J. Cent. South Univ. (2020) 27: 629-673

DOI: https://doi.org/10.1007/s11771-020-4322-1

Decision making tools for optimal material selection: A review

Divya ZINDANI, Saikat Ranjan MAITY, Sumit BHOWMIK

Department of Mechanical Engineering, National Institute of Technology Silchar, Silchar,Assam-788010, India

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2020

Abstract:

The present work reviews different decision making tools (material comparing and choosing tools) used for selecting the best material considering different parameters. In this review work, the authors have tried to address the following important enquiries: 1) the engineering applications addressed by the different material choosing and ranking methods; 2) the predominantly used decision making tools addressing the optimal material selection for the engineering applications; 3) merits and demerits of decision making tools used; 4) the dominantly used criteria or objectives considered while selecting a suitable alternative material; 5) overview of DEA on material selection field. The authors have surveyed literatures from different regions of the globe and considered literatures since 1988. The present review not only stresses the importance of material selection in the early design stage of the product development but also aids the design and material engineers to apply different decision making tools systematically.

Key words:

Cite this article as:

Divya ZINDANI, Saikat Ranjan MAITY, Sumit BHOWMIK. Decision making tools for optimal material selection: A review [J]. Journal of Central South University, 2020, 27(3): 629-673.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-020-4322-11 Introduction

Materials have a key role throughout the manufacturing as well as design process. However, selection of best possible material alternative is a challenging task [1] owing to the availability of large number of materials in our world [2, 3]. Furthermore, strength and weakness is idiosyncratic to material alternatives and therefore the various factors i.e., the mechanical properties, physical properties, thermal properties, magnetic properties, wear, oxidation, and corrosion behavior need to be considered while evaluating the available material alternative. Moreover, sustainable life style has become the need of the hour owing to the inadequate resources and environmental restrictions. Sustainable development that arose in 1980s [4] stresses the importance of material selection process in countering the negative social and environmental impact that came into existence due to unbridled economic development.

Material selection has been considered as one of the key elements of sustainable development as the process motivates selection of materials that aids in following cleaner production, saving resources, energy and also brings economic efficiency to any manufacturing enterprise.Therefore, sustainability adds another criteria that should be considered while selecting a suitable material. In short, material selection process is a multi-criteria decision making problem.

Researchers have proposed different procedural steps to arrive at the optimal decisions for material selection strategy [5-9]. The findings suggest the following stages of a typical material selection process: 1) creating a group of alternative solutions on the basis of the performance requirements; 2) screening of the initial solution; 3) ranking and comparing the set of alternatives and 4) arriving at an optimal solution. The findings of the past research have enunciated that regardless of the relation between material and process selection, the two main critical aspects for an appropriate material selection are screening and ranking.

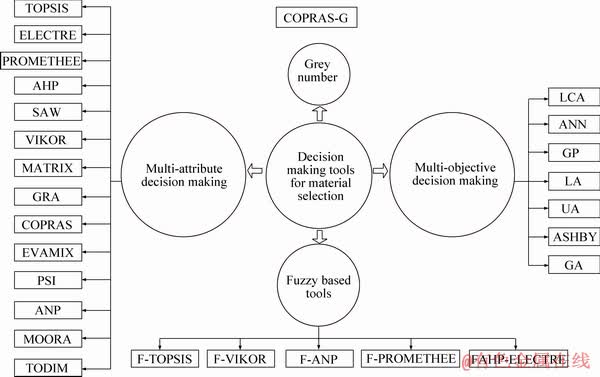

To address the first critical aspect of material selection i.e., material screening, researchers have adopted a number of screening methods: cost per unit property method [10], chart method [11-16], questionnaire method [10], knowledge base systems [17-22], case based reasoning [23], neural networks [24-27] and computer-aided materials selection systems [28-36]. While a number of decision tools have been developed for dealing with the ranking aspects of the material selection which is the most critical of the different phases. Figure 1 delineates the classification of different decision tools for ranking of the screened material alternatives.

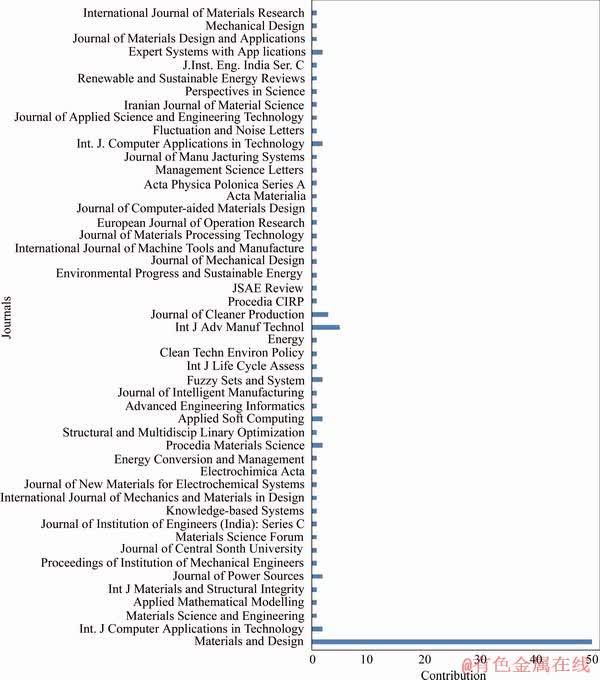

Given the importance of material selection in the early design stages and in sustainable development, the present study presents a comprehensive literature review on the different decision tools used for optimal selection of the material. The review work has considered scholarly articles published in different journals since 1988. The literature studied abetted to address the following important questions: 1) the engineering applications that have been addressed by the different material comparing and choosing methods; 2) the predominantly used decision making tools for material selection; 3) merits and demerits of decision making tools; 4) the predominantly used criteria for material selection and 5) overview of DEA on material selection problems.

Several aspects have been elaborated and discussed in each of the subsections. Future research trends have also been deduced in the present work.

2 Decision making tools for optimal material selection

The screening methods listed in the introduction screens down the available material alternatives to a limited number of alternatives. The narrowed alternatives are then ranked using the different material comparing and choosing methods. Different material comparing and choosing methods tools are used for choosing one or more optimal material to suit the design requirements after the initial screening stage of material selection has been performed. MCDM tools provides the optimal solution by evaluating different qualitative/ quantitative and often conflicting criteria [37]. MCDM tools can be divided into two main categories: multi-attribute decision making (MADM) that includes TOPSIS [38], ELECTRE [39], AHP [40], SAW [10], limits on property method [10], PROMETHEE, ORESTE [41, 42], OCRA [43], COPRAS [44], EVAMIX [45], MOORA [46], and multi-objective decision making (MODM) tools encompassing goal programming, life cycle assessment fuzzy logic has also been used to compare and choose the suitable material alternative. Further, combination of the MADM, MODM and fuzzy logic tools has also been used increasingly in the field of material selection. Each of the method has its own characteristics and therefore an array of reports have also been published on comparison analysis of the different material comparing and choosing methods.

Figure 1 Taxonomy of decision making tools used for material selection

This section therefore provides an overview of the different techniques used in the material selection literatures for making the best choice of a material amongst the different available candidate alternatives. The section also highlights the hybrid approaches and the reports on performance analysis as studied extensively in the literature surveyed.

2.1 Multi-attribute decision making methods

In the decision making through multi-attribute decision making (MADM) methods, the selection of an optimal material from amongst the two or more materials is made considering two or more different attributes that are often conflicting in nature [47]. These attributes can either be expressed in numbers, ranking (poor, good), images and texts. Decision matrix is the initializing step of the different MADM methods, in which the rows represents different alternatives and columns, consists of different attributes.

2.1.1 Technique for order preference by similarity to ideal solution (TOPSIS) method

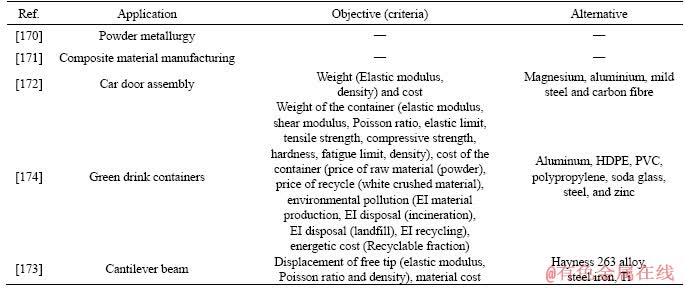

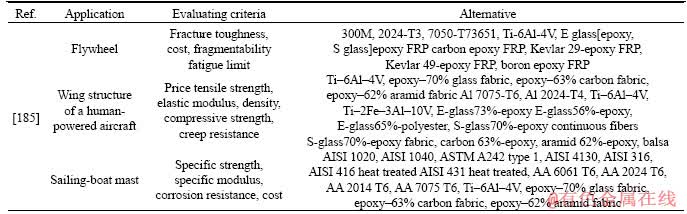

Numerous literatures have been reported related to the material selection problem using the TOPSIS method. Appendix 1 shows reports that have focused purely on the usage of TOPSIS methods. The applications addressed by the reports with their evaluating criteria and material alternatives have also been delineated in Appendix 1. JEE et al [48] used the TOPSIS method to develop an interactive program based on Visual Basic programming language. The interactive program was able to use the subjective weights to adjust the relative priority among the design requirement. The authors showed the applicability of the program by selecting the optimal material for flywheel. They highlighted the requirement of a more systematic design tool that could systematically map the requirements to performance index or material properties.

MILANI et al [49] evaluated the effect of different normalization algorithms on the TOPSIS rankings. The study was done for the gear material selection. It was established that linear normalization algorithms did not affect the rankings, however the rankings showed little deviation with the non-linear normalization algorithms. The authors suggested the development of simple multi axial strategy using both the linear and non-linear algorithms for the decision making problems.

SHANIAN et al [50] used the TOPSIS and Block TOPSIS method for selecting optimal material for bipolar plates of polymer electrolyte fuel cell. The material ranks were obtained considering the cost of production and without the consideration of the cost. The results obtained have shown good agreement with the CES database. They concluded that the method that determines both the rank and the score of the material alternatives can be preferred over those which determine only the rank of the alternatives.

GUPTA [51] applied the TOPSIS method for the material selection of absorbent layer for a thin film solar cell. Copper Indium Gallium Diselinide was the top ranked material. The findings were in agreement with the experimental results.

Different normalization techniques were developed and extended to the TOPSIS method. A new target based normalization technique was developed by JAHAN et al [52] that not only took into account the beneficial and the non-beneficial criteria but also the target values of the different criteria. The normalization technique was extended to the TOPSIS method and the established method was validated through four different material selection problems. It was concluded the proposed method could be used in making better decisions.

KUMAR et al [53] made use of TOSIS method for selection of suitable material for exhaust manifold. Nitride steel was found to be the best material amongst the material alternatives considered.

