Trans. Nonferrous Met. Soc. China 24(2014) 619-625

Microstructure and property of rheocasting AZ91 slurry produced via ultrasonic vibration process

Jun-ping YAO1,2, Zhong SUN1, Tao YANG2, Bharat BBUSHAN2, Wen-yuan LONG1, Lei ZHANG1

1. Department of Hangkong Manufacture and Engineering, Nanchang Hangkong University, Nanchang 330063, China;

2. Department of Materials Science and Engineering, Ohio State University, OH 43210, USA

Received 18 March 2013; accepted 5 November 2013

Abstract:

The microstructure and mechanical properties of rheocasting AZ91 magnesium alloy were investigated. The semisolid slurry of this alloy was prepared by ultrasonic vibration (USV) process and then shaped by high pressure diecasting (HPDC). The results show that fine and spherical α-Mg particles were obtained by USV at the nucleation stage, which was mainly attributed to the cavitation and acoustic streaming induced by the USV. Extending USV treatment time increased the solid volume fraction and average particle size, the shape factors were nearly the same, about 0.7. Excellent semisolid slurry of AZ91 magnesium alloy could be obtained within 6 min by USV near its liquidus temperature. The rheo-HPDC samples treated by USV for 6 min had the maximum ultimate tensile strength and elongation, which were 248 MPa and 7.4%, respectively. It was also found that the ductile fracture mode prevailed in the rheocasting AZ91 magnesium alloy.

Key words:

AZ91 magnesium alloy; ultrasonic vibration; rheocasting; semisolid slurry; mechanical properties; fracture surface;

1 Introduction

The semisolid metal (SSM) processing, including thixoforming and rheocasting, offers the opportunity to manufacture net-shaped components with complicated shape and good mechanical properties. More and more researches were focused on rheocasting in recent years because of its low cost and high productivity [1,2]. Rheocasting involves stirring the solidifying alloy to prepare non-dendritic semi-solid slurry, then directly shaping the slurry. Ultrasonic vibration (USV) has the potential to be a simple and effective process to produce semisolid metal slurry. Previous investigations have revealed that when USV is applied to the solidifying melt, microstructure changes occur, involving grain refinement, increased homogeneity, reduced micro-segregation as well as degassing [3-6].

Using USV to prepare semisolid slurry is a relatively new method in SSM processing. Currently, the USV process is mainly used in producing the semisolid slurry of aluminum alloys.  et al [7,8] prepared semi-solid aluminum alloy slurry through an direct and indirect USV process. Their results indicated that good semisolid slurry of aluminum alloy could be obtained in a short time by USV near its liquidus temperature, and a considerable improvement in the mechanical properties was achieved after rheocasting. There are few works on ultrasonic treatment of magnesium alloys as compared to those on aluminum alloys. ZHANG et al [9,10] investigated the effects of ultrasonic treatment on the microstructure and mechanical properties of Mg-9.0%Al binary and AZ80 magnesium alloys, and reported the effects of ultrasonic treatment on the size and morphology of Mg17Al12 phase. They showed that Mg17Al12 phase in the entire cross section of the castings was significantly refined and also lost its continuity along the grain boundaries. LIU et al [11] and GAO et al [12] studied the effects of ultrasonic power on the microstructure and mechanical properties of AZ91 magnesium alloy. These investigations showed that ultrasonic treatment resulted in the formation of fine non-dendritic grains in the solidified microstructures, and the tensile and compressive strengths as well as the fracture strains of the castings were improved by ultrasonic treatment. LAN et al [13] used ultrasonic treatment for dispersion of nano-sized SiC particles in molten AZ91D magnesium alloy to produce metal matrix nanocomposites. They showed a nearly uniform distribution and good dispersion of SiC nano-particles within the matrix. Most researches on the ultrasonic treatment of magnesium alloys focused on grain refinement, and studies on the rheocasting slurry preparation of magnesium alloy via the USV process were limited.

