TiNi/NbTi复合材料中微米片TiNi的回复应力特征

摘 要:

利用熔炼、锻造、轧制等手段成功制备出微米片TiNi/NbTi形状记忆合金原位复合材料, 冷轧退火处理后的复合材料中TiNi片厚度达微米尺度。基于微米片TiNi与基体NbTi之间的简化并联模型, 推导出微米片TiNi在约束态相变过程中的回复应力计算公式, 公式中回复应力与复合材料中两相的体积比、基体弹性模量以及复合材料预变形前后的热膨胀应变有关。利用公式计算了微米片TiNi在基体NbTi约束下升降温过程中的回复应力变化。计算结果表明, 在降温开始阶段, 回复应力随着温度的降低而减小, 未出现先减小后增大的变化, 也未表现出明显的滞后, 这与以往拉伸试验机测试的结果不同。随着温度进一步降低, 母相TiNi在基体的作用下逐渐转变成具有不均匀变形度的继承变形马氏体使回复应力逐渐减小;在升温阶段, 由于降温过程中形成的继承变形马氏体逐渐逆转变为母相而使回复应力随着温度的升高逐渐增大, 最高可达630 MPa。

关键词:

中图分类号: TG139.6

作者简介:姜大强 (1980-) , 男, 辽宁人, 博士, 工程师;研究方向:形状记忆合金;崔立山 (E-mail:dq80jiang@126.com) ;

收稿日期:2013-08-13

基金:国家自然科学基金 (51001119, 51071175) 资助项目;

Recovery Stress Characteristics of Micron-Lamella TiNi in TiNi/NbTi Composite

Jiang Daqiang Cui Lishan Zheng Yanjun Jiang Jiang Jiang Xiaohua

College of Science, China University of Petroleum

Abstract:

An in situ lamellar TiNi /NbTi shape memory composite was obtained by melting, hot-forging and cold-rolling of an as-cast NbTiNi alloy. The thickness of TiNi lamella achieved micron level after cold-rolling and annealing. Based on the parallel model of TiNi and NbTi, a formula was deduced for calculating the recovery stress of micron-lamella TiNi during the constrained martensitic transformation. The recovery stress was related to the volume ratio of the two components, the elastic modulus of matrix and the thermal expansion strain of samples before and after pre-straining, and was calculated by the formula during constrained thermal cycling. The results showed that the calculated recovery stress decreased with temperature decreasing at the initial cooling, and did not show an obvious hysteresis or a wavy shape with first decreasing and then increasing. It was different from the test of tensile machine before. When the temperature further decreased, the recovery stress decreased gradually due to the transformation of TiNi from parent to inheriting deformation martensite with non-uniform deformation degree. During heating, the recovery stress increased gradually up to the maximum of 630MPa because of the transformation from inheriting deformation martensite to parent.

Keyword:

shape memory alloy; TiNi; recovery stress;

Received: 2013-08-13

Ti Ni形状记忆合金 (SMA) 由于发生热弹性马氏体相变[1,2,3]而具有的优异形状记忆效应、超弹性特点, 使其广泛用于航空航天、生物医用等领域[4,5]。SMA在马氏体状态塑性变形后, 若在随后的加热过程中受到约束, 则会产生回复力。人们利用SMA的这一特性, 将其作为增强组元或驱动组元复合到各种基体材料中, 通过加热过程中SMA产生较大的回复应力达到控制或改善复合材料性能的目的, 例如, 使复合材料具有升温自增强[6,7]、抑制裂纹扩展[8]、减振降噪[9,10]等特性。因此, 了解复合材料中记忆合金相在受约束条件下的回复应力变化规律对其工程应用具有重要意义。以往有关回复应力的实验大多是采用Ti Ni合金丝在恒应变约束条件下, 利用变温拉伸机测试其在升降温过程中的变化[11,12]。由于在加热冷却过程中, 夹具的热胀冷缩将抵消记忆合金在升降温过程中部分收缩和膨胀, 导致测试结果不能完全反应复合材料中记忆合金的回复应力变化规律, 影响人们认知复合材料中记忆合金的驱动特性。

本文利用熔炼、锻造、轧制等手段制备出微米片Ti Ni/Nb Ti复合材料, 利用该复合材料具有原位形成, 界面结合强度高, 两相尺寸细小分布均匀的特点, 基于简化的并联模型推导出复合材料中微米片Ti Ni的回复应力计算公式, 并计算了预应变后的微米片Ti Ni在基体约束下的回复应力。