RASTOGI et al [54] employed the TOPSIS method for obtaining the final rankings of material for the phase change material. To validate the performance of the top ranked materials, simulation study was conducted. It was concluded that MCDM approach proves to be economical for screening and ranking of phase change material alternatives.

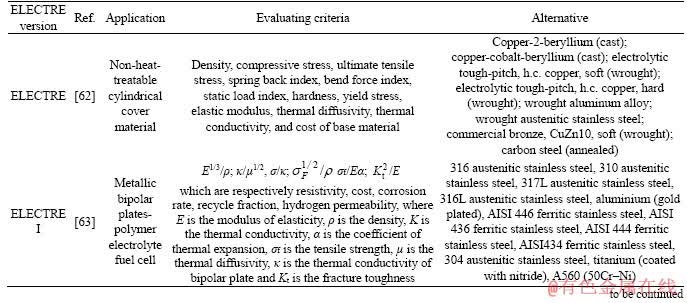

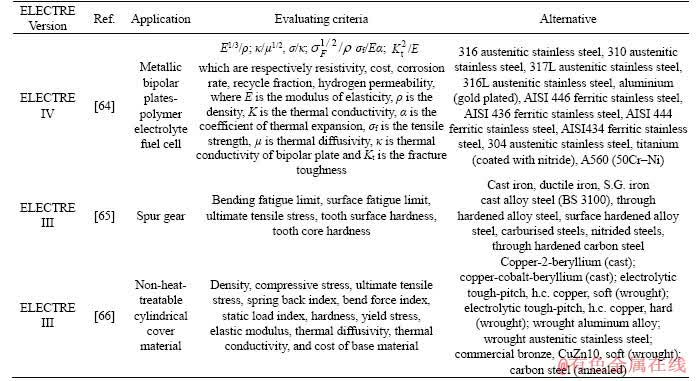

2.1.2 Elimination and choice expressing reality (ELECTRE) method

ELECTRE [55, 56] and its different versions: ELECTRE I, ELECTRE III [57, 58] and ELECTRE IV, ELECTRE IS [59], and ELECTRE IV have been used to solve the complex material selection problems. However, other versions of ELECTRE i.e., ELECTRE II, ELECTRE III, ELECTRE TRI [60] and ELECTRE TRI-nC [61] are still to be explored for addressing the material selection problems. Appendix 2 delineates the problems addressed by the ELECTRE and its group of methods. Appendix 2 also depicts the evaluating criteria and the material alternatives used for different applications addressed.

SHANIAN et al [62] used ELECTRE method for selecting the optimal material for thermally loaded conductor. A computer program based on Mathematica was developed to implement the ELECTRE method. The materials were ranked from best to worst. The results were compared with those obtained from the past researchers and were found to be in good agreement.

ELECTRE I method was used by SHANIAN et al [63] for the material selection of bipolar plates. The method was implemented using code developed in Mathematica. The sorting of all the candidate materials was also done using the net concordance and discordance methods. The results obtained were found to be in good agreement with that of the past researchers and the CES database.

SHANIAN et al [64] used the ELECTRE IV method for material selection of bipolar plate of polymer electrolyte fuel cell. They addressed the shortcoming of separate optimization of criteria. They also studied the effect on change in material rankings of the different components of performance indices. The results obtained were found to be in good agreement with those from the past reports.

MILANI et al [65] made use of ELECTRE III method for selection of optimal material for gear. The rankings were established individually considering the performance indices and the individual properties. It was observed that different solutions were obtained in the two cases. The rankings were also different when considering lower, average and upper limits for particular criteria. Further, there may be situation of indecision considering the lower and upper limit within the same criteria. The material data uncertainties and the incompleteness were taken into account considering the ELECTRE III method. Finally, it was shown that the hesitation of designer in determining the weight factors can be done away considering the iterative process of dilation and concentration.

The revised Simos’ method together with the ELECTRE III method was proposed by SHANIAN et al [66] to address the effects of separations in design preferences and the uncertainties in the mind of designers for the preferences for the design criteria. A post-aggregation strategy was followed to stabilize the ranks for the candidate materials. The proposed methodology was used successfully for the material selection of thermally loaded conductor.

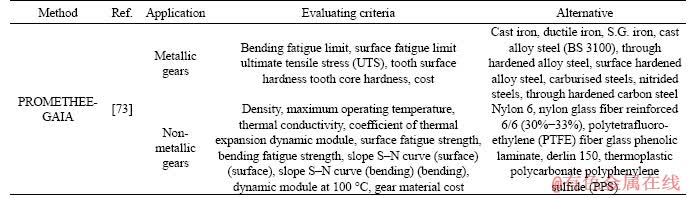

2.1.3 Preference ranking organization method for enrichment evaluations (PROMETHEE) method

PROMETHEE and its different versions PROMETHEE II and PROMETHEE-GAIA [67,68] have been reported in the literature surveyed to solve the material selection problems. The other versions of PROMETHEE: PROMETHEE I, PROMETHEE III, PROMETHEE IV, PROMETHEE V [69], PROMETHEE VI [70], PROMETHEE GDSS [71], PROMETHEE TRI [72], PROMETHEE CLUSTER [72] are still unexplored in the field of material selection.

Appendix 3 shows the application addressed by PROMETHEE method with summary on the criteria and material alternatives used. MAITY et al [73] used the PROMETHEE-GAIA method for selecting suitable material for metallic and non-metallic gear problems. Nitralloy 135 M and Nylon glass fibre reinforced 6/6 were the suitable material for the metallic and non-metallic gears. The method is a visual design aid for the design engineers where preferences of the criteria and the position of alternatives with respect to the criteria can be visualized clearly. The effect of the changing weights on the material rankings can be observed through the walking weight diagram. The proposed methodology was found to be free from any manual computation.

2.1.4 Analytical hierarchal process (AHP) method

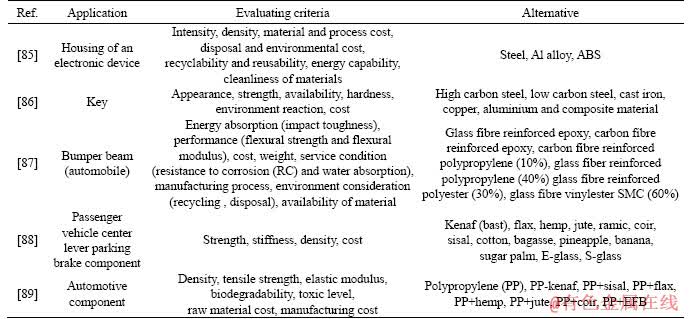

A number of reports have been published in the field of material selection that uses only the AHP [17, 74-84] method. These are listed in Appendix 4 with summary on the applications and their evaluating criteria and material alternatives.

In the field of material selection AHP method has been widely used. CAO et al [85] used the AHP method for the material selection of housing of electronic devices. They conclude that the method could be used to efficiently solve and analyze the most suitable alternative material alternative. For their problem, ABS-Polycarbonate was found to be the most suitable material.

DWEIRI et al [86] used the AHP method for selecting optimum material of key. The AHP method was found to be an efficient decision making tool for making choice of a suitable alternative material based on a number of multiple criteria and sub-criterion.

HAMBALI et al [87] explored the application of AHP in the early stage of product development. They demonstrated its applicability through the material selection problem of automotive bumper beam. Sensitivity analysis under different scenarios was also conducted to verify the final decision.Glass fibre epoxy was found to be the most optimum material.

AHP method was used by MANSOR et al [88] for selecting optimal material of passenger vehicle center lever parking brake component. Kenaf bast fibre was found to be the suitable material choice. They concluded that the AHP method was found to be an effective tool for decision making during conceptual stage of product design.

ALI et al [89] employed the AHP method via Expert choice software tool for making the automotive components from natural fibre reinforced composite materials. Higher rank was obtained for hemp and polypropylene. The methodology was recommended for other automotive components with sustainable material alternatives.

2.1.5 Simple additive weighting method

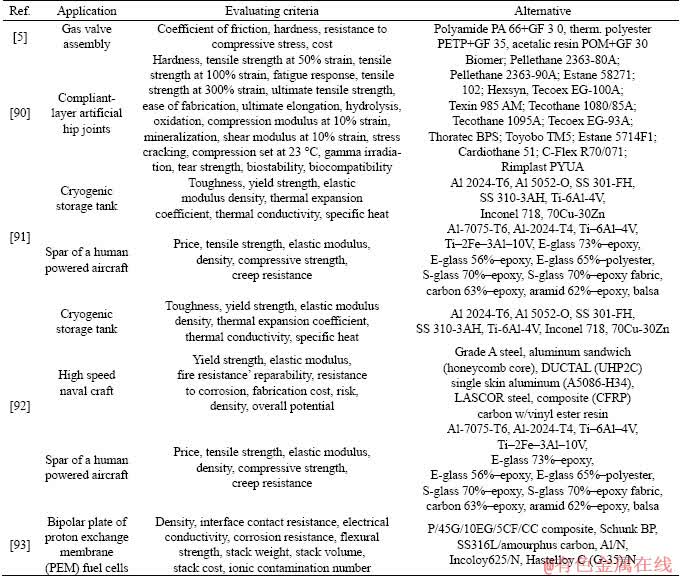

The simple additive weighting (SAW) [6] method has been used to address various material selection problems. The summary of different reports using is shown in Appendix 5. CHINER [5] used the SAW method to select the most suitable material for the silo of gas valve. Polyamide PA66+GF30 was established to be the most suitable material.

Material selection for compliant layer of artificial hip joints was carried out by QUIGLEY et al [90] using the SAW method. The most preferred materials identified for the application under consideration were Tecothane 1080/85A and Estane 5714F1. The preferred materials were then used for the fabrication of prototypes and subjected to durability tests. The tests supported the established material rankings.

DEHGAN-MANSHADI et al [91] proposed the modified digital logic method to make changes in the existing method for calculation of weight through the concept of non-linear normalization. The proposed method was applied to make material selection for the cryogenic storage tank and the spar of wing structure of a human powered aircraft. The study established the capability of the established method to provide for more reasonable selections in comparison to the existing weighted method.

The shortcomings of the modified digital logic were overcome through the proposal of new normalization function in the form of z-transformation by FAYAZBAKHSH et al [92]. The proposed methodology was validated using three examples of cryogenic storage tank, spar of human powered aircraft and high speed naval craft. The proposed method was found to be more suitable in cases where it is difficult to establish the superiority in properties of the candidate material. However, the material was found to be of not much use when only first ranked material is of much interest.

TAHERIN et al [93] proposed used SAW method for the material selection for bi-polar plates used in proton exchange membrane cells. Carbon-coated SS316L was found to be the most suitable material for the bi-polar plates.

