文章编号:1004-0609(2009)04-0625-08

不同挤压力下凝固的Al-Si-Cu-T4的组织与性能

张克武,赵海东,欧阳晓贤,张卫文,李元元

(华南理工大学 机械与汽车工程学院,广州 510640)

摘 要:

研究在不同挤压力下凝固的Al-Si-Cu-T4的显微组织和力学性能。结果表明:在挤压力下凝固时,该合金显微组织发生明显变化,其抗拉强度和伸长率均有明显提高。当挤压力为0.1~50 MPa时,随着挤压力的增加,初生α(Al)晶粒尺寸和共晶Si粒子长宽比均显著减小,Si相形貌由长针状变成粒状或圆棒状。同时,枝晶间距减小,Al2Cu相量和枝晶间孔洞数量减少,力学性能提高;而当挤压力为50~100 MPa时,挤压力的增加对合金显微组织和力学性能影响不大。因此,50 MPa为该合金的合适挤压力,在该条件下凝固的合金经T4热处理后,其抗拉强度和伸长率分别为323.6 MPa和8.51%。此外,分析讨论了不同挤压力下凝固的合金断口裂纹的形成。

关键词:

中图分类号:TG 214 文献标识码: A

Microstructures and mechanical properties of

Al-Si-Cu-T4 solidified at different squeeze pressures

2ZHANG Ke-wu, ZHAO Hai-dong, OUYANG Xiao-xian, ZHANG Wei-wen, LI Yuan-yuan

(3School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: Microstructures and mechanical properties of Al-Si-Cu-T4 solidified at different squeeze pressures were investigated. The results show that at the pressures applied during solidification, the microstructures of the alloy change significantly, and both tensile strength and elongation of the alloy are improved remarkably. When the squeeze pressure increases from 0.1 MPa to 50 MP, the size of primary α(Al) and aspect ratio of eutectic Si phase are decreased evidently and the morphology of eutectic Si particles is changed from long acicular to small granular, and the dendrite arm spacing, content of Al2Cu phase and porosities between dendrites are decreased, while the mechanical properties are increased. When the squeeze pressure increases from 50 MPa to 100 MPa, the microstructure and mechanical properties of the investigated alloy show little variation. It is indicated that the proper squeeze pressure of the investigated alloy is 50 MPa at which the tensile strength and elongation reach to 323.6 MPa and 8.51%, respectively, after solution heat treatment. Furthermore, the crack origin of the investigated alloys solidified at different squeeze pressures was analyzed and discussed.

Key words: Al-Si-Cu alloy; squeeze casting; mechanical property; microstructure

挤压铸造是一种结合铸造和锻造特点于一体的工艺[1-3],该工艺是将液态金属在高压下充型、结晶和凝固,从而获得所需形状的毛坯或零件,其特点是材料利用率高,铸件内部气孔和缩孔等缺陷显著减少,晶粒细化和组织致密等[4-5]。

Al-Si系铸造合金因其Si含量比较高,提高了合金的铸造性能,且收缩率和热裂倾向小,同时具有较好的耐腐蚀性和机械加工性能,在国内外得到广泛应用[6-8]。Al-Si-Cu合金(例如A319)在该系合金中具有比强度高、优良的抗腐蚀性能和热膨胀性能等特点,广泛应用于汽车轮毂、活塞和转向节等零部件[9],国外已有该合金系列的多项专利[10-11]。本文作者通过研究挤压铸造Al-Si-Cu合金T4固溶热处理的显微组织和力学性能,探讨不同挤压力下α(Al)相与Si相形貌、显微孔洞和Al2Cu相的变化,分析其对力学性能的影响。

1 实验

1.1 合金熔炼

将合金料在石墨坩埚中熔炼,加料前将坩埚烧至暗红。炉温在300~400 ℃时,同时加入A356和纯铝;炉温升至720 ℃时加入Al-50%Cu(质量分数)中间合金,730 ℃时加入Al-5%Ti-1%B,然后搅拌均匀;待炉料全部熔化后,精炼除气,加入除渣剂除渣,5 min后扒渣,用钢勺取少量合金液在Leemanlabs金属分析仪上进行化学成分测定,分析结果如表1所列;随后将合金液静置,待温度降至700 ℃时进行挤压铸造实验。

