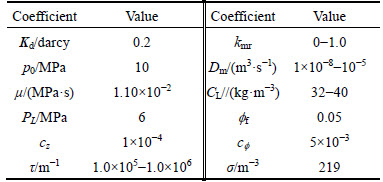

J. Cent. South Univ. (2016) 23: 3322-3331

DOI: 10.1007/s11771-016-3398-0

Investigation of Barree-Conway non-Darcy flow effects on coalbed methane production

YANG Lei(杨蕾)1, 2, RUI Hong-xing(芮洪兴)2, ZHAO Qing-li(赵庆利)3

1. College of Science, China University of Petroleum, Qingdao 266580, China;

2. School of Mathematics, Shandong University, Ji’nan 250100, China;

3. School of Science, Shandong Jianzhu University, Ji’nan 250101, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Central South University Press and Springer-Verlag Berlin Heidelberg 2016

Abstract:

Coalbed gas non-Darcy flow has been observed in high permeable fracture systems, and some mathematical and numerical models have been proposed to study the effects of non-Darcy flow using Forchheimer non-Darcy model. However, experimental results show that the assumption of a constant Forchheimer factor may cause some limitations in using Forchheimer model to describe non-Darcy flow in porous media. In order to investigate the effects of non-Darcy flow on coalbed methane production, this work presents a more general coalbed gas non-Darcy flow model according to Barree-Conway equation, which could describe the entire range of relationships between flow velocity and pressure gradient from low to high flow velocity. An expanded mixed finite element method is introduced to solve the coalbed gas non-Darcy flow model, in which the gas pressure and velocity can be approximated simultaneously. Error estimate results indicate that pressure and velocity could achieve first-order convergence rate. Non-Darcy simulation results indicate that the non-Darcy effect is significant in the zone near the wellbore, and with the distance from the wellbore increasing, the non-Darcy effect becomes weak gradually. From simulation results, we have also found that the non-Darcy effect is more significant at a lower bottom-hole pressure, and the gas production from non-Darcy flow is lower than the production from Darcy flow under the same permeable condition.

Key words:

1 Introduction

Coalbed methane (CBM) reservoirs are dual porosity systems, which consist of coal matrix and fracture network [1]. Most of coalbed gas is stored in the coal matrix as adsorbed gas, and only a small amount is stored in fracture systems as free gas. Usually, fracture systems are considered as the gas flow passage and the coal matrix is treated the source for fracture systems [2-7]. The gas transport in the dual porosity coal seam is governed by different flow mechanisms: gas diffusion process in the coal matrix is governed by Fick’s law, while gas seepage flow in fracture systems is usually described by Darcy’s law. Based on the above understandings about coalbed gas flow mechanism, a series of conventional mathematical and numerical models [8-11] have been developed, obtaining some useful computational and simulation results.

However, in recent years, the non-Darcy behaviors of coalbed gas flow have been observed in high permeable fracture systems such as the zones near the wellbore [12-13], which affects the coalbed gas extraction significantly. In 1901, according to the non-Darcy experiment data, FORCHHEIMER expanded Darcy’s linear form into a quadratic flow equation named as Forchheimer’s equation, which has been widely used in analyzing non-Darcy flow problem. For the past decades, the study about non-Darcy flow problem in porous media has been a research hotspot. Some application studies about non-Darcy flow have been carried out to study the effects of non-Darcy flow using Forchheimer model, and have obtained some useful computational and practical results. CLARKSON et al [14] conducted the production-data analysis for a single- phase coalbed gas well with Forchheimer non-Darcy flow, and found that the gas production rates were different at the early time and the later time. ZENG and ZHAO [15] studied the effects of Forchheimer non-Darcy flow on a coal seam gas well production at different bottom-hole pressures, and found that the non-Darcy flow results in a smaller production rate, a larger decline rate in the boundary-dominated period. WANG et al [12] developed a fully coupled finite element model to quantify the Forchheimer non-Darcy flow effects, and found that the non-Darcy effect is significant for high pressure drops and exists only within a small region near wellbore. In addition, some other studies about numerical method and numerical analysis for the Forchheimer non-Darcy model have also been carried out. GIRAULT and WHEELER [16] proposed a mixed finite element method for the Forchheimer problem using Crouzeix-Raviart element. RUI and PAN [17] considered a block-centered finite difference method for the Forchheimer model and second-order error estimates for both pressure and velocity were established.

