Trans. Nonferrous Met. Soc. China 23(2013) 3228-3234

Effects of samarium addition on microstructure and mechanical properties of as-cast Al-Si-Cu alloy

Zhi HU1,2, Hong YAN1, Yuan-sheng RAO1

1. Institute of Advanced Forming, Nanchang University, Nanchang 330031, China;

2. Jiangxi Key Laboratory for Advanced Copper and Tungsten Materials, Jiangxi Academy of Sciences, Nanchang 330029, China

Received 15 October 2012; accepted 14 April 2013

Abstract:

The effects of rare earth samarium (Sm) additions on the microstructure and mechanical properties of as-cast Al-Si-Cu alloy were investigated by optical microscopy and scanning electron microscopy (SEM). The results show that Sm can effectively refine the α(Al) dendrite and the eutectic silicon. In addition, the shape of iron-rich phases changes from the Chinese script-like to slender-like ones and the volume fraction of iron-rich phases is decreased by the addition of Sm. Two kinds of Sm-rich intermetallics are found: AlSiSm and AlSiCuSm. The plate-like AlSiCuSm phase always associates with the needle-like AlSiSm phase. The mechanical properties are improved by the addition of Sm, and the good ultimate tensile strength (220 MPa) and elongation (3.1%) are obtained from the Al-Si-Cu-1.0Sm alloy.

Key words:

aluminum alloys; rare earth; samarium; microstructure; mechanical properties;

1 Introduction

Al-Si-Cu alloys are the most widely used alloys owing to their superior castability and good balance of strength, ductility and corrosion resistance. With the development of magnesium alloy, titanium alloy and composite materials, it is necessary to improve the mechanical properties of Al-Si-Cu alloys to meet the higher requirements of materials [1-3]. Improvement in microstructure and properties of the alloys can be achieved by the addition of minor alloying elements. Rare earths are important alloying elements to aluminum alloys, which could improve mechanical property, casting characteristics and high temperature performance [4].

Recently, it has been reported that the addition of rare earth elements can change the microstructures by refining the grain size of the alloy and making the needle-like and laminar eutectic Si to a granular Si. With the increase of the rare earth content, the tensile strength and elongation of the alloy increase first and then fall down [5]. Sr is an effective element to modify the size and morphology of the intermetallic compounds in 319 alloys. The addition of Sr leads to the reduction of the platelet β-phase volume fraction [6,7]. ASHTARI et al [8] reported that Li successfully modified the morphology of the β-Al5FeSi phase from coarse intersected and branched platelets into finer and independent ones. YI et al [9] reported that the addition of 3% La in mass fraction has little modification effect on silicon phases in A390 as expected for the formation of the compounds Al7Si7Cu2La3.5 and Al5Mg8Cu6Si6.

According to the previous study [10], Sm was added as a modifier into Al-Si alloys, resulting in some changes in the appearance of eutectic silicon, but still unsatisfactory. Besides, there is a lack of analysis of mechanical properties when modified by Sm addition. Therefore, the present work is to investigate the microstructure and mechanical properties of as-cast Al-Si-Cu alloys with Sm addition.