2.1.6 Vlse kriterijumska optimizacija kompromisno resenje`(VIKOR) method

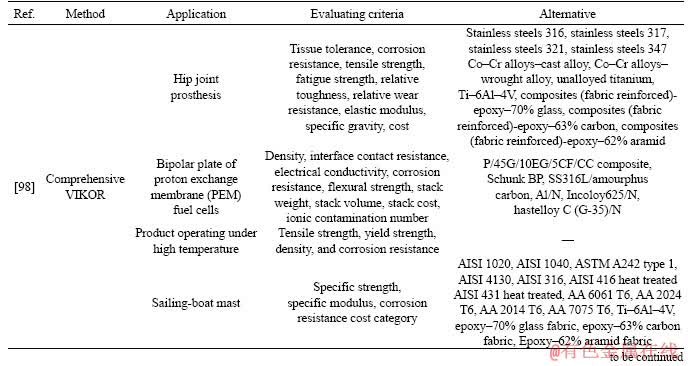

The Serbian name for VIKOR [94-97] is a useful tool for solving the material selection problems. It helps the designers in situations where they are unable to express the preferences at the start of the design phase of a product. The reports published solely on VIKOR method for the material selection problems depicted in Appendix 6 which summarizes the engineering applications addressed with the criteria and material alternatives adopted.

There have been improvements in the traditional VIKOR method leading to the development of newer versions of the VIKOR method. JAHAN et al [98] proposed a new method of VIKOR using a normalization technique based on the target values of the criteria. This method was known as the comprehensive VIKOR method. The proposed method could overcome the shortcomings of the traditional VIKOR method. The potentiality of the new method was proved through examples of hip prosthesis, polymer electrolyte fuel cell, product operating under high temperature, sailing boat mast.

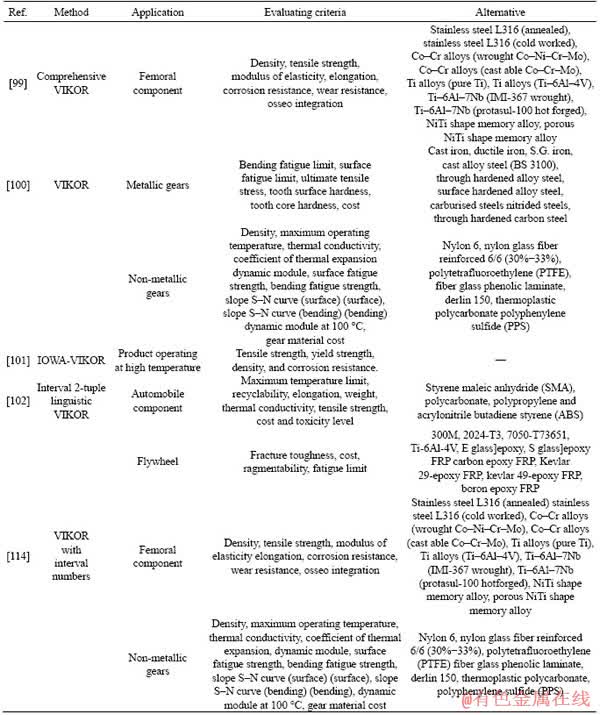

Comprehensive VIKOR method was used by BAHRAMINASAB et al [99] to rank the candidate materials for the selection of the femoral component of the total knee replacement. To achieve a more reliable result, sensitivity analysis was performed. Porous NiTi was found to be the most suitable material.

ATHAWALE et al [100] demonstrated the potentiality, applicability of the VIKOR method for material selection problem. Examples of metallic and non-metallic gear were solved using the VIKOR method to obtain the best material. Nylon reinforced 12 and carburized steel were found to be the best material for the metallic and non-metallic gears. The obtained results were found to be in match with those from the past researchers.

A new aggregation operator known as induced ordered weighted averaging standardized distance operator (IOWASD) was used with the VIKOR method by LIU et al [101]. The method was able to take into account the complex attitudinal character of the decision maker. The IOWASD operator was further extended to obtain the generalized IOWASD operator. The proposed method was illustrated using an example of a product operating at high temperature. It was established that the proposed method was able to provide a clear picture of the decision making process.

LIU et al [102] developed the VIKOR method with interval 2-tuple linguistic variables to solve the material selection problem under uncertain and incomplete information environment. The applicability of the proposed method was established using two examples of automotive component and flywheel. The results obtained were found to be in exact correlation with that from the past researchers.

SAYADI et al [103] proposed VIKOR method based on the interval data and was known as the extended VIKOR method. JAHAN et al [104] used the extended VIKOR method to address the material selection problems. Through the examples of femoral component for total knee replacement, and gear material selection, the efficiency of the proposed method to help the material and design engineers with mixed, precise and imprecise material data was established.

2.1.7 Graph theory and matrix method

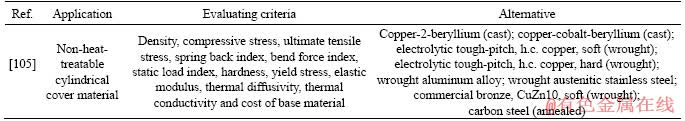

RAO [105] proposed a material selection method for a given engineering component using graph theory and matrix approach. The ranking of the material alternative is obtained using material suitability index. The index was obtained using material selection factor graphs which was developed using material selection factors and their relative importance. The method was found to be a general method which could be applied to any material selection problem with any number of attributes but limited to 20. Appendix 7 summarizes the application addressed by Graph theory and Matrix approach together with the evaluating criteria and the candidate materials.

2.1.8 Grey relational analysis method

Grey relational analysis (GRA) method was demonstrated by CHAN [106] for material selection problems using example of gear made from thermoplastics. The method was found to be suitable for ranking material options in preference order under uncertainties, conflicting objectives and non-linear constraints.

CHAN et al [107] suggested a method for combining the multi-dimensional alternatives into ordered pairs of single dimensions. The method was known as GRA that aids in ranking the material with respect to several criteria. The proposed GRA method makes global comparison instead of considering the hierarchy structure for the different objectives. Illustrative example of vacuum cleaner was studied to demonstrate the applicability of the method. Acrylonitrile butadiene styrene-recycling ordered pair was the top ranked alternative.

Appendix 8 highlights the applications to which the grey relational analysis was used. The evaluating criteria and the considered alternatives have also been depicted.

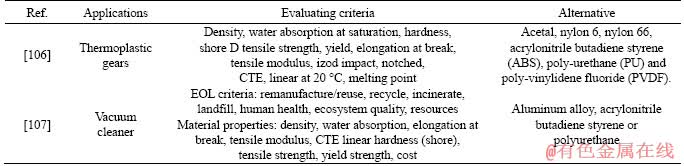

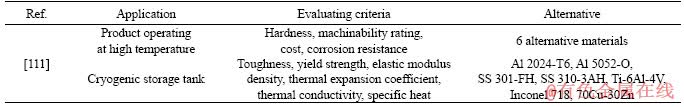

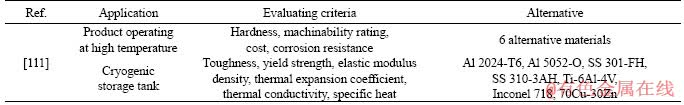

2.1.9 Complex proportional assessment method

The complex proportional assessment (COPRAS) method [44] has been used in different fields which include construction, property management, and economics [108-110]. Material selection problems have also been addressed using the COPRAS method. CHATTERJEE et al [111] proposed the COPRAS method for material selection of engineering components. The applicability and its potentiality to solve the complex material selection problems were established through examples of cryogenic storage tank and product operating under high temperature environment. The proposed method could aid the designers in the decision making process without being aware of the physical meaning of the process. The results obtained were in exact match with that from the past researchers. The addressed application is delineated in Appendix 9

2.1.10 Evaluation of mixed data method

The applicability of the evaluation of mixed data (EVAMIX) [45, 112-115] method in the domain of material selection has been demonstrated by CHATTERJEE et al [111]. The authors in their work have highlighted the advantage of the EVAMIX process to handle the coordinal and the ordinal data separately and the ranks are then obtained by combining the ranks obtained. Due to this, the chance of losing information is very small when employing EVAMIX method. The flexibility and the comprehensibility of the EVAMIX method was justified using two material selection examples of cryogenic storage tank and product under high temperature environment (Appendix 10). The results established were found to be in excellent match with that of the past researchers.

2.1.11 Preference selection index (PSI) method

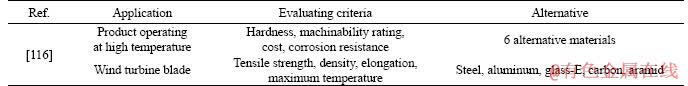

The method was proposed by MANIYA et al [116]. The preference selection index (PSI) method ranks the alternatives on the basis of preference selection index. MANIYA et al [116] used the PSI method to demonstrate its applicability as a decision making tool for the material selection problems. Two material selection problems, summarized in Appendix 11, were solved using the PSI method. The results obtained were in exact match to that obtained using other approaches i.e., graph theory, matrix approach and TOPSIS.

2.1.12 Analytic network process

Analytic network process (ANP) method [26, 117-119] has been employed by MILANI et al [120] in their study of material selection problems of non-metallic gears. Appendix 12 delineates the material alternatives and the evaluating criteria used in the case study. It was enunciated that the final material selection is dependent on the inner and outer dependencies of the criteria. Further, a greater degree of freedom was envisaged for the ANP method in comparison to the AHP method because of the clusters.

ANP method has also been used with other material comparing and choosing methods forming a hybrid approach towards material selection. These reports have been discussed in section 2.5.

2.1.13 Multi-optimization on basis of ratio analysis method

The multi-optimization on basis of ratio analysis (MOORA) [121-123] method ranks the material alternatives on the basis of assessment value. The applicability of the MOORA method has been demonstrated effectively in the literature surveyed. Appendix 13 summarizes the applications addressed using MOORA method.

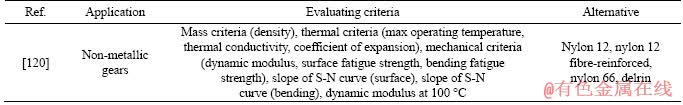

The updated form of MOORA known as MULTIMOORA method was extended by HAFEZALKOTOB et al [124] to use the target- based attributes. The relative importance of the different attributes were established using the combination of objective, subjective and inter- attribute correlation effects. The proposed methodology was illustrated by solving the two different biomedical engineering material selection problems of hip joint prosthesis and femoral component. The rankings obtained were compared with that from the earlier reports and were found to be an excellent match.

HAFEZALKOTOB et al [125] applied the extended MUTIMOORA method under an interval environment to solve the material selection problems. Fuzzy concept was used to obtain the subordinate assessment value. Interval comparison matrix was introduced to obtain the extremum and rankings. The subordinate rankings were aggregated using the dominance theory to obtain the final rankings. The applicability of the proposed method was established using the material selection problem of power gears. The established rankings were compared with different crisp MADM methods and were found to be in exact match.