Although the above studies about non-Darcy flow are mostly based on the Forchheimer model, we still need to point out that due to the assumption of a constant permeability, the Forchheimer model has some limitations in describing the non-Darcy flow in porous media. In 2004, BARREE and CONWAY [18] proposed a new non-Darcy flow model, which does not rely on the assumption of a constant Forchheimer factor β and could describe the entire range of relationships between flow velocity and pressure gradient from low to high flow velocity through porous media, including those in transitional zones. Therefore, the Barree-Conway non-Darcy model has attracted more and more attention in recent years. In 2007, through a series of intensive experiments, LOPEZ [19] verified the advantages of Barree-Conway model in describing relationships between flow rate and potential gradient, especially in transitional zones. WU et al [20] presented a general numerical model for incorporating the Barree-Conway model to simulate multiphase, multidimensional non-Darcy flow in porous media. Nevertheless, until now, we have not found any paper adopting Barree-Conway model to study the non-Darcy flow effects in coalbed gas production. Also, there is no paper conducting numerical analysis for the Barree-Conway non-Darcy flow problem.

The objective of this work is to investigate the effects of non-Darcy flow on coalbed gas well production performance, in which the non-Darcy flow is described by using the Barree-Conway model. For this purpose, an expanded mixed element approximation method is introduced to solve the coalbed gas Barree- Conway non-Darcy flow model, in which the gas pressure and velocity can be solved simultaneously, and error estimates for both pressure and velocity are established. A series of simulation scenarios were conducted to illustrate the non-Darcy flow characteristic with different non-Darcy parameters, e.g. minimum permeability ratio kmr, characteristic length τ, diffusion coefficient Dm, etc. Furthermore, the effects of non-Darcy flow on the performance of coalbed gas well are investigated by incorporating the Barree-Conway model in non-Darcy flow simulation.

2 Coalbed gas non-Darcy flow model

In this section, considering desorption-diffusion- seepage behaviors of coalbed gas in CBM reservoirs, we derive a coalbed gas non-Darcy flow model based on the Barree-Conway equation.

2.1 Basic assumptions

1) CBM reservoirs are treated as dual porosity systems consisting of coal matrix and fracture network.

2) CBM reservoirs are isothermal and the gas viscosity is constant under isothermal conditions.

3) Gas non-Darcy flow in fracture systems is described by the Barree-Conway model.

4) Gas diffusion process in the coal matrix is pseudo-static and described by the Fick’s first diffusion law.

5) Gas absorption/adsorption is described by Langmuir adsorption isotherm.

2.2 Gas state descriptions

The equation of real gas state is

(1)

(1)

where p is the gas pressure; V is the gas volume; n is the amount of substance; T is the gas temperature; m is the gas mass; M is the gas molar mass; Z is the gas deviation factor; and R is the ideal gas constant. From Eq. (1), the gas density ρ can be written as

(2)

(2)

From Langmuir isotherm formula and the state equation of real gas, the adsorbed gas concentration Cm in coal matrix and free gas concentration Cf in fracture systems can be written respectively as

(3)

(3)

where pm is the gas pressure in coal matrix; CL is the maximum adsorption concentration of the coal matrix; pL is the Langmuir pressure; pf is the gas pressure in fracture systems, and ff is the porosity of fracture systems.

2.3 Barree-Conway non-Darcy flow equation

The Barree-Conway model was proposed by BARREE and CONWAY in 2004, in which the Darcy’s law is still assumed to apply, but a apparent permeability Ka is introduced instead of conventional constant Darcy permeability Kd. The apparent permeability Ka is defined as

(4)

(4)

where kmr is the minimum permeability ratio in high rate (0≤kmr≤1); τ is the characteristic length; u is the gas flow velocity; μ is the gas viscosity and ρ is the gas density.

Substituting the apparent permeability Ka into Darcy’ law, the Barree-Conway model can be expressed as

(5)

(5)

When kmr=0, the Barree-Conway model Eq. (5) is just the Forchheimer model. And when kmr=1, the Barree-Conway model Eq. (5) is the Darcy model. We consider the case that the Darcy permeability tensor Kd is a diagonal matrix and the permeability is isotropic, k=kx= ky, for the two-dimensional problem. Then, from Eq. (5) we have

(6)

(6)

Solving the quadratic Eq. (6) and dropping the negative term, the gas flow velocity u can be written as

(7)

(7)

2.4 Continuity equation of gas flow in fracture systems

Then, according to the mass conservation law, the continuity equation of gas flow in fracture systems is

(8)

(8)

where qm is the gas volume of interporosity flow from the coal matrix to fracture systems. Combining with the state equation of real gas Eq. (1) and unfolding the two terms on the left-hand side of Eq. (8), the continuity equation of gas flow in fracture systems can rewritten as

(9)

(9)

where cf is the compressibility factor of ff and cz is the compressibility factor of Z, defined as

(10)

(10)

2.5 Gas diffusion equation in coal matrix

According to the Fick’s first diffusion law, the pseudo-steady state equation of gas diffusion in the coal matrix can be written as

(11)

(11)

where Cam is the average concentration of a coal matrix block; CE(pf) is the adsorbent concentration of the matrix block surface and defined as  τd is the diffusion time in a coal matrix block. Usually, the diffusion time τd can be expressed as

τd is the diffusion time in a coal matrix block. Usually, the diffusion time τd can be expressed as

(12)

(12)

where Dm is the gas diffusion coefficient in the coal matrix block, and σ is the geometrical factor.

