- Abstract:

- 1 Introduction ▲

- References

- Figure

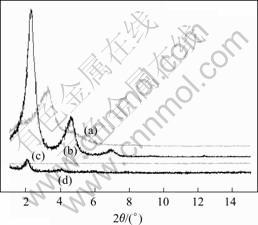

- Fig.1 XRD patterns of OMMT and modified bitumens: (a) HBM; (b) DOM; (c) HBM modified bitumen; (d) DOM modified bitumen

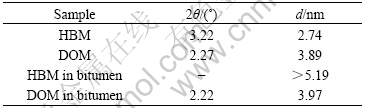

- Fig.2 Curves of G′ vs temperature for bitumens modified with different kinds of OMMT

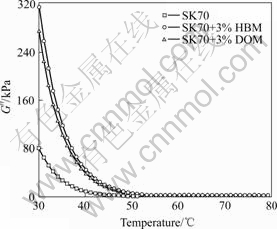

- Fig.3 Curves of G″ vs temperature for bitumens modified with different kinds of OMMT

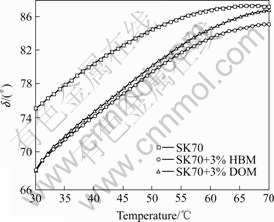

- Fig.4 Curves of phase angle δ vs temperature for bitumens modified with different kinds OMMT

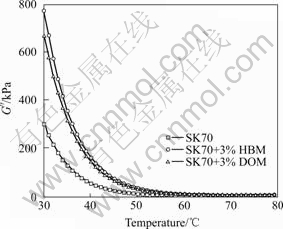

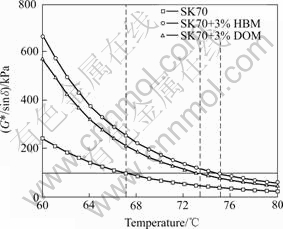

- Fig.5 Curves of G*/sin δ vs temperature for bitumen modified with different OMMT

J. Cent. South Univ. Technol. (2008) 15(s1): 172-175

DOI: 10.1007/s11771-008-340-0

![]()

Effect of different montmorillonites on rheological properties of bitumen/clay nanocomposites

TAO Yuan-yuan(陶园园), YU Jian-ying(余剑英), LI Bin(李 斌), FENG Peng-cheng(冯鹏程)

(School of Material Science and Engineering, Wuhan University of Technology, Wuhan 430070, China)

Abstract:

Different composites of organomodified montmorillonite (OMMT)/bitumen were prepared by melt blending with hexadecyl dimethyl benzyl ammonium modified montmorillonite (HBM) and double octadecyl dimethyl ammonium modified montmorillonite (DOM). The structures of two kinds of montmorillonite modified bitumen were characterized by X-ray diffraction (XRD). The effects of different montmorillonites on the dynamic rheological properties of the modified bitumens were investigated by dynamic shear rheometer (DSR). The XRD results show that DOM modified bitumen forms an intercalated structure, whereas the HBM modified bitumen forms an exfoliated structure. DSR results indicate that OMMT modified bitumens exhibit higher complex modulus, lower phase angle than pristine bitumen, which means that the resistance to rutting at high temperatures of pristine bitumen is improved due to the introduction of OMMT. Compared with DOM modified bitumen, HBM modified bitumen shows better rutting resistance, which is contributed to the formation of exfoliated structure in HBM modified bitumen.

Key words:

nanocomposites; modified bitumen; montmorillonite; rheological property;

1 Introduction

Recently, the layered silicates have been widely used for the modification of polymers[1-3]. Layered silicate is a type of mineral with low cost and abundance, which consists of layers of tetrahedral silicate sheets and octahedral hydroxide sheets[4]. Polymer chains can intercalate into the interlayer of clay, which makes the clay dispersed into the polymer matrix at nanometer scale. These lead to the significant improvements in the thermal, mechanical and barrier properties of polymers[5-6].