2.1.14 TOmada de decisao interativa multicriterio method

TOmada de decisao interativa multicriterio (TODIM) is a MCDM tool that is based on the concept of prospect theory [126]. As opposed to other MCDM tools, this method ranks alternatives on the basis of global measurement values. This tool was applied by ZINDANI et al [127] for the material selection problems. The applicability of the method was explored using two material selection problems of flywheel and spur gear (Appendix 14). The method was found to be easily comprehendible and robust for application to material selection problems.

The other MADM methods of material selection i.e., ORESTE (Organization, Rangement Et Synthese De DonnesRelationnelles), OCRA (Operation Competitiveness Rating Analysis) and ARAS (Additive Ratio Assessment) have been used prominently for carrying out comparative analysis, as discussed in section with the other material comparing and choosing methods.

2.2 Fuzzy based decision making tools

Fuzzy theory was first given by ZADEH [128]. In decision making, the role of fuzzy logic was reinforced by CARLSON et al [129]. There are certain situations where lack of information leads to unclear state of the system. In case of material selection, some of the attributes i.e., resistance to corrosion and wear, weldability, formability, castability, cannot be expressed in numbers. These are generally rated in linguistic terms: very good, good, and fair [130]. Further, the establishment of relative importance of criteria is another problem as these are usually expressed in linguistic manner and the quantification is difficult [131]. Therefore in such cases, usefulness of fuzzy logic can be realized. Fuzzy logic has proved to be useful during the earlier stages of design in an environment of uncertainty and imprecise relationships between different parameters. As far as material selection is concerned, trapezoidal membership functions are used for quantitative properties. For the qualitative properties, linguistic values are used. Therefore, one can arrive at different membership functions depending upon the property under consideration. The importance weights are then assigned directly or indirectly, depending on the number of properties to be compared.In case the number of material properties is very large then pair-wise comparisons are made to obtain a reciprocal matrix and hence the importance weights as described for AHP method. These weights are represented in the form of a trapezoidal membership function, used for assessing the suitability of the material. The desired property value is compared with the property value to compare the materials.

Fuzzy multi-criteria decision making can be categorized into fuzzy multi attribute decision making and fuzzy multi objective decision making [132-135]. An array of research reports on material selection using fuzzy logic has been reported. Appendix 15 illuminates the different applications addressed using fuzzy approach. The appendix also summarizes on the evaluating criteria and the material alternatives used for the application addressed.

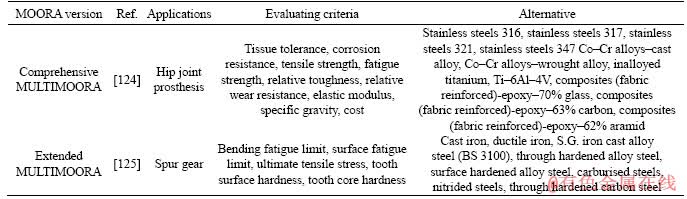

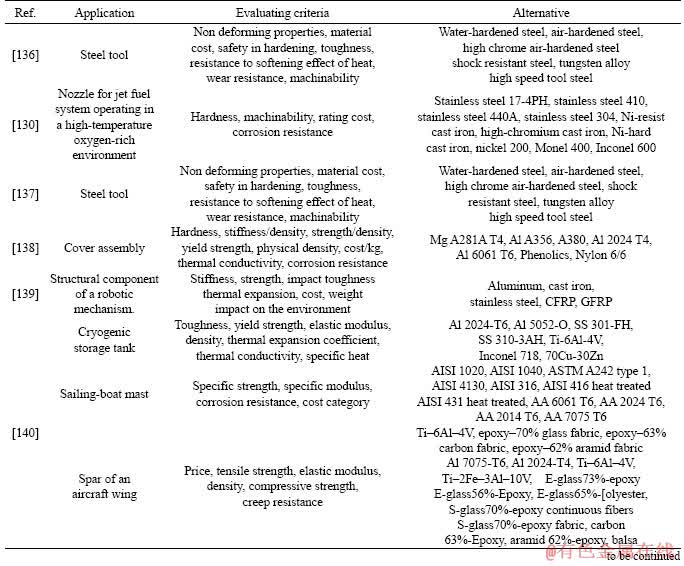

An algorithm was proposed by WANG et al [136] for addressing the material selection problem under fuzzy environment. The material selection approach proposed in the paper was illustrated using the material selection problem of tool steel. It was concluded that the fuzzy method could be used to evaluate any data (qualitative and quantitative) without any constraints.

A fuzzy multi criteria decision making system was proposed by LIAO [130]. The fuzzy characteristic for the material selection problems was discussed. The proposed methodology was demonstrated using the material selection problem of nozzle in jet fuel system that operates under high temperature environment. It was believed that the method could be extended for any general application. However, a modification of the methodology was recommended in case of high- performance components.

CHEN [137] proposed a new methodology to solve material selection problem under fuzzy environment, the relative importance of the different criteria and the rankings of the considered alternatives are assessed in linguistic terms represented by fuzzy numbers. The method was illustrated using tool steel material selection problem. The proposed methodology was found to be simple in calculations involving less computational time.

A decision support system integrating the material database and the multi-attribute decision making was proposed by GIACHETTI et al [138]. This was done using fuzzy set and possibility theory. The possibility and necessity measures were used for the assessment of compatibility ratings between the product requirements and each of the material alternatives.

An intelligent material selection tool based on fuzzy logic was proposed by ULLAH et al [139]. The material selection problem was expressed in linguistic terms and was one of the inputs for the proposed method. The material property charts was used as another input. The method was used for the material selection of robotics links. The composite materials were found to be much better alternative in comparison to the metallic materials for the robotic link. The robustness of the proposed methodology was demonstrated using the user-defined settings.

KHABBAZ et al [140] introduced a simplified approach of material selection using fuzzy logic. The proposed method was able to deal easily with the quantitative properties of the materials. There was a considerable reduction in the quantum of mathematics involved in comparison to the conventional methods. Three examples of material selection: cryogenic storage tank, spar of an aircraft wing and hollow cylinder mast for sailing boat were used to demonstrate the applicability of the proposed methodology. The results were found to be in excellent match with that from the past researchers.

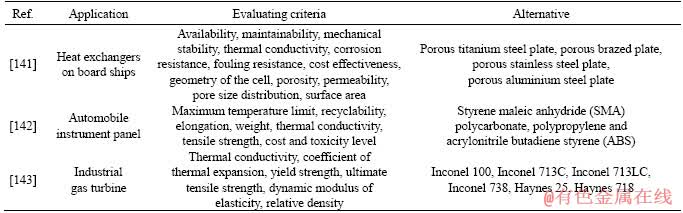

CICEK et al [141] proposed a methodology known as fuzzy axiomatic design (FAD) using the concept of fuzzy logic. The FAD method uses the advantages of fuzzy linguistic terms and triangular fuzzy numbers to deal with the issues of incomplete and vague information. The proposed methodology was used for the material selection of suitable material for plate type heat exchangers in the marine systems. Porous brazed plate was found to be the most suitable material candidate for the application under consideration.

A new fuzzy variable encapsulating the idea of intuitionistic linguistic variables known as uncertain membership linguistic variable (UMLV) was proposed by YANG et al [142] for addressing the drawbacks of losing information and lack of precise representation of the decision makers’ preferences in the various MCDM methods. Some aggregator operators include uncertain membership linguistic weighted geometric (UMLWG) operator, uncertain membership linguistic weighted average (UMLWA) operator, uncertain membership linguistic ordered weighted geometric (UMLOWG) operator and uncertain membership linguistic ordered weighted average (UMLOWA) operator were used in the proposed approach for the aggregation of uncertain membership linguistic information. Material selection problem of automotive component was used to illustrate the proposed material selection approach.

Risk based fuzzy MADM known as risk fuzzy axiomatic design was used for addressing the material selection problems under risk environment by HAFEZALKOTOB et al [143]. The applicability of the proposed method was illustrated using the real world industrial application of industrial gas turbine. The problem was also analyzed using the other approaches: FAD WFAD and WRFAD. The results were validated using the F-MULTIMOORA and EF-MULTIMOORA methods.

2.3 Multi objective decision making methods

The designer has to often make a compromise between the different objectives to arrive at the best solution. The material selection problems involve a number of conflicting objectives and therefore a trade-off must be stuck yielding a number of possible satisfactory solutions [1]. Further, the objectives must be achieved under some constraints.

2.3.1 Life cycle analysis (LCA) methods

Life cycle engineering (LCE), life cycle assessment (LCA), life cycle cost (LCC) and life cycle management (LCM) are different models to life cycle analysis. LCE [144-148] incorporates three dimensions of performance, environmental impacts and the cost. The LCC [149, 150] model consists of economic aspect, LCA [151, 152] covers the environmental impact and the LCM covers both the economic and the environmental impacts.

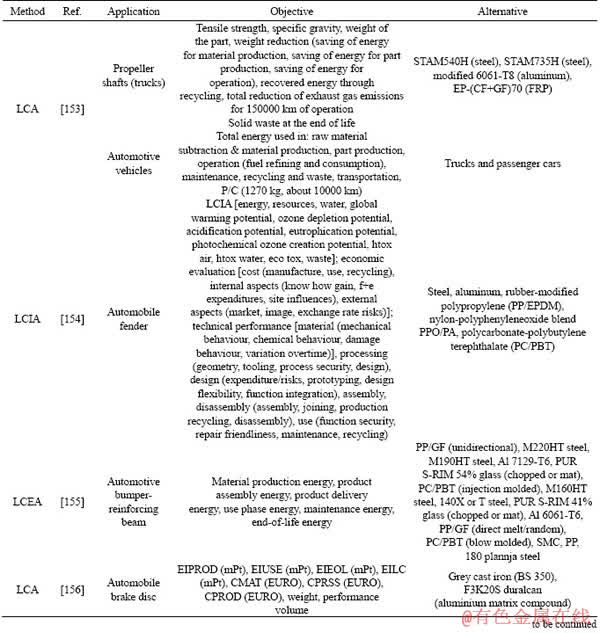

Field of material selection reports an array of work utilizing the life cycle strategies for number of engineering applications. The summary of different applications solved using the different life cycle strategies has been delineated in Appendix 16. KASAI [153] reported the use of life cycle assessment model for automotive application. The approach was used to evaluate the propeller shafts made of different material alternatives for medium duty trucks. Life cycle inventory (LCI) analysis was also conducted for passenger car and truck.

SAUR et al [154] employed the LCA methodology for the material selection of automobile fender. The case study consisted of five candidate material alternatives and eleven environmental metrics. The material alternatives were ranked on the basis of their sustainability metrics. The uncertainty in the case study was added as the subjective, scores from the experts and the public were also considered. The results obtained showed that polypropylene (PP)/ethylene- propylene-diene copolymer (EPDM) was the most suitable material alternative.

