱ����ۻ��ơ������������Mg-7Gd-5Y-1Nd-0.5Zr�Ͻ�������ZnԪ�أ������γ�LPSO�ṹ��Ҳ�ٽ���Mg5(RE, Zn)����������������Zr�γ�Zn-Zr�ࡣLPSO�ṹ�������谭��������ϸ��������Ҳ�ܹ��谭��̬�ٽᾧ���Ӷ��γɶ�̬�ٽᾧ�����ͱ��ξ��������˫ģ�ṹ����̬�ٽᾧ����Ϊ //ED֯�������ξ���Ϊ

//ED֯�������ξ���Ϊ //ED֯��������ߴ�Mg5(RE, Zn)�����ᵼ��Ӧ�����У��������Ƶ����������ͺϽ�����ԣ����ȷֲ�������Mg5(RE, Zn)������ڶ���ǿ�����ã����ܶ������磬�谭�������Ա�3�ּ�ѹ̬�Ͻ�Mg-7Gd-5Y-1Nd-2Zn-0.5Zr�Ͻ��������ŵ���ѧ���ܣ��俹��ǿ�ȡ�����ǿ�Ⱥ��쳤�ʷֱ�Ϊ365 MPa��276 MPa��17.5%��

//ED֯��������ߴ�Mg5(RE, Zn)�����ᵼ��Ӧ�����У��������Ƶ����������ͺϽ�����ԣ����ȷֲ�������Mg5(RE, Zn)������ڶ���ǿ�����ã����ܶ������磬�谭�������Ա�3�ּ�ѹ̬�Ͻ�Mg-7Gd-5Y-1Nd-2Zn-0.5Zr�Ͻ��������ŵ���ѧ���ܣ��俹��ǿ�ȡ�����ǿ�Ⱥ��쳤�ʷֱ�Ϊ365 MPa��276 MPa��17.5%��

�ؼ��ʣ�

þ�Ͻ�����ѹ�����̶Ѷ�����(LPSO)�ṹ��HAADF-STEM����ѧ������

���±�ţ�1004-0609(2021)-01-0009-12���� ��ͼ����ţ�TG146.2���� ���ױ�־�룺A

���ĸ�ʽ��������, ��־ΰ, ������, ��. Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�����֯����ѧ����[J]. �й���ɫ����ѧ��, 2021, 31(1): 9-21. DOI: 10.11817/j.ysxb.1004.0609.2021-36524

PENG Yong-gang, DU Zhi-wei, LI Yong-jun, et al. Microstructures and mechanical properties of extruded Mg-7Gd-5Y-1Nd-xZn-0.5Zr (x=0, 1, 2) alloys[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(1): 9-21. DOI: 10.11817/j.ysxb.1004.0609.2021-36524

þ�Ͻ���Ŀǰʵ��Ӧ������Ľ����ṹ���ϣ��㷺Ӧ���ں��պ��졢��ͨ���䡢���Ӳ�Ʒ������[1-4]����þ�Ͻ��ձ����ǿ�ȵͣ���ʴ���ܲ�����⣬�����������þ�Ͻ��Ӧ�á�ϡ��(Rare earth, RE)Ԫ����þ�Ͻ��о��������Ĺ���ǿ����ʱЧǿ�����ã����ֳ���������º�����ѧ�����Լ����õ����Ⱥ���ʴ����[5-7]�����У�Mg-Gd-Y-Zrϵ�кϽ��ǽ�Щ����о��ȵ�[8-10]����Mg-Gd��Ԫ�Ͻ�������Y�ܽ���Gd��þ�����еĹ��ܶȣ�ͬʱ����ߺϽ��ʱЧӲ��Ч������ߺϽ������[10]��

��Mg-RE�Ͻ�������ZnԪ�أ��γɳ��̶Ѷ�����(Long period stacking ordered��LPSO)�ṹ�����ֳ���������º���ǿ�ȡ��������쳤�ʺͽϸߵ�Ӧ�����ʳ����ԣ���չþ�Ͻ��Ӧ�÷�Χ[11-16]��

LPSO�ṹ�����͡���ò���������ֲ�����Ͻ�ijɷ֡��ȴ����ƶȼ��ӹ����յ��й�[17-23]�������ױ���[17-19]����Mg-RE-Zn�Ͻ��У�������Ѷ����еIJ�ͬ����4�ֳ�����LPSO�ṹ��10H��18R��14H��24R��LPSO�ṹ��Ҫ��3�ֲ�ͬ����ò���ֲ��ھ��紦��������״��LPSO�ṹ���ֲ��ھ����ڲ���Ƭ��״LPSO�ṹ�����ȵ�LPSO�ṹ������(Ҳ����Ϊ�Dz��(Stacking faults, SFs))[20-24]��һ����ΪLPSO�ṹ����ߺϽ���쳤�ʡ�HONMA��[12]��Mg-Gd-Y-Zr�Ͻ�������ZnԪ�أ��Ͻ�ǿ�����н��ͣ��������������쳤�ʡ�����ͬ��ò��LPSO�ṹ�ԺϽ���ѧ���ܵ�Ӱ�����������С��������״LPSO�ṹ����ѧ��Ӱ�첻���ԣ�SFs�ܽ��ͺϽ���쳤��[22]��XU��[23]��Ϊ������SFs�ĺϽ��뺬Ƭ��״LPSO�ṹ�ĺϽ���ȣ����и��ߵ�ǿ�ȣ������Խϵ͡���LI��[25]�Ľ��������SFs�ܹ��������ߺϽ���쳤�ʶ���Ӱ��ǿ�ȡ�

��Mg-Gd-Y-Zr�Ͻ�����NdԪ�أ������������̺Ͻ�ﵽ��ֵʱЧ��ʱ�䣬�����ӷ�ֵʱЧ��Ӳ��[26]��YU��[27]�о���Zn��Nd��Mg-Gd-Y-Zr�Ͻ���ѧ���ܺ��۽ṹ��Ӱ�죬Zn�����γ�LPSO�ṹ�࣬����˺Ͻ����ѧ���ܣ�Nd�ٽ���Mg5RE��������������˺Ͻ����ѧ���ܡ���ΰ��[28]���о���������Mg-Gd-Y-Zn-Zr�Ͻ�������NdԪ�أ��������̺Ͻ�ﵽʱЧ��ֵ��ʱ�䣬�Ҽ������ߺϽ�����ȶ��ԡ�

�����ڿ�����EW75�Ͻ�[29-30]�Ļ����ϣ�����ZnԪ�أ��о�3��Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2, ����������%)��ѹ̬�Ͻ�����֯�ṹ����ѧ���ܣ�ּ��̽��Zn���ںϽ�����Ӱ����ۻ��ƣ�Ϊ��ǿ����þ�Ͻ�������ṩһ��˼·��

1 ʵ��

3��Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2, ����������%)�Ͻ�(���ķֱ��Ϊ0Zn��1Zn��2Zn�Ͻ�)���Դ�Mg����Gd����Zn��Mg-30%Y(��������)��Mg-30%Nd(��������)��Mg-30%Zr(��������)�м�Ͻ�Ϊԭ�ϣ����õ���¯�������������죬��������Ϊ���+�ķ�����(������ķ�����������Ϊ4:1)������壬���յõ��������ߴ�Ϊd 120 mm��300 mm����̬�Ͻ�515 �桢48 h���Ȼ��ȴ�������¯����480 �汣��8 h��������ѹ��ģ���¶�480 �棬��ѹͲ�¶�450 �棬��ѹ��20:1��

����JSM-7900F�ͳ�����ɨ���������(SEM)�۲�Ͻ���Ʒ������֯�Լ�����Ͽ���ò���й۲죻�����丽��������(EDS)������ijɷ֣������õ��ӱ�ɢ�����似��(EBSD)�ԺϽ���Ʒ�ľ����ߴ����֯�����з�����Ϊ��֤���ݱ궨�Ŀ��Ŷ���90%���ϣ�����ָ��(Confidential index, CI) CI��0.1������Tecnai G2 F20-TWIN���ȳ��������������(TEM)�ԺϽ��еĵڶ�����ò�ͽṹ���з������������丽����EDS������ijɷ֡�EBSD���������ҺΪ20%�����Ҵ���Һ(�������)����ѹ20 V��Һ��������0 �����ҡ�TEM������ʹ�����پ�DUDILER����Ʒ�гɺ��1 mm���ҵı�Ƭ��Ȼ����ɰֽĥ��50 ��m��Ȼ�����Gatan PIPS 695���Ӽ����ǽ��м���������Һ����ȴ���¶�Ϊ-120 �档