Bitumen used as a binder for road-paving applications[7] is a form of liquid at high temperature and becomes brittle at low temperatures, which can cause high temperature rutting, low temperature cracking of pavement and limit its application[8]. This has resulted in the need to enhance the properties of existing bitumen material. Pavement distresses, such as rutting at high temperatures can be reduced by using modified binders. The addition of polymers to bitumen is known to impart enhanced service properties, such as improved thermo mechanical resistance, elasticity, and adhesivity[9]. However, the polymer modified bitumens are expensive, difficult to operation and incompatible[10-11]. Therefore, further efforts should be made for exploring new modifiers. Montmorillonite (MMT) modified bitumen composites have been successfully used to improve both the physical and rheological property of modified bitumen[12]. However, there have been few reports about the modified bitumen with different organomodified montmorillonite (OMMT) till now.

In this paper, different composites of OMMT/ bitumen were prepared by melt blending with hexadecyl dimethyl benzyl ammonium modified montmorillonite (HBM) and double octadecyl dimethyl ammonium modified montmorillonite (DOM). The structures of two kinds of montmorillonite modified bitumen composites were characterized by X-ray diffraction(XRD). The effects of different montmorillonites on the dynamic rheological properties of the modified bitumens were investigated by dynamic shear rheometer (DSR).

2 Experimental2.1 Materials

Bitumen, SK-70 bitumen was obtained from SK Corp., Korea. The organomodified montmorillonites (HBM and DOM) were supplied by Fenghong Clay Chemical Factory, Zhejiang, China.

2.2 Preparation of OMMT modified bitumen

The modified bitumens were prepared using a high shear mixer. Bitumen was first heated until it became a well fluid at around 150 ℃ in the mixer. After that, 3% OMMTs was added into bitumen and the mixtures were blended at 5 000 r/min rotation speed for about60 min.

The bitumen was also processed under the same conditions in order to compare with the modified bitumen.

2.3 XRD test

XRD graphs were obtained using a Rigaku D/max 2400 diffractometer with Cu Kα radiation (λ=0.154 nm, 40 kV, 120 mA) at room temperature, the diffraction to grams were scanned from 1.5? to 15? in 2θ range with 0.02? steps, and scanning rate was 2 (?)/min.

2.4 Dynamic shear rheometer test(DSR)

The rheological properties of all the samples were measured with dynamic shear rheometer (Model AR2000, TA Co., USA) over a broad range of temperatures. Temperature sweeps with 1 ℃ increment were applied at a fixed frequency of 10 rad/s and variable strain. The rheological parameters were measured for calculating viscoelastic parameters such as storage modulus (G′), loss modulus (G″), phase angle (δ) and rut factor (G*/ sin δ).

3 Results and discussion3.1 Structures of OMMT modified bitumen

The degree of exfoliation and dispersion of silicate layers of OMMT in the bitumen was investigated by XRD techniques from the position, shape and the intensity of the basal reflections in the XRD patterns. The XRD patterns of OMMT, and OMMT modified bitumens are shown in Fig.1. The interlayer spacing can be calculated according to Bragg equation (2 d sin θ=λ), which are given in Table 1. The interlayer spacing of DOM in modified bitumen is expanded from 3.89 to 3.97 nm. Therefore, it can be concluded that the bitumen is intercalated into the DOM gallery and the DOM modified bitumen forms an intercalated structure. But we could not observe any crystalline peak in XRD for the HBM modified bitumen, which implies that the interlayer spacing of HBM in the modified bitumen is more than 5.19 nm. It may suggest that the layer of DOM has already been peeled off and the DOM modified bitumen may form an exfoliated structure.

Fig.1 XRD patterns of OMMT and modified bitumens: (a) HBM; (b) DOM; (c) HBM modified bitumen; (d) DOM modified bitumen

Table 1 Interlayer spacing of montmorillonite

Above results can be explained by different chemistry structures between DOM and HBM. There is a benzene ring in HBM molecular structure, and the structure of bitumen molecule chain also processes massive benzene rings. Based on the principle of the dissolution in the similar material structure, the bitumen chains can intercalate into HBM layers more easily. Hence, most of HBM layers can be peeled off during the blending process and form the exfoliated structure.

3.2 Effects of OMMT on storage modulus (G′) and loss modulus (G″)

Complex modulus (G*) is defined as the ratio of maximum shear stress to maximum strain and provides a measure of the total resistance to deformation when the bitumen is subjected to shear loading. It includes two parts, storage modulus (G′=G*cos δ) and loss modulus (G″=G*sin δ)[13].

