文章编号:1004-0609(2008)S1-0264-04

铝酸钠溶液中和制备纳米丝状氢氧化铝

李 艳1, 2,张亦飞1,杨 超1

(1. 中国科学院 过程工程研究所,北京 100080;2. 中国科学院 研究生院,北京 100049)

摘 要:

研究铝酸钠溶液的盐酸中和过程对氢氧化铝晶体的形貌、晶型和铝酸钠溶液分解率的影响。结果表明:随着反应体系pH值的下降,氢氧化铝的形貌不断发生变化,且pH值越大,晶体越粗大;不论pH 值如何变化,氢氧化铝的晶型总是gibbsite型;铝酸钠溶液的分解率随溶液pH值降低而升高。

关键词:

中图分类号:TQ 16.1 文献标识码:A

Fibre-like aluminium hydroxide nanoparticles prepared by neutralization of sodium aluminate solution

LI Yan1, 2, ZHANG Yi-fei1, YANG Chao1, ZHANG Yi1

(1. Institute of Process Engineering, Chinese Academy of Sciences, Beijing 100080, China;

2. Graduate University, Chinese Academy of Sciences, Beijing 100049, China)

Abstract: Procedure for precipitating aluminium hydroxide from sodium aluminate solution was investigated, and hydrochloric acid was used as neutralization agent. Effects of pH value on the crystal morphology, crystal type and sodium aluminate decomposition ratio were studied. The experimental results show that the crystal morphology of aluminium hydroxide varies with the decreasing pH value of the solution, in addition, the higher the pH value, the larger the crystallites of the precipitates. No matter how the pH value changes, the precipitates always are gibbsite. The decomposition rate increases with the decrease of pH value.

Key words: sodium aluminate; aluminium hydrate; neutralization; nano-fibre

氢氧化铝粉末作为阻燃剂在电工、建筑材料、塑料和橡胶等行业中得到广泛的应用。目前,常用的阻燃剂可分为3种:反应型阻燃剂、有机添加型阻燃剂和无机添加型阻燃剂。反应型阻燃剂热稳定性好,毒性低,对高聚物的其它性能影响小,但其工艺复杂,成本较高;有机添加型阻燃剂往往会带来阻燃制品的发烟、毒气释放等环境和使用安全问题;无机添加型阻燃剂具有热稳定性好,毒性低,甚至无毒,不产生腐蚀气体,储存过程中不挥发,不析出,阻燃效果持久,原料来源丰富,价格低廉等优点,因而无机添加型阻燃剂获得了广泛的应用。在所有的无机添加型阻燃剂中,氢氧化铝具有热稳定好、无毒、不挥发、不产生腐蚀性气体、发烟量少、价格便宜等优点[1-4]。然而,普通市售氢氧化铝粒度通常为几微米,并且在大量填充时才能起到良好的阻燃效果,而大量填充粒度较粗的氢氧化铝会降低聚合物的力学性能和电性能,但纳米级的氢氧化铝不仅具有更好的阻燃性,且在大量填充时不会影响聚合物的性能,因而作为阻燃剂在聚合物中的应用日益广泛[5-10]。

本文作者研究以合成拜尔液为原料,以盐酸为中和剂时丝状氢氧化铝的析出过程,与以往文献报道的纳米氢氧化铝制备过程相比,本研究中制备的丝状氢氧化铝直径小于100 nm,作为阻燃剂可强化聚合物的力学性能,且其制备过程简单易行。

1 实验

实验所用的试剂(分析纯)有Al(OH)3,NaOH,HCl和C2H5OH,所有试剂均由北京化工厂生产。

将一定浓度的氢氧化钠溶液加热升温至110 ℃,再将一定量的氢氧化铝加入其中,继续加热,使料液温度保持在110-120 ℃,直至氢氧化铝完全溶解,趁热过滤,得到澄清的铝酸钠溶液。铝酸钠溶液的分解率根据铝酸钠溶液分解前后的分子比来计算[11-14],以铝酸钠溶液中氧化铝的分解率来表示:

本论文中使用的铝酸钠溶液的初始条件为:温度333 K,过饱和度2,氧化钠浓度100 g/L。

取一定量的铝酸钠溶液置于500 mL三口烧瓶中,三口烧瓶放置在恒温水浴中,一定浓度的盐酸由恒流泵以一定流速加入三口烧瓶中,搅拌分解一定时间后,得到氢氧化铝固体,固液分离后固体经洗涤干燥后得到氢氧化铝产品。