2 ��������

2.1 �Ͻ���֯����ṹ����

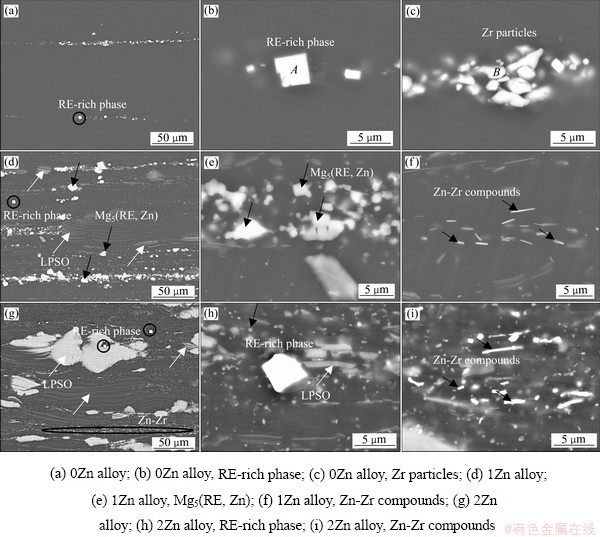

ͼ1��ʾΪMg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�ı�ɢ�������(BSE)��3�ֺϽ��еĵڶ�������͡���ò���ߴ�ͷֲ�������Zn�����IJ�ͬ�нϴ�IJ��0Zn�Ͻ��г�����ƽ�м�ѹ����ļ�ѹ���ߣ��ڼ�ѹ�����зֲ�������ڶ������(��ͼ1(a))���ֲ��Ŵ���Ҫ�з���״�ĵڶ���(��ͼ1(b))��Բ�ο���(��ͼ1(c))��EDS����������������A�ijɷ�Ϊ55.78Mg-9.47Gd-34.75Y(Ħ��������%)��Ϊ��RE�ࣻԲ�ο���B�ijɷ�Ϊ78.02Mg- 21.98Zr(Ħ��������%)��Ϊ��Zr��������1Zn��2Zn�Ͻ���Ҳ�۲쵽�˸�RE��(��ͼ1(d)��(g)�к�ɫԲȦ��ʾ)����RE���У�REԪ��ΪGd/Y��һ��Ϊ����״��ò��FCC�ṹ���������a=0.53 nm[31]��Zr��þ�Ͻ��е��ܽ�Ⱥܵͣ�һ����ϸ��������ϸ������������[26, 32-33]��

1Zn�Ͻ��г����˸�Ϊ������ƽ�м�ѹ����ļ�ѹ���ߣ�����Щ��ѹ�����зֲ�������ߴ����ĵڶ������(��ͼ1(d))����������������С����(��ͼ1(e))���ߴ�Ϊ������ʮ�����ף�EDS�������������Щ������ΪMg5(RE, Zn)��Ӧ���ڴ�ߴ��Mg5(RE, Zn)�����������У��������Ƶ�������Ϊ�����ھ������չ�ṩ·�������ºϽ�����Խ��͡�ͼ1(d)�У��۲쵽Ƭ��״��LPSO�ṹ(��ɫ��ͷ)��Ƭ��״��LPSO�ṹƽ���ڼ�ѹ�����ڼ�ѹ���ι�����ͨ��������Э�����Ρ����⣬1Zn�Ͻ��л��۲쵽�ؼ�ѹ����ֲ���Zn-Zr��(��ͼ1(f))��Zn-Zr����γɽ����˦�-Mg�����е�Zn�ĺ���������LPSO�ṹ���γɡ�ͬʱ���ٽ���̬�ٽᾧ(DRX)���谭��������ϸ������[34]��

ͼ1 Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ������֯(BSE��)

Fig. 1 Microstructures (BSE images) of Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2) extruded alloys

2Zn�Ͻ��г�����ƽ�м�ѹ����ļ�ѹ���ߣ���������״��LPSO�ṹ��Ƭ��״��LPSO�ṹ�����ż�ѹ������������ƽ���ڼ�ѹ����(��ͼ1(g))����ͼ1(g)~(i)�й۲쵽������������ϸС����������Ƭ��״��LPSO�ṹ��Χ��������������������ͼ4��TEM������������ϸС����ΪMg5(RE, Zn)�������ھ��ں;�����зֲ������⣬2Zn�Ͻ�Ҳ�۲쵽��Zn-Zr��(ͼ1(g)��ɫ��Բ��)����Ŵ���ͼ1(i)��ʾ��

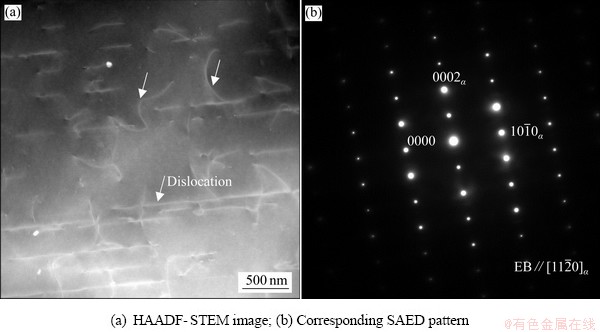

ͼ2��ʾΪMg-7Gd-5Y-1Nd-0.5Zr��ѹ̬�Ͻ��HAADF-STEM�����Ӧѡ����������(SAED)�ס�ͼ2(a)Ϊ0Zn�Ͻ����� ����۲��HAADF-STEM������ӦSAED����ͼ2(b)��ʾ������-Mg���������ߵ��Ⲣ����������ߵ㣬������û��ϸС��������������ͼ2(a)�й۲쵽������λ���ߣ���λ���켣ƽ����(0001)�����档

����۲��HAADF-STEM������ӦSAED����ͼ2(b)��ʾ������-Mg���������ߵ��Ⲣ����������ߵ㣬������û��ϸС��������������ͼ2(a)�й۲쵽������λ���ߣ���λ���켣ƽ����(0001)�����档

ͼ2 Mg-7Gd-5Y-1Nd-0.5Zr��ѹ̬�Ͻ��HAADF-STEM�����Ӧ��SAED��

Fig. 2 HAADF-STEM image and corresponding SAED pattern of Mg-7Gd-5Y-1Nd-0.5Zr extruded alloy

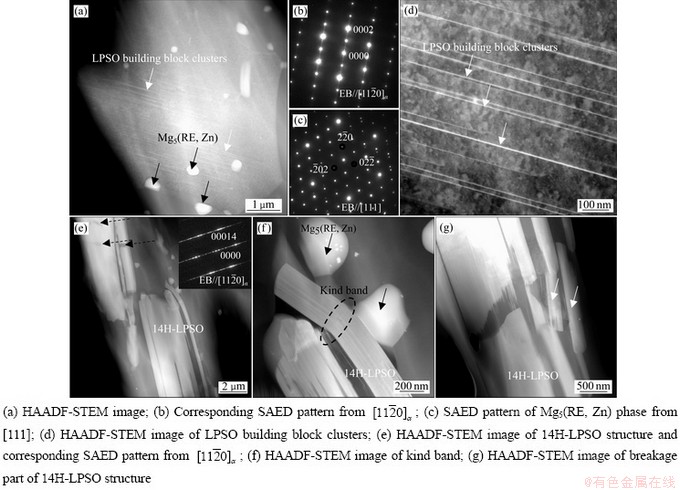

ͼ3 Mg-7Gd-5Y-1Nd-1Zn-0.5Zr��ѹ̬�Ͻ��HAADF-STEM�����Ӧ��SAED��

Fig. 3 HAADF-STEM images and corresponding SAED patterns of Mg-7Gd-5Y-1Nd-1Zn-0.5Zr extruded alloy