et al [7,8] prepared semi-solid aluminum alloy slurry through an direct and indirect USV process. Their results indicated that good semisolid slurry of aluminum alloy could be obtained in a short time by USV near its liquidus temperature, and a considerable improvement in the mechanical properties was achieved after rheocasting. There are few works on ultrasonic treatment of magnesium alloys as compared to those on aluminum alloys. ZHANG et al [9,10] investigated the effects of ultrasonic treatment on the microstructure and mechanical properties of Mg-9.0%Al binary and AZ80 magnesium alloys, and reported the effects of ultrasonic treatment on the size and morphology of Mg17Al12 phase. They showed that Mg17Al12 phase in the entire cross section of the castings was significantly refined and also lost its continuity along the grain boundaries. LIU et al [11] and GAO et al [12] studied the effects of ultrasonic power on the microstructure and mechanical properties of AZ91 magnesium alloy. These investigations showed that ultrasonic treatment resulted in the formation of fine non-dendritic grains in the solidified microstructures, and the tensile and compressive strengths as well as the fracture strains of the castings were improved by ultrasonic treatment. LAN et al [13] used ultrasonic treatment for dispersion of nano-sized SiC particles in molten AZ91D magnesium alloy to produce metal matrix nanocomposites. They showed a nearly uniform distribution and good dispersion of SiC nano-particles within the matrix. Most researches on the ultrasonic treatment of magnesium alloys focused on grain refinement, and studies on the rheocasting slurry preparation of magnesium alloy via the USV process were limited.

In this work, semisolid slurry of AZ91 alloy was prepared by USV process and the effects of USV treatment time on the microstructures of semisolid slurry and mechanical properties of rheo-HPDC samples were studied.

2 Experimental

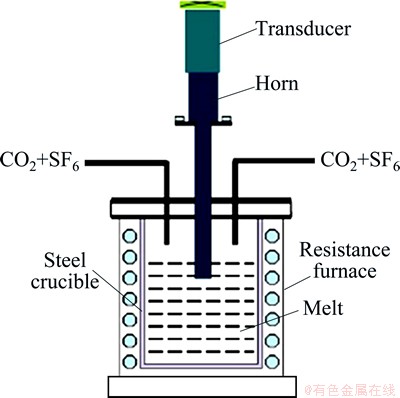

The experimental setup for this study is shown in Fig. 1. The USV device consisted of a transducer with a maximum power of 2 kW and frequency of about 20 kHz. In this work, the power of the ultrasonic generator was 0.7 kW. The alloy was first melt in the mild steel crucible under an atmosphere containing a gas mixture of CO2 and SF6. The ultrasonic probe was dipped into the melt for about 20 mm. A commercial ingot of AZ91 alloy with a nominal composition of Mg-8.56Al- 0.54Zn-0.31Mn was used as the principal alloy. The liquidus and the solidus temperature of this alloy were 598 and 431 °C, respectively, determined by differential scanning calorimetry (DSC) method. About 1.2 kg of melt was treated by USV at 600 °C and the melt was cooled down from the temperature at a rate of 3 °C/min. After being vibrated for 2, 4, 6 and 8 min, the temperature of melt was 594, 588, 582 and 576 °C, respectively. Some slurry was extracted out by a quartz tube with an inner diameter of 6 mm and quenched in water immediately, and the remaining semisolid slurry treated by USV was poured into the shot chamber of the cold-chamber diecasting machine (HPDC) to produce standard tensile test samples, with a diameter of 6.4 mm. The injection speed of diecasting was 4 m/s, and the specific pressure of injection was 40 MPa. The die was preheated to 200 °C before processing. Conventional liquid diecasting samples were also made without USV under a pouring temperature of 680 °C. The tensile tests were performed using a universal materials testing machine at a crosshead speed of 1.25 mm/min.

Fig. 1 Schematic of experimental setup for USV of magnesium melt

Specimens for the metallographic examination were cut from the quenched rods, then polished and etched by 4% (volume fraction) nitric acid ethanol solution. The microstructures and fracture surfaces of the tensile test specimens were examined by an Axiovert 200MAT optical microscope and a Quanta 200 environmental scanning electron microscope (SEM). Micrographs of the samples were analyzed by a quantitative metallographic analysis software, including the solid volume fraction, the average size and shape factor of solid particles. At least five representative areas with the total surface of 80 mm2 in each sample were studied through metallographic evaluations.