2 Experimental

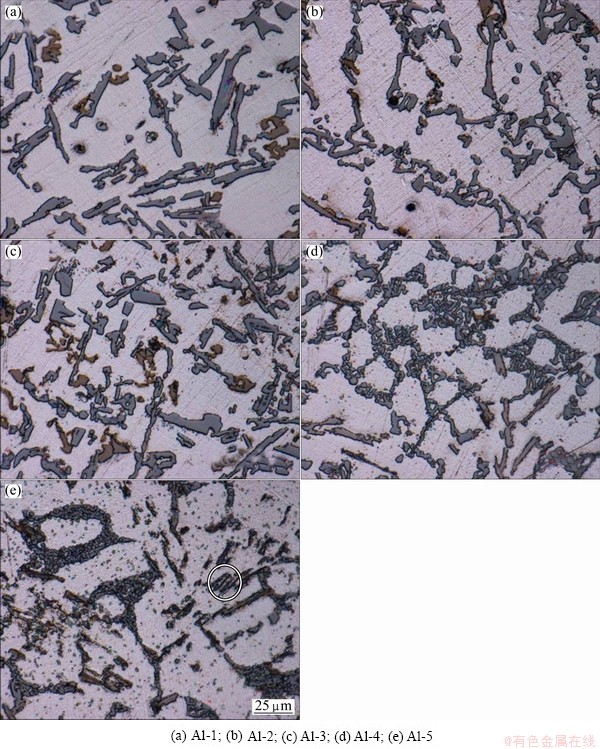

Five alloys with the basic composition of Al-Si-Cu alloy were melted in a clay/graphite crucible at 780-800 °C with an electric resistant furnace. And 0, 0.5%, 1.0%, 1.5%, and 2.5% Sm (in the form of Al-15% Sm master alloy) were added into the molten alloys, respectively. The chemical compositions of the as-cast alloys studied with the inductively coupled plasma mass spectrometer (ICP-MS) are listed in Table 1. Then, the melts were degassed with hexachloroethane and held at the decreased temperature of approximately 750 °C for 15-20 min. At last, the melt was poured into a metal mould at 680 °C after being degassed, cleared of dross, homogenized for 30-40 min and after temperature adjustment.

Microstructural evolution study was carried out on as-cast samples to investigate the morphological change of the compounds and the modification effect of Sm addition. Metallographic specimens were mechanically ground and polished through standard routines and examined with an optical microscope (Nican 300) at different magnifications to see the change of the compounds in the alloys with or without Sm additions. An etchant of 0.5% hydrofluoric acid (HF) water solution was used to reveal the microstructure of polishing samples. The precipitated phases of the specimens were characterized by Quanta 200 scanning electron microscope (SEM) with energy dispersive spectroscope (EDS). The tensile test was carried out at room temperature and a strain rate of 1 mm/min. Ultimate tensile strength (UTS) and elongation (EL) to failure were measured.

3 Results and discussion

3.1 Microstructures

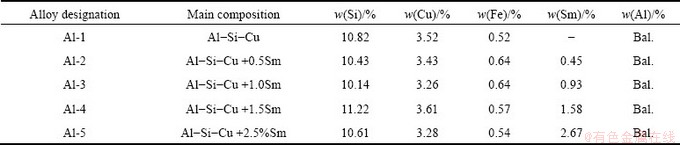

Figure 1 illustrates the optical microstructures of as-cast Al-Si-Cu alloys with different additions of Sm. A representative microstructure of Al-Si-Cu alloy prepared by a conventional casting route is shown in Fig. 1(a), and microstructural components precipitating during solidification are marked, respectively. As shown in the micrograph, the microstructure of alloy mainly consists of the α(Al) dendrites, the primary silicon (Si), the eutectic silicon and the iron-rich phases. The α(Al) phase is characterized by typical dendritic shape, but α(Al) grain in the unmodified Al-1 alloy is much coarser, whereas the finer grains and dendrites are obtained in the Al-Si-Cu alloys modified with Sm, depending on different additions of Sm.

