![]()

Trans. Nonferrous Met. Soc. China 22(2012) 2439-2443

Site occupation evolution of alloying elements in L12 phase during phase transformation in Ni75Al7.5V17.5

ZHANG Ming-yi1, 2, LIU Fu2, CHEN Zheng1, GUO Hong-jun2, YUE Guang-quan2, YANG Kun1

1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. Beijing Aeronautical Science and Technology Research Institute,Commercial Aircraft Corporation of China Ltd., Beijing 100083, China

Received 9 July 2012; accepted 1 August 2012

Abstract:

Correlation between site occupation evolution of alloying elements in L12 phase and growth of DO22 phase in Ni75Al7.5V17.5 was studied using microscopic phase field model. The results demonstrate that the growing process of DO22 phase can be divided into two stages. At the early stage, composition in the centre part of L12 phase almost remains unchanged, and the nucleation and growth of DO22 phase is controlled by the decrease of interface between L12 phases. At the late stage, part of V for growth of DO22 phase is supplied from the centre part of L12 phase and mainly comes from Al sublattice, the excess Ni spared from the decreasing L12 phase migrates into the centre part of L12 phase and occupies the Ni sublattices exclusively, while the excess Al mainly occupies the Al sublattice. At the late stage, the growth of DO22 phase is controlled by the evolution of antisite atoms and ternary additions in the centre part of L12 phase.

Key words:

nickel based superalloys; Ni75Al7.5V17.5 alloy; phase transformation; micro-phase field; grain growth; antisite defect;

1 Introduction

Site occupation behavior of alloying elements (including site preference of ternary alloying elements and antisites of constituent elements) in intermetallic compounds and their effects on physical property are subjects of not only great practical interests but also fundamental theoretical interests [1,2]. Site preference of alloying elements can be affected by changing temperature [3,4], composition [5,6], or magnetism [7]. The performance of alloy is strongly influenced by site preference of ternary additions and antisite atoms. CHIBA et al [8] found that when the ternary addition preferentially substitutes Ni on the face centered sites in Ni3Al, the ductility of Ni3Al can be improved significantly. Studies also demonstrate that site preference of alloying elements affects the solute segregation strongly [9,10]. However, to our best knowledge, attention has not been paid to the correlation between site occupation evolution of alloying elements and phase transformation. An understanding of the site occupation behavior of alloying elements during phase transformation is extremely useful in order to control the microstructure and to improve the physical properties of alloys.

The phase transformation in Ni75AlxV25-x alloys during aging process has been studied extensively both experimentally and theoretically. Most of the studies are focused on kinetics of phase separation and microstructure evolution [11-13]. The atomic ordering and composition clustering process were studied by PODURI and CHEN [14] and HOU et al [15], and LI et al [16] investigated the coarsening behaviors of L12 and DO22 in Ni75AlxV25-x alloys systematically. Few studies are focused on the correlation between the behavior of interfaces and phase transformation in Ni75AlxV25-x alloys [17-19]. However, the mechanism and kinetics of phase transformation between L12 and DO22 still need further understanding. In this work, site occupation behavior of alloying elements in L12 phase during phase transformation from L12 to DO22 in Ni75Al7.5V17.5 was studied, and their correlation was discussed. To our best knowledge, few studies have been carried out to study the kinetics of phase transformation by investigating the site occupation evolution of alloying elements at atomistic scale using a numerical simulation method. And understanding the correlation between site occupation behavior of alloying elements and growth of the second phase would make us know the kinetics of phase transformation better.

2 Microscopic phase-field model

The microscopic phase-field model describes the evolution of site occupation probability from the non-equilibrium distribution to an equilibrium one. It is firstly proposed by KHACHATURYAN [20] and developed by PODURI and CHEN [14] for the ternary alloy system. Equations for ternary alloy systems are written as:

(1)

(1)

For ternary systems, PC(r, t) =1-PA(r, t)-PB(r, t), where Pα(r, t) (α=A, B or C) represent the probabilities of finding atom α at a given lattice site r at a given time t, t is the reduced time, Lαb(r–r′) (α and β=A, B or C) is the kinetic coefficient which is proportional to the probability of elementary diffusional jumps from site r to r′ per unit time, and F is the total Helmholtz free energy of the system based on the mean-field approximation, which can be written as a function of single site occupation probability:

![]()

![]() (2)

(2)

where the effective pair interaction Vαb is deduced from pair interaction ωαb and Vαb =ωαα+ωbb–2ωαb.