An image analyzer was used to measure the average diameter  of the primary α-Mg particles using a mean line intercept method defined as

of the primary α-Mg particles using a mean line intercept method defined as

(1)

(1)

where LT is the overall length of a series lines measured; and N is the number of particles passed through by the measured lines.

The shape of a primary α-Mg particle is characterized by shape factor (FS), which was defined as

(2)

(2)

where A and P are the area and the perimeter of the primary particles, respectively. FS varies from 0 to 1, and when the value of FS is close to 1, the sectional shape of the particle approaches a circle. The average shape factor ( ) is based on counting all primary particles in a photograph.

) is based on counting all primary particles in a photograph.

3 Results and discussion

3.1 Effect of USV on microstructure of AZ91 slurry

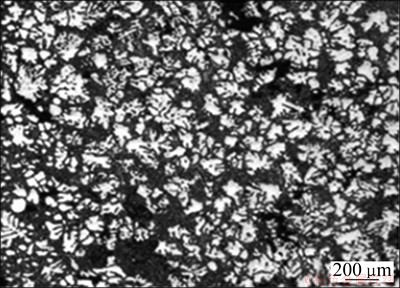

Figure 2 shows the quenched microstructures of as-cast AZ91 slurry without and with USV for 6 min. As seen, microstructure of the alloy in semisolid state consists of primary α-Mg particles which distribute in a liquid matrix. The liquid matrix forms due to the solidification of the remaining liquid in the semisolid slurry during water quenching. It is clear that the size and morphology of primary α-Mg particles are influenced significantly by USV. Without USV (see Fig. 2(a)), the α-Mg particles in the slurry show a coarse dendrite shape. After USV for 6 min (see Fig. 2(b)), the α-Mg particles become fine, spherical and uniformly disperse in the matrix.

Fig. 2 Quenched microstructures of AZ91 slurry

The refinement and spheroidization of the primary α-Mg particles could be mainly attributed to the cavitation and acoustic streaming induced by USV. Cavitation caused by USV will enhance heterogeneous nucleation. Cavitation refers to the phenomenon of growth and collapse of microbubbles under an ultrasonic field. During the growth period, the micro-bubbles expand and the melt evaporates inside the bubbles. The evaporation and expansion decrease the temperature of the micro-bubbles, therefore, undercooling happens around the microbubbles surfaces and makes these bubbles be the sources of nuclei [14,15]. In addition, cavitation cleans the surface of solid impurity particles that are poorly wetted by the melt, thereby enhancing heterogeneous nucleation [16].

In the presence of acoustic streaming, temperature and solute are distributed uniformly throughout the bulk melt, and solute concentration at the solidification front is removed, so that the nuclei almost have the same growth velocity in all directions and the dendritic growth of the nuclei is restricted [8]. Furthermore, the mechanical pressure caused by the acoustic streaming may fragment the dendrite arms or disintegrate the agglomerated inoculation surfaces [16]. Therefore, the dendritic growth of primary α-Mg is limited.

3.2 Effect of USV time on microstructure of semisolid AZ91 slurry

Figure 3 shows the quenched microstructures of the semisolid slurry treated by USV for different times. It has been reported that the microstructures with fine uniform grains are achieved under USV at the nucleation stage [17]. Figure 4 shows the influence of USV time on the solid volume fraction, average size and shape factor of the particles. As seen, both the solid volume fraction and average size of the particles increase with prolonged USV time. When the time is more than 4 min (ended at 588 °C), the solid volume fraction increases to 25% or even more. The increasing of solid volume fraction makes the intensity of convection in the slurry weaker, so it is difficult to separate the agglomeration particles if the time is much longer than 6 min (ended at 582 °C). The increasing of average particle size is mainly due to the extension of USV time which makes the primary α-Mg particles grow large. The shape factors of particles in the four slurries are nearly the same, about 0.7, corresponding to a good spherical degree.

The ideal semisolid slurry for rheological forming possesses an accurately specified volume fraction of fine and globular solid particles uniformly distributed in the liquid phase [18,19]. It is well accepted that the finer and rounder the particles are, the better the rheology of the semisolid slurry is [20]. It can be concluded that very good semisolid slurry with fine and spherical solid particles can be obtained within 6 min with USV process, and the average diameter and shape coefficient of primary α-Mg particles are 95 μm and 0.69, respectively.