Fig.2 and Fig.3 show the curves of storage modulus (G′) and loss modulus (G″) versus temperature for the bitumens modified with different OMMT. According to Fig.2 and Fig.3, the OMMT modified bitumens show higher G′ and G″ than the pristine bitumen. It can be interpreted that bitumen chains intercalated into OMMT

Fig.2 Curves of G′ vs temperature for bitumens modified with different kinds of OMMT

Fig.3 Curves of G″ vs temperature for bitumens modified with different kinds of OMMT

layers, and OMMT layers limited the movement of bitumen molecule. From Fig.2, HBM modified bitumen exhibites higher G′ than DOM modified bitumen at the same temperature due to the exfoliation of HBM layers in bitumen. Fig.3 shows curves of G″ versus temperature for the bitumens modified with different OMMT. G′′ reflects the energy dissipation produced by internal friction in deformation processes. OMMT modified bitumen shows higher G′′ than pristine bitumen. As the same as G′, HBM modified bitumen exhibits higher G″ than DOM modified bitumen. The results indicate that both HMB and DOM can improve the viscoelasticity of bitumen.

3.3 Effects of OMMT on phase angle (δ)

Phase angle is defined as the phase difference between stress and strain in an oscillatory test and usually measured for determining viscoelastic balance behavior of a material[13]. The deduction in δ value exhibits a more elastic behavior of bitumen[14].

Fig.4 shows the result of δ against temperature. Compared with pristine bitumen, δ of all modified bitumens decreases at the same temperature. This reveals the increase in elastic properties of the OMMT modified bitumen. Additionally, the HBM modified bitumen exhibits lower δ than DOM modified bitumen. However, a little difference in δ between the two OMMT modified bitumens is shown when temperature ranges from 30 ℃ to 55 ℃, whereas a lager difference in δ is shown when temperature ranges from 55 ℃ to 80 ℃, which indicates that the exfoliated structure exhibits a more elastic behavior than intercalated structure at higher temperature.

3.4 Effects of OMMT on rut factor (G*/sin δ)

In strategic highway research program(SHRP)

Fig.4 Curves of phase angle δ vs temperature for bitumens modified with different kinds OMMT

specifications, the rheological parameter, G*/sin δ, was selected to express the contribution of the bitumen binder to permanent deformation[13]. This value reflects the total resistance of a binder to deformation under repeated loading (G*) and the relative amount of energy dissipated into non-recoverable deformation (sin δ) during a loading cycle. The G*/sin δ value should be larger than 1 kPa at 10 rad/s (1.6 Hz) for the binder at a maximum pavement design temperature[15]. With a higher value of the parameter rate, there is higher resistance to permanent deformation.

Fig.5 shows the curves of G*/sin δ against temperature. It indicates that, when temperature ranges from 60 ℃ to 80 ℃, there is a great increase in rut factors of the modified bitumens compared with the pristine bitumen, which can be attributed to the increase in G* and decrease in δ with the addition of OMMT. Compared with DOM modified bitumen, HBM modified bitumen shows evidently higher G*/sin δ at the same temperature. It can be seen that the bitumen modified

Fig.5 Curves of G*/sin δ vs temperature for bitumen modified with different OMMT

with OMMT shows higher resistance to permanent deformation than the pristine bitumen. When G*/sin δ= 1 kPa, the temperature of HBM modified bitumen is 74.2 ℃, and the temperature of pristine bitumen is only 66.3 ℃. The temperature of DOM modified bitumen is little lower than that of HBM modified bitumen. Therefore, both the HBM and DOM modified bitumen can enhance the resistance to permanent deformation. This shows that OMMT is helpful for the improvement of rutting resistance.

4 Conclusions1) Different composites of OMMT/bitumen were prepared by melt blending with hexadecyl dimethyl benzyl ammonium modified montmorillonite (HBM) and double octadecyl dimethyl ammonium modified montmorillonite (DOM). The structures of two kinds of montmorillonite modified bitumen composites were characterized by XRD. The XRD results show that DOM modified bitumen composite forms an intercalated structure, whereas the HBM modified bitumen composite forms an exfoliated structure.