Equation (1) is solved in the reciprocal space using the Modified Euler’s method with the time increment equal to 0.0002. The real-space atomic site occupation probability of alloying elements is obtained by the Back-Fourier transformation of the solution of Eq. (1). The effective pair interactions (meV/atom), which have been used by PODURI and CHEN [14] and ZAPOLSY et al [21] in previous works and proved to fit for the real Ni-Al-V alloy system at a high temperature, are used as our simulation inputs. The applications of microscopic phase-field model on microstructure evolution of Ni-based alloys had shown an excellent agreement both with experiment results [21] and other simulation results [13].

3 Results and discussion

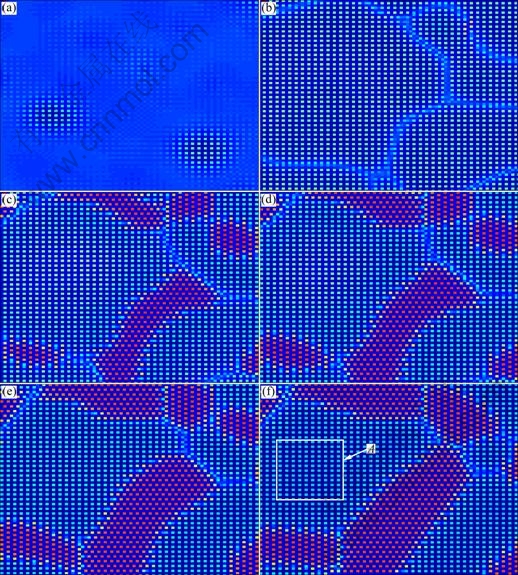

Ni75Al7.5V17.5 aged at 1185 K was simulated using microscopic phase-field model, and microstructure evolution during phase transformation is shown in Fig. 1. In Fig. 1, black sites represent Ni, gray sites represent V and white sites represent Al. L12-Ni3Al phases precipitate from the disordered phase first. And then, accompanying the formation and growth of L12 ordered domains, V atoms start to segregate to the interfaces of L12 ordered phase while the Al atoms deplete from the interfaces. As the degree of V segregation at the interfaces increases, the DO22-Ni3V ordered domains start to nucleate and grow at the interfaces of the L12 ordered phase. At last, a two-phase mixture is formed.

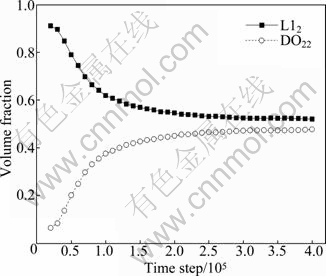

Figure 2 gives the volume fraction variation of L12 and DO22 phases during aging process. The volume of L12 phase decreases accompanied with the volume of DO22 phase increasing. This verifies that DO22 phases grow up at the expense of L12 phases after DO22 phases precipitate at the interfaces. As the volume of L12 phase decreases, Ni and Al will be spared from the decreasing L12 phase, whereas the growth of DO22 phase needs Ni and V. It has been reported that the content of Ni in L12 phase is slightly higher than that in DO22 phase, and the concentration of ternary addition V is about 10% (mole fraction) in L12 phase [21]. Thus, the Ni spared by the decreasing L12 phase can satisfy the need of Ni for DO22 growth, and part of V for DO22 growth can be supplied from the decreasing L12 phase. However, where does the other V come from to satisfy the growth of DO22, and where does the Al go away when the volume of L12 phase decreases? To answer this question, content evolution of alloying elements in L12 phase was studied.