采用美国Perkin-Elmer公司的Optima 5300DV 型ICP-AES分析铝酸钠溶液的组成;利用荷兰Panalytical公司X’Pert PRO MPD型多功能X射线衍射仪分析固相晶型;采用日本电子公司JSM-6700F型冷场发射扫描电镜测定固体颗粒形貌。

2 结果与讨论

取50 mL铝酸钠溶液加入三口烧瓶中,恒温(60℃)水浴,0.05 mol/L的盐酸作为中和剂,以1 mL/min的速度加入铝酸钠溶液中,60 ℃时的中和曲线如图1所示。

图1 铝酸钠溶液的中和曲线

Fig.1 Titration curve obtained by neutralizing sodium aluminate with hydrochloric acid

中和曲线反映了铝酸钠溶液与0.05 mol/L盐酸的中和过程,中和曲线可分为3个区域,在区域1中,盐酸带入的氢离子与铝酸钠溶液中游离的氢氧根发生中和反应,在区域1的终点(pH=12.5),氢氧化铝开始析出,溶液从澄清透明变为不透明,另外,在该点处铝酸钠溶液的缓冲能力?ρ(HNO3)/ ?pH迅速增大。在区域2,pH值几乎保持恒定,此时,根据下面的化学反应方程,氢离子的加入速度几乎等于氢氧根的释放速度:

![]()

![]()

![]()

在区域2中,很容易观察到不透明的液相转变为白色的沉淀,标志着液相中固体颗粒的形成。在区域3中,沉淀过程继续进行,pH值开始快速下降,此时,氢离子的加入速度远远大于氢氧根的释放速度,pH值迅速从12降至7。

图2所示为pH值与铝酸钠溶液分解率的关系曲线。

图2 pH值与铝酸钠溶液分解率的关系曲线

Fig.2 Relationship between sodium aluminate decomposition ratio and pH values

显而易见,随着盐酸的不断加入,铝酸钠溶液的分解率会不断增大,直至完全分解,从图2还可观测到,在pH值下降的过程中,铝酸钠溶液的分解速度也在逐渐下降。

图3所示为不同pH值对氢氧化铝晶型的影响。

图3 pH值对氢氧化铝晶型的影响

Fig.3 Effect of pH values on crystal type of aluminium hydrate

铝酸钠溶液终点pH 值不同时所得氢氧化铝晶体的XRD谱用分析软件X’Pert Highscore、调用数据库PDF-2进行分析。结果表明:不同pH值下得到的氢氧化铝晶体均为gibbsite型氢氧化铝,但随着pH值的下降,峰强略有下降。

图4所示为不同pH值对氢氧化铝晶体形貌的影响。从图4中可以看出,最初沉淀出来的氢氧化铝为六边形的柱体,随着盐酸的加入,沉淀出的氢氧化铝的形貌不断发生变化。pH值为11时,沉淀出的氢氧化铝为针状,继续加入盐酸,pH值达到10时,开始有丝状氢氧化铝析出,pH值下降为9时,析出的丝状氢氧化铝缠绕成网状。因此,可以认为随着盐酸的不断加入,沉淀出的氢氧化铝晶体的尺寸不断减小,也就是说,沉淀出的氢氧化铝晶体的尺寸随溶液pH值的降低而缩小,该结果与PANIAS等[15]的一致。

图4 pH值对氢氧化铝形貌的影响

Fig.4 Effect of pH value on aluminum hydrate morphology: (a) pH=12; (b) pH=11; (c) pH=10; (d) pH=9

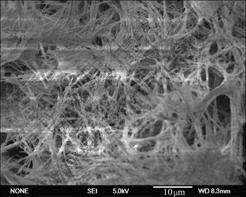

图5所示为丝状氢氧化铝的微观组织。由图5可观测到当pH值下降至10时,沉淀析出的氢氧化铝开始变为丝状,此时溶液中氧化铝的浓度大约为10 g/L。将原始铝酸钠溶液稀释至氧化铝的浓度为10 g/L,以同样的方式加入盐酸,可得到完全由丝状氢氧化铝缠绕而成的团。由图5还可以看到,氢氧化铝丝的直径小于100 nm。

