Article ID: 1003-6326(2005)02-0229-04

Effects of B2O3-SiO2 doping on electrical properties of Ba0.65Sr0.35TiO3 ceramics

ZHANG Tian-jin(章天金), JIANG Juan(江 娟), ZHANG Bai-shun(张柏顺),

GU Hao-shuang(顾豪爽), LIU Jiang-hua(刘江华)

(School of Physics and Electronic Technology, Hubei University, Wuhan 430062, China)

Abstract:

Ba0.65Sr0.35TiO3 ceramics doped with B2O3-SiO2 glass composition were prepared by using conventional solid-state reaction method. The effects of glass dopant on the dielectric and ferroelectric properties were investigated. The results show that the dielectric constant decreases while the dielectric loss increases after doping. And as the glass content increases the dielectric constant decreases while the dielectric loss changes slightly. From the complex impedance analysis the resistance and the relaxation time of the grain and the grain boundary can be calculated. Comparing the P—E hysteresis loop of undoped Ba0.65Sr0.35TiO3 ceramics with that of B2O3-SiO2 doped Ba0.65Sr0.35TiO3 ceramics, it can be seen that the remanent polarization decreases when the B2O3-SiO2 content is lower than 8%(molar fraction), and the coercive field increases with the increase of B2O3-SiO2 content.

Key words:

Ba0.65Sr0.35TiO3 ceramics; B2O3-SiO2; dielectric properties; impedance; ferroelectric properties CLC number: TB303;

Document code: A

1 INTRODUCTION

(Ba, Sr)TiO3 (abbreviated as BST) is a solid solution of BaTiO3 and SrTiO3, it exhibits excellent properties, such as high dielectric constant, low dielectric loss, low leakage current, high dielectric tunability, and huge pyroelectric coefficient. Besides, it has a remarkable characteristic that the Curie temperature of BST can be controlled by varying the molar content of the strontium to meet the requirement of various applications. Therefore BST is an attractive candidate for DRAM, phase shifter, tunable filters and infrared detectors and other fields[1, 2].

To date, much effort has been directed towards the investigation of the processing and the properties of BST ceramics[3-10]. SU et al[3] investigated the effects of processing on the properties of BST ceramics and Szymczak et al[4] investigated the sintering effects on the dielectric properties of BST ceramics. However, the sintering temperature of BST ceramics prepared by using conventional solid-state method is very high and the grains are not homogeneous in their investigation. Several studies have been carried out on the decrease of the sintering temperature and promoting the density[1, 11-18], but the results havent been satisfied. ZHAI et al produced glass doped BST powders by sol-gel processing, and calcining and sintering with conventional solid-state reaction method, then they obtained BST ceramics with glass-like materials. By this way, the sintering temperature of BST ceramics has been decreased, but the properties are not satisfactory.

Despite intensive experimental efforts, however, an effective measurement to decrease the sintering temperature of BST ceramics has been lack. In our work, BST ceramics were prepared by using conventional solid-state reaction method, and B2O3-SiO2 is added to decrease the sintering temperature. B2O3 has a melting point of 445℃, and it forms liquid during the sintering and promotes the sintering. Several reports have shown that when B2O3 is the only addition, it indeed decreases the sintering temperature but at the same time BaTi(BO3)2 and other materials form[13]. SiO2 has a melting point of 1670℃, and it cannot decrease the sintering temperature of BST ceramics[18]. But when B2O3-SiO2 is added, the sintering temperature of Ba0.65Sr0.35TiO3 ceramics is decreased and no second phase is detected from XRD patterns.

In this paper, the effects of B2O3-SiO2 doping on the dielectric and ferroelectric properties of Ba0.65Sr0.35TiO3 ceramics were investigated. The impedance plot was employed to estimate the resistance of the grains and the grain boundary, and the relaxation time was also estimated.

2 EXPERIMENTAL

Ba0.65Sr0.35TiO3 ceramics and B2O3-SiO2 doped Ba0.65Sr0.35TiO3 ceramics were prepared by conventional solid-state reaction method. BaCO3, SrCO3, TiO2, B2O3 and SiO2 were used as starting materials. The weighted stoichiometric powders were mixed by ball-milling in agate mortars for 4h, then dried and calcined at 1000℃ for 2.5h. The calcined aggregate were again ball-milled for 4h, then dried and pressed into d11mm×1.5mm green pellets at a pressure of 200MPa. The undoped green pellets were sintered at 1390℃ for 2h and B2O3-SiO2 doped green pellets were sintered at 1200℃ for 2h. Then the sintered specimens were polished to a thickness of 0.9mm and electroded with silver paste and dried.

