网络首发时间: 2019-12-02 09:46

稀有金属2019年第11期

钛基形状记忆合金的马氏体相变问题研究

李岩 李启泉 熊承阳 王俊 薛朋飞

北京航空航天大学材料科学与工程学院

摘 要:

近年来,以Ti-Nb, Ti-Zr, Ti-Ta, Ti-Mo为代表的新型钛基形状记忆合金在航空、航天、医疗和能源等领域展现出重要应用前景,但仍有一些共性的相变问题值得深入探讨。本文对钛基形状记忆合金中的应变马氏体稳定化、马氏体相变的可逆性、应力诱发马氏体相变与超弹性的复杂性和多样性等问题进行了总结和讨论,对深入揭示和理解钛基形状记忆合金的马氏体相变特征及其内在机制,发展高性能合金具有重要参考价值。

关键词:

形状记忆合金 ;钛合金 ;马氏体相变 ;形状记忆效应 ;超弹性 ;

中图分类号: TG139.6

作者简介: 李岩(1973-),男,辽宁辽阳人,博士,教授,研究方向:形状记忆合金、生物医用金属;电话:010-82315989;E-mail:liyan@buaa.edu.cn;

收稿日期: 2019-10-29

基金: 国家重点研发计划项目(2018YFC1106600); 国家自然科学基金项目(51831006)资助;

Study on Martensitic Transformations in Titanium Based Shape Memory Alloys Li Yan Li Qiquan Xiong Chengyang Wang Jun Xue Pengfei

School of Materials Science and Engineering,Beihang University

Abstract:

In recent years, the new titanium-based shape memory alloys represented by Ti-Nb, Ti-Zr, Ti-Ta and Ti-Mo have shown great application prospects in the fields of aviation, aerospace, medical and energy, there are still some common problems of phase transition worthy of further study. In this paper problems of martensite stabilization induced by strain, reversibility of martensitic transformation, complexity and persity of martensitic transformation and superelasticity induced by stress in titanium-based shape memory alloys were summarized and discussed. The research results have important reference value for revealing and understanding the characteristics and internal mechanism of martensitic transformation, and developing alloys with good performance.

Keyword:

shape memory alloys; titanium alloys; martensitic transformation; shape memory effect; superelasticity;

Received: 2019-10-29

以近等原子比镍钛基合金为代表的, 具有形状回复及超弹性功能特性的形状记忆合金已经在航空、 航天、 医疗、 电力和机械等多个领域得到广泛应用

[1 ,2 ,3 ,4 ,5 ]

。 近年来, 新型钛基形状记忆合金, 如Ti-Nb和Ti-Zr等已经成为金属智能材料领域的研究热点

[6 ,7 ,8 ]

。

钛基形状记忆合金与Ni-Ti基、 Cu基、 Ni-Mn-Ga

[9 ,10 ,11 ,12 ]

等形状记忆合金具有类似的相变和功能特征, 例如其记忆效应和超弹特性均起源于低温马氏体相与高温母相之间的可逆转变过程; 马氏体相变温度与合金元素的种类和含量直接相关; 应力和应变是影响相变的主要因素

[13 ,14 ]

。 钛基形状记忆合金的相变也存在特殊性, 如马氏体相的结构多样性, 纳米级ω相的析出等问题。 通过总结与分析现有的研究结果, 我们发现钛基形状记忆合金中存在的几个马氏体相变问题: 应变马氏体稳定化、 马氏体相变的可逆性、 应力诱发马氏体相变与超弹性的复杂性和多样性, 值得研究者们重点关注。

1 钛基形状记忆合金的基本相变特征

钛基形状记忆合金的主要相组成为低温马氏体相及高温母相, 其中低温相包括六方结构的α与α′相、 正交结构α″相, 高温相为体心立方结构β相。 钛基形状记忆合金在冷却过程中发生马氏体相变, 该过程中α′, α″马氏体相由母相经无扩散相变产生, 且通过热诱导或机械诱导可以实现α″与β两相间的可逆转变, 从而产生独特的功能特性。

另外, 合金还可能在热处理或者热循环过程中出现等温ω相, 其尺寸一般在2~10 nm, 通常弥散分布在基体中, 即使在透射电镜下也不易观察和确认

[15 ,16 ]