FITCH et al [155] presented a material selection based on the energy analysis known as life cycle energy analysis (LCEA). The material alternatives for automotive bumper reinforcing beam were analyzed using the LCEA method. The glass fibre composites and the high strength steel beams were found to be with the lowest energy consumption over the entire life cycle of the vehicle.

GIUDICE et al [156] reported a systematic method that leads to selection of material by taking into account the environmental aspects. The proposed methodology incorporated the importance of design which emphasized on harmonizing the performance characteristics and the economic compatibility of the product. The method was applied for selecting the appropriate material for the automotive disc brake. A direct comparison was made between the conventional design approach and the multi-objective approach.

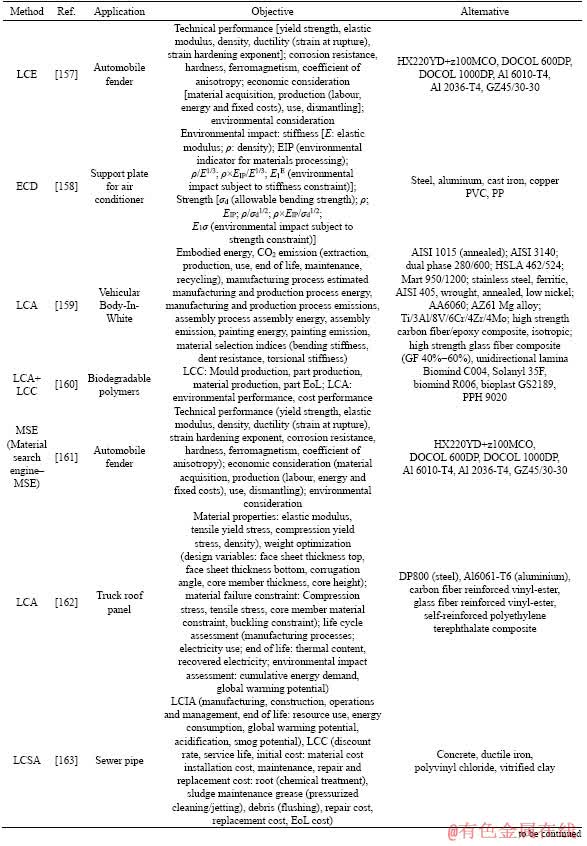

RIBEIRO et al [157] proposed life cycle engineering methodology to material selection integrating the different dimensions of technology, economy, environment and current practices in a single decision making tool. The proposed methodology was demonstrated for the automobile fender and it was revealed that the importance weights assigned to the technical, economic and environmental aspects played a critical role in the final evaluation of the different alternatives.Further, the collection of data at the initial stage and the choice of material alternatives were also equivalently important for making the suitable material choice.

Engineering conscious design (ECD) was proposed by HUANG et al [158] for the material selection problems. The proposed methodology integrates the life cycle performance index with the environmental impact. The established methodology was applied for selecting a suitable material for air conditioning support plate with the objective of minimizing the environmental impact under strength and stiffness constraints. It was established that the envisioned methodology can provide decision analysis guidelines for selection of suitable material with minimal environmental impact.

LCA based approach was proposed by MAYYAS et al [159] and was implemented to investigate the performance of material alternatives during the production stage of vehicle’s body-in- white. Less energy was consumed by aluminum and magnesium intensive structures for vehicle lifespan of over 200000 miles. However, when the lifespan was decreased to 50000 miles, steel and AHSS were the higher ranked materials in terms of CO2 emissions and energy savings.

RIBEIRO et al [160] proposed a life cycle framework to consider the concept of eco-design in material selection. The proposed framework was directed to obtain both the cost and the environmental performance of all the processes involved during product life cycle. The methodology was then applied to the case study of biodegradable polymers. The need to capture the different aspects throughout the entire life cycle for making a suitable material choice was established through the case study considered.

A material selection engine (MSE) contributing for a more informed life-cycle based decision-making process in material selection was proposed by PECAS et al [161]. The proposed methodology reduced the number of material alternatives on the basis of technical performance. The remaining material alternatives then follows through the cost and environmental impacts along different phases of life cycle. A case study of automobile fender was taken to demonstrate the applicability of the proposed method. However, the proposed method was proved to be laborious and time consuming.

POULIKIDOU et al [162] proposed a material selection framework integrating weight optimization and life cycle assessment for environment. The methodology was applied for roof panel of truck. The materials from metal, polymer and hybrid families were assessed along with a novel composite material. The material assessment showed that a limited life cycle environmental benefit was offered for lightweight materials.

Life cycle sustainability assessment (LCSA) method for the material selection of sewer pipe was used by AKHTAR et al [163]. Four different material alternatives i.e., polyvinyl chloride (PVC), vitrified clay, and ductile iron were compared and evaluated using the comprehensive life cycle sustainability assessment (LCSA) frameworks. The LCSA frameworks were emergy and AHP based. Pros and cons of the two frameworks were explored.

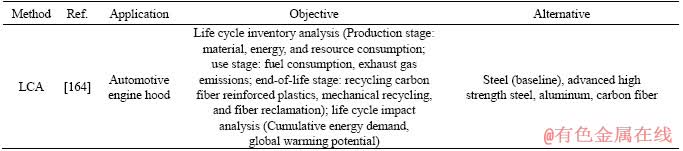

SUN et al [164] presented a LCA-based method for cumulative energy demand (CED) and global warming potential (GWP) associated with the selection of sustainable materials for vehicular engine hoods. The proposed methodology was used for the evaluation of environmental performances of different material alternatives namely carbon fibre, steel, aluminum and AHSS. The analysis showed that aluminum vehicular engine hood had the lowest CED and GWP.

2.3.2 Genetic algorithm and artificial neural networks

Genetic algorithm (GA) [165-169] makes use of biological evaluation principles to select the best solution. The prospects of GA as well as artificial neural networks (ANN) have been explored by different researchers in the field of material selection problems. Appendix 17 depicts different engineering applications addressed using GA and ANN techniques. Evaluating criteria and the material alternatives used have also been summarized in Appendix 17.

SMITH et al [170] employed the neural network method to arrive at input process settings for a process from the desired output and thereby fulfilling the customer’s requirement. Further the method could enable the manufacturer to produce material with the desired mechanical and physical properties. Power metallurgy was taken as an illustrative example which involves multiple input and outputs. The inputs deduced using the neural network had 36% lesser standard deviations of errors in comparison to the regression analysis method.

YANG et al [171] proposed genetically optimized neural network system method for selection of optimal material and operating conditions for manufacturing of composite materials. The performance of the proposed methodology was investigated using three case studies. It was established that the proposed method are very much suitable for systems that cannot be represented by conventional expressions.

CUI et al [172] formulated a new method for design of lightweight assemblies for automotive application using the concept of multi material concept. The design problem was formulated in the form of multi-objective nonlinear mathematical programming comprising of both the discrete and continuous variables. Genetic algorithm tool was then used for solving the formulated problem. The case study demonstrated that a low cost and lightweight assembly with good performance can be developed if proper materials are selected for the different parts. However, it was also suggested that the practicality of the method can be improved on inclusion of the aspects of joining and forming.

An improved genetic algorithm procedure together with the software prototype was developed by ZHANG et al [173] for selection of optimum material compositions and microstructures of components made of a multiphase material. The developed software prototype was demonstrated using the material selection for different regions of special cantilever beam and was found to provide efficient results.

ZHOU et al [174] proposed a model based on genetic algorithm and ANN to optimize the multi-objectives. A material selection problem of green drink containers was taken to optimize the multi objectives i.e., minimizing weight, cost and environmental impacts. It was shown that the system could select suitable materials on calculating and harmonizing different factors and therefore could be used effectively by the design engineers.

Genetic algorithm was used by BRADLEY et al [175] to solve the integrated framework combining life cycle cost, environmental and social metrics. The proposed framework could provide an enhanced overview on the product design.

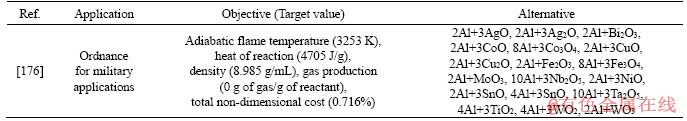

2.3.3 Goal programming

The goal programming (GP) method is generalization of linear programming handling multiple conflicting criteria. The alternatives are ranked on the basis of objective functions that are required to be optimized under conflicting criteria. SCHNIEDERJANS et al [176] used the goal programming for the determination of best composition for the energetic materials in accordance with the pre-specified goal targets. Eighteen different aluminothermic compositions were the candidate materials and on the basis of performance and cost criteria the best one was selected using the goal programming technique. A total of six goals were considered for the evaluation of the material alternatives. The case study demonstrated the efficacy of the proposed methodology to evaluate formulations where performance properties are critical. Appendix 18 highlights the case study addressed using GP technique.

2.3.4 Utility analysis

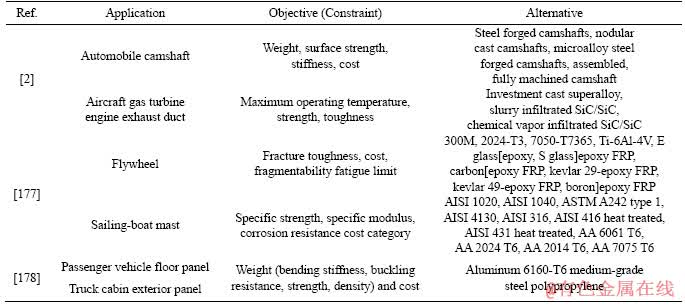

The material alternatives in the utility analysis are assessed on the basis of the respective utility scores. Von Neumann and Morgenstern laid the axiomatic foundation of the utility theory. In case of multi attribute utility analysis (MAUA), the alternatives are assessed on the basis of utility scores of the respective alternatives. The utility values are arrived using the questionnaire approach which is however tedious and time consuming. The literature surveyed enunciates the applicability of the utility analysis approach to address the material selection problems. The summary of the application addressed has been depicted in Appendix 19. ROTH et al [2] demonstrated the applicability of the multi-attribute utility analysis for the material selection problems. The example of automobile camshafts and exhaust duct for the aircraft’s gas engine turbine was solved using the multi attribute utility analysis. It was concluded that the utility analysis yielded results that could reflect on the accurate and flexible representations of the material selection process.

ATHAWALE et al [177] used the utility additive (UTA) method and demonstrated using two illustrative material selection problems of flywheel and mast for sailing boat that the method is practical and efficient in ranking of the alternatives with interdependence between the criteria. The rankings obtained for the alternatives in the two examples were found to be comparable with that obtained using other MCDM methods.

ALY et al [178] proposed a material selection procedure for material selection of sandwich panels with the objective to minimize weight and cost. The method makes use of pre-compiled library of candidate materials combination. The proposed methodology was demonstrated using two examples from the automotive industry. The results obtained from the case studies suggested that the proposed methodology was effective in obtaining the optimal solution.