3.3 Effect of USV time on microstructure of rheo- HPDC samples

Figure 5 shows the microstructures of the rheo-HPDC samples treated by USV for 2, 4, 6, 8 min, and the solid volume fractions are 17.5%, 22.6%, 31.2% and 39.7%, respectively. Spherical primary α-Mg particles are uniformly distributed in the matrix and their average diameters vary between 71 and 80 μm. However, the average shape factors of the primary α-Mg particles are not sensitive to USV treatment time and only vary between 0.69 and 0.72. It is also clear that some gas pores with diameter of about 100 μm are observed in the sample treated by USV for only 2 min. Increasing USV treatment time to 4 min, it is hard to find pores in the samples. Some pores occur in castings because gas dissolves in the melt. The solubility of gas in liquid Mg alloy will decrease during solidification, and gas holes will form easily. It is generally agreed that decreasing pore associates with the formation of cavitation in the melt. During the initial stages of the nucleation and growth of the cavitation bubbles, the gas diffuses into the cavitation bubbles through the bubble/melt interfaces. Some of these bubbles coalesce to form large bubbles and escape when cavitation bubbles collapse at the molten surface, thereby resulting in degassing. Some gas pores observed in the sample treated by USV for 2 min maybe associate with gas entrapped during diecasting because of turbulent mould filling.

Fig. 3 Microstructures of slurry treated by USV for different time

Fig. 4 Influence of USV time on solid volume fraction (a), average size and shape factor of particles (b)

The mechanical properties of rheo-HPDC samples are listed in Table 1. It can be known that the sample treated by USV for 6 min has the maximum mechanical properties. The maximum yield strength, ultimate tensile strength (UTS) and elongation are 152 MPa, 248 MPa and 7.4%, which are increased by 4%, 17% and 125%, respectively, compared to conventional liquid HPDC samples. However, insufficient treatment time (2 min) leads to poor mechanical properties because of the existence of large gas pores, as shown in Fig. 5(a). When the USV treatment reaches 8 min, the mechanical properties decrease slightly, and this might be due to the increased oxidation of melt surface when the vibration time is too long.

Fig. 5 Microstructures of rheo-HPDC samples treated by USV for different times

Table 1 Mechanical properties of samples in as-cast state

Higher mechanical properties of rheo-HPDC samples mainly benefit from the fine and uniform microstructure, as well as low porosity. The refinement and spheroidization of the microstructure could be mainly attributed to the cavitation and acoustic streaming induced by USV, and the acoustic streaming homogenizes the solute field and eliminates the macrosegregation.

Figure 6 shows the typical microstructure of the AZ91 alloy for the conventional liquid HPDC (without treated by USV) sample at pouring temperature of 680 °C. It is evident that the microstructure consists of dendritic grains for conventional liquid HPDC sample. In contrast, as shown in Fig. 5(c), remarkable grain refinement can be obtained when the melt is treated by USV for 6 min. Spherical primary α-Mg particles are distributed uniformly throughout the rheo-HPDC samples and no clustering is observed. The rheo-HPDC samples have finer microstructure than the quenched slurry treated by USV for 6 min, as shown in Fig. 3(c), which could be profited from the fragmentation of the congregated particles because of the intense shear during mould filling process.

Fig. 6 Microstructures of conventional liquid HPDC sample without USV

Figure 7 shows the SEM micrographs of the tensile fracture for the conventional liquid HPDC and rheo-HPDC samples. Pores can be observed from the fracture surface of liquid diecasting sample, as shown in Fig. 7(a), and they become the sources of fracture which reduce the mechanical properties of the casting. For rheo-HPDC sample, it is evident that fracture appears to initiate and propagate through the grain boundaries, and dimple-rupture morphology prevails throughout the fracture surface, as shown in Fig. 7(b). This indicates that rheo-HPDC sample has a ductile fracture mode, and the refinement of grains for rheo-HPDC sample suppresses deformation by twinning and increases deformation by sliding, leading to increase in ductilities.

Fig. 7 SEM micrographs of tensile fracture for samples produced under different processing conditions

4 Conclusions

1) The USV has a significant effect on the refinement and spheroidization of primary α-Mg particles at the nucleation stage, which is mainly attributed to the cavitation and acoustic streaming induced by the USV.