ͼ3��ʾΪMg-7Gd-5Y-1Nd-1Zn-0.5Zr��ѹ̬�Ͻ��HAADF-STEM�����ӦSAED�ס���ͼ3(a) ��ʾ���ھ�������(0001)���ֲ�������ϸС����״�ṹ����Ӧ��SAED����ͼ3(a)���Ͻ���ʾ����������ߵ�����â�ߣ�������Щ��״�ṹΪ���ȵ�LPSO�ṹ������[20, 23]������ά��ΪƬ��״��ͼ3(b)Ϊ�̰�״�ṹ�� ����۲��HAADF-STEM�����ϽDz�ͼΪ��Ӧ��SAED��ͼ����(0000)����(0002)��֮����ʮ��������ߵ㣬������Ϊ14H-LPSO�ṹ����Щ�̰�״��LPSO�ṹ��Ƭ��״��LPSO�ṹ�ڼ�ѹ���̶����γɵġ�ͼ3(c)ΪMg5(RE, Zn)������HAADF-STEM����EDS�ķ������Ϊ82.38Mg-7.09Gd-5.26Y-2.88Nd-2.38Zn (Ħ��������%)�����ϽDz�ͼΪ��Ӧ��SAED��ͼ��Mg5(RE, Zn)��ΪFCC�ṹ���������Ϊa=2.24 nm��ͼ3(d)ΪZn-Zr���HAADF-STEM�ʶ̰�״����EDS�ķ������Ϊ41.50Mg-18.89Zn-39.62Zr(Ħ��������%)��

����۲��HAADF-STEM�����ϽDz�ͼΪ��Ӧ��SAED��ͼ����(0000)����(0002)��֮����ʮ��������ߵ㣬������Ϊ14H-LPSO�ṹ����Щ�̰�״��LPSO�ṹ��Ƭ��״��LPSO�ṹ�ڼ�ѹ���̶����γɵġ�ͼ3(c)ΪMg5(RE, Zn)������HAADF-STEM����EDS�ķ������Ϊ82.38Mg-7.09Gd-5.26Y-2.88Nd-2.38Zn (Ħ��������%)�����ϽDz�ͼΪ��Ӧ��SAED��ͼ��Mg5(RE, Zn)��ΪFCC�ṹ���������Ϊa=2.24 nm��ͼ3(d)ΪZn-Zr���HAADF-STEM�ʶ̰�״����EDS�ķ������Ϊ41.50Mg-18.89Zn-39.62Zr(Ħ��������%)��

ͼ4��ʾΪMg-7Gd-5Y-1Nd-2Zn-0.5Zr��ѹ̬�Ͻ��HAADF-STEM���SAED�ס�ͼ4(a)�� ����۲��HAADF-STEM���ھ�������(0001)���ֲ��Ŵ���ϸСƬ��״���ȵ�LPSO�ṹ�����飬�ھ��ں;�����ȷֲ��������ĵڶ��������ͼ4(b)��ʾΪͼ4(a)��Ӧ��SAED�ף���������ߵ�����â�ߣ�Ϊ���ȵ�LPSO�ṹ�����飬��Ŵ�ͼ��ͼ4(d)��ʾ��ͼ4(a)�еڶ��������EDS�������Ϊ86.00Mg-6.16Gd-3.93Y-2.67Nd-1.24Zn (Ħ��������%)����Ӧ��SAED����ͼ4(c)��ʾ��������Щ�ڶ������ΪMg5(RE, Zn)�ࡣ�������ȷֲ���Mg5(RE, Zn)�������ڶ���ǿ�������ã���ߺϽ��ǿ�ȡ�ͬʱ�������ϵ�Mg5(RE, Zn)�ܹ����Ӷ�����������ã��谭��������ͼ4(e)��ʾΪƬ��״LPSO�ṹ��

����۲��HAADF-STEM���ھ�������(0001)���ֲ��Ŵ���ϸСƬ��״���ȵ�LPSO�ṹ�����飬�ھ��ں;�����ȷֲ��������ĵڶ��������ͼ4(b)��ʾΪͼ4(a)��Ӧ��SAED�ף���������ߵ�����â�ߣ�Ϊ���ȵ�LPSO�ṹ�����飬��Ŵ�ͼ��ͼ4(d)��ʾ��ͼ4(a)�еڶ��������EDS�������Ϊ86.00Mg-6.16Gd-3.93Y-2.67Nd-1.24Zn (Ħ��������%)����Ӧ��SAED����ͼ4(c)��ʾ��������Щ�ڶ������ΪMg5(RE, Zn)�ࡣ�������ȷֲ���Mg5(RE, Zn)�������ڶ���ǿ�������ã���ߺϽ��ǿ�ȡ�ͬʱ�������ϵ�Mg5(RE, Zn)�ܹ����Ӷ�����������ã��谭��������ͼ4(e)��ʾΪƬ��״LPSO�ṹ�� ����۲��HAADF-STEM�����ϽDz�ͼΪLPSO�ṹ��Ӧ��SAED�ף�Ϊ14H-LPSO�ṹ��LPSO�ṹͨ��������Ť��ʵ��Э�����Σ�Ť�۱��εĵ�����ò��ͼ4(f)��ʾ���ڴ�������������£�LPSO�ṹ����ͨ��������Ť��ʵ��Э�����Σ��ᷢ������(ͼ4(e)�к�ɫ����ͷ��ʾ)����Ŵ�ĵ�����ò��ͼ4(g)��ʾ���ȽϺ��Ƭ��״LPSO�ṹ���ѵĽӿڴ����ִ���˿״��LPSO�ṹ�����LPSO�ṹ��[0001]�����������йء�ͼ4(g)�а�ɫ��ͷ��ʾΪƬ��״LPSO�ṹ�ڼ�ѹ�����ж����γɵ�СƬ�Ρ�

����۲��HAADF-STEM�����ϽDz�ͼΪLPSO�ṹ��Ӧ��SAED�ף�Ϊ14H-LPSO�ṹ��LPSO�ṹͨ��������Ť��ʵ��Э�����Σ�Ť�۱��εĵ�����ò��ͼ4(f)��ʾ���ڴ�������������£�LPSO�ṹ����ͨ��������Ť��ʵ��Э�����Σ��ᷢ������(ͼ4(e)�к�ɫ����ͷ��ʾ)����Ŵ�ĵ�����ò��ͼ4(g)��ʾ���ȽϺ��Ƭ��״LPSO�ṹ���ѵĽӿڴ����ִ���˿״��LPSO�ṹ�����LPSO�ṹ��[0001]�����������йء�ͼ4(g)�а�ɫ��ͷ��ʾΪƬ��״LPSO�ṹ�ڼ�ѹ�����ж����γɵ�СƬ�Ρ�

ͼ4 Mg-7Gd-5Y-1Nd-2Zn-0.5Zr��ѹ̬�Ͻ��HAADF-STEM���SAED��

Fig. 4 HAADF-STEM images and corresponding SAED patterns of Mg-7Gd-5Y-1Nd-2Zn-0.5Zr extruded alloy