。 有关ω相的问题不在本文讨论之列。

2 应变马氏体稳定化

应变马氏体稳定化是指当马氏体态形状记忆合金在拉伸变形后, 其逆马氏体相变开始温度(A s )上升, 且A s 随变形量增加而增大的现象。 在早期的研究中, 已经在Cu基、 Ni-Ti基及Ni-Mn-Ga合金中观察到了应变马氏体稳定化现象。 目前认为, 其主要原因是应变改变了合金内部弹性能, 并进一步使晶体缺陷增加所致

[17 ,18 ,19 ,20 ,21 ,22 ,23 ]

。

近年来在钛基形状记忆合金中, 也发现了类似的马氏体稳定化现象。 Xiong等

[24 ]

的研究表明, Ti-20Zr-10Nb-4Ta合金的A s 为348 K, 在室温为完全的α″马氏体相。 当对合金施加预应变后, 其A s 明显升高, 由未变形前的348 K增加至363 K(预应变8%), 即存在应变马氏体稳定化。 透射电镜观察分析表明, 合金在预应变后存在去孪晶及位错堆积组织。

分析表明, 应变引起马氏体稳定化是由合金内部弹性能释放及位错堆积共同作用所致。 图1是Ti-20Zr-10Nb-4Ta合金拉伸应力应变曲线及A s 变化结果。 可以看到, 拉伸曲线分为3个阶段: 第一阶段, 应变0%~3%, 为合金弹性变形以及α″马氏体相的再取向过程(应力平台); 第二阶段, 应变3%~6%, 为α″马氏体相去孪晶和择优再取向过程; 第三阶段, 应变6%至断裂, 合金内部马氏体依靠位错滑移产生变形, 位错密度随变形量更大而不断增加。 在前两个阶段时, α″马氏体相的去孪晶及再取向过程释放了合金内部的弹性能, 使得逆马氏体转变困难, 从而提高了合金A s 温度; 在第三阶段, 马氏体相内部位错不断堆积, 使得逆相变过程马氏体相界面移动阻力增大, 从而使A s 点上升。

图1 Ti-20Zr-10Nb-4Ta合金拉伸后的As变化

Fig.1 Stress-strain curve and A s of Ti-20Zr-10Nb-4Ta alloy

[24]

但是, 在钛基形状记忆合金中也发现了应变马氏体不稳定化的情况。 Qu等

[25 ]

研究了Ti-30Zr-5Nb形状记忆合金在不同预应变作用下的相变特性, 结果表明, 随着预应变由0增加至8%, 合金的特征温度没有明显改变, 而是保持了良好的稳定性。 该现象与Ti-20Zr-10Nb-4Ta合金

[24 ]

的结果明显相反。 其原因在于, 该合金相变温度很高(A s =763 K, 比Ti-20Zr-10Nb-4Ta高415 K), 马氏体的内禀自由能很高。 尽管应变导致了弹性能变化, 位错也引起的耗散能变化, 但是这两部分之和对相变阻力的提升与马氏体自由能相比可以忽略。 因此合金的相变温度基本不受变形的影响。

综上所述, 钛基形状记忆合金的应变马氏体稳定化可能在相变温度较低的合金中出现。 而对于高相变温度合金来说, 其马氏体相变温度对应变不敏感。

3 马氏体相变的可逆性

形状记忆效应及超弹特性的内在机制在于: 低温马氏体相与高温母相之间通过热诱发或应力诱发而产生的可逆相变过程

[26 ,27 ]

。 近等原子比镍钛合金性能优异, 能在1×104 ~1×105 次热循环过程中保持良好的相变可逆性

[34 ]

