Effect of annealing temperature on ferroelectric properties of (Bi, Nd)4(Ti, V)3O12 thin films

YE Zhi(叶 志)1, TANG Ming-hua(唐明华)1, 2, CHENG Chuan-pin(成传品)1, ZHOU Yi-chun(周益春)1, 2,

ZHENG Xue-jun(郑学军)1, 2, HU Zeng-shun(胡增顺)1

1. Faculty of Materials and Optoelectronic Physics, Xiangtan University, Xiangtan 411105, China;

2. Key Laboratory of Advanced Materials and Rheological Properties of Ministry of Education, Xiangtan 411105, China

Received 10 April 2006; accepted 25 April 2006

Abstract:

Thin films of Nd3+/V5+-cosubstituted bismuth titanate, (Bi3.5Nd0.5)( Ti2.96V0.04)O12 (BNTV), were fabricated on the Pt(111)/Ti/SiO2/Si(100) substrates by a chemical solution deposition technique and annealed at different temperatures of 650, 700, 750 and 800 ℃. The surface morphology and ferroelectric properties of the samples were studied in detail. The result shows that the film annealed at 800 ℃ indicates excellent ferroelectricity with a remanent polarization of 2Pr=40.9 μC/cm2, a coercive field (EC) of 114 kV/cm at an applied electrical field of 375 kV/cm. The substitution of Ti-site ion by V5+ ions could improve the upper limit of the optimal annealing temperature by decreasing the space charge density in BNT thin film. Additionally, the mechanism concerning the dependence of ferroelectric properties of BNTV thin films on the annealing temperature was discussed.

Key words:

ferroelectric properties; annealing; scanning electron microscopy; crystallization;

1 Introduction

More and more attentions have been attracted to the ferroelectric thin films recently, because of its far-ranging applications such as nonvolatile random access memories (FeRAMs), microelectromechanical systems, pyroelectric detectors, integrated optical modulators, actuatiors and infrared sensors [1, 2]. Although lead zirconate titanate (PZT) has some of the better ferroelectric characteristics of lower processing temperature, PZT thin films suffer from serious fatigue and imprint problems [3]. As the instead of the conventional lead-based materials, films of some kinds of bismuth layer-structured ferroelectrics (BLSFs) have the characteristics of large remanent polarization, high fatigue resistance, good retention, lead-free chemical composition and so on [4, 5]. Among BLSFs, Bi4Ti3O12 (BIT) is the most widely studied thin film. Many researchers have attempted to enhance polarization of BIT thin films using various techniques. ‘Site engineering’ may be an effective technique for improving ferroelectric properties [6]. La-substituted Bi4Ti3O12(BLT) films have been very attractive for their larger ferroelectricity than BIT and good fatigue resistance. However, the reports of BLT thin films with large ferroelectricity are limited to the films prepared at relatively high temperature above 650 ℃. In order to obtain lower temperature deposition of BLT, WATANABE et al [7] reported that La and V-cosubstituted BIT (BLTV) thin films prepared at a relatively low temperature of 600 ℃ by MOCVD showed large ferroelectricity.

In our group, the BNT films of excellent ferroelectric properties have been fabricated by chemical solution deposition (CSD) [8, 9]. While UCHIDA et al [1] reported that substitution of Ti-site ion by other ions with higher charge valences (e.g., V5+ and W6+) improved the ferroelectric properties by the decrease of space charge density. So UCHIDA et al [1] fabricated Nd3+/V5+-cosubstituted BIT thin films (BNTV) by CSD, which showed larger remanent polarization than BNT thin films [(Bi3.5Nd0.5)Ti3O12: Pr=32 μC/cm2, EC=126 kV/cm; (Bi3.5Nd0.5)(Ti2.98V0.02)O12: Pr=37 μC/cm2, EC=119 kV/ cm, 450 kV/cm].

In the present study, Nd3+/V5+-cosubstituted BIT thin film was fabricated on platinum-coated silicon [Pt(111)/Ti/SiO2/Si(100)] substrate by CSD. In order to investigate the temperature dependence of ferroelectric properties of BNTV thin films, the films are crystallized at a moderate annealed temperature (650-800 ℃).