2) Effects of different montmorillonites on the dynamic rheological properties of the modified bitumens were investigated by DSR. DSR results indicate that both the OMMT modified bitumens exhibit higher complex modulus, lower phase angle than the pristine bitumen, which means that resistance to rutting at high temperatures of pristine bitumen is improved due to the introduction of OMMT. Compared with the DOM modified bitumen, the HBM modified bitumen shows the better rutting resistance, which is contributed to the formation of exfoliated structure in HBM modified bitumen.

References

[1] AHMED R, NEHAL S. Nanocomposite materials pristined on polyurethane intercalated into montmorillonite clay [J]. Mater Sci Eng A, 2005, 399: 368-376.

[2] AKELAH A, KELLY P, QUTUBUDDIN S, et al. Synthesis and characterization of epoxyphilic montmorillonites [J]. Clay Minerals, 1994, 29: 169-178.

[3] GULTEK A, SECKIN T, ONAL Y, ICDUYGU M G. Preparation and phenol captivating properties of polyvinylpyrrolidone- montmorillonite hybrid materials [J]. J Appl Polym Sci, 2001, 81: 512-519.

[4] ZILG C, DIETSCHE F, HOFFMANN B, DIETRICH C, MULHAUPT R. Nanofillers pristined upon organophilic layered silicates [J]. Macromol Symp, 2001, 169: 65-77.

[5] TIEN Yun-i, WEI Kung-hwa. The effect of nano-sized silicate layers from montmorillonite on glass transition, dynamic mechanical and thermal degradation properties of segmented polyurethane [J]. J Appl Polym Sci, 2002, 86: 1741-1748.

[6] WANJALE S D, JOG J P. Effect of modified layered silicates and compatibilizer on properties of PMP/clay nanocomposites [J]. J Appl Polym Sci, 2003, 90: 3233-3238.

[7] WHITEOAK D. Shell bitumen handbook [M]. Shell Bitumen: Riversdell Hause, Surrey, 1990.

[8] AO Ning-jian, WANG Qi, ZHANG Ai-min. Asphalt modified by SBS [J]. China Synthetic Rubber Industry, 2003, 26(2): 65-69.

[9] COLLINS J H, BOULDIN M G, GELLES R, BERKER A. Improved performance of paving grade asphalts by polymer modification [J]. J Assoc Asphalt Paving Technol, 1991, 60: 43–79.

[10] POLACCOA G, BERLINCIONIA S, BIONDIA D, STASTNAB J, ZANZOTTO L. Asphalt modification with different polyethylene-based polymers [J]. Eur Polym J, 2005, 41: 2831-2844.

[11] YEH Pei-hung, NIEN Yu-hsun, CHEN Jean-hong, CHEN Wei-chyum, CHEN Jian-shiuh. Thermal and rheological properties of maleated polypropylene modified asphalt [J]. Polym Eng Sci, 2005: 1152-1158.

[12] YU Jian-ying, ZENG Xuan, WU Shao-peng. Preparation and properties of montmorillonite modified asphalts [J]. Mat Sci Eng A, 2007, 47(1/2): 233-238.

[13] PETERSEN R E, ANDERSON D A, BUTTON J W. Strategic Highway Research Program, Binder characterization and evaluation, Volume 3: Physical Characterization [R]. Washington: SHRP-A-369, National Research Council, 1994.

[14] OUYANG Chun-fa, WANG Shi-feng, ZHANG Yong, ZHANG Yin-xi. Thermo-rheological properties and storage stability of SEBS/kaolinite clay compound modified asphalts [J]. Eur Polym J, 2006, 42(2): 446-457.

[15] PETERSEN R E, ANDERSON D A, BUTTON J W. Strategic Highway Research Program, Binder characterization and evaluation, Volume 4: Test methods [R]. Washington: SHRP-A-370, National Research Council, 1994.

Foundation item: Projects(50773061) Funded by the National Natural Science Foundation of China

Received date: 2008-06-25; Accepted date: 2008-08-05

Corresponding author: YU Jian-ying; Tel: +86-27-59735080; E-mail: jyyu@whut.edu.cn