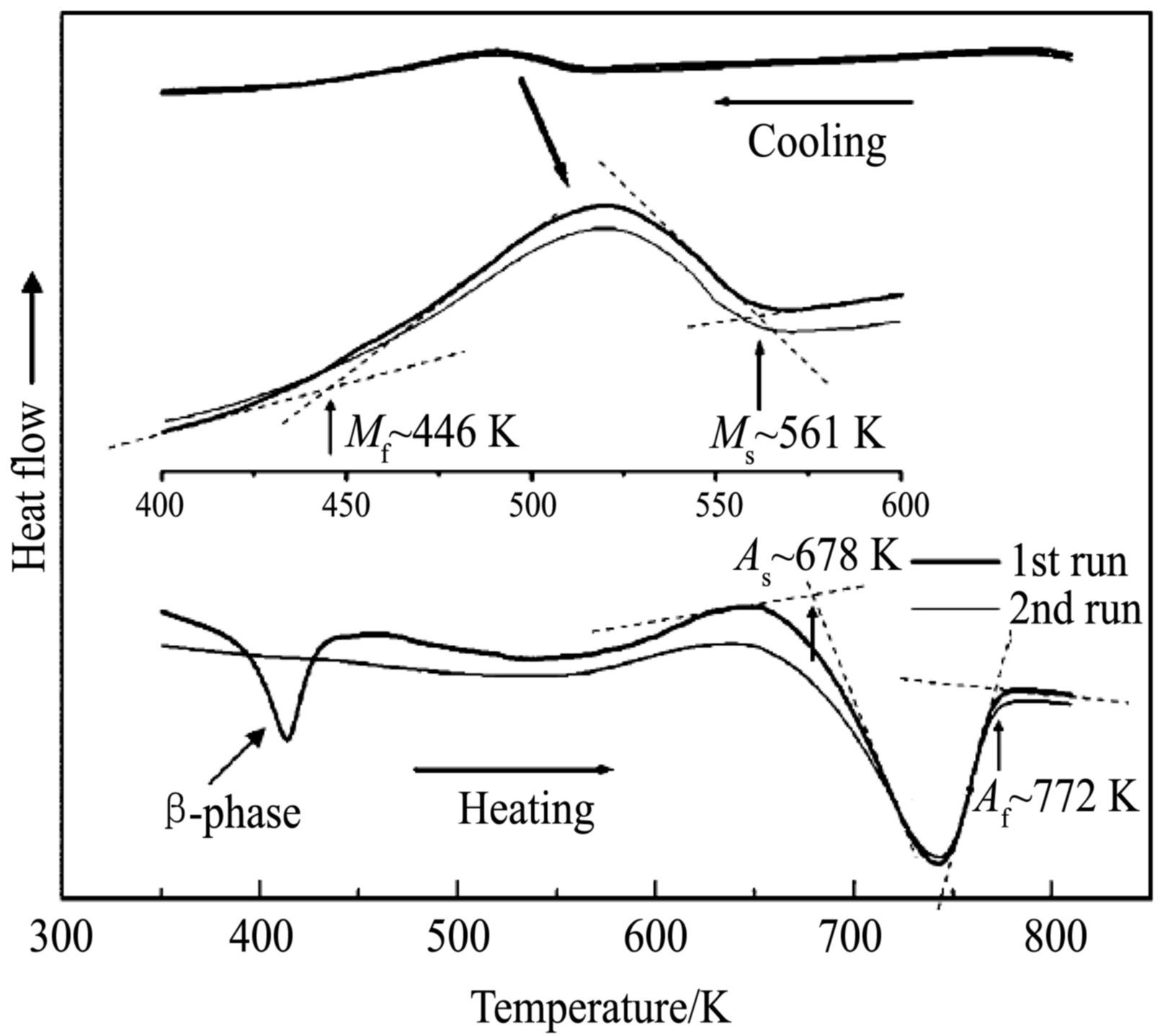

。 研究表明, 很多钛基形状记忆合金都具有可逆马氏体相变。 图2是Ti-30Nb-3Pd合金的差示扫描量热(DSC)曲线

[30 ]

。 可以看到, 合金在加热-冷却过程中出现明显吸热峰和放热峰, 分别对应合金的逆马氏体相变和马氏体相变, 说明该合金的相变具有可逆性。 表1所示为5种钛基形状记忆合金的A s 温度和马氏体相变温度(M s )。

图2 Ti-30Nb-3Pd合金DSC曲线

Fig.2 DSC curves of Ti-30Nb-3Pd alloys

[30]

表1 钛基形状记忆合金相变特征温度

Table 1 Characteristic temperatures of titanium-based shape memory alloys

Alloys

M s /KA s /KRefs.