图5 丝状氢氧化铝的微观组织

Fig.5 Microstructure of fibre-like aluminium hydrate

3 结论

1) 在溶液pH值下降的过程中,沉淀析出的氢氧化铝的形貌不断发生变化,且析出的氢氧化铝晶体的尺寸不断减小,铝酸钠溶液的分解率不断增大,但分解速率不断下降。

2) 沉淀析出的氢氧化铝的晶型基本不变,均为gibbsite型氢氧化铝。

3) 盐酸中和铝酸钠溶液可以制备直径小于100 nm的丝状氢氧化铝。

REFERENCES

[1] CUI Weng-guang, GUO Fen, CHENG Jian-feng, PANG Li-ping. Study on inflaming retarding and toughening of high impact polystyrene [J]. Application of Engineering Plastic, 2006, 34: 4-7.

[2] SHEN S C, NG W K, CHEN Q. Novel synthesis of lace-like nanoribbons of boehmite and γ-alumina by dry gel conversion method [J]. Materials Letters 2007, 61: 4280-4282.

[3] DU T B, JANG S M, CHEN B W. Manufacture of mesoporous alumina of boehmite type via subcritical drying and application to purity liquid crystal [J]. Chemical Engineering Science, 2007, 62: 4864-4868.

[4] GUBICZA J, DIRRAS G, SZOMMER P, BACROIX B. Microstructure and yield strength of ultrafine grained aluminium processed by hot isostatic pressing [J]. Materials Science and Engineering A, 2007, 458: 385-390.

[5] MAZLOUMI M, ARAMI H, KHALIFEHZADEH R, SADRNEZHAAD S K. Studies on synthesis of alumina nanopowder from synthesis Bayer liquor [J]. Materials Research Bulletin, 2007, 42: 1004-1009.

[6] RASMUSSEN D H, BRANCEWICZ C, DAS B. Precipitation of nanoscale aluminium hydroxide particles [J]. Journal of Dispersion Science and Technology, 2001, 22(5): 491-498.

[7] EL-KATATNY E A, HALAWY S A, MOHAMED M A. A novel synthesis of high-area alumina via H2O2-precipitated boehmite from sodium aluminate solution [J]. Chem Technol Biotechnol, 1998, 72: 320-328.

[8] GERSON A R, COUNTER J A, COOKSON D J. Influence of solution constituents, solution conditioning and seeding on the crystalline phase of aluminium hydroxide using in situ X-ray diffraction [J]. Journal of Crystal Growth, 1996, 160: 346-354.

[9] HAN Qin, LIU Zheng-hui, XU Ying-ying, ZHANG Han. Synthesis and magnetic properties of single-crystalline magnetite nanowires [J]. Journal of Crystal Growth, 2007, 307: 483-489.

[10] CHAKALOZ T, SENEL G. Filtration characteristics of aluminium hydroxide mixtures [J]. Chem Technol Biotechnol, 1973, 23: 357-361.

[11] ZHANG Xu-dong, LIU Hong, HE Wen, WANG Ji-yang. Novel synthesis of YAG by solvothermal method [J]. Journal of Crystal Growth, 2005, 275: 1913-1917.

[12] SATO T. Preparation of aluminium hydroxide by reacting sodium aluminate solutions with mineral acid [J]. Chem Technol Biotechnol, 1991, 31: 670-675.

[13] BYE G C, ROBINSON J G. The nature of pseudo-boehmite and its role in the crystallization of amorphous aluminium hydroxide [J]. Chem Technol Biotechnol, 1974, 24: 633-637.

[14] BLANKS K A. Novel synthesis of gibbsite by laser-stimulated nucleation in supersaturated sodium aluminate solutions [J]. Journal of Crystal Growth, 2000, 220: 572-578.

[15] PANIAS D, KRESTOU A. Effect of synthesis parameters on precipitation of nanocrystalline boehmite from aluminate solutions [J]. Powder Technology, 2007, 175: 163-173.

基金项目:国家重点基础研究计划资助项目(2007CB613501)

通讯作者:张亦飞,博士;电话:010-82610244;E-mail: yfzhang@home.ipe.ac.cn

(编辑 李向群)