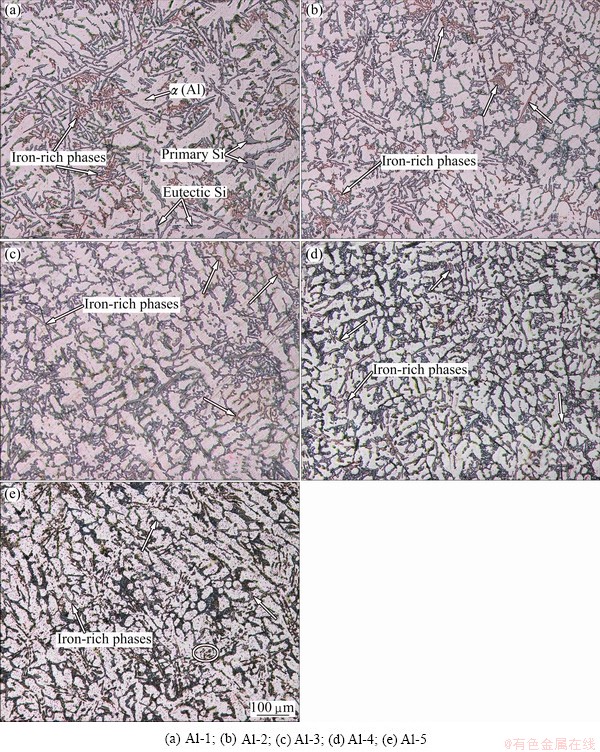

In alloys Al-1 and Al-2, iron-rich phases disperse in the form of the Chinese script morphology. However, their shape and cluster size are different. An increase of Sm content reduces the iron-rich phases cluster size. In Al-2 alloy with 0.5% Sm, iron-rich phases appear as incomplete Chinese script clusters with a size about 80 μm, as shown in Fig. 1(b) and marked with arrow. Increasing Sm content to 1.0% and 1.5%, iron-rich phases tend to be slender with a size of about 40 μm in Figs. 1(c) and (d). Further increasing Sm content to 2.5%, iron-rich phases also disperse as slender-like shape, but the volume fraction of iron-rich phases is decreased, as shown in Fig. 1(e). Similar results were reported by EIDHED [6]. Therefore, this clearly indicates that the shape of iron-rich phases changes from the Chinese script-like to slender-like and the volume fraction of iron-rich phases is decreased by the addition of Sm. Figure 2 shows the effect of Sm addition on the secondary dendrite arm spacing (SDAS) of these samples. The SDAS value became smaller with increasing Sm addition, and decreased slightly from the unmodified 32 μm to 25 μm.

Table 1 Chemical compositions of Al-Si-Cu alloy

Fig. 1 Optical microstructures of Al-Si-Cu alloys with different Sm additions

Fig. 2 SDAS of as-cast Al-Si-Cu aluminum alloys with different Sm additions

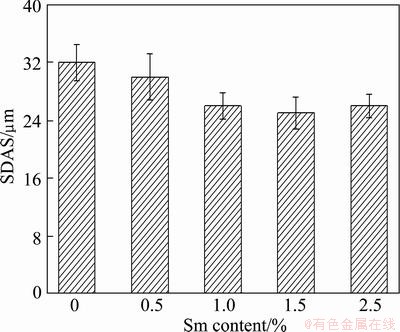

Fig. 3 Eutectic Si morphologies in Al-Si-Cu alloys with different Sm additions

Figure 3 shows the eutectic Si morphology in Al-Si-Cu alloys with different Sm additions. As shown in Fig. 3(a), the eutectic Si morphology of the unmodified alloy (Al-1) is relatively coarse, showing a lamellar-like shape with sharp edges. From Figs. 3(b) to (e), Sm addition is seen to have a significant effect on the size and morphology of the eutectic Si. For the 0.5% Sm treatment (Al-2), the amount of lamellar-like eutectic Si significantly decreases and the size of the eutectic Si is finer, as seen in Figs. 3(b). The eutectic Si morphology of samples in Figs. 3(c) and (d) became more lamellar in their structures and smaller in size. The 2.5% Sm treatment resulted in a complete fine particles (Fig. 3(e)). It is clear that the eutectic silicon has been refined with Sm modification. Much research also has revealed a modification effect of rare earth elements on the Si phase in Al-Si alloy [11-13]. It was found that orientation relationship between aluminum and silicon and the growth direction of eutectic silicon in the RE modified Al-Si alloy differed from that in the unmodified alloy, which suggested that RE modification was partly attributed to the rate reduction of silicon attachment by existence of RE solute in front of the advancing groove surfaces [14,15].