表1 实验Al-Si-Cu合金的化学成分

Table 1 Chemical compositions of Al-Si-Cu alloy (mass fraction, %)

1.2 试样制备

试验采用直接挤压铸造法。模具材料为H13钢,经调质后再进行氮化处理,模具结构如图1所示。将模具预热到200 ℃左右,采用1 000 kN压力机进行挤压铸造试验,用PLC调节控制压力。挤压压力分别为重力(0.1 MPa)、25、50、75和100 MPa,挤压速度为1~3 cm/s,保压30 s直至合金液完全凝固,从而制得外形为100 mm? 80 mm? 40 mm的铸件毛坯(如图1)。此前研究者主要使用简单圆柱形实验铸件,而本实验零件采用非对称形状,可在一定程度上考察不同部位力学性能的波动,为材料在实际复杂零件上的使用提供参考。

图1 挤压铸造模具示意图

Fig.1 Schematic diagram of squeeze casting mold

挤压铸造后,将所有铸件毛坯在坩埚炉中进行固溶热处理,具体工艺过程为:480 ℃固溶1 h,495 ℃固溶6 h,随后室温水淬。

1.3 测试分析

按照图1所示的取样位置将铸件线切割取出圆柱形试样,然后机械加工成如图2所示的圆棒拉伸试样(GBT228—2002),在INSTRON 8801材料试验机上进行力学性能测试,试验结果为5个以上试验值的平均值。合金的显微组织及拉伸断口观察在Leica 金相显微镜、EPMA-1600电子探针分析仪和LEO 1530 VP扫描电子显微镜上进行。

图2 拉伸试样尺寸

Fig.2 Dimension of tensile specimen (Unit: mm)

2 结果与讨论

2.1 压力对显微组织的影响

根据Al-Si-Cu三元相图,Al-6%Si-4%Cu合金在结晶过程中首先析出α(Al)初晶相,然后有L→α(Al)+ θ(Al2Cu)和L→α(Al)+Si二元共晶反应及L→α(Al)+Si+ θ(Al2Cu)三元共晶反应[12-13]。

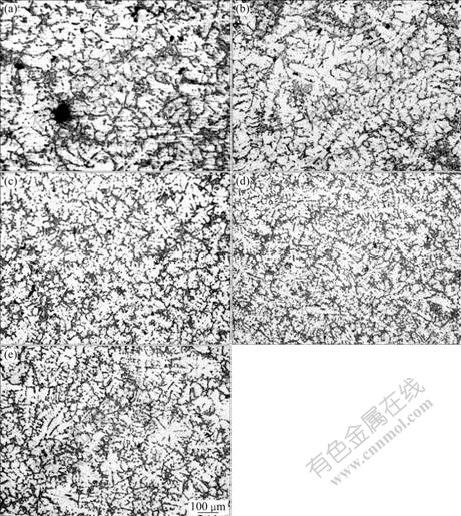

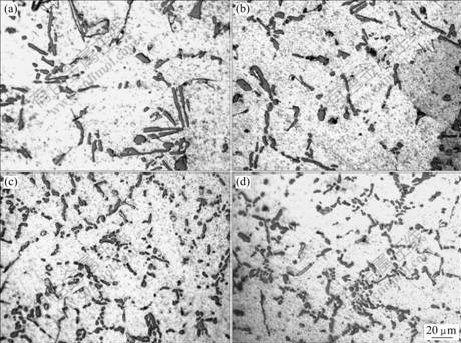

图3和4所示为不同压力凝固下合金固溶热处理后的显微组织。由图3和4可看出,合金总体包括α(Al)相和二元、三元共晶;合金主要由α相固溶体组成,呈亮白色,晶界分布着Si相和θ相共晶组织,晶内存在少量颗粒状的θ相。从α相晶粒尺寸可以看出,在未施加挤压力下,合金组织形成粗大的等轴晶,且晶界处存在缩孔和气孔等铸造缺陷;随着挤压力的增加,晶粒明显细化,铸件枝晶间孔洞等缺陷逐渐减少至消失,且枝晶间距显著减小。

