Optical diffraction gratings embedded in BK-7 glass by

low-density plasma formation using femtosecond laser

Jung-Kyu PARK1, Sung-Hak CHO1, Kwang-Ho KIM2, Myung-Chang KANG2

1. Nano Machining Laboratory, Korea Institute of Machinery and Material, Daejeon 305-343, Korea;

2. National Core Research Center for Hybrid Materials Solution, Pusan National University,

Busan 609-735, Korea

Received 21 April 2010; accepted 10 September 2010

Abstract:

The optical embedded diffraction gratings with the internal refractive index modification in BK-7 glass plates were demonstrated using low-density plasma formation excited by a high-intensity femtosecond (130 fs) Ti: sapphire laser (λp=790 nm). The refractive index modifications with diameters ranging from 400 nm to 4 μm were photoinduced after plasma formation occurred upon irradiation with peak intensities of more than 1×1013 W/cm2. The graded refractive index profile was fabricated to be a symmetric around the center of the point at which low-density plasma occurred. The maximum refractive index change (Δn) was estimated to be 1.5×10-2. Several optical embedded gratings in BK-7 glass plate were demonstrated with refractive index modification induced by the scanning of low-density plasma formation.

Key words:

BK-7 glass plate; diffraction grating; refractive index modification; plasma formation; femtosecond laser;

1 Introduction

The interaction between ultrashort, high-intensity laser light and transparent materials became the major concern after the advent of high-intensity femtosecond lasers[1-2]. The structural bulk modification of dielectrics by tight focusing of femtosecond laser pulses was demonstrated[3]. Also, a large increase (>10-2) in refractive index was obtained in a modified region of silica based glass by irradiation with femtosecond laser pulses[4]. The infrared photosensitivity of transparent materials allows the fabrication of three-dimensional photonic structures or devices through the translation of the sample with respect to the focal point. Although the physical mechanisms responsible for infrared photo- sensitivity are still under investigation, this technique was applied to three-dimensional optical storage, waveguided in a wide variety of glasses, couplers, and photonic crystals[5-6].

Plasma formation due to the self-focusing of ultrashort laser pulses in transparent materials is closely related to the occurrence of refractive-index change, micro-crack, three-dimensional microstructure and internal grating structure[7]. Optical damage occurred in the crystallization of silver nano-particles in silver-doped glass and the bulk modification of optical fibers[8]. Periodical arrays with grating structures on the surface of glass were also demonstrated using the holographic interference of two beams[9]. However, the related experiments for the optical plasma formation and bulk modification using high-intensity femtosecond laser pulses were reported mostly in silica based glasses.

In the meantime, several types of optical components based on BK-7 glass were developed in the fields of optical communications, medicine, and optical sensors because of their high transmission of UV to near-IR wavelength and low cost. In particular, an optical diffraction grating, which is a fundamental optical component used to periodically modulate the phase or amplitude of incident waves, was expected to be a useful device for wavelength division of propagated multi-wavelength beams into a single-wavelength beam in a multi-wavelength network system[10].

In this work, the plasma-induced bulk modification in optical planar plates of BK-7 glass was investigated using the low-density plasma formation excited by a tightly focused femtosecond laser. Temporal behaviors of plasma formation and photo-induced bulk refractive index modification were observed in situ. The relationship between plasma formation and induced bulk refractive index modification in the optical planar BK-7 plate was also clarified. In the experiments, optical planar plates composed of BK-7, used in optical communications, lasers and optical sensors were used to study the optical properties of the area of low-density plasma-induced refractive index modification.

2 Experimental

The irradiation laser used in the experiment was a Ti:sapphire oscillator-amplifier laser system (λp=790 nm) based on the chirped pulse amplification technique with a 130 fs pulse duration, 3.5 W maximum output power, and 1 kHz repetition rate. The linearly polarized laser beam with a Gaussian profile was focused tightly onto the planar BK-7 plate through an objective lens (X60, N.A.: 0.85). The planar BK-7 plate is commercially available provided by the CVI, USA. The size of BK-7 plate was 15 mm×25 mm×4 mm. The six sides of the BK-7 glass plate were optically polished for in situ observation. The sample (planar BK-7 plate) was set on the X-Y-Z stage with space resolution of 50 nm to be scanned. The power transmitted through the planar BK-7 plate was recorded using the optical powermeter connected to the computer. Optical images of the temporal behavior of plasma formation and photo-induced bulk structure transformations (refractive index modification and optical damage) were observed from a direction perpendicular to the optical axis using a trans-illuminated optical microscope (Leica M420) with a CCD camera (Pixera PVC 100C) connected to the computer.