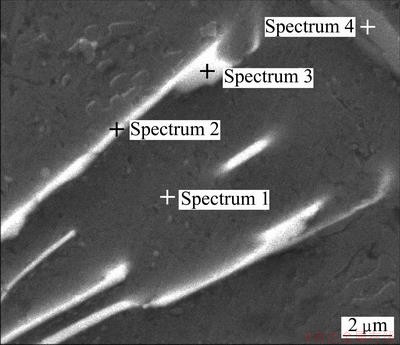

Fig. 4 SEM image of Al-5 alloy

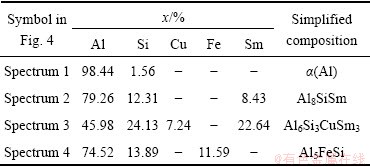

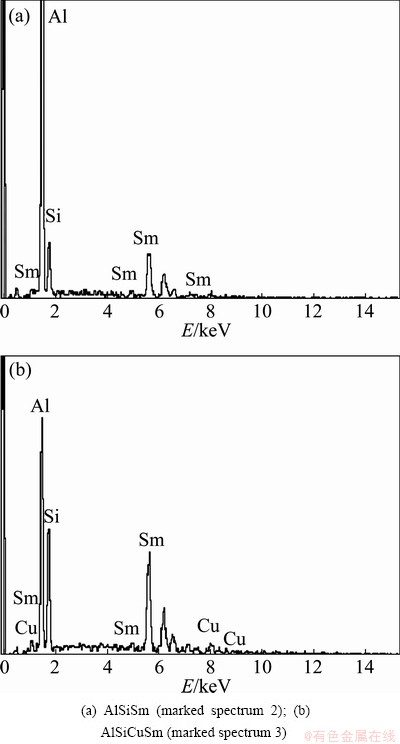

In Figs. 1(e) and 3(e), the needle-like phases marked with circles are different in morphology and shade from other phases. The SEM micrograph of as cast Al-5 alloy is shown in Fig. 4. The needle-like phase (marked spectrum 2) is an Al-rich intermetallic which contains Al, Si and Sm elements. The mole fractions are also calculated and listed in Table 2. It is worth mentioning here that the similar AlSiLa and AlSiCe phases had been observed in A356 aluminum alloy by TSAI et al [16,17], who reported that the influence of the rare earth metals La and Ce on the microstructures and mechanical properties of A356 alloy. The dark area (marked spectrum 1) is α(Al). And a little more bright area (marked spectrum 4) than the dark area is iron-rich phase. The EDS analysis results show that the mole ratio of Al to Fe to Si of β-AlFeSi is approximately 5:1:1. The plate-like intermetallic phase (marked spectrum 3) locates at the tip of the strips AlSiSm phase, as shown in Fig. 5. The EDS point analysis reveals that the plate-like phase is rich in Al, Si, Sm, and contains Cu elements, as shown in Fig. 4. And the plate-like phase is always associated with the AlSiSm phase. Therefore, the AlSiSm phase maybe grows out from the plate-like phase during the final complex eutectic reaction in the Al-Si-Cu alloys as Al5Mg8Cu2Si6 reported by SAMUEL et al [18]. According to the mole ratio of the plate-like intermetallic phase, the chemical composition of it can be interpreted as Al6Si3CuSm3. The Al6Si3CuSm3 phase also may be a mixture of AlSiSm and Cu-rich intermetallics. The concentration of the Al-Cu phase is much closer to the stoichiometric composition of Al2Cu.

Table 2 Summary of EDS point analysis corresponding to intermetallics marked in Fig. 4

Fig. 5 EDS analyses of locations marked spectrum 2 and spectrum 3 in Fig. 4

3.2 Mechanical properties

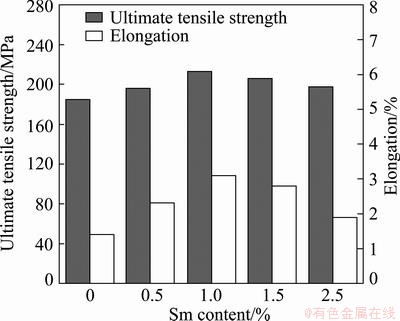

Figure 6 shows mechanical properties of Al-Si-Cu alloys with different Sm additions at room temperature. It can be seen that Sm addition has a significant influence on the mechanical properties of Al-Si-Cu alloys. Both the ultimate tensile strength (UTS) and elongation are enhanced with Sm increasing from 0.5% to 1.0%. Accordingly, the maximum of mechanical properties is obtained from the Al-3 alloy. The UTS and elongation are 220 MPa and 3.1%, respectively. A further addition of Sm results in a reduction in mechanical properties. Therefore, the amount of samarium addition to the Al-Si-Cu alloys must be limited within a rational range.

Fig. 6 Mechanical properties of Al-Si-Cu alloys with different Sm additions at room temperature

It is well known that the mechanical properties of the Al-Si alloys largely depend on the size and morphology of α(Al) dendrite, iron-rich phases and the eutectic silicon characteristics [19,20]. In the experiment, the fine α(Al) dendrite was obtained with Sm content increasing to 1.0% and 1.5%. The addition of Sm in alloys not only increases the undercooling but also forms adsorptive rare earth element films on the boundaries of growing crystals, resulting in a reduction of the grain growth rate, in turn, the formation of fine-grained structure [21]. The smaller the grain size is, the larger the deformation resistance is, and therefore the tensile strength and elongation are improved. On the other hand, the smaller Chinese script-like iron-rich phases and eutectic Si also have good effects on the mechanical properties of Al-Si-Cu alloy as discussed earlier [10,22]. Sm can effectively change the size and morphology of Chinese script-like iron-rich phases and eutectic Si phases, thus reducing the effects of the seperation of them to alloy martrix, and improving the mechanical properties of the Al-Si-Cu alloy. After further addition of Sm, the needle-like rare earth phase formed at the grain boundaries in Fig. 3(e) and slender like iron-rich phases would cause stress concentration and make the alloys prone to fracture during tensile test, resulting in low ultimate tensile strength and poor ductility.