Combining Eqs. (7), (9) and (11), we have the coalbed gas non-Darcy flow model as follows:

(13)

(13)

where Ω is the objective region for the two-dimensional problem with boundary  Ω, and [0,T] is a time interval with T∈(0,∞].

Ω, and [0,T] is a time interval with T∈(0,∞].

3 Expanded mixed element numerical method

In this section, we will present an expanded mixed element numerical method for the coalbed gas Barree-Conway non-Darcy flow model.

3.1 Some notations

For the convenience of subsequent analysis, we first give some notations. Define the inner product on Ω and its norm:

(14)

(14)

Define function spaces:

(15)

(15)

(16)

(16)

Let Wh×Λh ×Vh W×Λ×V be the mixed finite element function spaces such as RTk with index k and discretization parameter h.

W×Λ×V be the mixed finite element function spaces such as RTk with index k and discretization parameter h.

3.2 Numerical scheme for non-Darcy flow in fracture system

We introduce an auxiliary variable, defined by  Thus, coalbed gas non-Darcy flow in fracture system can be described as

Thus, coalbed gas non-Darcy flow in fracture system can be described as

(17)

(17)

Let △t>0, N=T/△t, an integer, and tn=n△t, n=0, 1, …, N. Also let pn≡p(x, tn) for any p defined on  . We define the full discrete expanded mixed element numerical scheme with backward Euler time-discretization, which is to find

. We define the full discrete expanded mixed element numerical scheme with backward Euler time-discretization, which is to find  Wh× Λh×Vh such that

Wh× Λh×Vh such that

(18)

(18)

3.3 Matrix form of numerical scheme and iterative algorithm

Let τh be a quasi-regular triangulation for the two- dimensional rectangular region Ω with mesh size h. For a triangular element T(A1A2A3), let xi=(xi, yi) be the coordinate of vertex Ai and γi be the edge opposite to vertex Ai. Let ni be the outward unit vector on the edge γi and hi be the length of the perpendicular dropped from the vertex Ai onto the edge γi, i = 1, 2, 3. We denote by Fh the set of all edges of the triangulation τh.

The scalar function space Wh is the space of piecewise constant functions:

(19)

(19)

The dimension of the space Wh is equal to m1, the total number of elements Tk in the triangulation τh. ψk(x) is the basis function of Wh associated with the element Tk.

The vector function spaces Vh and Λh are chosen to be the RT0(Ω, τh), defined as

(20)

(20)

and the dimension of vector function space is equal to m2, the total number of edges γi∈Fh. fi is the basis function of vector function space associated with the edge γi∈Fh.

Now, we use the basis functions ψk(x) (k=1, …, m1) and fj(x) (j=1, …, m2) to represent  and

and

(21)

(21)

Substituting Eq. (21) into Eq. (18), and setting ωh= ψk(x) (k=1, …, m1), vh =fj(x) (j=1, …, m2) and πh=fj(x) (j=1, …, m2), we introduce matrices and vectors as follows:

(22)

(22)

where

(23)

(23)

Therefore, Eq. (18) can be written in matrix form as follows:

(24)

(24)

Since gas diffusion Eq. (11) is an ordinary differential equation, when  is known, we can get Cam(tn) as follows:

is known, we can get Cam(tn) as follows:

(25)

(25)

Then, the gas volume of interporosity flow from coal matrix to fracture systems could be calculated as follows:

(26)

(26)

In practical calculation, alternative and iterative method is used to solve Eqs. (24)-(26), and specific calculation procedure is listed as follows:

1) For n=1, 2, …, N, when  is known, qm(

is known, qm( ) can be calculated using Eq. (26).

) can be calculated using Eq. (26).

2) Then, substituting into Eq. (24),

into Eq. (24), can be obtained by solving Eq. (24).

can be obtained by solving Eq. (24).

3) Lastly, when  is known, Cam(tn) can be calculated using Eq. (25).

is known, Cam(tn) can be calculated using Eq. (25).

4 Simulation results and evaluation of non- Darcy effects

In this section, we carry out numerical simulation by using the lowest order Raviart-Thomas mixed finite elements RT0 for the coalbed gas non-Darcy flow problem.