2) Good semisolid slurry with fine and spherical solid particles can be obtained within 6 min by USV near its liquidus temperature, and the average diameter and shape factor of primary α-Mg particles are 95 μm and 0.69, respectively. As USV treatment time increases, the solid volume fraction and average particle size increase, the shape factors are nearly the same, about 0.7.

3) Rheo-HPDC samples treated by USV for 6 min have the maximum yield strength, ultimate tensile strength and elongation, which are increased by 4%, 17% and 125%, respectively, compared to conventional liquid HPDC samples.

4) The rheo-diecasting sample has a ductile fracture mode.

References

[1] WANNASIN J, CANYOOK R, BURAPA R, SIKONG L, FLEMINGS M C. Evaluation of solid fraction in a rheocast aluminum die casting alloy by a rapid quenching method [J]. Scr Mater, 2008, 58: 1091-1094.

[2] WU S, XIE L, ZHAO J, NAKAE H. Formation of non-dendritic microstructure of semisolid aluminum alloy under vibration [J]. Scr Mater, 2008, 58: 556-559.

[3] JIAN X, XU H, MEEK T T, HAN Q. Effect of power ultrasound on solidification of aluminum A356 alloy [J]. Mater Lett, 2005, 59: 190-193.

[4] ESKIN G, ESKIN D. Production of natural and synthesized aluminum-based composite materials with the aid of ultrasonic (cavitation) treatment of the melt [J]. Ultrason Sonochem, 2003, 10: 297-301.

[5] DAS A, KOTADIA H. Effect of high-intensity ultrasonic irradiation on the modification of solidification microstructure in a Si-rich hypoeutectic Al-Si alloy [J]. Mater Chem Phys, 2011, 125: 853-859.

[6] ZHANG Song-li, ZHAO Yu-tao, CHENG Xiao-nong, CHEN Gang, DAI Qi-xun. High-energy ultrasonic field effects on the microstructure and mechanical behaviors of A356 alloy [J]. J Alloys Compd, 2009, 470: 168-172.

[7]  Shu-lin, WU Shu-sen, ZHU Ze-ming, AN Ping, MAO You-wu. Effect of semi-solid processing on microstructure and mechanical properties of 5052 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s3): s758-s762.

Shu-lin, WU Shu-sen, ZHU Ze-ming, AN Ping, MAO You-wu. Effect of semi-solid processing on microstructure and mechanical properties of 5052 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s3): s758-s762.

[8] WU Shu-sen,  Shu-lin, AN Ping, NAKAE H. Microstructure and property of rheocasting aluminum-alloy made with indirect ultrasonic vibration process [J]. Mater Lett, 2012, 73: 150-153.

Shu-lin, AN Ping, NAKAE H. Microstructure and property of rheocasting aluminum-alloy made with indirect ultrasonic vibration process [J]. Mater Lett, 2012, 73: 150-153.

[9] ZHANG Zhi-qing, LE Qi-chi, CUI Jian-zhong. Influence of high-intensity ultrasonic treatment on the phase morphology of a Mg-9.0wt.%Al binary alloy [J]. Rare Met, 2009, 28: 86-90.

[10] ZHANG Zhi-qing, LE Qi-chi, CUI Jian-zhong. Effect of high-intensity ultrasonic field on process of semi-continuous casting for AZ80 magnesium alloy billets [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(s2): s376-s381.

[11] LIU Xin-bao, OSAWA Y, TAKAMORI S, MUKAI T. Microstructure and mechanical properties of AZ91 alloy produced with ultrasonic vibration [J]. Mater Sci Eng A, 2008, 487: 120-123.

[12] GAO De-ming, LI Zhi-jun, HAN Qing-you, ZHAI Qi-jie. Effect of ultrasonic power on microstructure and mechanical properties of AZ91 alloy [J]. Mater Sci Eng A, 2009, 502: 2-5.

[13] LAN Jie, YANG Yong, LI Xiao-chun. Microstructure and microhardness of SiC nanoparticles reinforced magnesium composites fabricated by ultrasonic method [J]. Mater Sci Eng A, 2004, 386: 284-290.