�Ƚ�3�ֺϽ�ѹ̬������֯���Է��֣�3�ֺϽ���������Եļ�ѹ���ߣ�����ѹ�����ϵĵڶ�������ࡢ�����ͷֲ����нϴ���0Zn�Ͻ��еڶ�����ҪΪ����RE���Zr������1Zn�Ͻ��й۲쵽LPSO�ṹ��Mg5(RE, Zn)����������RE���Zn-Zr�ࣻ2Zn�Ͻ���ͬ���۲쵽LPSO�ṹ��Mg5(RE, Zn)����������RE���Zn-Zr�ࡣ��Mg-7Gd-5Y-1Nd-0.5Zr�Ͻ�������ZnԪ�أ������ٽ�LPSO�ṹ���γɣ�Ҳ�ٽ�Mg5(RE, Zn)��������������ZnԪ������ZrԪ���γ�Zn-Zr�ࡣLPSO�ṹ�ĺ�����Zn���������Ӷ����ӣ�1Zn�Ͻ��й۲쵽Ƭ��״LPSO�ṹ�����ȵ�LPSO�ṹ�����飻2Zn�Ͻ����ܹ۲쵽3�ֲ�ͬ��ò��LPSO�ṹ����������״��LPSO�ṹ��Ƭ��״LPSO�ṹ�����ȵ�LPSO�ṹ�����顣Mg5(RE, Zn)�����ĺ�����Zn���������Ӷ���С���ҳߴ�ͷֲ����������Ա仯��1Zn�Ͻ����ؼ�ѹ����ֲ��������ߴ�����Mg5(RE, Zn)�����ʹ�ߴ�Mg5(RE, Zn)����������С��������ЩMg5(RE, Zn)������Ҫ�ֲ��ھ����ϡ�2Zn�Ͻ���������Mg5(RE, Zn)�������ȷֲ��ھ��ں;��紦���������Ҿ��ȷֲ����ߴ��1Zn��Mg5(RE, Zn)����С1~2�����������ھ��紦�ܶ������磬�谭��������1Zn�Ͻ����ھ��Ȼ��ȴ��������У��ڶ�����ܳ�֣�þ������RE/Zn�����ͶȽϸߣ�����������ߴ��Mg5(RE, Zn)�������2Zn�Ͻ����γɵ�LPSO�ṹ�����˴�����RE/ZnԪ�أ��������˦�-Mg�����еĹ����Ͷȣ��ڼ�ѹ���ι����������ȷֲ���������Mg5(RE, Zn)������

2.2 ��ѹ̬�Ͻ��֯���Ͷ�̬�ٽᾧ����

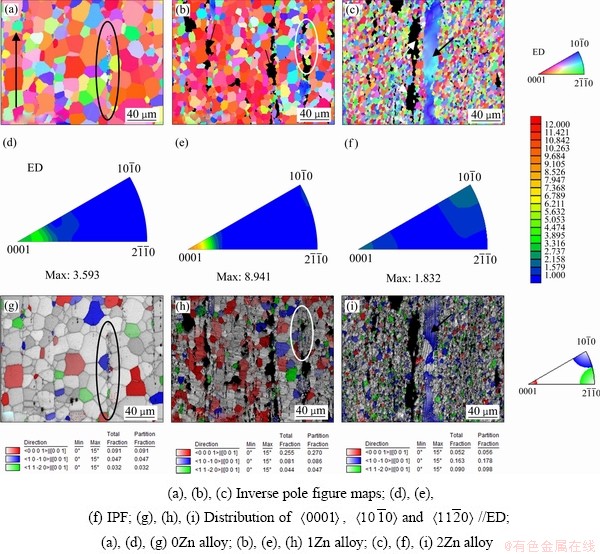

��EBSD������3��Mg-7Gd-5Y-1Nd-xZn-0.5Zr (x=0, 1, 2)��ѹ̬�Ͻ�����˷�����3�ֺϽ�ķ���ͼ��ֲ�ͼ�ͷ���ͼ(Inverse pole figure, IPF)�� ��

�� ��

�� //��ѹ��(Extrusion direction, ED)����ֲ�ͼ����ͼ5��ͼ5�к�ɫ����ΪEBSDδʶ����࣬ͨ��������֯(��ͼ1)�Աȿ�֪��ͼ5(b)�к�ɫ����ΪMg5(RE, Zn)�����ڵ����ʱ��ʴ���γɵĿ���ͼ5(c)�к�ɫ����Ϊ��������״��LPSO�ṹ��ͨ������δ�ܽ���궨����������LPSO�ṹ���-Mg����IQֵ���������ȥ����鲻�����LPSO�ṹ��ֻ������-Mg��������ݡ��������Ǽ�ѹ���ģ�ֻ��ȷ��ED��������������������ȷ�����ʰ�ED��ΪZ����д������ݷ�����

//��ѹ��(Extrusion direction, ED)����ֲ�ͼ����ͼ5��ͼ5�к�ɫ����ΪEBSDδʶ����࣬ͨ��������֯(��ͼ1)�Աȿ�֪��ͼ5(b)�к�ɫ����ΪMg5(RE, Zn)�����ڵ����ʱ��ʴ���γɵĿ���ͼ5(c)�к�ɫ����Ϊ��������״��LPSO�ṹ��ͨ������δ�ܽ���궨����������LPSO�ṹ���-Mg����IQֵ���������ȥ����鲻�����LPSO�ṹ��ֻ������-Mg��������ݡ��������Ǽ�ѹ���ģ�ֻ��ȷ��ED��������������������ȷ�����ʰ�ED��ΪZ����д������ݷ�����

3��Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ��DRX�ʷֱ�Ϊ99.1%��95.5%��82.1%(���徧����ƽ��ȡ���С��0.8Ϊ������DRX)����Zn�������ӣ�DRX�ʼ��١�2Zn�Ͻ��г�����un-DRX�ı��δ�����DRXС������˫ģ�ṹ�����ֽṹ�Ĵ��ڣ������þ�Ͻ����ѧ����[32]�����δ����ڲ��д�����Ƭ��״LPSO�ṹ(ͼ5(c)��(i)�к�ɫ��ͷ��ʾ)������Ƭ��״��LPSO�ṹ�ܹ��谭DRX��

��ͼ5(a)~(c)�п������Կ�����3�ּ�ѹ̬�Ͻ�ľ����ߴ����Լ�С�������ߴ�ֱ�Ϊ20 ��m��11 ��m��8.9 ��m��2Zn�Ͻ���DRXС������ƽ�������ߴ�Ϊ4.3 ��m�������ߴ簴GB/T 36165��2018[35]���㣬ͳ�ƾ�����1500�����ϡ�����ϸ������Ҫԭ��1) LPSO�ṹ���������ȴ����������谭��������ʹ�ü�ѹǰ��3�ֺϽ�ԭʼ������С��Zn�������Ӷ���С��Ҳ���ڼ�ѹ�����У��谭��������2) 2Zn�Ͻ��зֲ�������Mg5(RE, Zn)�����ɴٽ�DRX�����ھ��紦�ܶ������磬�谭��������ȡ����⣬�ڼ�ѹ�����У�0Zn�Ͻ�ѹ�����ϵĵڶ��������ϸ������(ͼ5(a)��(g)��ɫ��Բ��ʾ)��Ƭ��״��LPSO�ṹ�����谭DRX�����о����ij���(ͼ5(b)��(h)�а�ɫ��Բ��ʾ)��ϸ��������Ƭ��״��LPSO�ṹ���ƾ����ڳ�ʼ���總������ת��Ҳ��ֹ�˾����߽��Ǩ�ơ�

ͼ5(d)~(f)��ʾΪMg-7Gd-5Y-1Nd-xZn-0.5Zr (x=0, 1, 2)��ѹ̬�Ͻ���[001]����(ED)�ķ���ͼ(IPF)�����������0Zn��1Zn�Ͻ��֯�����;�Ϊ //ED֯����(0001)���洹ֱ�ڼ�ѹ����ֵ�ֱ�Ϊ3.593��8.941��2Zn�Ͻ��֯��������������֯������������

//ED֯����(0001)���洹ֱ�ڼ�ѹ����ֵ�ֱ�Ϊ3.593��8.941��2Zn�Ͻ��֯��������������֯������������ //ED��

//ED�� //ED(����֯��������(0001)ƽ���ڼ�ѹ��)��ͨ��ͼ5(c)��(i)�ܹ����Կ���2Zn�Ͻ��б��δ�����֯��Ϊ

//ED(����֯��������(0001)ƽ���ڼ�ѹ��)��ͨ��ͼ5(c)��(i)�ܹ����Կ���2Zn�Ͻ��б��δ�����֯��Ϊ //ED������֯������������[27, 36]�б�����һ�¡�Mg-Gd-Y-Zn-Zr��ѹ̬�Ͻ��е�֯��ͨ��Ϊ����֯��������(0001)ƽ����ED����

//ED������֯������������[27, 36]�б�����һ�¡�Mg-Gd-Y-Zn-Zr��ѹ̬�Ͻ��е�֯��ͨ��Ϊ����֯��������(0001)ƽ����ED���� ƽ����ED[27, 36-37]�����0Zn��1Zn��DRX��֯�����ͣ�����˵��

ƽ����ED[27, 36-37]�����0Zn��1Zn��DRX��֯�����ͣ�����˵�� //ED֯��������DRX���µġ�����

//ED֯��������DRX���µġ����� // ED֯������Ϊ��һ���ٽᾧ֯��������ȡ�������������[38]��ͼ5(g)~(i)��ʾΪMg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ��

// ED֯������Ϊ��һ���ٽᾧ֯��������ȡ�������������[38]��ͼ5(g)~(i)��ʾΪMg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�� ��

�� ��

�� �ֱ�ƽ����ED����ֲ�ͼ(���ܵ�ȡ���Ϊ15��)��

�ֱ�ƽ����ED����ֲ�ͼ(���ܵ�ȡ���Ϊ15��)�� //ED����������ֱ�Ϊ9.1%��27.0%��5.6%���Ƚ�ͼ5(b)��(h)��

//ED����������ֱ�Ϊ9.1%��27.0%��5.6%���Ƚ�ͼ5(b)��(h)�� //ED�ľ�����Ҫ����Mg5(RE, Zn)������ѹ�����ܼ��ĸ�����Զ��Ƭ��״LPSO������Ϊ1Zn�Ͻ���ǿ֯��������Mg5(RE, Zn)�������谭þ�����������ת���γɵģ���LPSO�ṹ����������֯�����γɡ�

//ED�ľ�����Ҫ����Mg5(RE, Zn)������ѹ�����ܼ��ĸ�����Զ��Ƭ��״LPSO������Ϊ1Zn�Ͻ���ǿ֯��������Mg5(RE, Zn)�������谭þ�����������ת���γɵģ���LPSO�ṹ����������֯�����γɡ�

ͼ5 Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�EBSD����

Fig. 5 EBSD results of Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2) extruded alloy

2.3 Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ���ѧ����

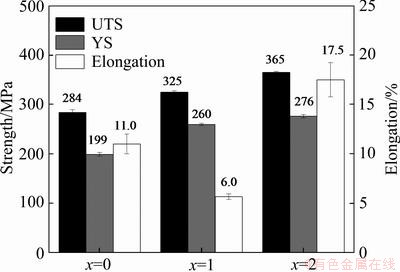

ͼ6��ʾΪMg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ��������ѧ���ܡ�0Zn�Ͻ�Ŀ���ǿ��(UTS)������ǿ��(YS)���쳤��(EL)�ֱ�Ϊ284 MPa��199 MPa��11.0%��1Zn�Ͻ��UTS��YS��EL�ֱ�Ϊ325 MPa��260 MPa��6.0%��2Zn�Ͻ��UTS��YS��EL�ֱ�Ϊ365 MPa��276 MPa��17.5%��������ʵ����ұ����С�������ұ��ι���Ҳ��ͬ�ڹ�ҵ���������������빤ҵ����EW75����ɱȽϡ��ڱ�ʵ�������£��Ƚ�3�ּ�ѹ̬�Ͻ��������ѧ���ܣ���֪����Zn���������ߣ�����ǿ��(UTS)������ǿ��(YS)�����ߣ�2Zn�Ͻ��������ŵ���ѧ���ܡ�

ͼ6 Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2, ����������%)��ѹ̬�Ͻ��������ѧ����

Fig. 6 Mechanical properties of Mg-7Gd-5Y-1Nd-xZn- 0.5Zr (x=0, 1, 2, mass fraction, %) extruded alloys at room temperature

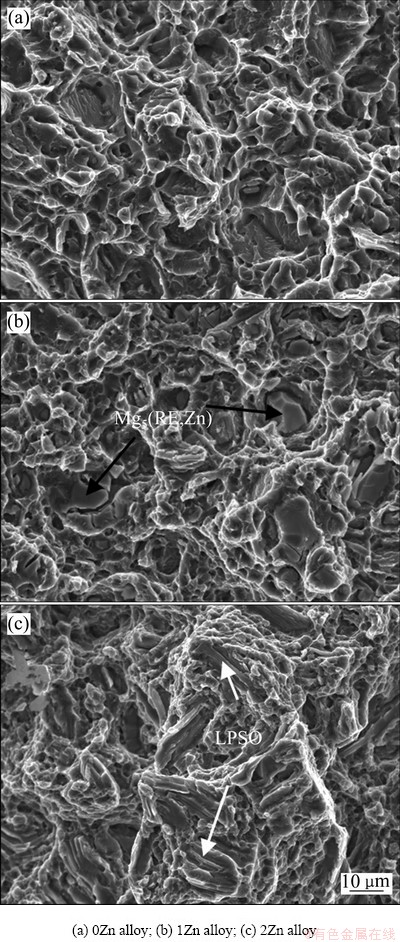

ͼ7��ʾΪMg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�Ͽ���ò��0Zn�Ͻ�ĶϿڱ�����òΪ����״��Ϊ���͵����Զ���������1Zn�Ͻ�Ͽڱ�����òΪ����״�������������д�������Mg5(RE, Zn)�������ڣ���ЩMg5(RE, Zn)�����д������ơ���������ι��̣���ߴ��Mg5(RE, Zn)�������-Mg���洦����Ӧ�����������ƣ����صؽ����˸úϽ���쳤��[39]��2Zn�Ͻ�Ͽڱ�����˴����������⣬���۲쵽����˺���⣬��Щ˺����������ڿ�״LPSO�ṹ�ദ������þ�����û�����ԵĽ��ޣ����TEM�Ľ��������Ӧ��Դ�ڿ�״LPSO�ṹ�ڼ�ѹ�������γɵĶϿڴ���

��������ǿ���Ļ���;�����谭λ���˶���������֯�ṹ���[15]������EBSD�����Ľ����Mg-7Gd-5Y-1Nd-xZn- 0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�ľ����ߴ���Zn���� ��������С������Hall-Petch��ϵ

(

( Ϊ����ǿ�ȣ�

Ϊ����ǿ�ȣ� Ϊ����Ħ������KΪ������dΪ�����ߴ�)��֪�������ߴ�ԽС���Ͻ������ǿ��Խ��ͬʱ�������ߴ��С��������ߺϽ�����Ժ����ԡ�

Ϊ����Ħ������KΪ������dΪ�����ߴ�)��֪�������ߴ�ԽС���Ͻ������ǿ��Խ��ͬʱ�������ߴ��С��������ߺϽ�����Ժ����ԡ�

ͼ7 Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�Ͽ���ò

Fig. 7 Microstructures of fracture position of tensile specimens of Mg-7Gd-5Y-1Nd-xZn-0.5Zr (x=0, 1, 2) extruded alloys

1Zn�Ͻ���ڵ�LPSO�ṹ��Mg5(RE, Zn)������Zn-Zr���ڶ���ǿ�������ã���1Zn�Ͻ�Mg5(RE, Zn)�����ijߴ�ϴ�Ӧ������Щ�������Mg5(RE, Zn)�����������У��������Ƶ�������Ϊ�����ھ������չ�ṩ·�������ºϽ�����Խ��͡�2Zn�Ͻ��е�LPSO�ṹ�࣬���ȷֲ�������Mg5(RE, Zn)����ڶ���ǿ�����ã���������״LPSO�ṹ��������άǿ�������á�LPSO�ṹ��Ϊ�����࣬����ߺϽ�ǿ�ȵ�ͬʱ��������ߺϽ�����ԡ�LPSO�ṹǿ�ͻ��Ļ�����Ҫ�У�1) LPSO�ṹ����Ч�ٽ����ι�����DRX������ϸ����2) LPSO�ṹ����֯�������þ�Ͻ�����ԣ�3) LPSO�ṹ��Mg������ȫ����4) LPSO�ṹŤ�۱��Ρ�

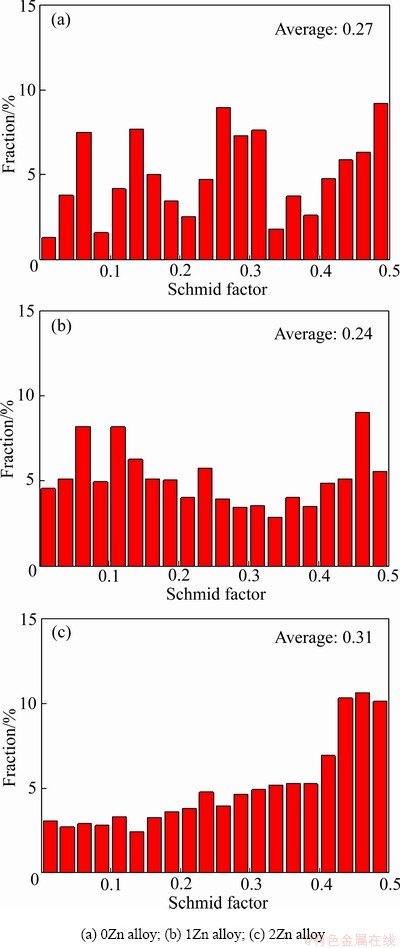

�������ֺϽ��δ�۲쵽�Ͼ���{1001} ���滬������þ�Ͻ������µ����Ա��Ρ�ͼ8��ʾΪMg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�(0001)

���滬������þ�Ͻ������µ����Ա��Ρ�ͼ8��ʾΪMg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�(0001) ��Schmid���ӷֲ�ֱ��ͼ��ƽ��Schmid���ӷֱ�0.27��0.24��0.31��1Zn�Ͻ��е�Schmid������ͣ���������滬�����Լ��ͳ��3�ֺϽ�ѹ̬��Schmid������0.4~0.5�ķ������ֱ�Ϊ26.14%��21.44%��37.77%����һ��������1Zn�Ͻ𣬻��滬�����Լ����������ٽ��ͼ4��

��Schmid���ӷֲ�ֱ��ͼ��ƽ��Schmid���ӷֱ�0.27��0.24��0.31��1Zn�Ͻ��е�Schmid������ͣ���������滬�����Լ��ͳ��3�ֺϽ�ѹ̬��Schmid������0.4~0.5�ķ������ֱ�Ϊ26.14%��21.44%��37.77%����һ��������1Zn�Ͻ𣬻��滬�����Լ����������ٽ��ͼ4�� //ED�������(9.1%��27.0%��5.6%)��1Zn�Ͻ����غɷ���ֱ��������������࣬�����ֲ��������ѣ����ͺϽ�����ԡ�

//ED�������(9.1%��27.0%��5.6%)��1Zn�Ͻ����غɷ���ֱ��������������࣬�����ֲ��������ѣ����ͺϽ�����ԡ�

ͼ8 Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2)��ѹ̬�Ͻ�(0001) ��Schmid���ӷֲ�ֱ��ͼ

��Schmid���ӷֲ�ֱ��ͼ

Fig. 8 Schmid factor distribution histograms of (0001)  for Mg-7Gd-5Y-1Nd-xZn-0.5Zr (x=0, 1, 2) extruded alloys

for Mg-7Gd-5Y-1Nd-xZn-0.5Zr (x=0, 1, 2) extruded alloys

3 ����

1) ��Mg-7Gd-5Y-1Nd-0.5Zr������ZnԪ�أ��������γ�LPSO�ṹ��Ҳ�ٽ���Mg5(RE, Zn)������������LPSO�ṹ����������ò��Mg5(RE, Zn)�����Ĵ�С���ֲ���Zn�����йء�1Zn�Ͻ��й۲쵽Ƭ��״LPSO�ṹ�����ȵ�LPSO�ṹ�����飻2Zn�Ͻ����ܹ۲쵽3�ֲ�ͬ��ò��LPSO�ṹ����������״��LPSO�ṹ��Ƭ��״LPSO�ṹ�����ȵ�LPSO�ṹ�����顣1Zn�Ͻ����ؼ�ѹ����ֲ��������ߴ��Mg5(RE, Zn)��������Ҫ�ֲ��ھ����ϣ�2Zn�Ͻ���������Mg5(RE, Zn)�������ȷֲ��ھ��ں;��紦���ߴ��1Zn��Mg5(RE, Zn)����С1~2����������

2) 3�ּ�ѹ̬�Ͻ�ľ����ߴ�����Zn���������Ӷ���С��DRX����Zn���������Ӷ����ͣ�0Zn��1Zn�Ͻ��Ϊ //ED֯����2Zn�Ͻ�Ϊ

//ED֯����2Zn�Ͻ�Ϊ //ED֯����

//ED֯���� //ED���֯������֯������������DRX����Ϊ

//ED���֯������֯������������DRX����Ϊ //ED֯�������δ���Ϊ

//ED֯�������δ���Ϊ //ED֯����

//ED֯����

3) 2Zn�Ͻ��������ŵ���ѧ���ܣ��俹��ǿ�ȡ�����ǿ�Ⱥ��쳤�ʷֱ�Ϊ365 MPa��276 MPa��17.5%����Ҫ�����ھ���ϸ���ľ���ǿ�����ã�LPSO�ṹ������Mg5(RE, Zn)�ࡢZn-Zr��ĵڶ���ǿ�������붯̬�ٽᾧ�����ͱ��ξ��������˫ģ�ṹ��

REFERENCES

[1] �����, ����ʨ, ���Ľ�. þ�Ͻ��ں��պ��������о�Ӧ����״��չ��[J]. ���˺���, 2016, 22(3): 281-292.

WU Guo-hua, CHEN Yu-shi, DING Wen-jiang. Current research, application and future prospect of magnesium alloys in aerospace industry[J]. Manned Spaceflight, 2016, 22(3): 281-292.

[2] ������, ������, ���Ľ�. ��������������:��/þ�Ͻ�����ͼ�����չ��̬[J]. �й����̿�ѧ, 2018, 20(1): 84-90.

FU Peng-huai, PENG Li-ming, DING Wen-jiang. Automobile lightweight technology: Development trends of aluminum/magnesium alloys and their forming technologies[J]. Strategic Study of CAE, 2018, 20(01): 84-90.

[3] Ԭ ��, ������. Mg�Ͻ���������ҵ�е�Ӧ�ý�չ[J]. ���켼��, 2017(12): 2799-2804.

YUAN Jie, GUO Bao-hui. Research advances of magnesium alloys in automobile applications[J]. Foundry Technology, 2017(12): 2799-2804.

[4] �� ��, �ź���, ����ƽ. þ�Ͻ���3C��Ʒ��Ӧ����״��ǰ��չ��[J]. �����豸�о�, 2005(6): 46-49.

YANG Cheng, DU Hong-xing, LIU Xiao-ping. Application and developing tendency of magnesium alloys in 3C products[J]. Foundry Equipment and Technology, 2005(6): 46-49.

[5] NIE J F. Precipitation and hardening in magnesium alloys[J]. Metallurgical and Materials Transactions A, 2012, 43(11): 3891-3939.

[6] ��С��, ʷ��ӱ. ϡ��þ�Ͻ�ǿ��������뿪��[J]. ���ղ���ѧ��, 2017, 37(1): 18-25.

ZENG Xiao-qin, SHI Xiao-ying. Strengthening and toughening design and development of Mg-rare earth alloys[J]. Journal of Aeronautical Materials,2017, 37(1): 18-25.

[7] JUNG I H, SANJARI M, KIM J, et al. Role of RE in the deformation and recrystallization of Mg alloy and a new alloy design concept for Mg-RE alloys[J]. Scripta Materialia, 2015, 102: 1-6.

[8] ZHANG Jing-huai, LIU Shu-juan, WU Rui-zhi, et al. Recent developments in high-strength Mg-RE-based alloys: Focusing on Mg-Gd and Mg-Y systems[J]. Journal of Magnesium and Alloys, 2018, 6(3): 277-291.

[9] ������, �� ��, �� ��, ��. Mg-Gd-Y-Zr��ǿ����þ�Ͻ���о���չ[J]. �й���ɫ����ѧ��, 2011, 21(11): 2709-2718.