图3 不同压力下凝固的Al-Si-Cu合金的显微组织

Fig.3 Microstructures of Al-Si-Cu alloys solidified at different pressures: (a) 0.1 MPa; (b) 25 MPa; (c) 50 MPa; (d) 75 MPa: (e) 100 MPa

图4 不同压力下凝固的Al-Si-Cu合金高放大倍数的组织

Fig.4 Microstructures of Al-Si-Cu alloys solidified at different pressures at high magnification: (a) 0.1 MPa; (b) 25 MPa; (c) 50 MPa; (d) 100 MPa

关于挤压铸造合金凝固组织明显细化的形成原因,CHADWICH和YUE[14]认为,合金在压力下凝固可减小或消除铸件与模具之间的空隙,提高界面传热系数,使得铸件冷却速度加大,最终使组织细化;而FRANKLIN和DAS[15]及CHEN[16]根据Clasius- Clapeyron定律认为,压力使合金共晶温度上移,凝固过冷度增大,形核几率加大,从而使挤压铸造组织细化。在本研究中,当压力为50~100 MPa时,根据Clasius-Clapeyron定律,增加压力会使合金的共晶点温度继续上移,但实验结果表明,铸件晶粒尺寸变化不大,组织没有细化,与Franklin的解释存在差异;当压力为0.1~50 MPa时,增加压力可使铸件与模具之间空隙减小,界面传热系数增加,铸件组织明显细化;在压力为50 MPa时,铸件与模具已紧密接触,即使继续提高压力,该界面传热系数也仅略微增加,铸件组织无进一步的细化。因此,可以认为界面传热系数的增加是本实验合金组织细化的主要原因。

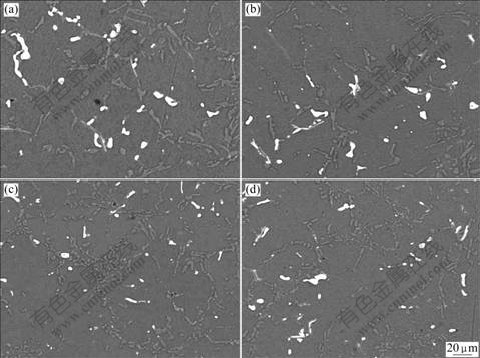

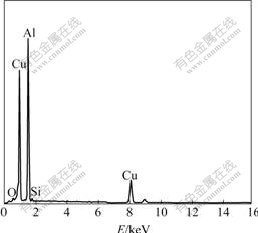

图5所示为不同压力下凝固的Al-Si-Cu合金组织的背散射电子像,其中浅灰色粒子为Si相。图6所示为图5(a)中亮白色相的能谱分析结果,可知该相主要组成元素是Al和Cu,结合Al-Si-Cu三元合金相图,可以判断该亮白色相为共晶Al2Cu相。由图5(a)可知,

图5 不同压力下凝固的合金组织的背散射电子像

Fig.5 Back-scattered electron images of Al-Si-Cu alloys solidified at different pressures: (a) 0.1 MPa; (b) 25 MPa; (c) 50 MPa; (d) 100 MPa

图6 在图5(a)中Al-Si-Cu合金的亮白色相的能谱分析

Fig.6 EDS analysis of white phases of Al-Si-Cu alloy in Fig.5(a)