2 ExperimentalThe (Bi3.5Nd0.5)(Ti2.96V0.04)O12 (BNTV) thin films were fabricated on Pt(111)/Ti/SiO2/Si(100) substrates using a CSD technique at room temperature. The precursor solution for the coating was prepared by first dissolving appropriate amounts of bismuth nitride [Bi(NO3)3?5H2O], neodymium nitride [Nd(NO3)3] and vanadium (III) acetylacetonate [V(C5H8O2)3] in acetic acid [CH3COOH]. The 10%(in more fraction) excess bismuth nitride was needed to compensate the Bi loss during the high thermal process. A stoichiometric amount of titanium butoxide [Ti(OC4H9)4] was added to the mixed precursor solution rapidly. Then, acetylacetone as a stabilizing agent to stabilize the solution was added to the solution. Finally, glacial acetic was mixed to adjust the concentration. A clear yellow sol with a molar concentration of 0.05 mol/L was obtained. The solution was spin-coated on substrates at a rate of 3 000 r/min for 50 s, followed by a drying process at 100 ℃ for 5 min and a pyrolysis process at 400 ℃ for 5 min with a rise rate of 1 ℃/s to remove residual organic compounds. These processes were repeated eight times to achieve desired film thickness. The resultant films were annealed for crystallization for 10 min in air by a rapid thermal annealing process at various temperatures of 650, 700, 750 and 800 ℃, respectively.

The constituent phase and crystal orientation of the films were identified by X-ray diffraction (XRD) using a Rigaku D/max-rA diffractometer with Cu Kα radiation at 40 kV. The surface morphology and the thickness of the films were investigated using a JSM-5600LV scanning electron microscope (SEM). For electrical measurements, Au was sputtered on the surface of the films as top electrode with diameters of 0.2 mm using a metal mask. Then, the ferroelectric properties were measured using a radiant technology precision workstation ferroelectric tester with the virtual ground mode.

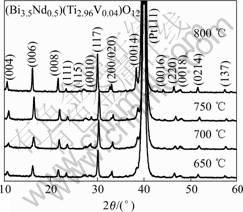

3 Results and discussionFig.1 shows the XRD patterns of BNTV thin films annealed under various temperatures ranging from 650 to 800 ℃ at an interval of 50 ℃. The diffraction peaks were identified and indexed using the standard XRD data of Bi3.6Nd0.4Ti3O12 powder. It is found that all of the films consist of a single phase of a bismuth layered structure showing the preferred (00l) and (117) orientation. This indicates that the film already have the good crystallinity when the annealing temperature is above 650 ℃. With increasing annealing temperature, it can be seen from Fig.1 that the (00l) and (117) diffrac- tion peaks become stronger and sharper. Compared with those of films annealed at other temperatures, the film annealed at 800 ℃ has stronger (00l) and (117) peaks, and the latter peak is the strongest one. Moreover, the intensity of (0014) peak rapidly increases with increasing annealing temperature, and finally equals to the (006) peak which is the second stronger peak. Thus, we can see that the film annealed at 800 ℃ has better crystallinity. ZHONG et al [8] reported that the BNT thin films exhibit preferred (00l) orientation at an annealing temperature above 700 ℃. While some researchers reported that the BNT films have the absolute (117) preferred orientation compared with the (00l) peaks [1, 10]. However, the XRD results of our V-doped BNT films reveal that the mixed (00l) and (117) orientations have the comparable intensity.