913

933

[28]

776

790

[29]

711

762

[29]

561

678

[30]

201

214

[31]

395

491

[32]

615

710

[33]

然而, 近年来对钛基形状记忆合金研究中也发现了一些奇特的相变现象, 例如降温过程中马氏体相变行为难以检测, 相变温度难以确认。 Takahashi等

[35 ]

采用差示扫描量热(DSC)法测量Ti-16Nb-4Sn合金的相变行为, 在加热过程中得到了明显的吸热峰, 但是在冷却过程中却没有发现明显的放热峰。 Zheng等

[36 ]

研究了Y元素对于Ti-30Ta合金马氏体相变过程的影响, 发现在Ti-30Ta合金的DSC冷却曲线上没有明显的放热峰, 而在(Ti-30Ta)99.5 Y0.5 合金的DSC冷却曲线上则可以明确找到M s 温度为474 K的马氏体相变放热峰, 如图3所示。 而且这种情况在Ti-19Nb-14Zr

[37 ]

, Ti-20Zr-10Nb

[38 ]

和Ti-20Zr-10Nb-4Ta

[24 ]

合金的研究中均有发现。 虽然这个奇特现象尚未有明确的研究结论, 但是研究者们也给出了推测性解释

[30 ,36 ,38 ]

: 采用差示扫描量热分析(DSC)测得的吸/放热峰的大小取决于合金的相变焓大小。 因为某些合金的马氏体相变温度区间太宽, 导致其相变焓太小, 而DSC检测不到; 或者相变过程中仅有部分β母相转变成了马氏体相, 从而使相变焓太小, 而难以检测(这种情况说明马氏体相变只是部分可逆)。

图3 Ti-30Ta, (Ti-30Ta)99.5Y0.5合金DSC测量曲线

Fig.3 DSC curves of Ti-30Ta and (Ti-30Ta)99.5 Y0.5 alloys

[36]

上述结果表明, 钛基形状记忆合金在马氏体相变可逆性能方面表现出一定的复杂性与多样性。 不同合金体系的马氏体相变可逆性差异很大, 需要进一步的深入研究和系统分析。

4 超弹性与应力诱发马氏体相变

形状记忆合金的超弹性是指其在应力作用下发生远大于其弹性极限应变量的变形, 在应力卸载后, 应变仍能回复的现象。 超弹性源于应力诱发马氏体正逆相变: 母相状态下的合金受到外加应力作用时, 发生马氏体相变; 而当应力卸载时, 处于亚稳状态的马氏体又会逆转变为母相, 该过程从宏观上伴随着远高于弹性应变量的形状回复

[39 ,40 ,41 ]

。

一般来说, 形状记忆合金中的应力诱发马氏体相变与超弹性往往同时存在。 近等原子比镍钛合金的超弹性应变可以达到8%~10%, 并具有良好的循环稳定性

[42 ]

