Preparation and microwave dielectric properties of Csf/Si3N4 composites

WANG Xiao-yan(王晓艳), LUO Fa(罗 发), LI Peng(李 鹏), SU Xiao-lei(苏晓磊),

ZHU Dong-mei(朱冬梅), ZHOU Wan-cheng(周万城)

State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China

Received 15 July 2007; accepted 10 September 2007

Abstract:

The Csf/Si3N4 composites were prepared by hot-press sintering method using α-Si3N4 power, short carbon fibers and La2O3-Y2O3 sintering additives. The mechanical and microwave dielectric properties of Csf/Si3N4 composites were studied and discussed. The results show that the addition of the short carbon fibers can not destroy the relative density of the sintered samples, but it deteriorates the flexural strength of the sintered samples, so the flexural strength of the silicon nitride matrix is the highest among the samples. The real part (ε′) and the imaginary part (ε″) of the permittivity of Csf/Si3N4 composites greatly increase with increasing volume fraction of the short carbon fibers, achieve the maximum 73.1 and 101.5, respectively. A strong frequency dependence of the imaginary part (ε″) of the permittivity is observed.

Key words:

Csf/Si3N4; composites; short carbon fibers; mechanical property; dielectric properties;

1 IntroductionSilicon nitride based ceramics (Si3N4) have been widely studied because of their potential applications as structural components at room and elevated temperatures[1-3]. Silicon nitride is also a candidate for high temperature microwave transmission due to the high mechanical strength, good thermal shock resistance, excellent resistance to rain erosion and an acceptable dielectric property[4].

Carbon fibers combine exceptional mechanical properties and low mass, making them ideal reinforcements for composite materials to be employed in aerospace and sport applications. An important amount of scientific and technological work has been done to improve the mechanical properties of carbon fibers and carbon fiber composites[5-7]. Increasing attention has been directed to continuous fiber reinforced ceramic matrix composites for structural applications due to their excellent thermal stability, light mass and damage tolerance imparted by the reinforcing fibers[8]. Short-fiber-reinforced composites will increasingly be used in a wide range because of their easy adaptability to conventional manufacturing techniques and low cost of fabrication[9-10]. Although various ceramic matrix composites have been developed, there are a few composites appropriate for microwave dielectric properties. In our earlier work, we have introduced short carbon fibers into composites, which not only achieve reinforcement for composites, but also have wave dielectric properties by controlling content for composites[11].

In this study, Csf/Si3N4 composites were prepared by hot-press sintering method. And the mechanical and microwave dielectric properties of Csf/Si3N4 composites were studied.

2 Experimental2.1 Experimental materials and preparation method

Commercial Si3N4 powder (α-Si3N4 phase content≥95%) and the short carbon fibers (about 1 mm) were used to prepare the Cfiber/Si3N4 composites. La2O3 and Y2O3 in a molar ratio of 1:1 were used as sintering additives. Powder batches were planetary ball milled using ethanol. The resultant slurries were dried and sieved. Then the powder and short carbon fibers were blended by machine. The mixture was pressed into plum baginous die and then sintered at 1 800 ℃ for 1 h under the nitrogen atmosphere at 25 MPa.

2.2 Test method

The densities of the machined samples were measured using the Archimedes method in distilled water.

Flexural strength of the composites was determined by three-point flexural test. Specimens were cut from measurement. All tests were carried out using an Instron universal testing machine (2-20 kN) with a cross-head speed of 0.5mm/min. The samples were observed with the scanning electrical microscope (SEM) after three-point flexural test. The sintered samples were cut into cubes for permittivity tests in a frequency range of 8.2-12.4 GHz using E8362B PNA series network analyzer.

3 Results and discussion3.1 Mechanical properties and microstructure

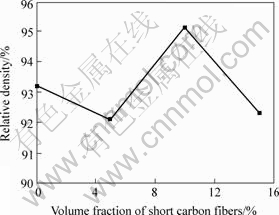

Fig.1 shows the relative density of the sintered samples of the Csf/Si3N4 composites. The relative density of the sintered samples is characterized by the highest value of 95.1% when the volume fraction of carbon fiber is 10%. The relative density of the all sintered samples is above 90%, indicating that the addition of the short carbon fibers can not destroy the relative density of the sintered samples.

Fig.1 Relative density of Csf/Si3N4 composites with different volume fractions of short carbon fibers

Fig.2 shows the microphotographs of the Csf/Si3N4 composites with 5% short carbon fibers. The rod-like Si3N4 grains form a three dimension interlocked network. The short carbon fiber can not keep its nature integrity. The short carbon fiber shows exfoliation after sintering, indicating that the short carbon fibers underwent degradation during the sintering. Cavities are developing on the fiber surface, which can lead to a total disappearance of carbon fibers from the structure. We ascribe this degradation to chemical reactions taking place during sintering. There is reported study which shows the carbon fibers are exhausted from composites (in the form of CO, CO2) during the procedure[12].

Fig.2 Microphotograph of Csf/Si3N4 composites with 5% short carbon fibers

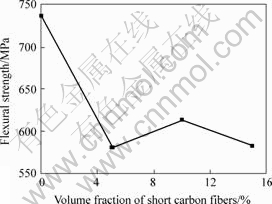

Fig.3 shows the relationship between the short carbon fibers content and the flexural strength of the sintered samples. It can be seen that the addition of the short carbon fibers deteriorate the flexural strength of the sintered samples. The flexural strength of the silicon nitride matrix is the highest among the samples. The results also show that the flexure strength falls down. Then it goes up with the increase of fibers content. When the carbon fiber content continues to increase, the flexure strength of the samples decreases, which is closely related with the relative density and microstructure of the samples. The addition of the short carbon fibers break up the moiety of the matrix, which weakens the carrying capacity of the matrix, so the flexural strength of the composites decreases when the carbon fiber content is less. When the carbon fiber content increases, the short carbon fibers will carry the load and the flexural strength of the composites will be enhanced by cracks initiation and deflection. When the short carbon fibers content continues to increase, the flaws increase and the flexure strength of the samples decrease.