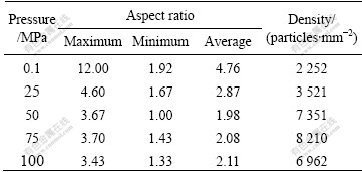

合金在重力下凝固时,Si相大多呈长条状或针状;随着挤压力的增加,Si相逐步呈现粒状或棒状,对基体的割裂作用减小,使合金得到强化(图5(b)和5(c))。比较图5(c)和5(d)可知,压力达到50 MPa之后,继续增加压力时,Si相形貌无明显变化。表2所列为不同压力下凝固时合金中Si粒子特征数据,其中长宽比(Aspect ratio)为粒子长度值与垂直宽度值之比。从表2可知,随着挤压力的增加,共晶Si粒子长宽比平均值和偏差值明显减小,颗粒圆整度增加,单位面积内Si粒子数目显著增多;但压力达到50 MPa之后,继续增加压力,Si粒子长宽比变化不大,数目无明显增加。这说明压力达到50 MPa之后,继续增加压力对共晶Si相形貌影响不大。此外,合金在重力下凝固时,其中的共晶Al2Cu相颗粒较大,数量较多;随着压力的增加,共晶Al2Cu相颗粒变小,数量减少。这表明在一定压力下凝固时,共晶Al2Cu相更易于固溶到α(Al)基体中。

表2 不同压力下凝固的Al-Si-Cu合金中Si粒子特征

Table 2 Si particle characteristics of Al-Si-Cu alloy solidified at different pressures

2.2 压力对显微孔洞的影响

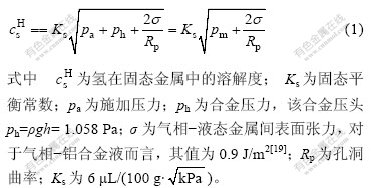

虽然试样制备经过了挤压铸造和T4热处理过程,但没有研究表明在热处理过程中,溶解于铝合金固相中的氢可以形成孔洞,因此,通常认为铝合金铸件中的孔洞形成于凝固过程[17]。挤压力的作用可以对合金液凝固收缩进行强制补缩,使铸件缩孔收缩等缺陷消失。根据Sieverts方程[18],氢在固态金属中的溶解度与压力密切相关:

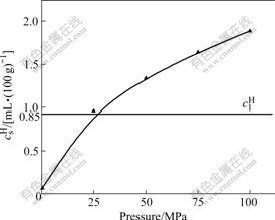

本试验中,铝合金液温度为700 ℃,在大气压力下氢在铝合金中的溶解度![]() 可达8.5 μL/g[17]。假设Rp=100 μm,则2σ/Rp =18 kPa,当pa为25、50、75和100 MPa时,ph和2σ/Rp两项值相对于pa可忽略不计。根据式(1),此时氢在铝合金固相中的溶解度如图7所示,说明挤压力大大提高了氢在铝合金固相中的溶解度,可以消除铸件气孔缺陷。由图7可知,在25 MPa时,氢在铝合金固相中的溶解度已经超过其在液相的含量,铝合金液中的氢在压力下凝固时,可完全溶解到所形成的固相中,因此,如图3(b)所示,合金在25 MPa下凝固时,微观组织致密,未观察到明显的微观孔洞。

可达8.5 μL/g[17]。假设Rp=100 μm,则2σ/Rp =18 kPa,当pa为25、50、75和100 MPa时,ph和2σ/Rp两项值相对于pa可忽略不计。根据式(1),此时氢在铝合金固相中的溶解度如图7所示,说明挤压力大大提高了氢在铝合金固相中的溶解度,可以消除铸件气孔缺陷。由图7可知,在25 MPa时,氢在铝合金固相中的溶解度已经超过其在液相的含量,铝合金液中的氢在压力下凝固时,可完全溶解到所形成的固相中,因此,如图3(b)所示,合金在25 MPa下凝固时,微观组织致密,未观察到明显的微观孔洞。

图7 不同压力下氢在铝合金固相中的溶解度

Fig.7 Solubility of hydrogen in solid phase of Al alloys solidified at different squeeze pressures