4.1 Error and convergence analysis

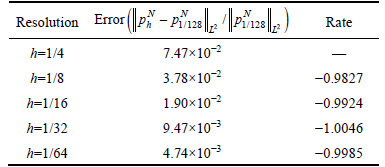

In order to verify the convergence, the test region is selected as unit square, i.e., Ω=[0, 1]×[0, 1], and 6 levels for uniform mesh size h=1/4,1/8,1/16,1/32,1/64,1/128 are computed to estimate the convergence rate. Since we can not get the analytical solution pf, u and λ for problem Eq. (13), we use

and

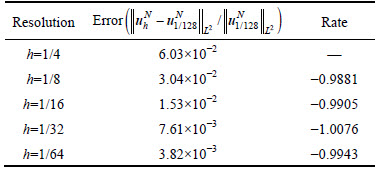

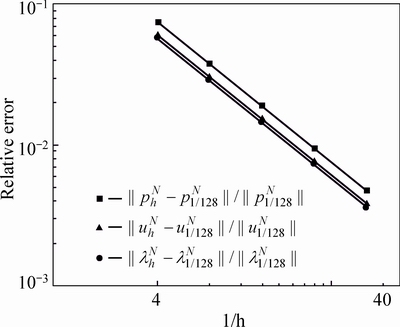

and  as the criterion of convergence for the numerical solutions ph, uh and λh. The relative error and convergence rate estimates for ph, uh and λh are listed in Table 1, Table 2 and Table 3, respectively. We can find that the numerical solutions ph, uh and λh could achieve first-order convergence rate (see Fig. 1).

as the criterion of convergence for the numerical solutions ph, uh and λh. The relative error and convergence rate estimates for ph, uh and λh are listed in Table 1, Table 2 and Table 3, respectively. We can find that the numerical solutions ph, uh and λh could achieve first-order convergence rate (see Fig. 1).

4.2 Non-Darcy dynamic characteristics of coalbed gas flow

For a simple application, the scale of objective region Ω is 200 m×200 m, and the mesh size h=10 m.

Table 1 Relative errors and convergence rates for ph

Table 2 Relative errors and convergence rates for uh

Table 3 Relative errors and convergence rates for λh

Fig. 1 Convergence rates for  ,

,  and

and

There is a production well at the center of region Ω with constant bottom-hole pressure pw. Simulation parameters are listed in Table 4.

Substituting the parameter value into calculation procedure, we can get the numerical solution, so as to analyze the dynamic characteristic of coalbed gas non-Darcy flow in CBM reservoirs.

Table 4 Parameters for simulation

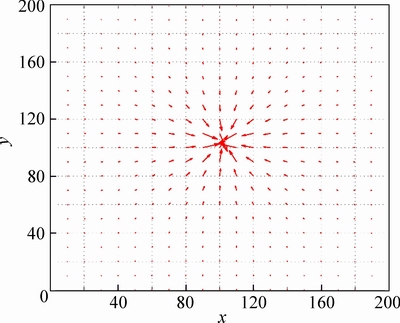

4.2.1 Distribution characteristic of non-Darcy effects

From the description of non-Darcy flow phenomenon, we know that non-Darcy effect is dependent on the gas flow velocity. Figure 2 presents a typical velocity distribution of gas flow at the stable stage (t=104 h). In Fig. 2, we have found that the coalbed gas flows toward production well, and flow velocity is much higher in the zone near the wellbore than the zone faraway from wellbore. Therefore, we could give a possible conclusion that the non-Darcy effect may be more significant in the zone near the wellbore than the zone faraway from wellbore.

Fig. 2 Gas flow velocity distribution in CBM reservoirs

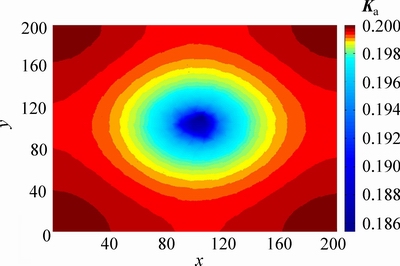

In order to further illustrate the distribution characteristic of non-Darcy effect, Fig. 3 presents the distribution of apparent permeability Ka in the Barree-Conway non-Darcy model. From the definition of apparent permeability Ka, we know that Ka is dependent on the properties of porous media and pore fluid including permeability, characteristic length, viscosity, density and flow velocity, and is a decreasing function of flow velocity. Therefore, Ka could reflect the effects of inertial flow resistance on the Darcy permeability Kd, and could be as an indicator for the non-Darcy effect. In Fig. 3, we have found that Ka increases gradually from 0.186 to 0.2 with the distance from the wellbore increasing, which again indicates that the non-Darcy effect is more significant in the zone near the wellbore than the zone faraway from wellbore. This also verifies that the Barree-Conway model has advantages in describing the non-Darcy flow characteristic in transitional zones, being capable of overcoming the limitation of constant permeability in Forchheimer model.