2.3.5 Ashby approach

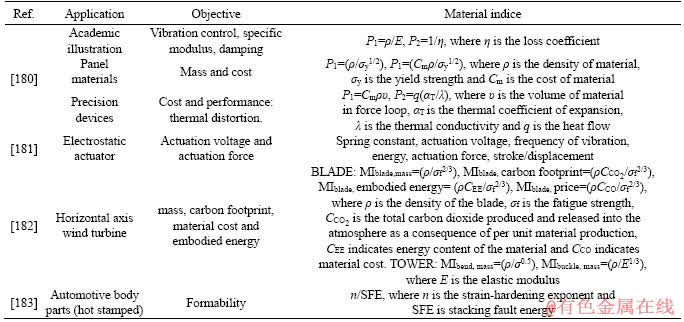

The Ashby method [179] selects the optimal material on the basis of performance index. The material with the highest performance index is chosen to be the best amongst all the other materials. There have been a number of reports that have employed the Ashby approach for the material selection problems. Appendix 20 summarizes the applications addressed with the alternative materials considered and the objectives undertaken.

ASHBY [180] put forth a methodology to select suitable materials meeting multiple objectives. Each objective was characterized using performance metrics which are combination of mechanical properties. The trade-off plot is then used to identify an optimal trade-off surface on which lies the best material alternatives. The method was demonstrated using multiple examples and proving the proposed methodology to effectively select the suitable material alternatives fulfilling multiple objectives.

PARATE et al [181] applied the Ashby approach for selecting the suitable material for electrostatic micro actuators. The material selection chart is plotted on the basis of developed performance and material indices. Diamond was the most suitable material for case of high voltage and actuation force, while it was aluminum for the case of high speed electrostatic microactuators.

Material selection indices for blade and tower of horizontal axis wind turbine were established by RASHEDI et al [182]. The Ashby’s approach was then employed for material selection of both the small and large scale horizontal axis wind turbines. The study proved to be an efficient tool for selection of materials for wind turbines with relatively higher structural strength, which is economically and environmentally viable harnessing more energy.

A material selection strategy based on Ashby’s approach was proposed by ANTUNES et al [183] for hot stamped automotive parts. The material was done on the objective of formability which was based on stacking fault energy and strain hardening exponent. Austenitic high-Mn steels were the suitable material alternatives.

2.3.6 Linear assignment method

The method was proposed by ASGARPOUR [184]. It was applied for material selection by JAHAN et al [185]. The method was found to be relatively simpler in comparison to the other MCDM tools and doesn’t require to normalize the criteria. However, since the proposed method takes input only as ordinal data, imprecise results could be expected in case that material selection is based on cardinal data. The addressed case study is summarized in Appendix 21.

2.4 Grey numbers

A new class of material comparing and choosing tool for addressing the material selection problems are grey methodologies. Grey basically emanates from the grey theory dealing with insufficient and incomplete information [186, 187]. The uncertainty levels are classified using white numbers, grey numbers and black numbers. The grey method therefore deals with the grey data. In the literature surveyed on material comparing and choosing methods, the grey method has only been employed in tandem with the other MADM tool i.e., COPRAS. Therefore, in the present work the literature on the proposed integrated framework has been discussed within the hybrid approaches (Section 2.5).

2.5 Hybrid methods in MCDM for material selection

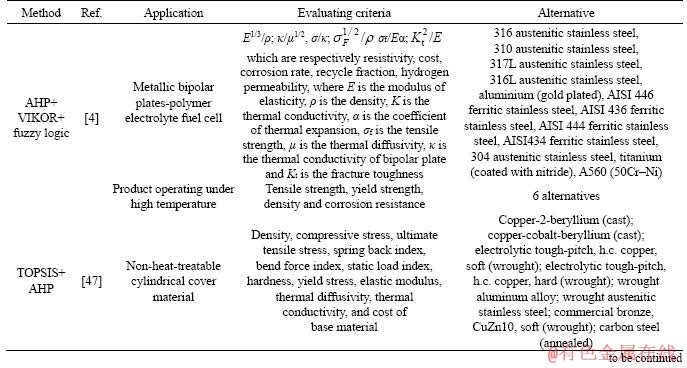

The combination of different materials comparing and choosing tools have also been adopted to solve the complex material selection problems. An array of reports has been published on using hybrid methods addressing material selection problems. The different applications addressed using the hybrid methodologies have been summarized in Appendix 22 along with the evaluating criteria and the material alternatives. RAO [47] integrated three decision making tools of AHP, VIKOR and fuzzy logic to develop an improvised material selection procedure. With the illustrative examples of engineering importance i.e., bipolar plates for polymer electrolyte fuel cell and for material operating under high temperature, it was demonstrated that the proposed hybrid approach is a general method considering any number of qualitative and quantitative attributes.

A hybrid material selection approach combining TOPSIS and AHP methodology was put forth by RAO et al [47]. The proposed integrated framework was illustrated using example of non-heat treatable cylindrical cover and it was shown that the proposed integrated approach could be used for material selection of any type of problem involving any number of attributes.

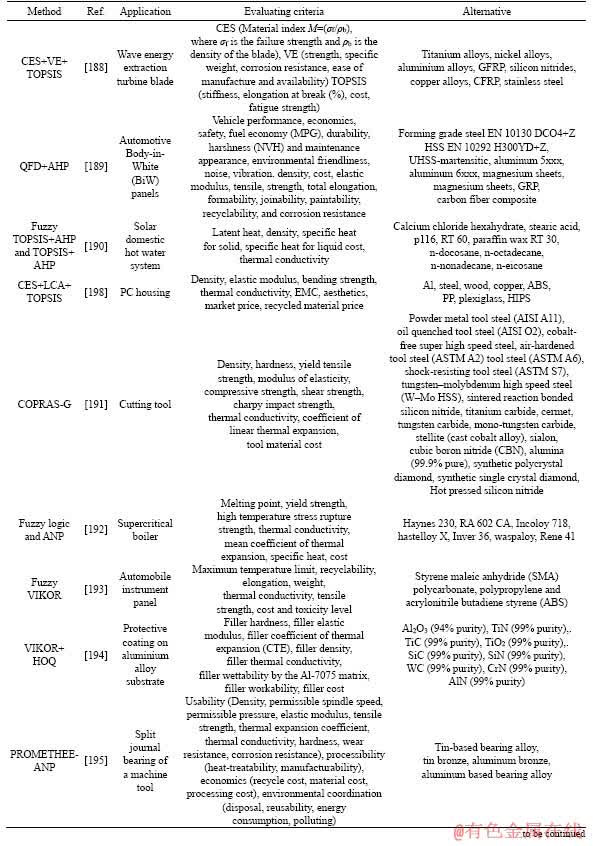

An attempt to streamline the material selection process, combination of three well known methods i.e., value engineering technology, TOPSIS and Cambridge Selector (Ashby approach) was proposed by THAKKER et al [188]. The developed integrated framework was applied for the material selection of blade for wave extraction impulse turbine. The robustness of the proposed method showed that the method could be used for other rotating machinery.

MAYYAS et al [189] used the hybridization of QFD (Quality function deployment) and AHP for the material selection of automotive body-in-white (BiW) panels. It was shown that different grades of steel were the preferred material alternatives for BiW panels.

Two different hybrid material selection approaches i.e., TOPSIS and AHP and TOPSIS, AHP and fuzzy logic were proposed by RATHOD et al [190]. The effectiveness and the feasibility of the hybrid models were demonstrated by solving material selection problem for a domestic solar heating water system. The results obtained proved the viability of the proposed framework to solve the material selection problems. Further, it was established that TOSIS in combination with AHP is more suitable when precise information regarding the attributes are available whereas for vague and inaccurate information, fuzzy TOPSIS in combination with AHP was found to be a more suitable model.

MAITY et al [191] used the integrated framework of grey numbers and COPRAS method i.e., COPRAS-G to make material selection of the cutting tool. The method was found quiet useful in many real time decision making situations where the criteria are expressed in intervals.

Fuzzy analytic network process was employed by MAITY et al [192] for selecting suitable material for the supercritical boiler. The best material identified for the supercritical boiler was Rene 41, and Haynes 230 was the worst of the candidate materials considered.

GIRUBHA et al [193] used the integrated methodology based on fuzzy logic and VIKOR for solving the material selection problem of automotive instrument panel. The results obtained were compared by that obtained from the environmental impact analysis. Both the analysis recommended Polypropylene as the alternative material for the automotive instrument panel.

CAVALLINI et al [194] developed a new material selection model integrating House of Quality (HoQ) and Comprehensive VIKOR method. The developed method was known as integral aided material selection (IAMS) and was proposed to overcome the main drawbacks of the traditional material selection approaches i.e., absence of an aided support for proper selection of criteria and the lack of proper guidelines for the usage of suitable weighting method. The feasibility of the IAMS methodology was proved using an illustrative example to select the suitable coating material for protection of aluminum alloy substrate.

The method of PROMETHEE was combined with ANP method by PENG et al [195] for selection of appropriate material for a given application. The decision making framework was enunciated using the example of material selection for a journal bearing. It was shown that the proposed methodology could be used for beneficial, non-beneficial, fixation, deviation, interval and deviated interval attribute types. For the attribute ratings the method could be used both for the exact and interval values. The method expresses the qualitative attributes in terms of 2-tuple linguistic terms, which was found to be more convenient than triangular or trapezoidal fuzzy numbers. Further, the use of ANP for weight calculation was found to give a more accurate result than the AHP method. The results obtained for the case study using the developed framework was found to be in excellent match from that obtained using other methods: TOPSIS, ELECTRE and WAA.

JAHAN et al [196] extended the concept of dependent weighting to cover the target based criteria and an alternative methodology was proposed that incorporated the subjective, correlational and subjective weightings under the situation of uncertainty for the three types of weights. The illustration for the material selection of hip joint prosthesis outlined the whole material selection process which consisted of calculation of all the three types of weights and then combining them, selection of proper material selection methods making use of the resulting weights and then finally aggregating the rankings to obtain the final rank. The results obtained highlighted the effectiveness of the proposed methodology to aid the design engineers to suitably select the materials for complex design problems.

A hybrid multiple criteria decision making approach was proposed by LIU et al [197] that combines the DEMATEL-based ANP with the modified VIKOR method. The beneficial, cost and target based criteria were assessed simultaneously in the proposed framework. A case study of material selection for bust of split journal bearing was undertaken to demonstrate the potentiality of the proposed methodology. The results from the case study demonstrated the effectiveness of the proposed method.

YANG et al [198] proposed a decision making framework based on fuzzy TOPSIS highlighting the strategic importance of material selection in the remanufacturing process for automobile components. The proposed method allowed for the incorporation of remanufacturing conditions during the material selection process. The results from the research work highlighted the importance of using light duty materials in automotive design for remanufacturing from the life-cycle perspective.