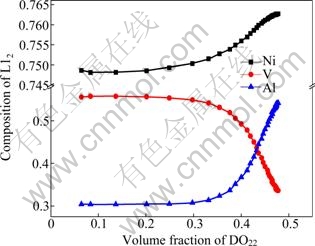

Considering the L12 phase in the vicinity of interface will transform into DO22 phase, only the content evolution of alloying elements in the centre part of L12 phase (as the square denoted by arrow A in Fig. 1(f)) was investigated. Figure 3 shows that contents of Ni and Al in L12 phase increase and content of V decreases during the phase transformation. The content of V is higher than that of Al in the centre of L12 phase first, and it is reversed at later. This illustrates that part of V for growth of DO22 phase can be supplied from the centre of L12 phase, and the Al and Ni spared from decreasing L12 phase migrate from the interface to the centre of L12 phase.

Fig. 1 Microstructure evolution during phase transformation from disordered (FCC-A1) phase to ordered (L12 and DO22) phase of Ni75Al7.5V17.5 aged at 1185 K: (a) t=8000; (b) t=20000; (c) t=70000; (d) t=100000; (e) t=200000; (f) t=400000

Fig. 2 Volume fraction variation of L12 and DO22 phases of Ni75Al7.5V17.5 aged at 1185 K

Fig. 3 Composition evolution of centre part of L12 phase in Ni75Al7.5V17.5 aged at 1185 K

Figure 4 illustrates the relationship between volume fraction of DO22 phase and composition of L12 phase. From Fig. 4, the growth of DO22 phase can be divided into two stages. At the early stage, volume fraction of DO22 phase increases from about 0.05 to 0.35 quickly, and the composition of the centre part of L12 phase almost remains unchanged. As mentioned above, the decreasing of L12 phase cannot supply enough V for the growth of DO22 phase. However, V segregates at the interface of L12 phase, and the amount of interfaces between L12 phases decreases quickly with the nucleation and growth of DO22 phase. Thus, the V for growth of DO22 phase at the early stage is supplied from both the decreasing L12 phase and interfaces between L12 phases. At the late stage, volume fraction of DO22 phase grows up slowly from 0.35 to about 0.48, accompanied with the contents of Al and Ni increasing, and content of V deceasing in the centre part of L12 phase. This implies that the growth of DO22 phase at the late stage is controlled by the content evolution of alloying elements in the centre part of L12 phase.

Fig. 4 Variation of composition of L12 phase with volume fraction of DO22 phase in Ni75Al7.5V17.5 aged at 1185 K

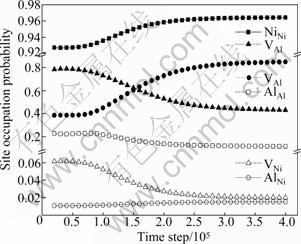

As the L12 phase consists of two sublattices, content evolution of alloying elements at both Ni and Al sublattices in the centre of L12 phase was studied. Figure 5 shows that the ternary addition V prefers to occupy the Al sublattice, which is in consistent with the previous study [22]. As the DO22 phase grows up, the content of host atoms AlAl (AlAl denotes the Al atom at the Al sublattice) and NiNi increase, the contents of ternary additions of VNi and VAl decrease, and content of antisite atoms NiAl decreases but that of AlNi increases.

Fig. 5 Site occupation of alloying elements in L12 phase during phase transformation from L12 to DO22 in Ni75Al7.5V17.5

The site occupation decrement of NiNi is larger than the site occupation decrement of NiAl, thus content of Ni in the centre of L12 phase increases. This demonstrates that the excess Ni from decreasing L12 phase occupies the Ni sublattice. The site occupation decrement of VNi is less than that of VAl, and the site occupation increment of AlNi is less than that of AlAl. This demonstrates that part of V for growth of DO22 phase supplied from the centre of L12 phase mainly comes from Al sublattice, and Al from decreasing L12 phase mainly occupies the Al sublattice. Considering the discussion above, it can be concluded that the growth of DO22 phase is mainly controlled by the decrease of interface between L12 phases at the early stage, but at the late stage, it is mainly controlled by the evolution of antisite atoms and ternary additions in the centre part of L12 phase.