[14]  Shu-lin, WU Shu-sen, ZHU Ze-ming, AN Ping. Preparation and rheocasting of semisolid slurry of 5083 Al alloy with indirect ultrasonic vibration process [J]. Mater Sci Eng A, 2011, 528: 8635-8640.

Shu-lin, WU Shu-sen, ZHU Ze-ming, AN Ping. Preparation and rheocasting of semisolid slurry of 5083 Al alloy with indirect ultrasonic vibration process [J]. Mater Sci Eng A, 2011, 528: 8635-8640.

[15] ABRAMOV V, ABRAMOV O, BULGAKOV V, SOMMER F. Solidification of aluminium alloys under ultrasonic irradiation using water-cooled resonator [J]. Mater Lett, 1998, 37: 27-34.

[16] KHOSRO-AGHAYANI M, NIROUMAND B. Effects of ultrasonic treatment on microstructure and tensile strength of AZ91 magnesium alloy [J]. J Alloys Compd, 2011, 509: 114-122.

[17] LIU X B, OSAWA Y, TAKAMORI S, MUKAI T. Grain refinement of AZ91 alloy by introducing ultrasonic vibration during solidification [J]. Mater Lett, 2008, 62: 2872-2875.

[18] KLEINER S, BEFFORT O, UGGOWITZER P J. Microstructure evolution during reheating of an extruded Mg-Al-Zn alloy into the semisolid state [J]. Scripta Mater, 2004, 51: 405-410.

[19] FAN Z. Semisolid metal processing [J]. Int Mater Rev, 2002, 47: 49-85.

[20] TZIMAS E, ZAVALIANGOS A. A comparative characterization of near equiaxed microstructures as produced by spray casting, magnetohydrodynamic casting and the stress induced, melt activated process [J]. Mater Sci Eng A, 2000, 289: 217-227.

超声振动制备流变铸造AZ91镁合金浆料的微观组织和性能

尧军平1,2,孙 众1,杨 涛2,Bharat BBUSHAN2, 龙文元1,张 磊1

1. 南昌航空大学 航空制造工程学院,南昌 330063;

2. Department of Materials Science and Engineering, Ohio State University, OH 43210, USA

摘 要:研究AZ91镁合金流变铸造的微观组织和力学性能。采用超声振动方法和压铸成型制备镁合金半固态浆料。结果表明:由于超声振动的空化、声流效应,在成核阶段获得细小圆整的初生α-Mg颗粒;随着超声振动时间延长,初生α-Mg颗粒的固相体积分数和平均尺寸增大,但形状系数基本不变,为0.7;在液相线以下温度附近超声振动6 min可获得最佳的AZ91镁合金半固态浆料,其压铸后的拉伸强度和伸长率分别是248 MPa和7.4%。流变铸造AZ91镁合金的断裂机制是韧性断裂。

关键词:AZ91镁合金;超声振动;流变铸造;半固态浆料;力学性能;断裂表面

(Edited by Chao WANG)

Foundation item: Project (51164027) supported by the National Natural Science Foundation of China; Project (20121BBE50002) supported by the Key Scientific and Technological Project of Jiangxi Province, China

Corresponding author: Jun-ping YAO; Tel: +86-13870070136; Fax: +86-791-83863028; E-mail: yyyjpsz@126.com

DOI: 10.1016/S1003-6326(14)63103-4

Abstract: The microstructure and mechanical properties of rheocasting AZ91 magnesium alloy were investigated. The semisolid slurry of this alloy was prepared by ultrasonic vibration (USV) process and then shaped by high pressure diecasting (HPDC). The results show that fine and spherical α-Mg particles were obtained by USV at the nucleation stage, which was mainly attributed to the cavitation and acoustic streaming induced by the USV. Extending USV treatment time increased the solid volume fraction and average particle size, the shape factors were nearly the same, about 0.7. Excellent semisolid slurry of AZ91 magnesium alloy could be obtained within 6 min by USV near its liquidus temperature. The rheo-HPDC samples treated by USV for 6 min had the maximum ultimate tensile strength and elongation, which were 248 MPa and 7.4%, respectively. It was also found that the ductile fracture mode prevailed in the rheocasting AZ91 magnesium alloy.