1 实验

按Nb60Ti25Ni15 (%, 原子分数) 成分配比, 选取高纯Ti, Ni, Nb原料, 采用电弧熔炼获得质量为500 g的铸锭, 将铸锭进行950℃, 10 h真空均匀化退火后热锻至10 mm厚板材, 随后进行冷轧—退火加工, 冷轧中间退火工艺为800℃保温20 min, 最后一道轧制后进行500℃保温20 min的退火处理, 最终获得厚度为0.7 mm的板材。利用线切割从轧后的板材上切下宽1.5 mm, 长120 mm的丝, 然后深冷至马氏体状态并对其预应变至6.1%, 预应变方向平行于轧制方向。从预应变后的丝上截取长25 mm的样品用于热膨胀测试。热膨胀测试是在WRP-1型膨胀仪上进行的, 升降温速率为10℃·min-1。

2 结果

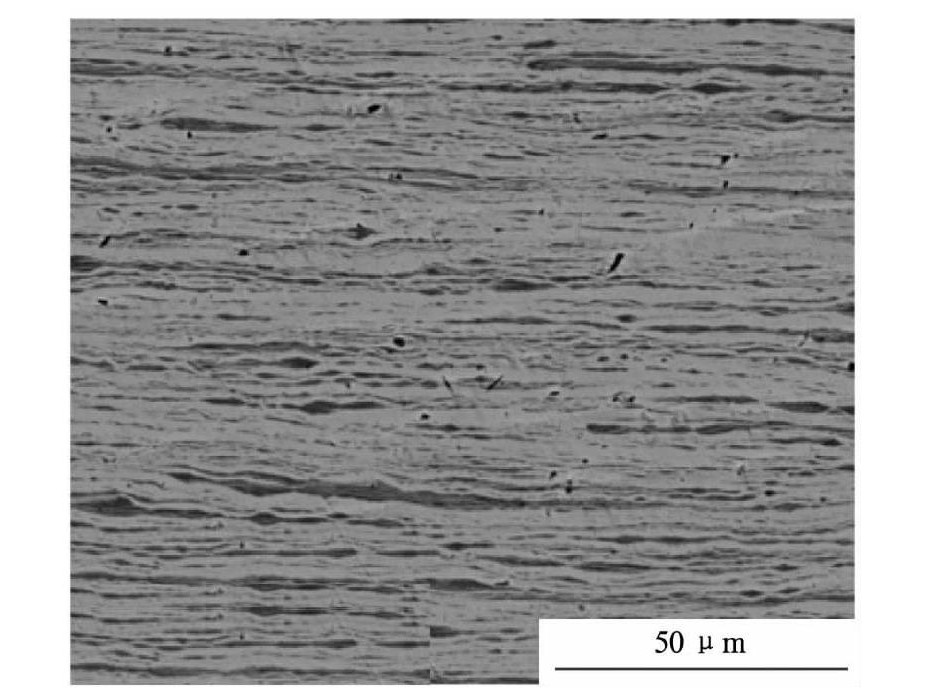

图1为冷轧退火后复合材料的扫描电镜背散射电子像, 经能谱和XRD确定其中白色为Nb Ti相 (含少量Ni元素) , 灰色为Ti Ni相 (含少量Nb元素) 。两相间界面结合良好, 没有冶金缺陷, 从图中可以看到Ti Ni片厚度仅几微米。