Fig. 3 Distribution characteristic of apparent permeability Ka

4.2.2 Non-Darcy pressure dynamic characteristics

In order to illustrate the decrement of reservoir driving energy during production process, Figs. 4 and 5 present the evolution of gas average pressure in fracture systems with time t, and show the effects of coal matrix adsorption capacity CL and bottom-hole pressure pw on average pressure, respectively. In Fig. 4, the model has the initial reservoir pressure of 10 MPa, and CL is taken as 32, 36 and 40 kg/m3, respectively, so as to analyze the effects of CL on average pressure in fracture systems. In Fig. 4, we have found that pressure drop curves could be divided into 3 stages: Firstly, at the initial stage, because the fracture systems could not get sufficient pressure compensation instantly from coal matrix or outer boundary, the pressure drop speed increases gradually such that the average pressure drops sharply from 10 MPa to about 9.9 MPa. Also, at this stage, the effect of CL is not evident and pressure drop curves with different CL are almost coincident. Secondly, at the transition stage, with the pressure compensation from the outer boundary and coal matrix increasing, the average pressure in fracture systems drop speed slows down and pressure drop curves become apart. Lastly, at the stable stage, pressure drop and pressure compensation gradually achieve a balance state, and average pressure in fracture systems tends to a constant value. From the definition of coal matrix adsorption capacity CL, we know that the coal matrix with larger CL could supply more gas compensation for fracture systems, such that fracture systems could maintain higher pressure. Therefore, at the stable stage, we have found that the larger the CL is, the higher the average pressure will be.

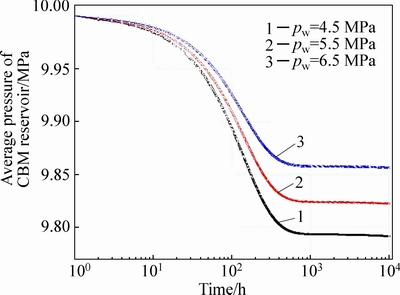

In Fig. 5, the bottom-hole pressure pw is set as 4.5, 5.5 and 6.5 MPa, respectively, so as to illustrate the effects of pw on average pressure in fracture systems. We have found that the effect of pw is not evident and pressure drop curves with different pw are almost coincident at early time. Then, at the later stage, in Fig. 5 we have found that the pressure drop curves become apart, and the difference of average pressure with different pw becomes wider. Also, the larger the pw is, the higher the average pressure will be.

Fig. 4 Gas average pressure of CBM reservoir with different CL values

Fig. 5 Gas average pressure of CBM reservoir with different pw values

4.2.3 Dynamic process of coalbed gas desorption

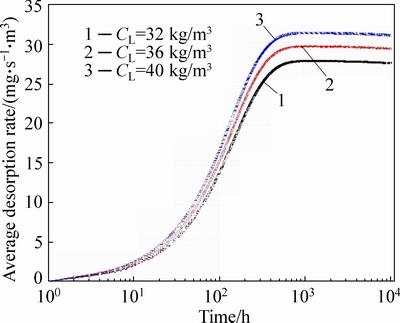

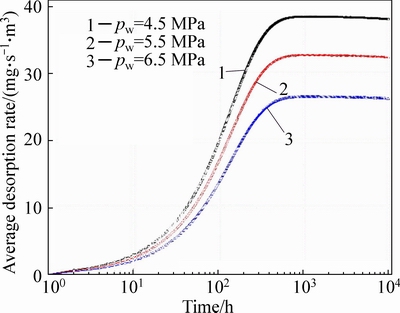

In Figs. 6 and 7, we show the evolution of gas average desorption rate with time t. In Fig. 6, the coal matrix adsorption capacity CL is also taken as 32, 36 and 40 kg/m3, respectively, so as to analyze the effects of CL on gas desorption process. According to equilibrium desorption model, we know that gas desorption rate is dependent on the coal matrix adsorption capacity CL, fracture pressure pf diffusion coefficient Dm. During gas desorption process, there are 2 stages. At the first stage, duo to quick drawdown of fracture pressure, gas concentration CE(pf) on matrix surface declines sharply, and then the gas desorption rate increases gradually to the maximum. Then, at the second stage, as the fracture pressure drop speed slows down and achieves a stable state, the desorption rate gradually declines and tends to a constant value at last. From the definition of coal matrix adsorption capacity, the value of CL directly determines the initial adsorbed gas concentration C0 in coal matrix. Therefore, in Fig. 6, we have also found that when CL is larger, gas desorption rate will be higher. Also, the effects of CL on desorption rate become more significant with time going on. In Fig. 7, the bottom-hole pressure pw is set as 4.5, 5.5 and 6.5 MPa, respectively, so as to illustrate the effects of pw on gas desorption rate. In Fig. 7, we have found that the variation of gas desorption rate is similar to the case in Fig. 6. We have also found that the higher the pw is, the lower the desorption rate will be.