。

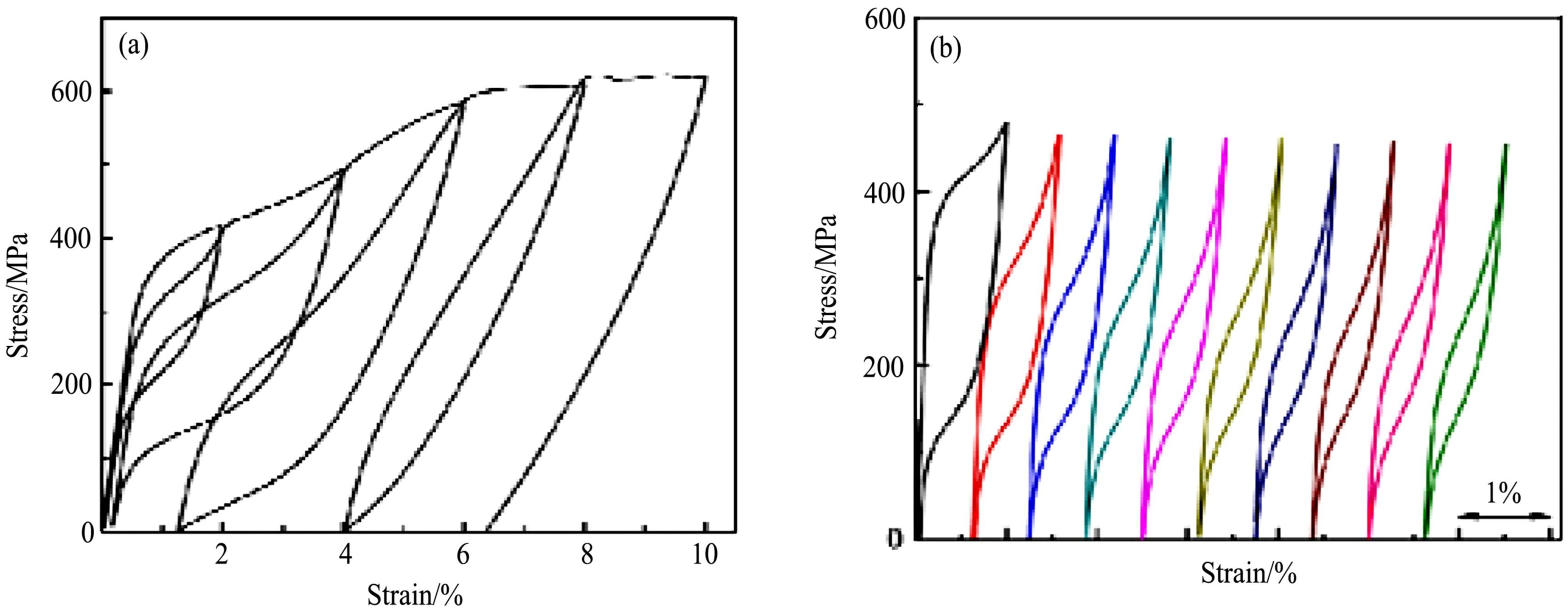

研究表明, 很多钛基形状记忆合金也具有一定的超弹性, 例如: Xue等

[43 ]

研究表明对Ti-19Zr-10Nb-1Fe合金施加10%预应变可得到4.7%的超弹性应变, 如图4所示。 低温时效处理后Ti-19Nb-14Zr合金具有最大约6%的超弹性应变

[37 ]

; Kim等

[44 ]

发现Ti-26Nb经一定热处理后获得3.3%的最优超弹性性能。

图4 Ti-19Zr-10Nb-1Fe合金2%-10%循环拉伸加卸载曲线和10次循环加卸载曲线

Fig.4 Stress-strain curves obtained by 2% incremental loading-unloading tensile (a), 10 times cyclic tensile stress-strain curves of Ti-19Zr-10Nb-1Fe alloy (b)

[43]