Fig.1 XRD patterns of BNTV thin films annealed at different temperatures varying from 650 to 800 ℃

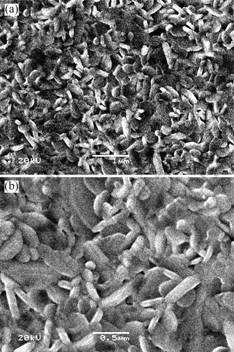

The surface morphologies of the sample annealed at 800 ℃ is shown in Fig.2. It is found that the film shows dense and smooth microstructure in Fig.2 (a) which is observed at a relatively low magnification, and the average grain size of the sample is approximately 0.25 μm. We also find from Fig.2 (b), with a relatively high magnification, that the grains randomly distributed on the substrate are not uniform, but consist of mixed rod-like and plated-like ones, which is in good agreement with [10]. It has been reported that, for La-doped BIT thin films, the rod-like grains are presented in (117) preferentially oriented films, while the plate-like grains may correspond to the c-axis or (00l) preferred orientation [1, 11, 12]. Thus, the mixed rod-like and plated-like grains found in the present BNTV thin films are consistent with the XRD results shown in Fig.1, where

Fig.2 SEM surface morphology of BNTV thin film annealed at 800 ℃ under two different magnifications

mixed (00l) and (117) orientations are observed. Additionally, the film thickness estimated from the cross-sectional micrograph by SEM is about 400 nm.

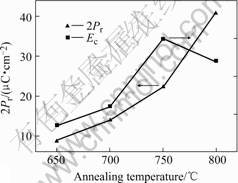

Fig.3 shows the polarization-electric field (P-E) hysteresis loops of the prepared BNTV thin film annealed at temperatures in the range from 650 ℃ to 800 ℃. The hysteresis loops of all the films are well saturated. By increasing the annealing temperature of the films, the degree of squareness of the hysteresis loops of the cosubstituted films is clearly improved. Fig.4 shows the changes of 2Pr and EC with the various annealing temperatures. Under a maximum applied field of 375 kV/cm, the 2Pr values of the prepared films annealed at 650, 700, 750 and 800 ℃ are 8.8, 13.8, 22.3 and 40.9 μC/cm2, and corresponding EC are 97, 102, 120 and 114 kV/cm, respectively. Obviously, the 2Pr increases with increasing the annealing temperature and the film has the largest 2Pr value of 40.9 μC/cm2 at 800 ℃. But there is a sudden decrease of EC with increasing annealing temperature, when the temperature increases above 750 ℃. Therefore, the BNTV film has a lower EC at 800 ℃ than at 750 ℃. Some articles reported that the remnant polarization of BNT thin films often decreases with increasing the annealing temperature at an optimal crystalline temperature below 800 ℃ [8, 10, 13]. Two possible reasons are suggested for the phenomena. One is that the element of bismuth in the film is evaporative at higher annealing temperature. Another is that the relative intensity of the (00l) and (117) in the films will change with the crystalline temperature [14]. Our experimental results have confirmed that the cosubstitution of Nd and V is effective to improve the optimal crystalline temperature. The reasons may be due to that the V5+ substitution would lead to a decrease of the space charge density of BNT thin film by compensating the charge valence of oxygen vacancies [7]. Therefore, with increasing annealing temperature, the intensity of (00l) peaks increases rapidly to catch up with the (117) peak, and the ferroelectric properties of the films become well.

Fig.3 P-E hysteresis loops of BNTV thin films annealed at different temperatures

Fig.4 Variations of 2Pr and EC against annealing temperature of BNTV thin films

4 ConclusionsIn summary, Nd3+/V5+ -cosubstituted BIT thin films [(Bi3.5Nd0.5)(Ti2.96V0.04)O12] were fabricated on Pt(111)/Ti/SiO2/Si(100) substrates using a CSD technique. The effect of higher charge valences V5+ ions substitution of Ti-site ion on ferroelectric properties under different crystalline temperatures was investigated. The surface morphologies confirm the good crystallinity and crystalline orientation of mixed a axis and c axis at 800 ℃. Due to the improvement of crystalline of BNTV thin films with increasing annealing temperature, the 2Pr values of the samples increase with increasing annealing temperature, while EC values begin to decrease with further increasing annealing temperature when the annealing temperature is above 750 ℃. So a well saturated hysteresis loop with better squareness is obtained for the polycrystalline BNTV thin films annealed at 800 ℃. The 2Pr and EC are 40.9 μC/cm2 and 114 kV/cm (at the electric field of 375 kV/cm), respectively. Thus, the effect of V5+ substitution of Ti-site to improve the upper limit of optimal annealing temperature of BNT thin film is obvious.