3 Results and discussion

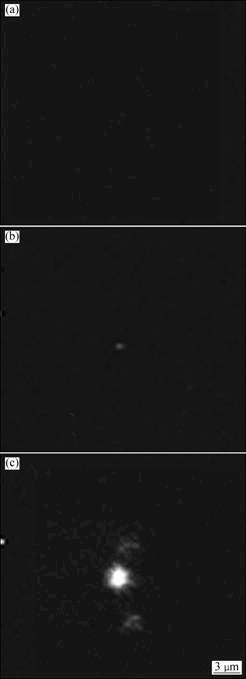

Microscopic side views of plasma formation in a planar BK-7 plate upon irradiation of single pulses of various intensities are shown in Fig.1. Side views of plasma formation were observed using a microscope with a CCD camera and recorded into the computer. When the laser pulse is irradiated on the planar BK-7 plate, the BK-7 plate was scanned at a speed of 500 μm/s using the optical X-Y-Z stage to avoid multi-irradiation in the same area of bulk BK-7 glass. Therefore, optical images of the temporal behavior of plasma formation and photo-induced bulk modification induced by the irradiation of single laser pulse could be observed in situ. The peak intensity at the tightly focused point was calculated using Kirchhoff’s diffraction theory[11]. The nonlinear effect due to self-focusing was not considered in the calculation of the peak intensity because of tight focusing by the high-NA objective lens (X60, N.A.: 0.85). No plasma formation is observed when the intensity of the incident beam is 5×1012 W/cm2 (Fig.1(a)). When the intensity of the incident beam reaches 1×1013 W/cm2, the formation of plasma with the diameter of 400 nm in a planar BK-7 plate is first observed (Fig.1(b)). When the intensity of the incident beam was 8×1013 W/cm2, the plasma formation is observed more clearly and the plasma is of a larger size (Fig.1(c)). The diameter of the induced plasma formation is 2.5 μm. In the case of irradiation of 4×1014 W/cm2, plasma with a diameter of 8 μm is formed. The depth of plasma formation is 1 mm from the irradiated input surface of the sample. In the view of the theory of the cutoff frequency, the low-density plasma excited by a femtosecond laser is lower than the critical density of plasma electrons that can induce the optical damages.

Fig.1 Microscopic side views of photoinduced plasma formation in planar BK-7 glass plate upon irradiation of single pulses with various input intensities (The pictures, which were recorded using CCD camera and microscope, were taken with exposure time of 1 s): (a) 5×1012 W/cm2; (b) 1×1013 W/cm2; (c) 8×1013 W/cm2

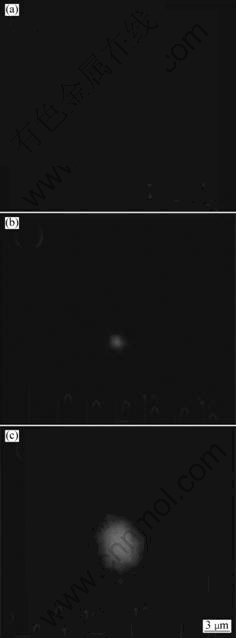

Fig.2 shows the microscopic side views of areas of induced bulk modification after plasma formation occurs. No bulk modification is observed when a plasma formation does not occur (Fig.2(a)). However, modification is visible when plasma formation occurs (Figs.2(b), (c)). Refractive index modification areas with a diameter in the range of 400 nm-4 μm are induced (Figs.2(b), (c)). The depth of the induced refractive index modification is 1 mm from the irradiated input surface of the sample. With an irradiation intensity lower than 1×1014 W/cm2, the power of the transmitted incident beam decreases to 96% of that of the incident beam because of the plasma formation. Refractive index modifications are induced by plasma formation upon irradiation of the incident laser beam. No cracks are observed in the region of refractive index modification. However, when the intensity exceeds 1×1014 W/cm2, some cracks, i.e., optical damage, are deserved. In this case, the transmitted beam power is decreased to 40% of that of the incident beam because of scattering or diffraction loss from the induced plasma.

Fig.2 Microscopic side views of bulk refractive index modification induced by plasma formation upon irradiation at different intensities: (a) 5×1012 W/cm2; (b) 1×1013 W/cm2; (c) 8×1013 W/cm2

The beam intensity of 1.5×1014 W/cm2 was reported as the damage threshold for transparent silica glasses, in the recent studies of damage with femtosecond laser pulses. It is inferred that the optical damage of cracks is induced by plasma formation in the breakdown region.