WU Wen-xiang, JIN Li, DONG Jie, et al. Research progress of high strength and heat resistant Mg-Gd-Y-Zr alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(11): 2709-2718.

[10] PENG Q M, WU Y M, FANG D Q, et al. Microstructures and properties of Mg-7Gd alloy containing Y[J]. Journal of Alloys and Compounds, 2007, 430(1): 252-256.

[11] ������, ��С��. ��ǿ�ܻ�þϡ���Ͻ���о���չ[J]. ���ղ���ѧ��, 2018, 38(4): 4-13.

LI Yang-xin, ZENG Xiao-qin. A review on Mg-RE alloys with high product of strength and elongation[J]. Journal of Aeronautical Materials, 2018, 38(4): 4-13.

[12] HONMA T, OHKUBO T, KAMADO S, et al. Effect of Zn additions on the age-hardening of Mg-2.0Gd-1.2Y-0.2Zr alloys[J]. Acta Materialia, 2007, 55(12): 4137-4150.

[13] XU D, HAN E, XU Y. Effect of long-period stacking ordered phase on microstructure, mechanical property and corrosion resistance of Mg alloys: A review[J]. Progress in Natural Science: Materials International, 2016, 26(2): 117-128.

[14] �� ��, ëƼ��, �� ��, ��. ����������Ѷ���(LPSO)���о���״����þ�Ͻ��е�����[J]. ���ϵ���, 2019, 33(4): 1182-1189.

LI Xiang, MAO Ping-li, WANG Feng, et al. A literature review on study of long-period stacking ordered phase and its effect on magnesium alloys[J]. Materials Review, 2019, 33(4): 1182-1189.

[15] WANG Ya-fei, ZHANG Fan, WANG Yu-tian, et al. Effect of Zn content on the microstructure and mechanical properties of Mg-Gd-Y-Zr alloys[J]. Materials Science and Engineering A, 2019, 745: 149-158.

[16] ZHOU Xiao-jie, LIU Chu-ming, GAO Yong-hao, et al. Microstructure and mechanical properties of extruded Mg-Gd-Y-Zn-Zr alloys filled with intragranular LPSO phases[J]. Materials Characterization, 2018, 135: 76-83.

[17] WU X, PAN F, CHENG R. Formation of long period stacking ordered phases in Mg-10Gd-1Zn-0.5Zr (wt.%) alloy[J]. Materials Characterization, 2019, 147: 50-56.

[18] ONO A, ABE E, ITOI T, et al. Microstructure evolutions of rapidly- solidified and conventionally-cast Mg97Zn1Y2 alloys[J]. Materials Transactions, 2008, 49(5): 990-994.

[19] ZHU Y M, MORTON A J, NIE J F. The 18R and 14H long-period stacking ordered structures in Mg-Y-Zn alloys[J]. Acta Materialia, 2010, 58(8): 2936-2947.

[20] CHEN Tao, CHEN Zhi-yong, SHAO Jian-bo, et al. Evolution of LPSO phases in a Mg-Zn-Y-Gd-Zr alloy during semi-continuous casting, homogenization and hot extrusion[J]. Materials & Design, 2018, 152: 1-9.

[21] CHEN Tao, CHEN Zhi-yong, SHAO Jian-bo, et al. The role of long-period stacking ordered phases in the deformation behavior of a strong textured Mg-Zn-Gd-Y-Zr alloy sheet processed by hot extrusion[J]. Materials Science and Engineering A, 2019, 750: 31-39.

[22] WU Xia, PAN Fu-sheng, CHENG Ren-ju, et al. Effect of morphology of long period stacking ordered phase on mechanical properties of Mg-10Gd-1Zn-0.5Zr magnesium alloy[J]. Materials Science and Engineering A, 2018, 726: 64-68.

[23] XU Chao, NAKATA T, QIAO Xiao-guang, et al. Effect of LPSO and SFs on microstructure evolution and mechanical properties of Mg-Gd-Y-Zn-Zr alloy[J]. Scientific reports, 2017, 7: 40846.

[24] KIM J K, KO W S, SANDL�OBES S, et al. The role of metastable LPSO building block clusters in phase transformations of an Mg-Y-Zn alloy[J]. Acta Materialia, 2016, 112: 171-183.

[25] LI M, WANG X, FENG Q Y, et al. The effect of morphology of the long-period stacking ordered phase on mechanical properties of the Mg-7Gd-3Y-1Nd-1Zn-0.5Zr (wt.%) alloy[J]. Materials Characterization, 2017, 125: 123-133.

[26] ʯ�鼪, ������, �� ��, ��. Nd������Mg-6Gd-2.5Y-0.5Zr�Ͻ�����֯����ѧ���ܵ�Ӱ��[J]. �й���ɫ����ѧ��, 2017, 27(9): 1785-1793.

SHI Hong-ji, DENG Yun-lai, ZHANG Kai, et al. Effects of Nd addition on microstructure and mechanical properties of Mg-6Gd-2.5Y-0.5Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1785-1793.

[27] YU Zi-jian, XU Chao, MENG Jian, et al. Microstructure evolution and mechanical properties of as-extruded Mg-Gd-Y-Zr alloy with Zn and Nd additions[J]. Materials Science & Engineering A, 2018, 713: 234-243.

[28] �� ΰ. Mg-Gd-Y-Znϵ�Ͻ�ʱЧ������Ϊ���о�[D]. ����: ������ɫ�����о���Ժ, 2019.

LIU Wei. Study on the precipitation behavior of Mg-Gd-Y-Zn based alloys during aging treatment[D]. Beijing: Beijing General Research Institute for Nonferrous Metals, 2019.

[29] ������, �� ��, ���˸�, ��. ��ѹ���ζ�Mg-5.0Y- 7.0Gd-1.3Nd-0.5Zr�Ͻ���֯�����ܵ�Ӱ��[J]. �й���ɫ����ѧ��, 2010, 20(9): 1692-1697.

LI Yong-jun, ZHANG Kui, LI Xing-gang, et al. Influence of extrusion on microstructures and mechanical properties of Mg-5.0Y-7.0Gd-1.3Nd-0.5Zr magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(9): 1692-1697.

[30] LI Ting, DU Zhi-wei, ZHANG Kui, et al. Characterisation of precipitates in a Mg-7Gd-5Y-1Nd-0.5Zr alloy aged to peak-ageing plateau[J]. Journal of Alloys and Compounds, 2013, 574: 174-180.

[31] LI Ting, ZHANG Kui, LI Xing-gang, et al. Dynamic precipitation during multi-axial forging of an Mg-7Gd-5Y-1Nd-0.5 Zr alloy[J]. Journal of Magnesium and Alloys, 2013, 1(1): 47-53.

[32] XU C, NAKATA T, FAN G H, et al. Microstructure and mechanical properties of extruded Mg-Gd-Y-Zn alloy with Mn or Zr addition[J]. Journal of Materials Science, 2019, 54(14): 10473-10488.

[33] ZHANG Jin-shan, ZHANG Wen-bo, BIAN Li-ping, et al. Study of Mg-Gd-Zn-Zr alloys with long period stacking ordered structures[J]. Materials Science and Engineering: A, 2013, 585: 268-276.

[34] BASU I, AI-AAMMAN T. Triggering rare earth texture modification in magnesium alloys by addition of zinc and zirconium[J]. Acta Materialia, 2014, 67: 116-133.

[35] GB/T 36165��2018. ����ƽ�������ȵIJⶨ���ӱ�ɢ������(EBSD)��[S].

GB/T 36165��2018. Determination of average grain size of metal electron backscatter diffraction (EBSD) method[S].

[36] XU C, NAKATA T, QIAO X G, et al. Ageing behavior of extruded Mg-8.2Gd-3.8Y-1.0Zn0.4Zr (wt.%) alloy containing LPSO phase and �á� precipitates[J]. Scientific Reports, 2017, 7: 43391.