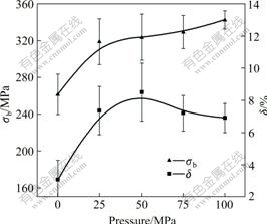

2.3 压力对力学性能的影响

图8所示为不同压力下凝固的Al-Si-Cu-T4的力学性能。从图8可以看出:相比于重力金属型铸造(0.1 MPa),合金经挤压铸造后由于显微组织得到明显细化,其力学性能有了较大提高;当压力为25~50 MPa时,由于合金晶粒明显细化,铸件枝晶间孔洞等缺陷减少,且枝晶间距显著减小,其力学性能随挤压力的增加而提高;而当挤压力为50~100 MPa时,铸件组织无明显细化,挤压力的增加对合金力学性能的提高无明显作用,合金抗拉强度有小幅提高,而伸长率由8%略微下降至7%。虽然理论上随着压力的增加,合金力学性能逐步提高,但铝合金材料易受多种因素影响而出现一定波动,因此,实验中压力增加时,伸长率稍微下降应属于实验正常波动,其他文献也有类似结果报道[5, 21]。由图8可知,挤压力大于50 MPa时,继续增大挤压力对该合金意义不大,反而会浪费能源和降低模具寿命,因此该合金的合适挤压力为50 MPa。

图8 不同压力下凝固的Al-Si-Cu合金的力学性能

Fig.8 Mechanical properties of Ai-Si-Cu alloys solidified at different pressures

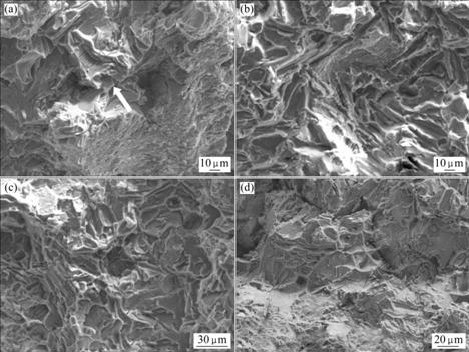

图9所示为合金室温拉伸断口形貌。该合金在重力下凝固时的拉伸断口形貌主要由孔洞、少量韧窝和脆性解理平台构成,孔洞大而深(见图9(a)),其解理面是显微缩松在外力作用下沿一定晶体学平面产生的穿晶断裂所造成,按图中箭头所示,裂纹起源于孔洞,塑性不好,伸长率只有3.08%;随着凝固时的挤压力增加,合金孔洞减少或消除,韧窝明显增多,均匀度增加,深度增大,因此合金的塑性显著提高(见图9(b)~(d))。

图9 不同压力下凝固的Ai-Si-Cu合金的拉伸断口形貌

Fig.9 Fracture morphologies of Ai-Si-Cu alloys solidified at different pressures: (a) 0.1 MPa; (b) 25 MPa; (c) 50 MPa; (d) 100 MPa

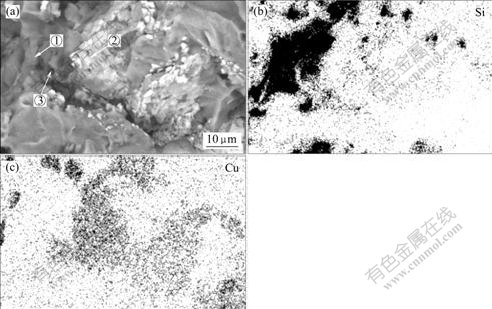

图10所示为100 MPa下凝固的Al-Si-Cu合金拉伸断口EDS面扫描分析。图10(a)所示为该合金在高

的拉伸断口形貌;图10(b)和(c)所示分别为拉伸断口EDS面扫描下的Si元素和Cu元素分布,其中黑色部分分别为Si元素和Cu元素。分析结果表明:图10(a)中箭头①所指区域为共晶Si粒子;箭头②所指处为合金二元和三元共晶相集聚区域。由于Si为非金属元素,与Al基体形成非共格界面,存在空位缺陷,在受力过程中脆性的共晶Si相处易产生应力集中[21-22],割裂基体的连续性,严重影响合金的力学性能,特别是塑性。由图10可知,在挤压力下凝固时,Al-Si-Cu合金断裂裂纹起源于共晶Si粒子,如图10(a)中箭头③所示,并沿合金二元、三元共晶晶界扩展,至沿晶断裂。