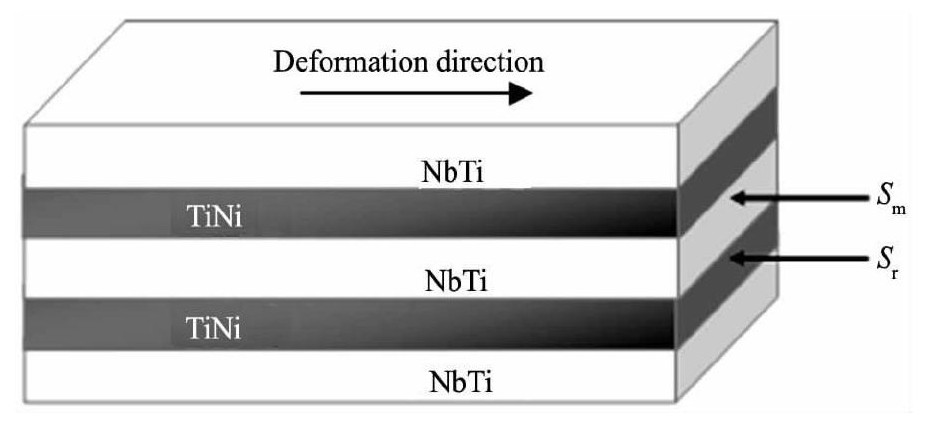

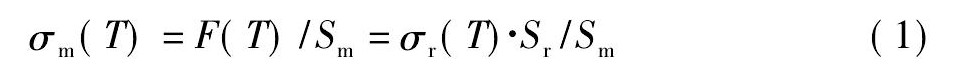

在升温过程中, 预变形样品中Ti Ni片的回复由于受基体约束而产生回复力, 该回复力反作用于基体上, 用Fr (T) 表示Ti Ni片在加热过程中所产生的回复力, Fm (T) 表示Nb Ti基体受到的作用力, 则Fm (T) =Fr (T) =F (T) 。取复合材料中某一单元, 简化两相间并联关系如图2所示, 设与回复力方向垂直的Ti Ni片与Nb Ti基体的截面积分别为Sr和Sm, Ti Ni片在升降温过程中产生的回复应力为σr (T) , 则回复力为F (T) =σr (T) ·Sr, 那么基体Nb Ti受到的应力为:

图1 冷轧退火后复合材料的扫描电镜背散射电子像Fig.1 Back scattered electron image of composite after rolling and annealing

图2 计算Ti Ni/Nb Ti复合材料中回复应力的并联模型Fig.2Parallel model for calculating recovery stress of lamella Ti Ni in composite