4 Conclusions

1) Correlation between site occupation evolution of alloying elements in L12 phase and volume of DO22 phase indicates that the process of growth of DO22 phase can be divided into two stages.

2) At the early stage, composition in the centre part of L12 phase almost remains unchanged, and the nucleation and growth of DO22 phase is controlled by decrease of interface between L12 phases. At the late stage, the growth of DO22 phase is controlled by site occupation evolution of alloying elements in the centre part of L12 phase.

3) At the late stage, Ni and Al spared from decreasing L12 phase migrate from the interfaces between L12 and DO22 phases to the centre of L12 phase, and the excess Ni exclusively occupies the Ni sublattice and Al mainly occupies the Al sublattice. Part of V for growth of DO22 phase is supplied from the centre part of L12 phase and mainly comes from Al sublattice.

References

[1] PRINS S, ARROYAVE R, LIU Z K. Defect structures and ternary lattice site preference of the B2 phase in the Al-Ni-Ru system [J]. Acta Mater, 2007, 55: 4781-4787.

[2] NISHINO Y, KUMADA C, ASANO A. Phase stability of Fe3Al with addition of 3d transition elements [J]. Scripta Mater, 1997, 234-236: 461-466.

[3] RUBAN A V, SKRIVER L. Calculated site substitution in ternary γ′-Ni3Al: Temperature and composition effects [J]. Phys Rev B, 1997, 55: 856-874.

[4] JIANG C. Site preference of transition-metal elements in B2 NiAl: A comprehensive study [J]. Acta Mater, 2007, 55: 4799-4806.

[5] ZHANG J, CHEN Z, LU Y L, ZHANG M Y, WANG Y X. Microscopic phase field study of the antisite defect of Ni3Al in binary Ni-Al alloys [J]. Science in China Series G: Physics, Mechanics & Astronomy, 2010, 53(11): 2047-2053.

[6] ALMAZOUZI A, NUMAKURA H, KOIWA M, HONO K, SAKURA T. Site occupation preference of Fe in NiAl: An atom-probe study [J]. Intermetallics, 1997, 55: 37-43.

[7] SLUTIER M H F, KAWAZOE Y. Site preference of ternary additions in Ni3Al [J]. Phys Rev B, 1995, 51: 4062-4073

[8] CHIBA A, HANADA S, WATANABE S, ABE T, OBANA T. Relation between ductility and grain boundary character distributions in Ni3Al [J]. Acta Mater, 1994, 42: 1733-1738.

[9] KITASHIMA T, YOKOKAWA T,YEH A C, HARADA H. Analysis of element-content effects on equilibrium segregation at γ-γ′ interface in Ni-base superalloys using the cluster variation method [J]. Intermetallics, 2008, 16: 779-784.

[10] MOSCA H O, BOZZOLO G, GARC?S J E. Site preference, size effects and segregation in RuAlB alloys [J]. Scripta Materialia, 2008, 58: 1025-1028.

[11] BENDERSKY L A, BIANCANIELLO F S, WILLIAMS M E. Evolution of the two-phase microstructure L12+DO22 in near-eutectoid Ni3(Al, V) alloy [J]. J Mater Res, 1994, 9: 3068-3082.

[12] TANIMURA M, KOYAMA Y. The role of antiphase boundaries in the kinetic process of the L12→DO22 structural change of an Ni3Al0.45V0.50 alloy [J]. Acta Mater, 2006, 54: 4385-4391.

[13] PAREIGE C, BLAVETTE D. Simulation of the FCC-FCC+ L12+DO22 kinetic reaction [J]. Scripta Mater, 2001, 44: 243-247.

[14] PODURI R, CHEN L Q. Computer simulation of atomic ordering and compositional clustering in the pseudobinary Ni3Al-Ni3V system [J]. Acta Mater, 1998, 46: 1719-1729.

[15] HOU H, ZHAO Y H, ZHAO Y H. Simulation of the precipitation process of ordered intermetallic compounds in binary and ternary Ni–Al-based alloys by the phase-field model [J]. Mater Sci Eng A, 2009, 499: 204-207.