[37] CHI Y Q, XU C, QIAO X G, et al. Effect of trace zinc on the microstructure and mechanical properties of extruded Mg-Gd-Y-Zr alloy[J]. Journal of Alloys and Compounds, 2019, 789: 416-427.

[38] ROBSON J D, TWIER A M, LORIMER G W, et al. Effect of extrusion conditions on microstructure, texture, and yield asymmetry in Mg-6Y-7Gd-0.5 wt% Zr alloy[J]. Materials Science and Engineering A, 2011, 528(24): 7247-7256.

[39] YU Zi-jian, XU Chao, MENG Jian, et al. Effects of extrusion ratio and temperature on the mechanical properties and microstructure of as-extruded Mg-Gd-Y-(Nd/Zn)-Zr alloys[J]. Materials Science and Engineering A, 2019, 762: 138080.

Microstructures and mechanical properties of extruded Mg-7Gd-5Y-1Nd-xZn-0.5Zr (x=0, 1, 2) alloys

PENG Yong-gang1, 2, 3, 4, DU Zhi-wei1, 2, 3, 4, LI Yong-jun5, LI-Ting1, 2, 3, 4, HAN Xiao-lei1, 2, 4, MA Ming-long5, PANG Zheng1, 2, 3, 4, XU Yun-pei1, 2, 4, LI Cong1, 2, 4, YUAN Jia-wei5, SHI Guo-liang5

1. National Center of Analysis and Testing for Nonferrous Metals and Electronic Materials, GRINM Group Co., Ltd., Beijing 100088, China;

2. China United Test and Certification Co., Ltd., Beijing 101407, China;

3. Beijing General Research Institute for Nonferrous Metals, Beijing 100088, China;

4. Guobiao (Beijing) Testing and Certification Co., Ltd., Beijing 101407, China;

5. State Key Laboratory of Nonferrous Metals and Processes, GRIMAT Engineering Institute Co., Ltd., Beijing 101407

Abstract: The microstructure and mechanical properties of extruded Mg-7Gd-5Y-1Nd-xZn-0.5Zr (x=0, 1, 2, mass fraction, %) alloys were investigated by scanning electron microscope(SEM), transmission electron backscattered diffraction(EBSD) and high-angle annular dark-field scanning transmission electron microscopy(HAADF-STEM). The addition of Zn element can form long period stacking ordered (LPSO) structures, promote the precipitation of Mg5(RE, Zn) phases and form Zn-Zr compounds with Zr element. LPSO structures can not only restrict grain growth, refines grain, but also prevent dynamic recrystallization, resulting in dynamic recrystallization grains and deformable grains coexisted, the DRX grains with a  //ED texture, and the deformed grains with

//ED texture, and the deformed grains with  //ED texture. The large size micron-scale Mg5(RE, Zn) particles can reduce the toughness and plasticity of the alloy, the uniformly distributed submicron-scale Mg5(RE, Zn) particles play the role of second phase strengthening and can nail grain boundaries, and hinder grain growth. For three extruded alloys, the Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy obtains the optimal mechanical properties, the tensile strength, yield strength and elongation are 365 MPa, 276 MPa and 17.5%, respectively.

//ED texture. The large size micron-scale Mg5(RE, Zn) particles can reduce the toughness and plasticity of the alloy, the uniformly distributed submicron-scale Mg5(RE, Zn) particles play the role of second phase strengthening and can nail grain boundaries, and hinder grain growth. For three extruded alloys, the Mg-7Gd-5Y-1Nd-2Zn-0.5Zr alloy obtains the optimal mechanical properties, the tensile strength, yield strength and elongation are 365 MPa, 276 MPa and 17.5%, respectively.

Key words: magnesium alloys; extrusion; long-period stacking ordered (LPSO) structures; HAADF-STEM; mechanical properties

Foundation item: Project(51871195) supported by the National Natural Science Foundation of China

Received date: 2020-02-25; Accepted date: 2020-10-08

Corresponding author: DU Zhi-wei; Tel: +86-10-82241349-8009; E-mail: duzhiwei@gbtcgroup.com

LI Yong-jun; Tel: +86-13601076520; E-mail: liyongjun8158@163.com

(�༭ ����)

������Ŀ��������Ȼ��ѧ����������Ŀ(51871195)

�ո����ڣ�2020-02-25�������ڣ�2020-10-08

ͨ�����ߣ���־ΰ�����ڼ�������ʦ����ʿ���绰��010-82241349-8009��E-mail��duzhiwei@gbtcgroup.com

�����������ڼ�������ʦ����ʿ���绰��13601076520��E-mial��liyongjun8158@163.com

ժ Ҫ������ɨ��������������ӱ�ɢ�����䡢������������߽ǶȻ��ΰ���-ɨ���䣬������Mg-7Gd-5Y-1Nd-xZn-0.5Zr(x=0, 1, 2, ����������%)��ѹ̬�Ͻ�����֯�ṹ����ѧ���ܣ�ּ��̽��Zn���ںϽ�����Ӱ����ۻ��ơ������������Mg-7Gd-5Y-1Nd-0.5Zr�Ͻ�������ZnԪ�أ������γ�LPSO�ṹ��Ҳ�ٽ���Mg5(RE, Zn)����������������Zr�γ�Zn-Zr�ࡣLPSO�ṹ�������谭��������ϸ��������Ҳ�ܹ��谭��̬�ٽᾧ���Ӷ��γɶ�̬�ٽᾧ�����ͱ��ξ��������˫ģ�ṹ����̬�ٽᾧ����Ϊ //ED֯�������ξ���Ϊ

//ED֯�������ξ���Ϊ //ED֯��������ߴ�Mg5(RE, Zn)�����ᵼ��Ӧ�����У��������Ƶ����������ͺϽ�����ԣ����ȷֲ�������Mg5(RE, Zn)������ڶ���ǿ�����ã����ܶ������磬�谭�������Ա�3�ּ�ѹ̬�Ͻ�Mg-7Gd-5Y-1Nd-2Zn-0.5Zr�Ͻ��������ŵ���ѧ���ܣ��俹��ǿ�ȡ�����ǿ�Ⱥ��쳤�ʷֱ�Ϊ365 MPa��276 MPa��17.5%��

//ED֯��������ߴ�Mg5(RE, Zn)�����ᵼ��Ӧ�����У��������Ƶ����������ͺϽ�����ԣ����ȷֲ�������Mg5(RE, Zn)������ڶ���ǿ�����ã����ܶ������磬�谭�������Ա�3�ּ�ѹ̬�Ͻ�Mg-7Gd-5Y-1Nd-2Zn-0.5Zr�Ͻ��������ŵ���ѧ���ܣ��俹��ǿ�ȡ�����ǿ�Ⱥ��쳤�ʷֱ�Ϊ365 MPa��276 MPa��17.5%��

[1] �����, ����ʨ, ���Ľ�. þ�Ͻ��ں��պ��������о�Ӧ����״��չ��[J]. ���˺���, 2016, 22(3): 281-292.

[2] ������, ������, ���Ľ�. ��������������:��/þ�Ͻ�����ͼ�����չ��̬[J]. �й����̿�ѧ, 2018, 20(1): 84-90.

[3] Ԭ ��, ������. Mg�Ͻ���������ҵ�е�Ӧ�ý�չ[J]. ���켼��, 2017(12): 2799-2804.

[4] �� ��, �ź���, ����ƽ. þ�Ͻ���3C��Ʒ��Ӧ����״��ǰ��չ��[J]. �����豸�о�, 2005(6): 46-49.

[6] ��С��, ʷ��ӱ. ϡ��þ�Ͻ�ǿ��������뿪��[J]. ���ղ���ѧ��, 2017, 37(1): 18-25.

[11] ������, ��С��. ��ǿ�ܻ�þϡ���Ͻ���о���չ[J]. ���ղ���ѧ��, 2018, 38(4): 4-13.

[28] �� ΰ. Mg-Gd-Y-Znϵ�Ͻ�ʱЧ������Ϊ���о�[D]. ����: ������ɫ�����о���Ժ, 2019.

[35] GB/T 36165��2018. ����ƽ�������ȵIJⶨ���ӱ�ɢ������(EBSD)��[S].