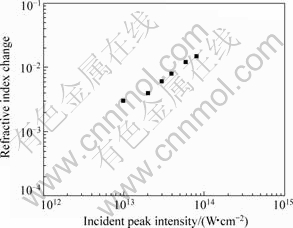

By scanning the planar BK-7 plate, using the optical X-Y-Z stage during laser irradiation, periodically arrayed structures of modified bulk were fabricated with irradiation at different intensities. Based on the diffraction efficiency of Kogelnik’s coupled mode theory, photoinduced refractive index changes (Δn) upon irradiation at various intensities were measured (Fig.3). The measured minimum value of refractive index change (Δn) is 2×10-3 for irradiation at 1×1013 W/cm2. The maximum value of refractive index change (Δn) is estimated to be 1.5×10-2. As the irradiated intensity increases, the refractive index change (Δn) increases linearly in the range from 2×10-3 to 1.5×10-2 at intensities higher than 1.0×1013 W/cm2. The measured error of refractive index change is less than ±15%.

Fig.3 Variation of refractive index change (Δn) induced by single pulse irradiation at various peak intensities

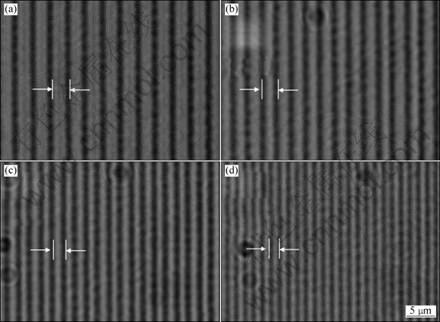

Periodically arrayed structures of modified bulk are demonstrated with irradiation at different intensities (Fig.4). The depth of such periodically arrayed structures is 1 mm from the irradiated surface of the BK-7 substrate. Periodic structures with refractive index modification are fabricated due to low-density plasma formation upon single-shot irradiation. Fig. 4 shows the microscopic side views of internal grating patterns in BK-7 glass with different pitches at the irradiation of different intensities. Periodic structures with refractive index modification are fabricated due to plasma formation upon single-shot irradiation. The diameter of structures with refractive index modification is 600 nm-1.3 μm.

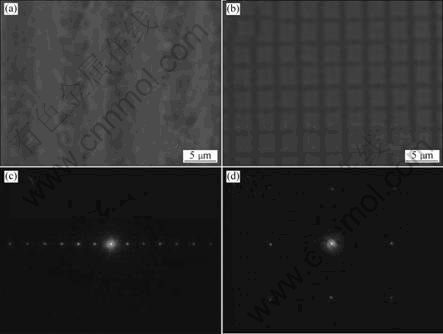

By scanning planar BK-7 plates using the optical X-Y-Z stage during laser irradiation, two types of structures of the internal grating in planar BK-7 plates are obtained, as shown in Fig.5. Both line structure (Fig.5(a)) and cross line structure (Fig.5(b)) are fabricated using low-density plasma formation induced by irradiation of a tightly focused femtosecond laser pulse. The structure of the internal grating can be controlled using both the shutter and optical X-Y-Z stage during laser irradiation. The planar BK-7 plate is scanned at the speed of 1 mm/s using the optical X-Y-Z stage. The laser pulse of 5 μJ/pulse is irradiated onto the BK-7 plate. Figs.5(c) and (d) show the diffraction images from internal grating with refractive index modification fabricated using single-wavelength light source (He-Ne laser, 632.8 nm). The refractive index change (Δn) of the areas of induced bulk modification is 4.0×10-3, which is a relatively low change of the refractive index. The maximum value of refractive index change (Δn) can be controlled by the irradiation conditions of the incident beam. A diffraction image of 4 order is observed. Efficiency rates (%) of diffraction are 7.7% (±1 order), 2.7% (±2 order), and 0.5% (±3 order). In the case of a relatively high refractive index change (Δn), e.g., 1×10-2, the diffraction image of ±8 order is observed. The efficiency rates of the diffraction are 10.6% (±1 order), 3.1% (±2 order), and 1.2% (±3 order). The adjustment of the refractive index change can control the efficiency rate of diffraction order (Fig.5(c)). It is inferred that the low-density plasma formation by tightly focused femtosecond beams is useful for fabricating internal gratings with refractive index modification in BK-7 glass plates.

Although the details of the physical mechanisms responsible for infrared photosensitivity in the femtosecond regime are still under investigation, low-density plasma formation can easily induce refractive index modification with defects in transparent material. The diffraction images of the output beam transmitted through the periodically arrayed internal structures show that refractive index modification results in an embedded optical grating structure. Plasma-induced refractive index modification in transparent bulk materials is a useful technique for the design of optical devices with limited refractive index change for applications, such as optical sensors and near infrared optical communications. In comparison with conventional fabrication methods based on surface processing, the fabrication of internal diffraction gratings using low-density plasma induced by a compact femtosecond laser has the merits of low cost and simple fabrication technology. The fabrication method of the internal diffraction grating in planar BK-7 glass plates using low-density plasma can be a useful tool in a variety of applications such as the arrayed-waveguide grating (AWG) and the single-wavelength beam divider in wavelength division multiplexing (WDM) systems in near infrared optical communications and optical sensors.