[16] LI Y S, CHEN Z, LU Y L, XU G D. Dynamic scaling behaviour of late-stage phase separation in Ni75AlxV25-x alloys [J]. Chin Phys B, 2007, 16: 854-861.

[17] TANIMURA M, HIRATA A, KOYAMA Y. Kinetic process of the phase separation in the alloy Ni3Al0.52V0.48 [J]. Phys Rev B, 2004, 70: 094111.

[18] ZHANG Ming-yi, CHEN Zheng, WANG Yong-xin, MA Guang, LU Yan-li, FAN Xiao-li. Effect of atomic structure on migration characteristic and solute segregation of ordered domain interfaces formed in Ni75AlxV25-x [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(3): 604-611.

[19] ZHANG Ming-yi, CHEN Zheng, WANG Yong-xin, LU Yan-li, ZHANG Li-peng, ZHAO Yan. Microscopic phase field simulation of ordered domain interfaces formed between DO22 phases along [100] direction [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(3): 686-693.

[20] KHACHATURYAN A G. Theory of structural transformations in solids [M].New York: Wiley, 1983.

[21] ZAPOLSKY H, PAREIGE C, MARTEAU L, BLAVETTE D, CHEN L Q. Atom probe analyses and numerical calculation of ternary phase diagram in Ni-Al-V system [J]. Calphad, 2001, 25: 125-134.

[22] JIANG C, GLEESON B. Site preference of transition metal elements in Ni3Al [J]. Scripta Mater, 2006, 55: 433-436.

Ni75Al7.5V17.5相变过程中L12相合金元素占位几率演化的微观相场模拟

张明义1, 2,刘 富2,陈 铮1,郭红军2,岳广全2,杨 坤1

1. 西北工业大学 凝固技术重点实验室,西安 710072;

2. 中国商用飞机有限责任公司 北京民用飞机技术研究中心,北京100083

摘 要:基于微观相场模型,研究Ni75Al7.5V17.5合金在相变过程中L12相内合金元素演化与DO22相生长之间的关系。研究表明,在L12相向DO22相转变的过程中,DO22相的长大可以分为两阶段。在早期,L12相内合金元素的成分基本不变,DO22相的长大主要受L12相间有序畴界的减少所控制。在后期,DO22相长大所需的V一部分来自L12相内部,一部分来自L12相体积的减少,其中,相内部为DO22相长大所提供的V则主要来自Al格点位置,由于L12相体积减少而富余的Al向L12相内部扩散迁移并主要占据Al格点位置,富余的Ni则同时向L12相内部和DO22相内部扩散,主要占据L12相的Ni位置。DO22相长大的后期主要受L12相内反位缺陷和第三组元的演化所控制。

关键词:镍基合金;Ni75Al7.5V17.5合金;相变;微观相场;晶粒生长;反位缺陷

(Edited by LI Xiang-qun)

Foundation item: Projects (50941020, 10902086, 50875217, 20903075) supported by the National Natural Science Foundation of China; Projects (SJ08-ZT05, SJ08-B14) supported by the Natural Science Foundation of Shaanxi Province, China

Corresponding author: ZHANG Ming-yi; Tel: +86-29-88486023; E-mail: zmy1688@gmail.com

DOI: 10.1016/S1003-6326(11)61482-9

Abstract: Correlation between site occupation evolution of alloying elements in L12 phase and growth of DO22 phase in Ni75Al7.5V17.5 was studied using microscopic phase field model. The results demonstrate that the growing process of DO22 phase can be divided into two stages. At the early stage, composition in the centre part of L12 phase almost remains unchanged, and the nucleation and growth of DO22 phase is controlled by the decrease of interface between L12 phases. At the late stage, part of V for growth of DO22 phase is supplied from the centre part of L12 phase and mainly comes from Al sublattice, the excess Ni spared from the decreasing L12 phase migrates into the centre part of L12 phase and occupies the Ni sublattices exclusively, while the excess Al mainly occupies the Al sublattice. At the late stage, the growth of DO22 phase is controlled by the evolution of antisite atoms and ternary additions in the centre part of L12 phase.