4 Conclusions

1) The α(Al) dendrites and the eutectic silicon in as- cast Al-Si-Cu alloys were effectively fined with different Sm additions. SDAS value decreased slightly from the unmodified 32 μm to 25 μm when the Sm content approached to 1.5%.

2) The addition of Sm to give a content of 0-2.5% in Al-Si-Cu alloys transformed the shape of iron-rich phases from the Chinese script-like to slender-like ones. As the Sm content exceeded 1.5%, two kinds of Sm-rich intermetallics are found in Al-Si-Cu alloys: the plate-shaped AlSiCuSm phase always associates with the needle-like AlSiSm phase.

3) The mechanical properties of Al-Si-Cu alloys were improved with Sm addition up to 0-1.0%, but were subsequently degraded as the Sm content exceeded 1.0%. The maximum values of the ultimate tensile strength and elongation were 220 MPa and 3.1%, respectively.

References

[1] EMMA S, SALEM S. The heat treatment of Al-Si-Cu-Mg casting alloys [J]. Journal of Materials Processing Technology, 2010, 210: 1249-1259.

[2] IBRAHIM M F, SAMUEL E, SAMUEL A M, AL-AHMARI A M A, SAMUEL F H. Metallurgical parameters controlling the microstructure and hardness of Al-Si-Cu-Mg base alloys [J]. Materials and Design, 2011, 32: 2130-2142.

[3] KARIMIAN M, OURDJIMI A, HASBULLAH IDRIS M, JAFARI H. Effect of pattern coating thickness on characteristics of lost foam Al-Si-Cu alloy casting [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(9): 2092-2097.

[4] WANG Ming-xing, ZHOU Hong, WANG Lin. Effect of yttrium and cerium addition on microstructure and mechanical properties of AM50 magnesium alloy [J]. Journal of Rare Earths, 2007, 25(2): 233-237.

[5] WAN Wei-wei, HAN Jian-min, LI Wei-jing, WANG Jin-hua. Study of rare earth element effect on microstructures and mechanical properties of an Al-Cu-Mg-Si cast alloy [J]. Rare Metals, 2006, 25(6): 129-132.

[6] EIDHED W. Modification of β-Al5FeSi compound in recycled Al-Si-Fe cast alloy by using Sr, Mg and Cr additions [J]. Journal of Materials Science and Technology, 2008, 24(1): 45-47.

[7] KIM M, HONG Y, CHO H. The Effects of Sc on the microstructure and mechanical properties of hypo-eutectic Al-Si alloys [J]. Metals and Materials International, 2004, 10(6): 513-520.

[8] ASHTARI P, TEZUKA H, SATO T. Influence of Li addition on intermetallic compound morphologies in Al-Si-Cu-Fe cast alloys [J]. Scripta Materialia, 2004, 51: 43-46.

[9] YI H K, ZHANG D, SAKATA T, MORI H. Microstructures and La-rich compounds in a Cu-containing hypereutectic Al-Si alloy [J]. Journal of Alloys and Compounds, 2003, 354: 159-164.

[10] NOGITA K, MCDONALD S D, DAHLE A K. Eutectic modification of Al-Si alloys with rare earth Metals [J]. Materials Transactions, 2004, 45(2): 323-326.

[11] RAVI M, PILLAI U T S, PAI B C, DAMODARAN A D, DWARAKADASA E S. Study of the influence of mischmetal additions to Al-7Si-0.3Mg (LM 25/356) alloy [J]. Metallurgical and Materials Transactions A, 1996, 27(5): 1283-1292.

[12] CHANG J Y, KIM G H, MOON I G, CHOI C S. Rare earth concentration in the primary Si crystal in rare earth added Al-21wt.%Si alloy [J]. Scripta Materialia, 1998, 39(3): 307-314.

[13] XING Peng-fei, GAO Bo, ZHUANG Yan-xin, LIU Kai-hua, TU Gan-feng. On the modification of hypereutectic Al-Si alloys using rare earth Er [J]. Acta Metallurgica Sinica, 2010, 23(5): 327-333.

[14] CHANG J Y, KO H S. Twin probability of eutectic Si in rare earth modified Al-7wt%Si alloy [J]. Journal of Materials Science Letters, 2000, 19(3): 197-199.

[15] CHANG J Y. Crystal morphology of eutectic Si in rare earth modified Al-7wt%Si alloy [J]. Journal of Materials Science Letters, 2001, 20(14): 1305-1307.