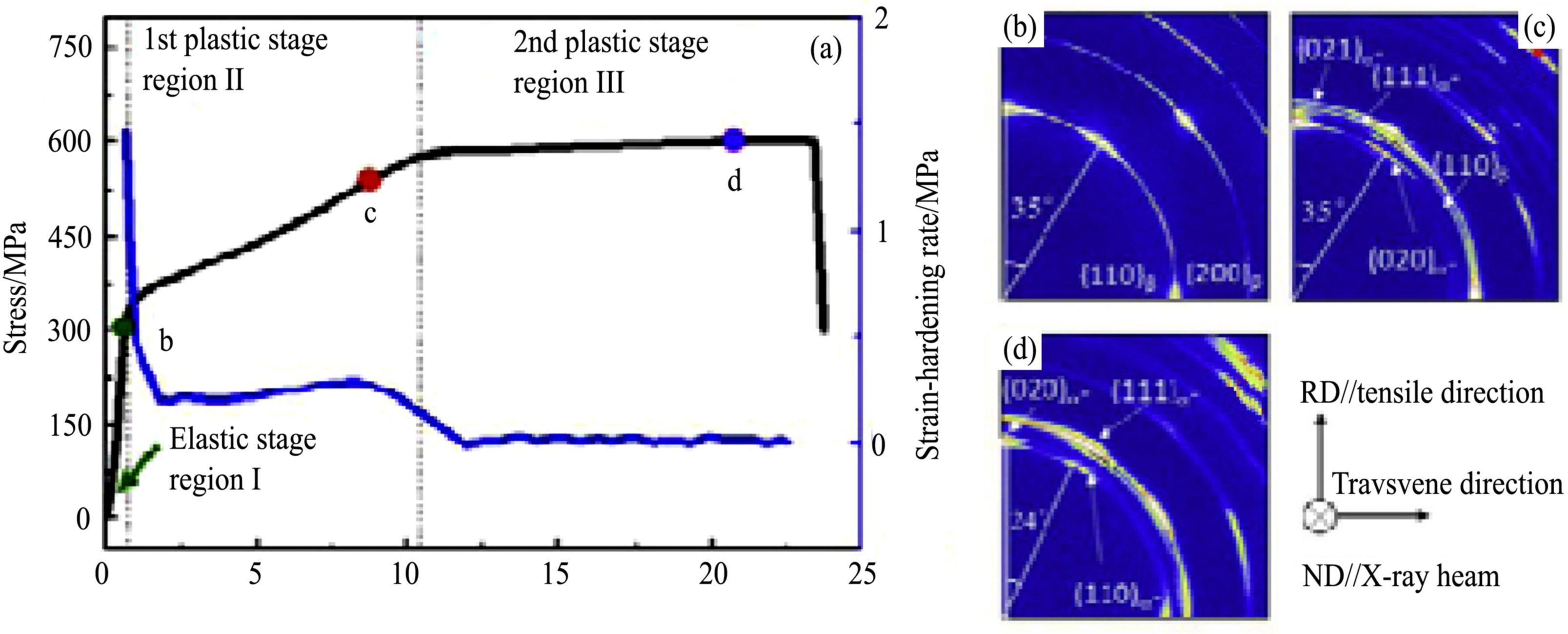

图5 Ti-30Zr-10Nb合金应力应变曲线及相应应变硬化情况, 以及各应力点的2D HE-XRD衍射花样: 300, 530, 597 MPa

Fig.5 Uniaxial tensile true stress-strain (S-S) curve with the strain hardening rate of Ti-30Zr-10Nb alloy (a). 2D HE-XRD patterns at different stresses as noted in (a): 300 MPa (b), 530 MPa (c), 597 MPa (d)

[45]

近期Zhu等

[45 ]

利用原位同步辐射分析了室温β型Ti-30Zr-10Nb合金在拉伸变形过程中的组织结构演变, 如图5所示: 当应力由图5中b点达到c点时(第一个塑性形变阶段)产生了明显的诱发马氏体过程, {200}β相消失而(020), (111), (021)取向的α″马氏体相产生, 而由c点达到d点的拉伸过程中(第二个塑性形变阶段)伴随着一定的马氏体再取向与塑性应变。 但是后续的研究表明

[46 ]

, Ti-30Zr-10Nb合金在拉伸加—卸载过程并没有出现超弹性行为。 结构分析发现, 卸载后样品中出现了部分α″马氏体相, 说明拉伸过程中产生的应力诱发α″马氏体相并没有在应力卸载时逆转变为β相, 所以合金未出现超弹性行为。 另外, 这种情况下的应力诱发α″马氏体相还呈现出如第2节所述的马氏体稳定化行为。

这些实验结果表明, 某些钛基记忆合金在拉伸变形过程中, 尽管可以从母相(β相)产生应力诱发马氏体, 但是, 并不能在应力卸载后回复到原始母相。 其原因尚待深入研究。

5 结 语

本文对钛基形状记忆合金中存在的几个相变问题: 应变马氏体稳定化, 马氏体相变可逆性, 应力诱发马氏体相变与超弹性进行了综述分析。 与传统的Cu基和NiTi基合金相比, 钛基记忆合金的这些问题展现出一定的复杂性和多样性, 而相关研究和认识仍然处于初期阶段。 上述相变问题的内在微观机制非常值得深入探讨和系统分析, 相关研究将为深入理解钛基记忆合金功能特性的起源, 为发展高性能钛基记忆合金材料提供理论基础。

参考文献

[1] Prasad N E,Wanhill R J H.Aerospace Materials and Material Technologies [M].Singapore:Springer,2017.467.

[2] Petrini L,Migliavacca F,MASsarotti P,Schievano S,Dubini G,Auricchio F.Computational studies of shape memory alloy behavior in biomedical applications [J].Journal of Biomechanical Engineering,2015,127(4):716.

[3] Majima S,Kodama K,Hasegawa T.Modeling of shape memory alloy actuator and tracking control system with the model [J].IEEE Transactions on Control Systems Technology,2001,9(1):54.

[4] Duerig T W,Melton K N,St?ckel D,Wayman C M.Engineering Aspects of Shape Memory Alloys [M].London:Butterworth-Heinemann,2013.452.

[5] Jani J M,Leary M,Subic A,Gibson M A.A review of shape memory alloy research,applications and opportunities [J].Materials & Design (1980-2015),2014,56:1078.

[6] Xue P F,Zhang F,Li Y,Zhang D Y.Research progress in titanium-based shape memory alloys [J].Chinese Journal of Rare Metals,2015,39(1):84.(薛朋飞,张菲,李岩,张德元.钛基形状记忆合金研究进展 [J].稀有金属,2015,39(1):84.)

[7] Li Y,Cui Y,Zhang F,Xu H.Shape memory behavior in Ti-Zr alloys [J].Scripta Materialia,2011,64(6):584.