Fig.4 Microscopic side views of internal grating patterns in BK-7(under 1 mm from surface) with different pitches: (a) 3 μm at 5×1013 W/cm2; (b) 2.5 μm at 4×1013 W/cm2; (c) 2 μm at 2×1013 W/cm2; (d)1.5 μm at 1×1013 W/cm2

Fig.5 Two types of internal gratings with refractive index modification by scanning planar BK-7 glass plate using optical X-Y-Z stage for line structure (a) and cross line structure (b) and diffraction images of fabricated internal diffraction grating using He-Ne laser (632.8 nm) through line structure (c) and cross line structure (d)

4 Conclusions

1) A fabrication method of embedded optical diffraction gratings with bulk refractive index modification is demonstrated in planar BK-7 glass plates using plasma formation induced by a tightly focused femtosecond laser.

2) The bulk refractive index modification results in a graded refractive index profile, and the value of refractive index change (Δn) varies in the range from 2×10-3 to 1.5×10-2? at intensities higher than 1.0×1013 W/cm2.

3) By scanning a planar BK-7 glass plate, the embedded diffraction gratings with refractive index modification are demonstrated.

References

[1] CHO S H, CHANG W S, KIM J G, WHANG K H. Self-fabricated single mode waveguide in fluoride glass excited by self-channeled plasma filaments [J]. Appl Phys Lett, 2007, 91: 121907.

[2] LINDE D V D, SCHULER H. Breakdown threshold and plasma formation in femtosecond laser-solid interaction [J]. Opt Soc Am B, 1996, 13: 216-222.

[3] Nagata T, Kamata M, Obara M. Optical waveguide fabrication with double pulse femtosecond lasers [J]. Appl Phys Lett, 2005, 86: 251103.

[4] CHO S H, KUMAGAI H, MIDORIKAWA K, OBARA M. Fabrication of double cladding structure in optical multimode fibers using plasma channeling excited by a high-intensity femtosecond laser [J]. Opt Comm, 1999, 168: 287-295.

[5] DAI Y, ZHU B, QIU J, MA H, LU B, CAO S, YU B. Direct writing three-dimensional Ba2TiSi2O8 crystalline pattern in glass with ultrashort pulse laser [J]. Appl Phys Lett, 2007, 90: 181109.

[6] Miura K, QIU J, Inoue H, Mitsuyu T, Hirao K. Photowritten optical waveguides in various glasses with ultrashort pulse laser [J]. Appl Phys Lett, 1997, 71: 3329-3331.

[7] Cheng Y, Sugioka K, Masuda M, Shihoyama S, Toyota K, Midorikawa K. Optical gratings embedded in photosensitive glass by photochemical reaction using a femtosecond laser [J]. Opt Express, 2003, 11: 1809-1816.

[8] Kondo Y, Suzuki T, Inoue H, Miura K, Mitsuyu T, Horao K. Three-dimensional microscopic crystallization in photosensitive glass by femtosecond laser pulses at nonresonant wavelength [J]. Jpn J Appl Phys, 1998, 37: L94-L96.

[9] Kawamura K, Sarukura N, Hirano M, Hosono H. Holographic encoding of fine-pitched micrograting structures in amorphous SiO2 thin films on silicon by a single femtosecond laser pulse [J]. Appl Phys Lett, 2001, 78: 1038-1040.

[10] Efimove M, Gabel K, Garnov S V, Glebov L B, Grantham S, Richardson M, Soileau M J. Color-center generation in silicate glasses exposed to infrared femtosecond pulses [J]. Opt Soc Am B, 1998, 15: 193-199.

[11] Hecht E. Fiber optics [M]. 2nd. New York: Addison-Wesley Publishing Co., 1974: 392-464.

(Edited by CHEN Wei-ping)

Foundation item: Projects(2010-0001-226, 2010-0008-277) supported by NCRC(National Core Research Center) Program through the National Research Foundation of Korea funded by the Ministry of Education, Science and Technology

Corresponding author: Sung-Hak CHO; Tel: +82-42-868-7077; E-mail: shcho@kimm.re.kr; Myung-Chang KANG; Tel: +82-51-510-2361; E-mail: kangmc@pusan.ac.kr