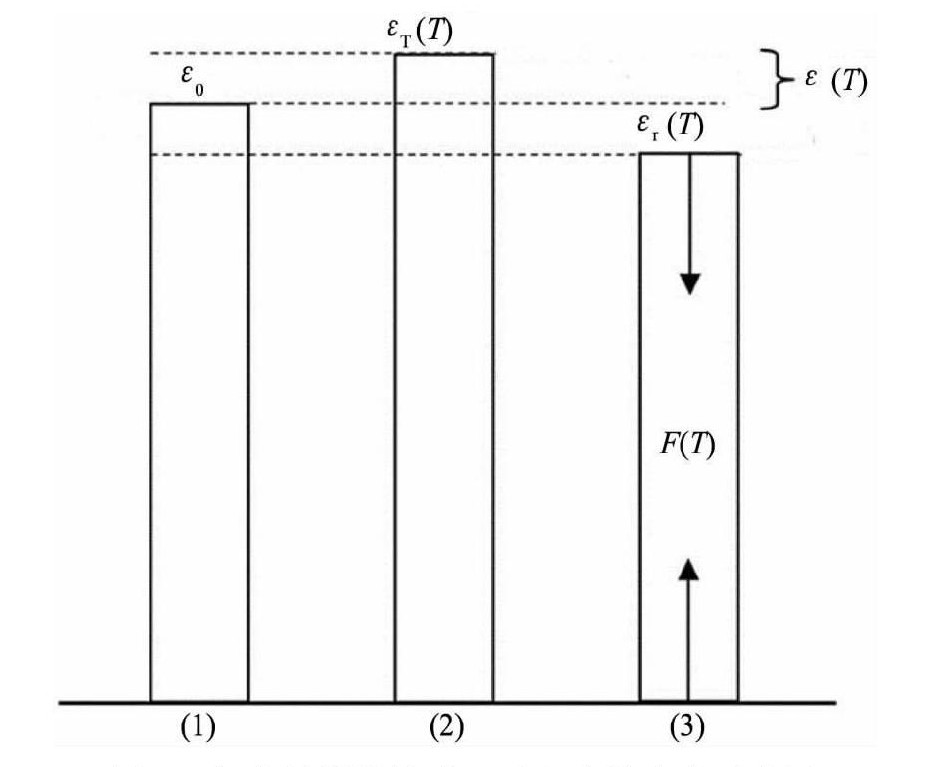

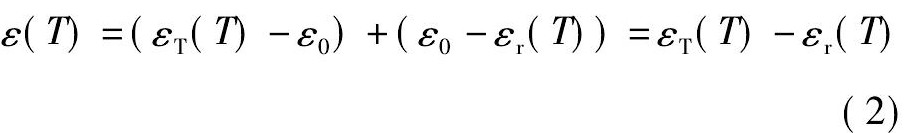

图3为复合材料样品升温过程中热膨胀示意图, 设预变形后样品初始应变为ε0 (图3 (1) ) 。对于预应变样品, 若其中的Ti Ni相被基体取代而不具有记忆效应, 则加热至温度T时, 样品将不收缩, 而是正常膨胀至应变εT (T) (图3 (2) ) 。实际上, 预应变后的样品在加热过程中, 由于Ti Ni相回复受限而产生回复力, 使复合材料收缩至应变εr (T) 。因此, 该过程可以视为当温度升高到T时, 回复力使Nb Ti基体由原本在此温度下的膨胀应变εT (T) 收缩至εr (T) , 产生大小为ε (T) 的应变, 则:

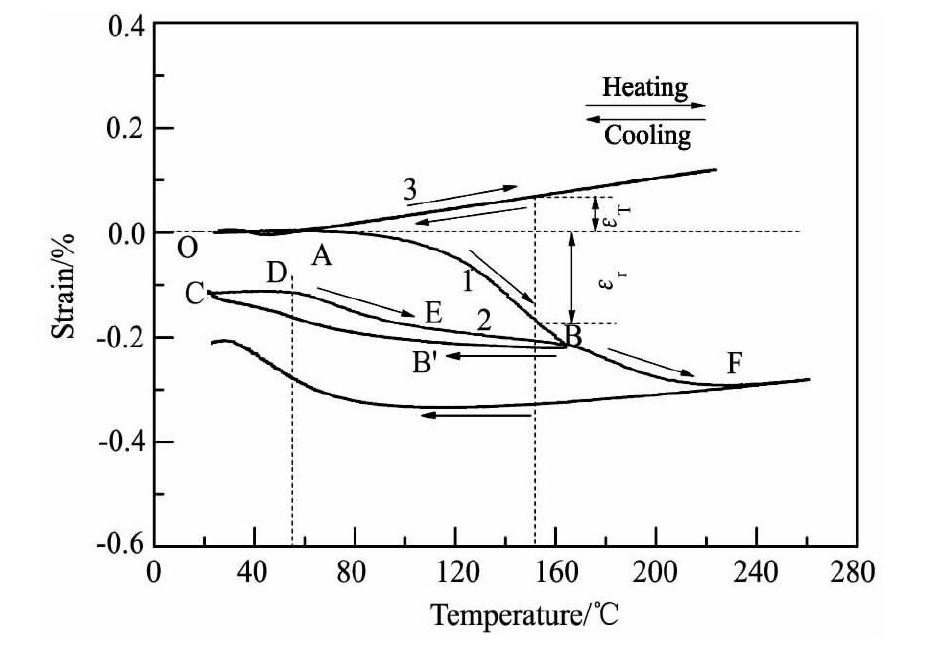

用未预应变样品的膨胀曲线代替基体Nb Ti的膨胀曲线 (此时, 记忆合金在升降温过程中不产生回复力, 且其体积百分数较少, 忽略其对基体热膨胀的影响) , εT (T) 和εr (T) 可由未预应变样品与预应变样品的热膨胀曲线获得, 如图4所示。

当基体发生弹性变形时, 根据胡克定律, 基体所受应力可表示为:

图3 复合材料样品升温过程中热膨胀示意图Fig.3 Schematic thermal dilatation of the samples upon heating

(1) Pre-strained sample before heating, (2) At temperature T, pre-strained sample dilates toεT (T) if Ti Ni is substituted by matrix, (3) At temperature T, pre-strained sample contracting toεr (T) due to recovery stress of the Ti Ni

图4预应变6.1%样品热循环膨胀曲线Fig.4 Thermal dilatation results of sample with 6.1%prestrain in first heating-cooling (curve 1) and second heating-cooling (curve 2) .Curve 3 being curve of undeformed specimen

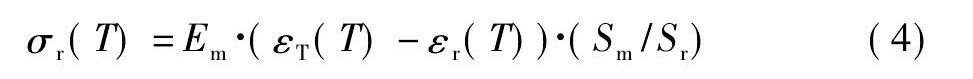

其中Em为基体Nb Ti弹性模量, 由公式 (1) , (2) , (3) 得:

公式 (4) 中 (Sm/Sr) 可通过“Ti Ni-Nb”伪二元共晶相图结合扫描电镜照片获得[13,14], 约为3.5∶1, 从而可计算获得复合材料中Ti Ni相在基体约束下的回复应力随温度变化曲线。