[8] Kim H Y,Ikehara Y,Kim J I,Hosodab H,Miyazakia S.Martensitic transformation,shape memory effect and superelasticity of Ti-Nb binary alloys [J].Acta Materialia,2006,54(9):2419.

[9] Cai W,Meng X L,Zhao L C.Recent development of TiNi-based shape memory alloys [J].Current Opinion in Solid State and Materials Science,2005,9(6):296.

[10] Sar? U,K?r?nd? T.Effects of deformation on microstructure and mechanical properties of a Cu-Al-Ni shape memory alloy [J].Materials Characterization,2008,59(7):920.

[11] Karaca H E,Karaman I,BASaran B,Chumlyakov Y I,Maier H J.Magnetic field and stress induced martensite reorientation in NiMnGa ferromagnetic shape memory alloy single crystals [J].Acta Materialia,2006,54(1):233.

[12] Guo S H,Zhang Y H,Wang X L.Research status and development of magnetic shape memory alloys [J].Chinese Journal of Rare Metals,2005,29(3):339.(郭世海,张羊换,王新林.磁性形状记忆合金的研究现状及发展 [J].稀有金属,2005,29(3):339.)

[13] Wang J,Li Q Q,Xiong C Y,Li Y,Sun B H.Effect of Zr on the martensitic transformation and the shape memory effect in Ti-Zr-Nb-Ta high-temperature shape memory alloys [J].Journal of Alloys and Compounds,2018,737:672.

[14] Kim H Y,Hashimoto S,Kim J I,Hosoda H,Miyazaki S.Mechanical properties and shape memory behavior of Ti-Nb alloys [J].Materials transactions,2004,45(7):2443.

[15] Bekker A,Brinson L C.Temperature-induced phase transformation in a shape memory alloy:phase diagram based kinetics approach [J].Journal of the Mechanics and Physics of Solids,1997,45(6):949.

[16] Deng A H.Martensitic transformation of titanium alloy [J].Nonferrous Metal Materials and Engineering,1999,20(4):193.(邓安华.钛合金的马氏体相变 [J].上海有色金属,1999,20(4):193.)

[17] Sakamoto H,Otsuka K,Shimizu K.Rubber-like behavior in a CuAlNi alloy [J].Scripta Metallurgica,1977,11(7):607.

[18] Santamarta R,Segu? C,Pons J,Cesari E.Martensite stabilisation in Ni50 Ti32.2 Hf17.7 [J].Scripta Materialia,1999,41(8):867.

[19] Xin Y,Li Y,Chai L,Xu H B.The effect of aging on the Ni-Mn-Ga high-temperature shape memory alloys [J].Scripta Materialia,2006,54(6):1139.

[20] Li G T,Liu Z H,Ma X Q,Yu S Y,Liu Y.Grinding-induced martensite stabilization in Mn50 Ni33.5 Sn8 Co8.5 alloy [J].Materials Letters,2013,107:239.

[21] Niendorf T,Krooβ P,Somsen C,Eggeler G,Chumlyakov Y I,Maier H J.Martensite aging-Avenue to new high temperature shape memory alloys [J].Acta Materialia,2015,89:298.

[22] Cui L,Li Y,Zheng Y,Yang D.Two-stage recovery strain of prestrained TiNi shape memory alloy after phase transformations under constraint [J].Materials Letters,2001,47(4-5):286.

[23] Li Y,Cui L,Zheng Y,Yang D.DSC study of the reverse martensitic transformation in prestrained TiNi shape memory alloy in different composites [J].Materials Letters,2001,51(1):73.

[24] Xiong C,Yao L,Yuan B,Qu W,Li Y.Strain induced martensite stabilization and shape memory effect of Ti-20Zr-10Nb-4Ta alloy [J].Materials Science and Engineering:A,2016,658:28.

[25] Qu W T,Sun X G,Yuan B F,Xiong C Y,Li Y,Nie Y S.Phase transformation and microstructure evolution of the deformed Ti-30Zr-5Nb shape memory alloy [J].Materials Characterization,2017,126:81.

[26] Waitz T,Kazykhanov V,Karnthaler H P.Martensitic phase transformations in nanocrystalline NiTi studied by TEM [J].Acta Materialia,2004,52(1):137.