Two new TOPSIS methods integrated with interval type 2 fuzzy sets were proposed by LIAO [199]. The proposed method stressed upon the importance of desired properties. The study was also made for effects of fuzziness percentage, soft constraints and on definition for upper membership function (UMF) and lower membership function (LMF). The proposed methods were integrated with the material database to aid in automatic material selection process. The integrated framework was found to be good enough for general use.

XUE et al [200] proposed an integrated material selection approach combining interval- valued intuitionistic fuzzy sets and multi-attribute border approximation area comparison (MABAC) methods. The linear programming model was used for the identification of weights. The proposed methodology was illustrated using examples of automotive instrument panels in which case polypropylene was the best candidate material while Co-Cr alloys were the preferred choice for hip prosthesis. The results obtained were validated using experimentation and were found to be consistent.

An integrated framework combining Suh’s design axioms, AHP and Multi attribute utility analysis was proposed by DAS et al [201] for material selection problems. The method stressed on rational design by addressing simultaneously the selection of material as well as geometric variables which inherits the customer requirements.

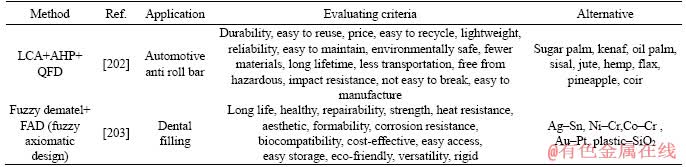

MASTURA et al [202] carried out the material selection of automotive anti-roll bar using combination of AHP, QFD and life cycle assessment methodologies. The suitable fibre was selected using the combination of AHP and QFD. Sugar palm fibres followed by kenaf were the suitable fibres for the application meeting the design requirements. Life cycle assessments for both the fibres showed that sugar palm fibre was a much better option than kenaf.

An integrated methodology combining fuzzy axiomatic design and fuzzy DEMATEL was proposed by CANDAN et al [203] for selection of suitable material for dental filling. The results obtained showed that health was the most important criterion and the best material alternative was Ag-Sn.

2.6 Comparative analysis of decision making tools in material selection

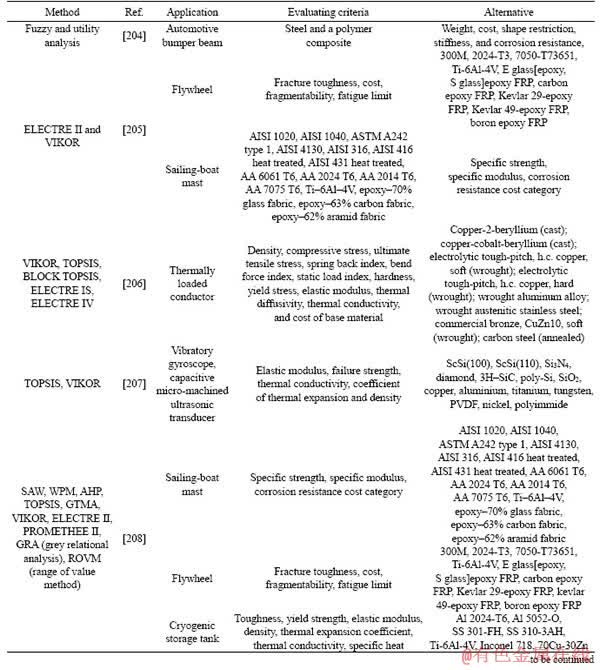

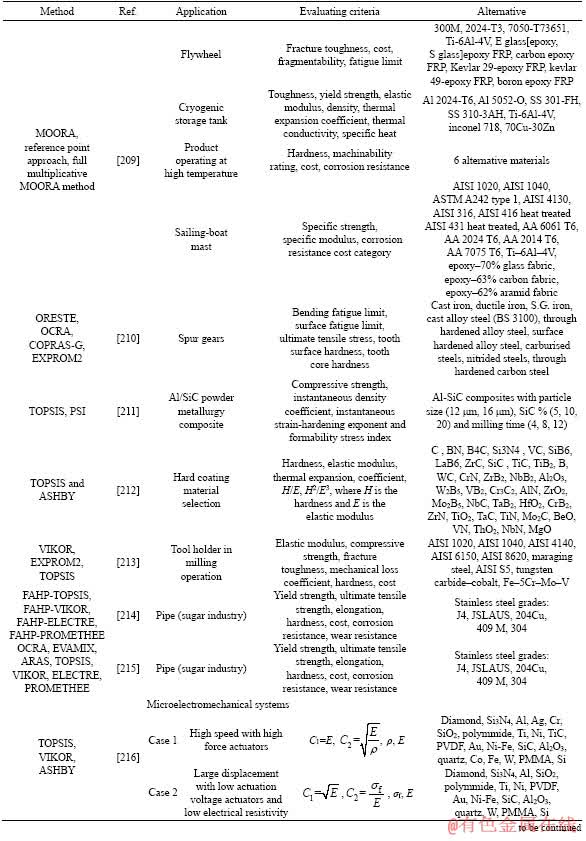

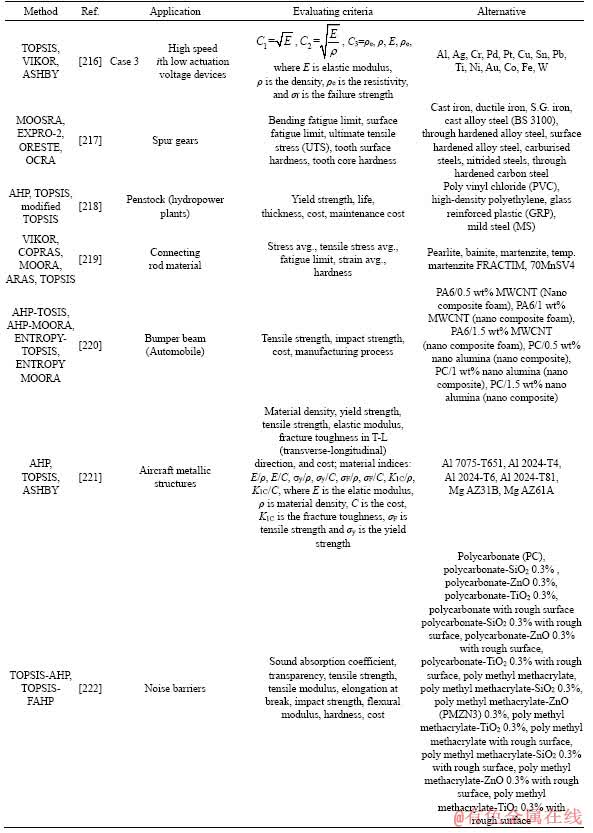

An array of reports has been reported on the comparative analysis between different material comparing and choosing methods. The reports mainly investigate the performance analysis of the different material comparing and choosing tools. Appendix 23 enunciates different applications and methods used for carrying out the comparative analysis. THURSTON et al [204] demonstrated the use of two methods: fuzzy analysis and utility analysis through illustrative example of material selection for automotive bumper beam. Several differences were highlighted between the two methods. On the one hand fuzzy analysis was recommended to be a suitable method of evaluation at early design stage, on the other hand utility analysis was found to be more appropriate in the latter stages of design.

Two material selection problems were solved using the two potential MCDM approaches: ELECTRE and VIKOR by CHATTERJEE et al [205].The performances of the two methods were compared. The two material selection problems undertaken were that of flywheel and sailing boat mast. On comparison it was established that compromise rankings were established by VIKOR method whereas ELECTRE II method could establish the entire ranking. The two MCDM tools were found to be easily implementable for any material selection problem. Further, the results obtained showed an excellent correlation with that from the past researchers.

SHANIAN et al [206] compared some of the prominent MCDM tools for addressing all the stages of material selection problem for a thermally loaded conductor. The compensatory methods used were ELECTRE IS and ELCTRE IV and the non-compensatory methods adopted were TOPSIS, Block TOPSIS and VIKOR. The result obtained from the illustration was used to compare the effects of compensation and non-compensation and were found to be in good agreement with that obtained using CES databases. The study suggested that the material design engineer should be cautious in accepting the results from the MCDM tools.

A comparative study between VIKOR, TOPSIS and the Ashby approach was carried out by CHAUHAN et al [207] on material selection of micro-electromechanical systems (MEMS). The study was carried out on two MEMS devices and the results obtained using VIKOR and TOPSIS methodology showed congruency with that obtained using Ashby approach. The study demonstrated the capability and potentiality of the MADM methods to solve the material selection problems without prior mathematical calculations and equations.

A comparison analysis amongst the ten prominent MCDM tools was made by ATHAWALE et al [208]. The relative performance was compared by considering three examples of material selection: a sailing boat mast, a flywheel and a cryogenic storage tank. It was established that all the methods result in almost the same ranking of alternative materials, VIKOR being relatively better while AHP had a relatively poor performance. It was concluded that more attention needs to be paid towards selection of criteria and the material alternatives than on choosing the most appropriate MCDM tool.

KARANDE et al [209] used and compared the three material selection methods independent of the criteria weights and the normalization procedure. The three methods: multi-objective optimization on the basis of ratio analysis method (MOORA), reference point approach and the full multiplicative MOORA, were tested and compared for their performance on the four material selection problems. The results obtained for the rankings were almost accurate and comparable with the results obtained from the past research.

The performance analysis and applicability of four MCDM tools: extended PROMETHEE II, ORESTE, COPRAS and OCRA was investigated by CHATTERJEE et al [210] using the material selection problem of spur gears. It was established that the best and the worst selected materials were the same for all four methods. The results obtained from the four methods were validated form that of the past researchers.

KHORSHIDI et al [211] studied the comparative performance of TOPSIS and PSI in selection of a suitable material determining the desired combination of workability and strength for Al/SiC powder metallurgy composite. The findings from the two methods suggest Al-5%SiC composite with particle size of 16 μm with relative density of 90% milled for 12 h.

CHAUHAN et al [212] used the two MCDM methods for selecting a suitable material for hard coating. TOPSIS, a MADM tool, was used to rank the different material alternatives. The results obtained were compared with that obtained using the Ashby approach, a MODM tool. It was established that the rankings from the two methods showed a good agreement with one another.

Material selection of tool holder working under hard milling conditions was investigated by CALISKAN et al [213] using TOPSIS, EXPROM2 and VIKOR. The rankings established using the three MCDM tools were compared using the Spearman’s rank correlation and were found to be reasonable.

ANOJKUMAR et al [214] described the application of four integrated MCDM tools: FAHP- TOPSIS, FAHP-VIKOR, FAHP-PROMETHEE and FAHP-ELECTRE for the material selection problem of pipes used in sugar industry. The rankings of the four integrated tools were compared with one another producing significant results. Further it was enunciated that the integrated tools were simple, convenient, precise and efficient.