[16] TSAI Y C, CHOU C Y, JENG R R, LEE S L, LIN C K. Effect of rare earth elements addition on microstructures and mechanical properties of A356 alloy [J]. International Journal of Cast Metals Research, 2011, 24(2): 83-87.

[17] TSAI Y C, CHOU C Y, LEE S L, LIN C K, LIN J C, LIM S W. Effect of trace La addition on the microstructures and mechanical properties of A356 (Al-7Si-0.35Mg) aluminum alloys [J]. Journal of Alloys and Compounds, 2009, 487: 157-162.

[18] SAMUEL F H, SAMUEL A M, OUELLET P, DOTY H W. Effect of Mg and Sr Additions on The formation of intermetallics in Al-6 wt pct Si-3.5 wt pct Cu- (0.45) to (0.8) wt pct Fe 319-type alloys [J]. Metallurgical and Materials Transactions A, 1998, 29(12): 2871-2884.

[19] HU Xiao-wu, JIANG Fu-gang, AI Fang-rong, YAN Hong. Effects of rare earth Er additions on microstructure development and mechanical properties of die-cast ADC12 aluminum alloy [J]. Journal of Alloys and Compounds, 2012, 538: 21-27.

[20] CESCHINI L, MORRI A, MORRI A, GAMBERINI A, MESSIERI S. Correlation between ultimate tensile strength and solidification microstructure for the sand cast A357 aluminium alloy [J]. Materials and Design, 2009, 30: 4525-4531.

[21] WANG Shao-hong, ZHOU He-ping, KANG Yu-ping. The Influence of rare earth elements on microstructures and properties of 6061 aluminum alloy vacuum-brazed joints [J]. Journal of Alloys and Compounds, 2003, 352: 79-83.

[22] SAMUEL A M, SAMUEL F H, DOTY H W. Observation on the formation of β-Al5FeSi phase in 319 type Al-Si alloy [J]. Journal of Materials Science, 1996, 31(20): 5529-5539.

稀土Sm元素对铸态Al-Si-Cu合金组织和力学性能的影响

胡 志1, 2, 闫 洪1, 饶远生1

1. 南昌大学 先进成形研究所,江西 330031;

2. 江西省科学院 江西省铜钨新材料重点实验室,江西 330029

摘 要:通过光学显微镜、扫描电镜及能谱分析,研究了稀土元素钐对铸态Al-Si-Cu 合金组织和力学性能的影响。结果表明:稀土元素钐的添加不仅能有效地细化Al-Si-Cu合金中的α(Al)枝晶和共晶硅相,而且使得富铁相的体积分数下降,其形状从中国汉字状转变为板条状。发现了两种富钐的金属间化合物:AlSiSm相和AlSiCuSm相,块状的 AlSiCuSm 相通常与针状的AlSiSm相连。稀土元素钐的添加使得Al-Si-Cu合金的力学性能得到改善,当钐含量为1.0%时,合金的抗拉强度和伸长率分别为220 MPa和 3.1%。

关键词:铝硅合金;稀土;钐;显微组织;力学性能

(Edited by Hua YANG)

Foundation item: Project (51165032) supported by the National Natural Science Foundation of China; Project (20122BAB216017) supported by the Natural Science Foundation of Jiangxi Province, China; Project (2011-TW-03) supported by the Open Foundation of Jiangxi Key Laboratory for Advanced Copper and Tungsten Materials, China

Corresponding author: Zhi HU; Tel: +86-791-83968873; E-mail: huzhi215@163.com

DOI: 10.1016/S1003-6326(13)62857-5

Abstract: The effects of rare earth samarium (Sm) additions on the microstructure and mechanical properties of as-cast Al-Si-Cu alloy were investigated by optical microscopy and scanning electron microscopy (SEM). The results show that Sm can effectively refine the α(Al) dendrite and the eutectic silicon. In addition, the shape of iron-rich phases changes from the Chinese script-like to slender-like ones and the volume fraction of iron-rich phases is decreased by the addition of Sm. Two kinds of Sm-rich intermetallics are found: AlSiSm and AlSiCuSm. The plate-like AlSiCuSm phase always associates with the needle-like AlSiSm phase. The mechanical properties are improved by the addition of Sm, and the good ultimate tensile strength (220 MPa) and elongation (3.1%) are obtained from the Al-Si-Cu-1.0Sm alloy.