Fig.3 Relationship between volume fraction of short carbon fibers and flexural strength of Csf/Si3N4 composites

3.2 dielectric properties

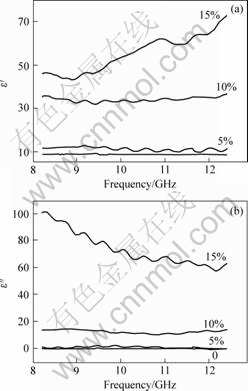

Fig.4 shows the relationship between permittivity of the Csf/Si3N4 composites and frequency. It shows that both the real and imaginary parts of the permittivity of the Csf/Si3N4 composites increase with the increase of short carbon fibers content. The real part (ε′) of the permittivity of the Csf/Si3N4 composites varies from 8.2 to 73.1 when the volume fraction of short carbon fibers is in the range of 0%-15%. The imaginary part of the pure silicon nitride matrix is close to zero but the imaginary parts of the Csf/Si3N4 composites were enhanced greatly with the addition of short carbon fibers. It varies from 0.05 to 101.5 when the volume fraction of short carbon fibers is in the range of 0%-15%. The short carbon fiber is a conductive phase with higher permittivity and dielectric loss. Therefore, the direct current conductivity and dielectric loss of the Csf/Si3N4 composites increase obviously as the short carbon fibers content increase. A strong frequency dependence of the imaginary part (ε″) of the permittivity is observed.

Fig.4 Real part (ε′) and imaginary part (ε″) of permittivity of Csf/Si3N4 composites as function of frequency at different volume fractions of short carbon fibers

4 Conclusions1) The addition of the short carbon fibers deteriorates the flexural strength of the sintered samples, so the flexural strength of the silicon nitride matrix is the highest among the samples. When the volume fraction of the short carbon fibers is 10%, the short carbon fibers would carry the load and the flexural strength of the composites would be enhanced by cracks initiation and deflection.

2) The real and imaginary parts of the permittivity of the Csf/Si3N4 composites greatly increase because of the direct current conductivity and dielectric loss increase obviously as the short carbon fibers content increases.

References

[1] BALDACIM S A, SANTOS C, SILVA O M M, SILVA C R M. Ceramics composites Si3N4–SiC(w) containing rare earth concentrate (CRE) as sintering aids[J]. Mater Sci Eng A, 2004, 367: 312-316.

[2] ZHANG Y H, EDWARDS L. Cyclic fatigue crack growth behaviour of silicon nitride at 1 400℃[J]. Mater Sci Eng A, 1998, 256:144-151.

[3] LIU Xue-jian, HUANG Zhi-yong, GE Qi-ming, SUN Xing-wei, HUANG Li-ping. Microstructure and mechanical properties of silicon nitride ceramics prepared by pressureless sintering with MgO–Al2O3–SiO2 as sintering additive[J]. J Eur Ceram Soc, 2005, 25: 3353-3359.

[4] BARTA J, MANELA M. Si3N4 and Si2N2O for high performance radomes[J]. Mater Sci Eng, 1985, 71: 26-272.

[5] MONTES-MORAN M A, GAUTHIER W, MARTINEZ-ALONSO A, TASCON J M D. Mechanical properties of high-strength carbon fibres. Validation of an end-effect model for describing experimental data[J]. Carbon, 2004, 42: 1275–1278.

[6] VIDAL-SETIF M H, LANCIN M, MARHIC C, VALLE R, TAVIART J L, DAUX J C, RABINOVITCH M. On the role of brittle interfacial phases on the mechanical properties of carbon fibre reinforced Al-based matrix composites[J]. Mater Sci and Eng A, 1999, 272: 321-333.

[7] KORAB J, STEFANIK P, KAVECKY S, SEBO P, KORB G.. Thermal expansion of cross-ply and woven carbon fibre-copper matrix composites[J]. Compo part A, 2002, 33: 133-136.

[8] QI G J, ZHANG C R, HU H E, CAO F. Effects of precoating on mechanical properties and microstructures of 3D SiO2f/Si3N4 composites using polyhydridomethylsilazane[J]. Mater Sci Eng A, 2006, 416: 317-320.

[9] HE Xiu-lan, ZHOU Yu, JIA De-chang, GUO Ying-kui. Effect of sintering additives on microstructures and mechanical properties of short-carbon-fiber-reinforced SiC composites prepared by precursor pyrolysis-hot pressing[J]. Ceram Int, 2006, 32: 929-934.

[10] LEE J S, YOSHIDA K, YANO T. Influence of fiber volume fraction on the mechanical and thermal properties of unidirectionally aligned short-fiber-reinforced SiC composites[J]. J Ceram Soc Jpn, 2002, 110: 981-985.

[11] WANG Xiao-yan, LUO Fa, YU Xin-min, ZHU Dong-mei, ZHOU Wan-cheng. Influence of short carbon fiber content on mechanical and dielectric properties of Cfiber/Si3N4 composites[J]. Scripta Mater, 2007, 57: 309–312.

[12] BALAZSI C S, KONYA Z, WEBER F, BIRO L P, AROTO P. Preparation and characterization of carbon nanotube reinforced silicon nitride composites[J]. Mater Sci Eng C, 2003, 23: 1133-1137.

Corresponding author: WANG Xiao-yan; Tel: +86-29-88488007; E-mail: wxydnwpu@yahoo.com.cn