The application of the four MCDM tools: extended TODIM, ARAS, OCRA and EVAMIX, was demonstrated by DARJI et al [215] for pipe material selection in sugar industry. The rankings established using ARAS, OCRA and EVAMIX were compared with one another and were found in good agreement with those from the past researchers.On the other hand, the rankings from Extended TODIM showed deviations from the results of past researchers, the reason being the greater influence of cost criteria on the method.

YAZDANI et al [216] delineated the material selection process for microelectromechanical systems (MEMS) devices using Ashby, TOPSIS and VIKOR approach. Three different cases based on actuation voltage and force, electrical resistivity and speed of actuation. A good agreement between the results obtained was established. Diamond and silicon carbide were the best ranked material for the case of high actuation force and speed devices, Polymethyl methacrylate and Polyvinylidene fluoride were the options for large displacements with low actuation voltage actuators and aluminum was recommended for the devices with low electrical resistivity possessing high speed with low actuation voltage.

A comparative analysis between multi- objective optimization on the basis of simple ratio analysis (MOOSRA), EXPROM-2, ORESTE and OCRA methods was carried out by KUMAR et al [217]. On analysis using the coefficient of variation and Spearman’s Rank correlation, it was established that EXPROM-2 and OCRA were better MCDM tools in comparison to the other two tools for the case study undertaken.

The material selection problem for penstock in small hydro power plants was addressed by KUMAR et al [218] using AHP, TOPSIS and Modified TOPSIS method. The applicability and performance of the three methods were compared and it was found that TOPSIS and Modified TOPSIS were suitable for solving penstock material selection problems. Mild steel was the best ranked materials amongst the alternatives considered.

SEN et al [219] investigated the authentic materiality and cogency of some of the well-known MCDM techniques using the example of connecting rod. TOPSIS and VIKOR methods were the advisable MCDM tools for a focused decision making task. Pearlite and bainite were found to be the most assertive materials for the example of connecting rod under study.

Material selection problem of automotive bumper beam was dealt by HASANZADEH et al [220] using four integrated MCDM tools: AHP- TOPSIS, AHP-MOORS, Entropy-TOPSIS and Entropy-MOORA. The alternatives considered were obtained by using the injection molding manufacturing process. The rankings obtained from the four integrated approaches were compared with one another. All the four methods suggested Polycarbonate containing 0.5 wt% of nano alumina to be the most suitable material for the automotive bumper beam.

An overview of the knowledge-based systems (KBS) was presented by ADHIKARI et al [221] in context of lightweight aircraft metallic structures. The problem was addressed using two material selection tools: TOPSIS, AHP and Ashby approach. The rankings obtained from the MCDM tools were compared with one another and found to be in good agreement. Al-2024-T81 was the best ranked material.

NADERZADEH et al [222] carried out a comparative analysis of AHP-TOPSIS and Fuzzy AHP for selection of suitable material for environmental noise barrier applications. Polycarbonate-SiO2 0.3% with roughened surface was the best ranked material when using both the methods. The comparison between the two methods was made after addition of Gaussian noise to the data which showed deviations in the initial and final rankings established using the two methods. The calculated mean and variance results for the two methods showed that the fuzzy method could rank the material alternatives with certainty.

3 Observations

The present work reviews exhaustive literature on material comparing and choosing methods since 1988 till date. The report has highlighted the importance of various decision making tools predominantly applied in the domain of material selection for given engineering applications. With the quest of demanding precision in selection of a suitable material, a number of individual strategies, their hybrids and comparative analysis have been investigated. Appendix A delineates the various applications addressed, criteria used, objectives undertaken and the material alternatives considered.The following sub-sections address the questions raised by the authors in this work.

3.1 Engineering applications targeted by various decision making tools

Appendix A highlights different engineering applications based on optimal material selection. Some of the following novel engineering applications: “Housing of an electronic device”, “Key”, “lever for parking brake”, “artificial hip joints”, “Gas valve assembly”, “Vacuum cleaner”, “Nozzle for jet fuel system”, “Heat exchangers on board ships”, “Industrial Gas Turbine”, “Automobile brake disc”, “Support plate for air conditioner”, “Biodegradable polymers”, “Truck roof panel”, “Sewer pipe”, “Car door assembly”, “Green drink containers” and “Cantilever beam”, have been addressed by adopting the individual material comparing and choosing tools demonstrating the potentiality of the individual tools to efficiently handle the material selection problems. Some of the other applications: “Wave energy extraction turbine blade”, “Automotive Body-in-White (BiW) panels”, “Solar domestic hot water system”, “Supercritical Boiler”, Protective coating on aluminium alloy substrate”, “Split journal bearing of a machine tool”, “Engine block”, “Intake Manifold”, “Two stages spur gear reduction unit”, “Automotive Anti Roll Bar” and “Dental filling” have been investigated for demonstrating the hybrid approaches that exploits the advantages of the individual tools while mitigating the limitations. The investigation on the performance analysis and even the validation of the different tools have been carried out using applications of “Flywheel”, “Sailing-boat mast”, “cover for Thermally loaded conductor”, “Cryogenic storage tank”, “Product operating at high temperature”, “Spur Gears”, “Pipe (sugar industry)”, “Microelectromechanical systems”, “Connecting rod material”, “Bumper beam (Automobile)” and “Noise barriers.”

3.2 Commonly used decision making tool for optimal material selection

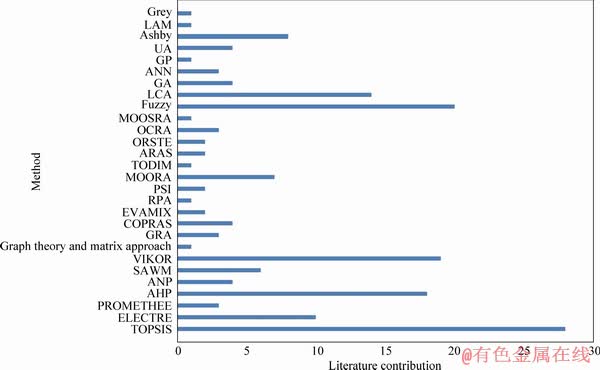

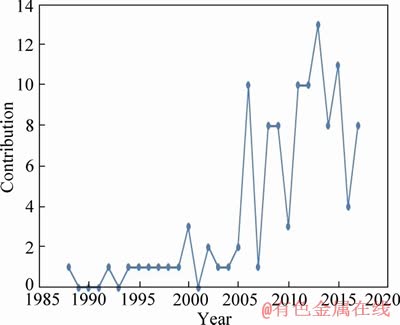

Figure 2 depicts the contribution of different material comparing and choosing tools employed to address various engineering applications. It is clearly delineated the predominantly used tools in the domain of material selection and therefore the second question raised in this work is answered. The most used methodology is TOPSIS tool which has been used individually, in an integrated framework and also used for investigating the performance analysis of the other tools. The popularity of TOPSIS tool amongst the material and design community may be attributed to its simplistic approach. The disadvantage of TOPSIS methodology to address only quantitative properties has been mitigated by different proposed integrated framework. Next on the list of popularity are the fuzzy based tools that address the qualitative properties as well as the vagueness and uncertainties associated with the material data. The other popular tools, as clearly depicted in Figure 2 are VIKOR, AHP (being used dominantly for the calculation of criteria weights), and life cycle models (addressing the economic and environmental aspects associated with material selection). The applicability of other methods i.e., ANN, UA, GA, COPRAS, PROMETHEE and ELECTRE have also been used to address the problems in material selection field, but not so prominently owning to the complexity involved in employing these tools. Further, to have a more transparent view of the different tools, the advantages and disadvantages of the prominently used tools are tabulated in Table 1.

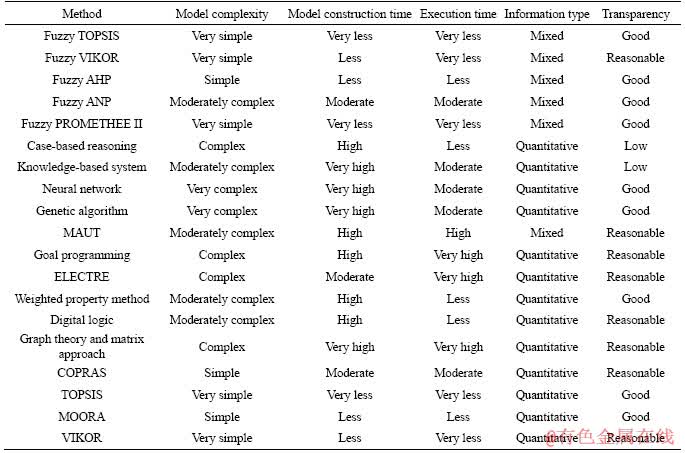

3.3 Merits and demerits of decision making tools

The present section delineates the merits and demerits associated with different material selection tools. This section therefore addresses the third objective of the review work. The merits and demerits have been depicted in terms of model characteristics with due consideration to the following parameters: model complexity, model construction time, execution time, information type handled and transparency of obtained results. Table 1 depicts the model characteristics of different methods for solving material selection problems.

3.4 Commonly used criteria/objectives for optimal material selection

The fourth objective of the review work is to perceive the most commonly used criteria/ objectives for addressing the different engineering applications. From the Appendices A, it can be clearly observed that numerous criteria have been used for the different engineering applications. Some of the prominently used criteria are “Cost”, “Fatigue limit”, “Toughness”, “Yield strength”,“Density”, “Thermal conductivity”, “Hardness”, “Tensile strength”, “Elongation”, “Recyclability”, “Corrosion resistance”, “Wear resistance”, “Fatigue strength” and “Machinability”. The objectives that have been dominantly employed are “environmental impact”, “Life cycle cost”, “End of life” and “Weight”. The diverse criteria can be compared with each other on normalization. Different normalization techniques have been identified by JAHAN et al [223] in their state-of-the- art review to address different types of criteria: target criteria, cost and beneficial criteria.

Figure 2 Contribution of different material comparing and choosing tools

Table 1 Model characteristics of different methods for solving material selection problems

3.5 Overview of DEA on material selection problems

DEA aids in assessment of efficiency for various decision making units (DMUs) which are used as inputs to create a number of outputs. The original DEA framework was introduced by CHARNES et al [224] which was referred to as CCR model. A more detailed study on the different DEA models can be referenced from Refs. [225, 226]. DEA models can be further classified to output-oriented DEA and input-oriented DEA. DEA has number of advantages: it is a non-parametric method and doesn’t require a production function for variables, no requirement of decision maker to set the weights as inputs or outputs, doesn’t require to transfer variables into a single unit, comparatively more precise to regression techniques. However, classical DEA also suffers from two key disadvantages: low power of discrimination and idealistic weight dispensation. To tackle these drawbacks, various DEA models have been introduced which indeed are intricate and requires decision makers with deep knowledge in DEA domain.