3 讨论

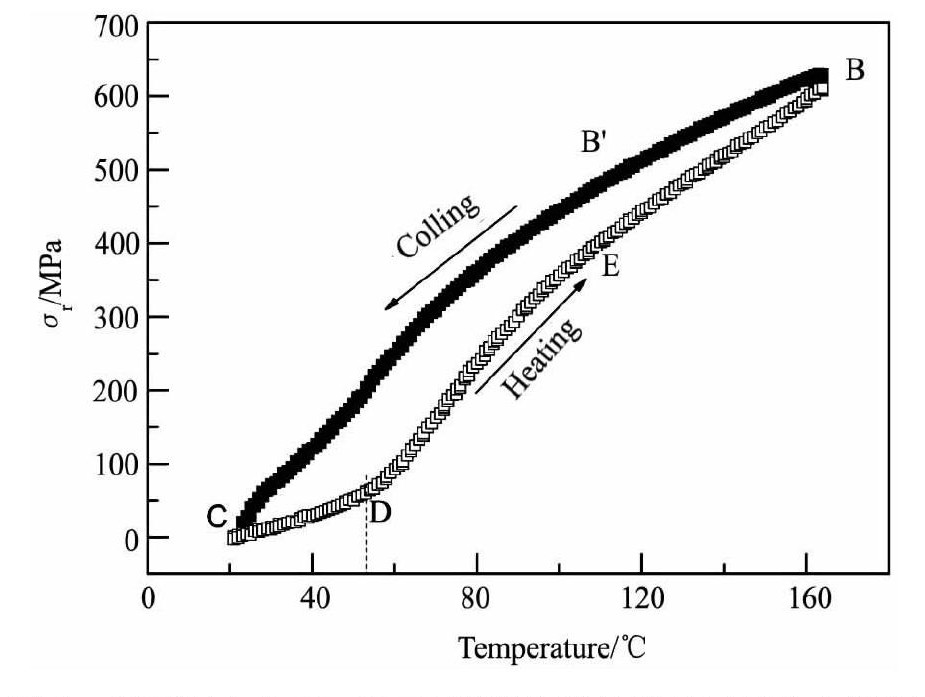

从图4可以发现, 预应变样品在第一次升降温循环后 (OABC) , C点和O点不重合, 这可能是在第一次加热过程中, 较高的回复力导致复合材料中产生少量塑性变形, 以及基体Nb Ti相和Ti Ni相存在少量串联导致加热过程中Ti Ni回复不受约束所引起的。在第一次降温与第二次升温 (BB'CDEB) 的Ti Ni与Nb Ti相互耦合中, 热膨胀曲线形成闭合环路, 表明此过程中Nb Ti仅发生弹性变形, 因此, 在此循环过程中可利用公式 (4) 计算回复应力随温度变化规律。

图5是计算出的复合材料中Ti Ni相在第一次冷却和第二次加热过程中的回复应力-温度关系曲线, 实验中弹性模量ENb Ti取93 GPa[15]。由图5可见, 在第一次降温过程中, 回复应力没有表现为先减小后增大再减小的现象, 而是随着温度的降低而单调减小, 降温立即发生马氏体正相变, 说明此时相变滞后很小, 几乎为零。而以往采用拉伸机测试, 由于测试过程中夹具热胀冷缩的影响, 导致测试结果出现非单调性变化的情况[11,12]。在降温过程中, 母相将在回复应力的诱发下转变成具有一定变形度的继承变形马氏体, 由于诱发马氏体相变而产生相变应变释放回复应力, 因而随着温度降低, 回复应力逐渐减小, 形成的继承变形马氏体的变形度也逐渐减小, 即在整个降温过程中形成不均匀变形度的继承变形马氏体。在第二次加热过程中, 当加热温度高于D点温度时, 具有不均匀变形度的继承变形马氏体逐渐转变成母相使回复应力逐渐增大, 最高可达630 MPa。

图5 利用图4中BB'CDEB膨胀曲线计算的回复应力随温度变化曲线Fig.5 Recovery stress curve calculated from dilatation curve of BB'CDEB in Fig.4

4 结论

利用微米片Ti Ni/Nb Ti复合材料, 通过简化并联模型计算预应变样品中微米片Ti Ni在加热冷却过程中的回复应力变化。在降温过程中, 回复应力随着温度的降低而单调减小, 降温初始阶段没有表现出滞后;在升温阶段, 回复应力随着温度的升高而逐渐增大。

参考文献