Fig. 6 Gas desorption rate of coal matrix with different CL values

Fig. 7 Gas desorption rate of coal matrix with different pw values

4.3 Effects of non-Darcy on coalbed gas well production performance

In this section, through incorporating the Barree- Conway equation in non-Darcy flow simulation, we investigate the effects of non-Darcy flow on the performance of coalbed gas well, and analyze the sensitivity of non-Darcy parameters, e.g. minimum permeability ratio kmr, characteristic length τ, diffusion coefficient Dm, etc. Main simulation parameters are listed in Table 4.

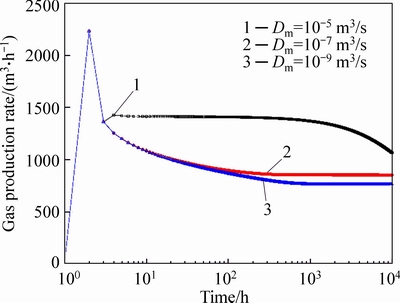

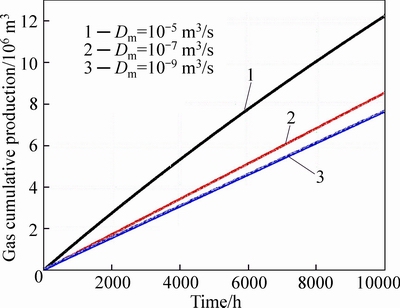

4.3.1 Non-Darcy effect with different diffusion coefficients Dm

In Fig. 8, the bottom-hole pressure pw is set as 6 MPa, and the diffusion coefficient Dm is taken as 10-5, 10-7 and 10-9 m3/s, respectively, so as to illustrate the effects of Dm on gas production rate. In Fig. 8, we have found that production rate increases sharply and achieves the peak rate (2236 m3/h) after starting production. Then, as the gas pressure decreases, the production rate also declines and tends to be a stable state at last. Also, after a sharp decreasing, due to the gas compensation from coal matrix, the production rate shows a modest recovery in the curve (Dm=10-5). In addition, due to the delay phenomenon of gas desorption, we have found that the effects of diffusion coefficient Dm on production rate are not evident at early time, and then the effects become more and more significant at later stage. Also, the larger the Dm, the higher the gas production rate. Figure 9 presents the gas cumulative production varying with time t, and shows the effects of diffusion coefficient. In Fig. 9, we have found that the effect of Dm on production is very evident, and becomes more and more significant with time going on. This illustrates that the CBM reservoirs with higher diffusion coefficient may supply more gas production.

Fig. 8 Gas production rate with different Dm values

Fig. 9 Gas cumulative production with different Dm values

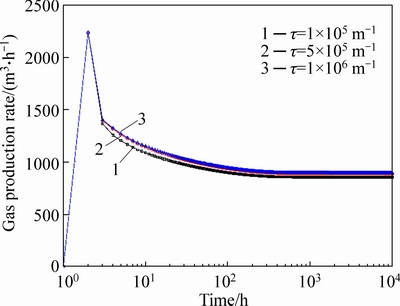

4.3.2 Non-Darcy effect with different characteristic lengths τ

In Figs. 10 and 11, characteristic length τ is taken as 1×105, 5×105 and 1×106 m-1, respectively. In Figs. 10 and 11, we have found that the curves with different τ are almost coincident at early time, and then with the time going on, the effects of τ on production rate and cumulative production become evident at the transitional stage. Nonetheless, at the stable stage, due to the smaller and smaller difference of velocity between Darcy flow and non-Darcy flow, non-Darcy effect becomes weak gradually. Also, we have found that the larger the τ is, the higher the production rate and cumulative production will be. In addition, according to the definition of Reynolds number Re=ρv/μτ, we know that when τ is increasing, the inertial flow resistance decreases and apparent permeability Ka increases, resulting in non-Darcy effect becoming weak. Therefore, from the above analysis, we can conclude that non-Darcy effect will cause the gas production declining. That is to say, under high flow velocity condition, if we do not consider the non-Darcy effect, we may overestimate the coalbed gas production.