图10 在100 MPa下凝固时Al-Si-Cu合金EDS面扫描分析

Fig.10 Area scanning EDS analysis of Al-Si-Cu alloy solidified at 100 MPa: (a) Secondary electron image; (b) Si; (c) Cu

3 结论

1) Al-6%Si-4%Cu-T4合金在0.1~50 MPa 压力下凝固时,随压力的增加,初生α相晶粒尺寸显著减小,Si相由长针状向粒状或圆棒状转变,枝晶间距减小,Al2Cu相数量和枝晶间孔洞数量均减少,力学性能提高;而在50~100 MPa压力下凝固时,压力的增加对合金显微组织和力学性能影响不大。该合金挤压铸造的合适挤压力为50 MPa。

2) 该合金在重力下凝固时,其裂纹起源于枝晶间的孔洞和缩松等缺陷;合金经挤压铸造后,外加挤压力的强制补缩及氢在固相中的溶解度大大提高,消除了合金的收缩缺陷和气孔,此时合金断裂裂纹起源于脆性的共晶Si相,并沿合金二元和三元共晶晶界扩展,至沿晶断裂。

REFERENCES

[1] 齐丕骧. 国内外挤压铸造技术发展概况[J]. 特种铸造及有色合金, 2002, 22(2): 20-23.

QI Pi-xiang. Survey of squeezing casting technology development home and abroad[J]. Special Casting & Nonferrous Alloys, 2002, 22(2): 20-23.

[2] 罗守靖, 陈炳光, 齐丕骧. 液态模锻与挤压铸造技术[M]. 北京: 化学工业出版社, 2007.

LUO Shou-jing, CHEN Bing-guang, QI Pi-xiang. Liquid forging and squeeze casting[M]. Beijing: Chemical Industry Press, 2007.

[3] GHOMASHCHI M R, VIKHROV A. Squeeze casting: an overview[J]. Journal of Materials Processing Technology, 2000, 101: 1-9.

[4] ZEREN M, KARAKULAK E. Influence of Ti addition on the microstructure and hardness properties of near-eutectic Al-Si alloys[J]. Journal of Alloys and Compounds, 2008, 450: 255-259

[5] ZHANG Ming, ZHANG Wei-wen, ZHAO Hai-dong, ZHANG Da-tong, LI Yuan-yuan. Effect of pressure on microstructures and mechanical properties of Al-Cu-based alloy prepared by squeeze casting[J]. Trans Nonferrous Met Soc China, 2007, 17: 496-501.

[6] 罗继相, 白旭白, 谌 伟, 潘 欣. 铝合金挤压铸造技术的研究与应用[J]. 铸造, 2002, 51(8): 464-469.

LUO Ji-xiang, BAI Xu-bai, CHEN Wei, PAN Xin. Study and application on squeezing casting technology of aluminium alloys[J]. Foundry, 2002, 51(8): 464-469.

[7] 胡茂良, 赵 密, 吉泽升, 孙光滨, 朴永吉. 挤压铸造工艺对汽车空调器摇盘组织和性能的影响[J]. 中国有色金属学报, 2006, 16(3): 400-405.

HU Mao-liang, ZHAO Mi, JI Ze-sheng, SUN Guang-bin, PIAO Yong-ji. Effect of squeezing casting technology on structures and properties of air-conditioner swaying tray of automobile[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 400-405.

[8] 齐丕骧, 吴岳壹, 齐 霖. 挤压铸造合金材料的研究进展[J]. 特种铸造及有色合金, 2005, 25(1): 28-31.

QI Pi-xiang, WU Yue-yi, QI Lin. Progress in alloy materials in squeezing casting[J]. Special Casting & Nonferrous Alloys, 2005, 25(1): 28-31.

[9] AMMAR H R, SAMUEL A M, SAMUEL F H. Effect of casting imperfections on the fatigue life of 319-F and A356-T6 Al-Si casting alloys[J]. Mater Sci Eng A, 2008, 473: 65-75.

[10] SUZUKI T, OSHIRON. High-strength aluminum alloy for casting, contains preset amounts of copper, silicon, magnesium, iron, phosphorus, antimony, aluminum and impurities. EP1371741-A2[P]. 2003-10-17.