References

[1] Uchida H, Yoshikawa H, Okada I, Matsuda H, Iijima T, Watanabe T, Kojima T, Funakubo H. Approach for enhanced polarization of polycrystalline bismuth titanate films by Nd3+/V5+ cosubstitution [J]. Appl Phys Lett, 2002, 81(12): 2229-2230.

[2] Scott J F, Araujo C A. Ferroelectric memories [J]. Science, 1989, 246: 1400-1405.

[3] Zheng X J, Zhou Y C, Zhong H. Dependence of fracture toughness on annealing temperature in PZT thin films produced by metal organic decomposition [J]. Journal of Materials Research, 2003, 18(3): 578-584.

[4] Araujo C A, Cuchiaro J D, McMillan L D, Scott M C, Scott J F. Fatigue-free ferroelectric capacitors with platinum electrodes [J]. Nature (London), 1995, 374: 627-629.

[5] Park B H, Kang B S, Bu S D, Noh T W, Lee L, Jo W. Lanthanum-substituted bismuth titanate for use in non-volatile memories [J]. Nature (London), 1999, 401: 682-684.

[6] Watanabe T, Kojima T, Sakai T, Funakubo H, Osada M, Noguchi Y, Miyayama M. Large remnant polarization of Bi4Ti3O12 based thin films modified by the site engineering technique [J]. J Appl Phys, 2002, 92: 1518-1521.

[7] WATANABE T, FUNAKUBO H,OSADA M, Noguchi Y, Miyayama M. Effect of cosubstitution of La and V in Bi4Ti3O12 thin films on the low-temperature deposition [J]. Appl Phys Lett, 2001, 80(1): 100-102.

[8] Zhong X L, Wang J B, Zheng X J, Zhou Y C, Yang G W. Structure evolution and ferroelectric and dielectric properties of Bi3.5Nd0.5Ti3O12 thin films under a moderate temperature annealing [J]. Appl Phys Lett, 2004, 85(23): 5661-5663.

[9] Zhong X L, Wang J B, Y C Zhou, Liu J J, Zheng X J. Electrical properties of Nd-substrated Bi4Ti3O12 thin films fabricated by chemical solution deposition [J]. J Crystal Growth, 2005, 277(1-4): 233-237.

[10] Hou F, Shen M. Crystallization of (Bi,Nd)4Ti3O12 films in N2 environment by chemical solution deposition [J]. Appl Phys A: Mater Sci Process, 2005, 81: 1249-1252.

[11] Yeom S J, Yang W S, Kim N K, Kweon S Y, Choi E S, Roh J S. Thickness effects on physical and ferroelectric properties of Bi3.35La0.85Ti3O12 (BLT) films with c-axis-preferred and random orientations [J]. Jpn J Appl Phys, 2003, 42: 182-185.

[12] Ryu S O, Lee W J, Shin W C, You I K, Cho S M, Yoon S M, Yu B G, Koo J K, Kim J D. Crystallographic orientations and electrical properties of Bi3.47La0.85Ti3O12 thin films on Pt/Ti/SiO2/Si and Pt/SiO2/Si substrates [J]. Jpn J Appl Ahys, 2003, 42: 1665-1669.[13] HOU F, SHEN M, CAO W, Ferroelectric properties of neodymium-doped Bi4Ti3O12 thin films crystallized in different environments [J]. Thin Solid Films, 2004, 471: 35-39.

[14] Sun Y M, Chen Y C, Gan J Y, Hwang J C. Ferroelectric properties of (117) and (001) oriented Bi3.25La0.75Ti3O12 polycrystalline thin films [J]. Appl Phys Lett, 2002, 81: 3221-3223.

Foundation item: Project (05FJ2005) supported by the Key Project of Scientific and Technological Department of Hunan Province, China; Project(05C095) supported by the Research Funds of Educational Department of Hunan Province of China

Corresponding author: TANG Ming-hua; Tel.: +86-732-8293577; Fax: +86-732-8292468. E-mail address: mhtang@xtu.edu.cn