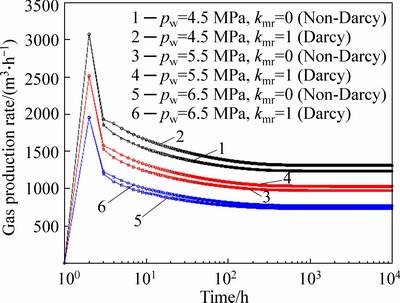

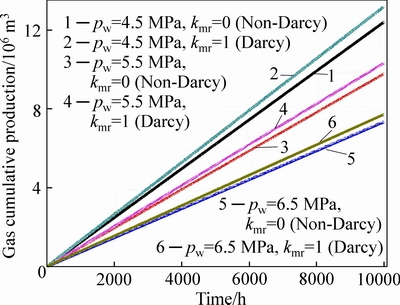

4.3.3 Non-Darcy effects at different bottom-hole pressures

In Figs. 12 and 13, we set the bottom-hole pressure pw as 4.5, 5.5 and 6.5 MPa, respectively, so as to illustrate the effects of non-Darcy on gas production at different bottom-hole pressure. In Fig. 12, we have found that the lower the bottom-hole pressure is, the higher the production rate will be. Also, with the bottom-hole pressure decreasing from 6.5 to 4.5 MPa, the peak production rate increases from 1956 to 3075 m3/h. In addition, comparing the production rates of Darcy (kmr= 1) flow and non-Darcy (kmr=0) flow, we have found that the effects of non-Darcy are not evident at early time, and with the time going on, the effects become significant at the transitional stage. Further, at the stable stage, the non-Darcy effect becomes weak gradually. Comparing the effects of non-Darcy at different bottom-hole pressures (pw=4.5, 5.5 and 6.5 MPa), it has been found that when pw is lower, the effects of non-Darcy on production rates will be more significant. The maximum differences between Darcy and non-Darcy production rates are 77 m3/h (at pw=4.5 MPa), 55 m3/h (at pw=5.5 MPa) and 36 m3/h (at pw=6.5 MPa), respectively.

Fig. 10 Gas production rate with different τ values

Fig. 11 Gas cumulative production with different τ values

Fig. 12 Effects of pw and kmr on gas production rate

Fig. 13 Effects of pw and kmr on gas cumulative production

Similarly, in Fig. 13, it has been found that the lower the bottom-hole pressure is, the higher the cumulative production will be. Also, with the time going on, effects of non-Darcy on cumulative production will become more and more significant. In addition, we have also found that when bottom-hole pressure is lower, the non-Darcy effects will be more evident. At different bottom-hole pressures (pw=4.5, 5.5 and 6.5 MPa), the difference of ultimate production (t=104 h) between Darcy and non-Darcy are 9.75×105 m3 (at pw=4.5MPa), 5.55×105 m3 (at pw=5.5 MPa) and 3.62×105 m3 (at pw= 6.5 MPa), respectively. This indicates that it is very necessary to consider the non-Darcy effects on coalbed gas production, especially at a lower bottom-hole pressure. Otherwise, the gas production may be overestimated under Darcy condition.

5 Conclusions

1) Through incorporating the Barree-Conway equation in coalbed gas flow problem, we present a more general coalbed gas non-Darcy flow model, in which both the desorption-diffusion-seepage behaviors of coalbed gas and effects of non-Darcy flow have been considered. Further, an expanded mixed element method is introduced to solve the Barree-Conway non-Darcy flow model.

2) Error estimate results indicate that the numerical solutions ph and uh could achieve first-order convergence rate. Non-Darcy simulation results have shown that the non-Darcy flow affects the dynamic characteristics of gas pressure, velocity and desorption rate, and the non-Darcy effects are more significant in the zone near wellbore. Simulation results also indicate that the non-Darcy effect affects the coalbed methane production rate and cumulative production, and the non-Darcy effect is more significant at a lower bottom-hole pressure. To be specific, the gas production from non-Darcy flow is lower than the production from Darcy flow under the same permeable condition, and the difference of production rates from both Darcy flow and non-Darcy flow becomes narrower due to their smaller and smaller difference of velocity, at stable stage.

References

[1] LU M, CONNELL LD. A dual-porosity model for gas reservoir flow incorporating adsorption behavior-part I. Theoretical development and asymptotic analyses [J]. Transp Porous Med, 2007, 68: 153-173.

[2] PILLALAMARRY M, HARPALANI S, LIU S. Gas diffusion behavior of coal and its impact on production from coalbed methane reservoirs [J]. Int J Coal Geol, 2011, 86: 342-348.

[3] CLARKSON C R, BUSTIN R M. Coalbed methane: current field-based evaluation methods [J]. SPE Reserv Eval Eng, 2011, 14: 60-75.

[4] RANJBAR E, HASSANZADEH H. Matrix-fracture transfer shape factor for modeling flow of a compressible fluid in dual-porosity media [J]. Adv Water Resour, 2011, 34: 627-639.

[5] AMINIAN K, AMERI S. Predicting production performance of CBM reservoirs [J]. J Nat Gas Sci Eng, 2009, 7: 25-30.