[11] YAMADA K, HATANO T, MIYAKAWA S, TAKAGI H, HORIKAWA H, HASHIMOTO A. Aluminum alloy casting, e.g. spiral scroll of compressor of air-conditioner, is obtained by casting aluminum alloy containing silicon, copper, magnesium, iron, manganese and aluminum, to which silver is added. JP2004091822-A[P]. 2002-8-29.

[12] 龚磊清, 金长庚, 刘发信, 李文林. 铸造铝合金金相图谱[M]. 长沙: 中南工业大学出版社, 1987.

GONG Lei-qing, JING Chang-geng, LIU Fa-xin, LI Wen-lin. Metallographical diagram of cast aluminum alloys[M]. Changsha: Central South University of Technology Press, 1987.

[13] 胡德林, 张 帆. 三元合金相图[M]. 西安: 西北工业大学出版社, 1995.

HU De-lin, ZHANG Fan. Metallographs of ternary alloy[M]. Xi′an: Northwest Polytechnical University Press, 1995.

[14] CHADWICH G A, YUE T M. Principles and applications of squeeze castings[J]. Metallurgical and Materials Transactions, 1989, 5: 6-12.

[15] FRANKLIN J R, DAS A A. Squeeze casting—A review of the status[J]. Foundryman, 1984, 77(3): 150-158.

[16] CHEN Z W. Skin solidification during high pressure die casting of Al-11Si-2Cu-1Fe alloy[J]. Mater Sci Eng A, 2003, 348: 145-153.

[17] CAMPBELL J. Castings[M]. Oxford: Butterworth Heinemann, 2003.

[18] ZHU J D, COCKCROFT S L, MAIJER D M. Modeling of microporosity formation in A356 aluminum alloy casting[J]. Metall Mater Trans A, 2006, 37: 1075-1085.

[19] PEQUET C, GREMAUD M, PAPPAZ M. Modeling of microporosity, macroporosity and pip-shrinkage formation during the solidification of alloys using a mushy-zone refinement method: application to aluminum alloys[J]. Metall Mater Trans A, 2002, 33: 2095-2106.

[20] KUBO K, PEHLKE R D. Mathematical modeling of porosity formation in solidification[J]. Metallurgical Transactions B, 1985, 16: 359-366.

[21] SUKUMARAN K, RAVIKUMAR K K, PILLAI S G K. Studies on squeeze casting of Al2124 alloy and 2124-10%SiCp metal matrix composite[J]. Mater Sci Eng A, 2008, 490: 235-241.

[22] LEE K H, KWON Y N, LEE S H. Effects of eutectic silicon particles on tensile properties and fracture toughness of A356 aluminum alloys fabricated by low-pressure-casting, casting-forging, and squeeze-casting processes[J]. Journal of Alloys and Compounds, 2008, 461: 532-541.

基金项目:广东省科技攻关资助项目(2006B12001001);广州市有色金属铸造行业工程技术研究中心资助项目

收稿日期:2008-05-25;修订日期:2008-11-25

通讯作者:赵海东,副教授,博士;电话:020-87112948-302;E-mail: hdzhao@scut.edu.cn

摘 要:研究在不同挤压力下凝固的Al-Si-Cu-T4的显微组织和力学性能。结果表明:在挤压力下凝固时,该合金显微组织发生明显变化,其抗拉强度和伸长率均有明显提高。当挤压力为0.1~50 MPa时,随着挤压力的增加,初生α(Al)晶粒尺寸和共晶Si粒子长宽比均显著减小,Si相形貌由长针状变成粒状或圆棒状。同时,枝晶间距减小,Al2Cu相量和枝晶间孔洞数量减少,力学性能提高;而当挤压力为50~100 MPa时,挤压力的增加对合金显微组织和力学性能影响不大。因此,50 MPa为该合金的合适挤压力,在该条件下凝固的合金经T4热处理后,其抗拉强度和伸长率分别为323.6 MPa和8.51%。此外,分析讨论了不同挤压力下凝固的合金断口裂纹的形成。