[27] Orgéas L,Favier D.Stress-induced martensitic transformation of a NiTi alloy in isothermal shear,tension and compression [J].Acta Materialia,1998,46(15):5579.

[28] Li Y,Cui Y,Zhang F,Xu H B.Shape memory behavior in Ti-Zr alloys [J].Scripta Materialia,2011,64(6):584.

[29] Qu W T,Sun X G,Yuan B F,Xiong C Y,Zhang F,Li Y,Sun B H.Microstructures and phase transformations of Ti-30Zr-x Nb (x =5,7,9,13 at.%) shape memory alloys [J].Materials Characterization,2016,122:1.

[30] Ping D H,Mitarai Y,Yin F X.Microstructure and shape memory behavior of a Ti-30Nb-3Pd alloy [J].Scripta Materialia,2005,52(12):1287.

[31] Fukui Y,Inamura T,Hosoda H,Wakashima K,Miyazaki S.Mechanical properties of a Ti-Nb-Al shape memory alloy [J].Materials Transactions,2004,45(4):1077.

[32] Khan W Q,Wang Q,Jin X.Transformation temperatures,shape memory and magnetic properties of hafnium modified Ti-Ta based high temperature shape memory alloys [J].High Temperature Materials and Processes,2017,36(2):113.

[33] Zheng X H,Sui J H,Zhang X,Yang Z Y,Wang H B,Tian X H,Cai W.Thermal stability and high-temperature shape memory effect of Ti-Ta-Zr alloy [J].Scripta Materialia,2013,68(12):1008.

[34] Liu Y,Xie Z,Van Humbeeck J.Cyclic deformation of NiTi shape memory alloys [J].Materials Science and Engineering:A,1999,273:673.

[35] Takahashi E,Sakurai T,Watanabe S,MASahashi N,Hanada S.Effect of heat treatment and Sn content on superelasticity in biocompatible TiNbSn alloys [J].Materials Transactions,2002,43(12):2978.

[36] Zheng X H,Sui J H,Zhang X,Tian X H,Cai W.Effect of Y addition on the martensitic transformation and shape memory effect of Ti-Ta high-temperature shape memory alloy [J].Journal of Alloys and Compounds,2012,539:144.

[37] Ma L W,Cheng H S,Chung C Y.Effect of thermo-mechanical treatment on superelastic behavior of Ti-19Nb-14Zr (at.%) shape memory alloy [J].Intermetallics,2013,32:44.

[38] Cui Y,Li Y,Luo K,Xu H B.Microstructure and shape memory effect of Ti-20Zr-10Nb alloy [J].Materials Science and Engineering:A,2010,527(3):652.

[39] Huang X,Liu Y.Effect of annealing on the transformation behavior and superelasticity of NiTi shape memory alloy [J].Scripta Materialia,2001,45(2):153.

[40] Chowdhury P,Patriarca L,Ren G,Sehitoglu H.Molecular dynamics modeling of NiTi superelasticity in presence of nanoprecipitates [J].International Journal of Plasticity,2016,81:152.

[41] Bourke M A M,Vaidyanathan R,Dunand D C.Neutron diffraction measurement of stress induced transformation in superelastic NiTi [J].Applied Physics Letters,1996,69(17):2477.

[42] Nemat-Nasser S,Guo W G.Superelastic and cyclic response of NiTi SMA at various strain rates and temperatures [J].Mechanics of Materials,2006,38(5-6):463.

[43] Xue P F,Li Y,Li K M,Zhang D Y,Zhou C C.Superelasticity,corrosion resistance and biocompatibility of the Ti-19Zr-10Nb-1Fe alloy [J].Materials Science and Engineering:C,2015,50:179.

[44] Kim H Y,Ikehara Y,Kim J I,Hosoda H,Miyazaki S.Martensitic transformation,shape memory effect and superelasticity of Ti-Nb binary alloys [J].Acta Materialia,2006,54(9):2419.

[45] Zhu Z W,Xiong C Y,Wang J,Li R G,Ren Y,Wang Y D,Li Y.In situ synchrotron X-ray diffraction investigations of the physical mechanism of ultra-low strain hardening in Ti-30Zr-10Nb alloy [J].Acta Materialia,2018,154:45.

[46] Song X Y,Xiong C Y,Zhang F,Nie Y S,Li Y.Phase transformations of the stress induced martensite in Ti-30Zr-10Nb shape memory alloy [J].Materials Letters,2020,259:126914.