[6] ZHANG Yu-jun, YANG Chao-shuai. FEM analyses for influences of stress-chemical solution on THM coupling in dual-porosity rock mass [J]. Journal of Central South University, 2012, 19: 1138-1147.

[7] ZHANG Yu-jun, YANG Chao-shuai. Coupled thermo-hydro- mechanical-migratory model for dual-porosity medium and numerical analysis [J]. Journal of Central South University, 2011, 18: 1256-1262.

[8] YOUNG G B C. Computer modeling and simulation of coalbed methane resources [J]. Int J Coal Geol, 1998, 35: 369-379.

[9] UNSAL E, MATTHAI S K, BLUNT M J. Simulation of multiphase flow in fractured reservoirs using a fracture-only model with transfer functions [J]. Computat Geosci, 2010, 14: 527-538.

[10] THARAROOP P, KARPYN Z T, ERTEKIN T. Development of a coal shrinkage-swelling model accounting for water content in the micropores [J]. Int J Mining and Mineral Engineering, 2009, 1: 346-364.

[11] THARAROOP P, KARPYN Z T, ERTEKIN T. Development of a multi-mechanistic, dual-porosity, dual-permeability, numerical flow model for coalbed methane reservoirs [J]. J Nat Gas Sci Eng, 2012, 8: 121-131.

[12] WANG J G, KABIR A, LIU J S, CHEN Z W. Effects of non-Darcy flow on the performance of coal seam gas wells [J]. Int J Coal Geol, 2012, 93: 62-74.

[13] YE Z H, CHEN D, WANG J G. Evaluation of the non-Darcy effect in coalbed methane production [J]. Fuel, 2014, 121: 1-10.

[14] CLARKSON C R, BUSTIN R M, SEIDLE J P. Production-data analysis of single-phase (gas) coalbed-methane wells [J]. SPE Reserv Eval Eng, 2007, 10: 312-331.

[15] ZENG F, ZHAO G. The optimal hydraulic fracture geometry under non-Darcy flow effects [J]. J Petrol Sci Eng, 2010, 72: 143-157.

[16] GIRAULT V, WHEELER M F. Numerical discretization of a Darcy-Forchheimer model [J]. Numer Math, 2008, 110: 161-198.

[17] RUI H X, PAN H. A block-centered finite difference method for the Darcy-Forchheimer model [J]. SIAM J Numer Anal, 2012, 50: 2612-2631.

[18] BARREE R D, CONWAY M W. Beyond beta factors: A complete model for Darcy, Forchheimer and trans-Forchheimer flow in porous media [C]// SPE Annual Technical Conference and Exhibition. Houston, Texas, USA; 26-9 September 2004.

[19] LOPEZ H D. Experimental analysis and macroscopic and pore-level flow simulations to compare non-Darcy flow models in porous media [D]. Golden: Colorado School of Mines, 2007.

[20] WU Y S, LAI B T, MISKIMINS J L, FAKCHAROENPHOL P, DI Y. Analysis of multiphase non-darcy flow in porous media [J]. Transp Porous Med, 2011, 88: 205-223.

(Edited by YANG Hua)

Foundation item: Projects(91330106, 11171190) supported by the National Natural Science Foundation of China; Projects(15CX05065A, 15CX05003A) supported by the Fundamental Research Funds for the Central Universities, China

Received date: 2015-07-08; Accepted date: 2015-12-11

Corresponding author: RUI Hong-xing, Professor, PhD; Tel: +86-531-88369816; E-mail: hxrui@sdu.edu.cn

Abstract: Coalbed gas non-Darcy flow has been observed in high permeable fracture systems, and some mathematical and numerical models have been proposed to study the effects of non-Darcy flow using Forchheimer non-Darcy model. However, experimental results show that the assumption of a constant Forchheimer factor may cause some limitations in using Forchheimer model to describe non-Darcy flow in porous media. In order to investigate the effects of non-Darcy flow on coalbed methane production, this work presents a more general coalbed gas non-Darcy flow model according to Barree-Conway equation, which could describe the entire range of relationships between flow velocity and pressure gradient from low to high flow velocity. An expanded mixed finite element method is introduced to solve the coalbed gas non-Darcy flow model, in which the gas pressure and velocity can be approximated simultaneously. Error estimate results indicate that pressure and velocity could achieve first-order convergence rate. Non-Darcy simulation results indicate that the non-Darcy effect is significant in the zone near the wellbore, and with the distance from the wellbore increasing, the non-Darcy effect becomes weak gradually. From simulation results, we have also found that the non-Darcy effect is more significant at a lower bottom-hole pressure, and the gas production from non-Darcy flow is lower than the production from Darcy flow under the same permeable condition.