The dielectric constant, the dielectric loss and the impedance were measured with HP4192A low frequency impedance analyzer. The P—E hysteresis loops were measured with a Sawyer-Tower circuit at 12℃.

3 RESULTS AND DISCUSSION

3.1 Dielectric properties

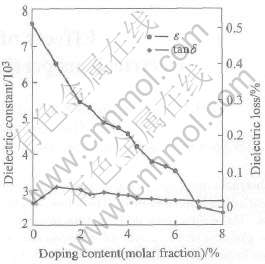

Fig.1 shows the relationship between the dielectric properties and glass-doped content at room temperature. It can be seen that the dielectric constant decreases and the dielectric loss increases when B2O3-SiO2 content is lower than 1%(molar fraction). However, the dielectric constant decreases sharply as the doping glass content increases while the dielectric loss changes slightly. This can be explained by that in ceramics the dielectric constant is strongly affected by the composition of Ba0.65Sr0.35TiO3 and B2O3-SiO2, while the dielectric loss is strongly affected by the distribution of these two phase[19]. As B2O3-SiO2 content increases, the change of the composition is larger than that of the distribution, which causes the larger change of the dielectric constant. When B2O3-SiO2 distributes homogeneously in Ba0.65Sr0.35TiO3 ceramics, the dielectric constant of the doped ceramics can be calculated by logarithmic mixture rule[20], which can be expressed as

lgε=y1lgεBST+y2lgεB-Si(1)

where ε is the dielectric constant of doped Ba0.65-Sr0.35TiO3 ceramics, εBST and εB-Si are the dielectric constants of undoped Ba0.65Sr0.35TiO3 ceramics and B2O3-SiO2 glass respectively, and y1, y2 are the volume fractions of Ba0.65Sr0.35TiO3 ceramics and B2O3-SiO2, respectively. The dielectric constant of B2O3-SiO2 is less than 4.5, which is much lower than that of undoped Ba0.65Sr0.35TiO3 ceramics, so the dielectric constant of doped Ba0.65Sr0.35TiO3 ceramics is smaller. This is also confirmed in Fig.1. In our work, the experimental data of the dielectric constant of doped Ba0.65Sr0.35TiO3 ceramics is smaller than the calculated data, which may be caused by the defects in the grain boundary.

Fig.1 Dielectric properties vs B2O3-SiO2 content

3.2 Impedance analysis

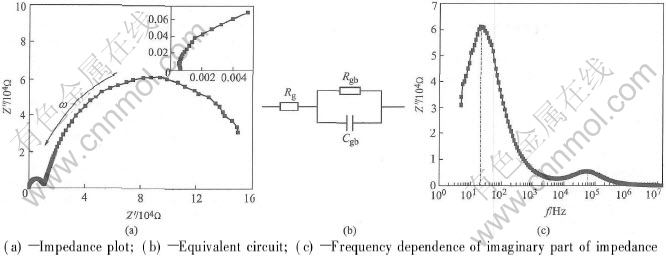

Complex impedance plot of Ba0.65Sr0.35TiO3 ceramics at 355℃ and its equivalent circuit are shown in Figs.2(a) and (b), respectively. In Fig.2(a), the experimental data can be well fitted into semicircles except at very low frequency. It is very clear that there are two semicircles for the impedance plot of Ba0.65Sr0.35TiO3 ceramics in the frequency range from 5Hz to 13MHz. The semicircle in low frequency can be equalized as a parallel circuit of a resistor and a capacitor and the semicircle in high frequency can be equalized as a resistor[21, 22], as shown in Fig.2(b). The complex impedance Z of Ba0.65Sr0.35TiO3 ceramics can be expressed with the following formulation[23]:

![]()

where Rg is the resistance of grains, Rgb is the resistance of grain boundary and ω is the angular frequency. From the formulation above, the real part of the complex impedance can be expressed as

![]()

It indicates that when ω∞, Z′Rg. Fitting the curve, on the real axis the interception can be considered as Rg. From Eqn.(2), the imaginary part of the impedance can be deduced as

![]()

At the maximum of the imaginary part of the impedance, the relation is satisfied:

ωCgbRgb=1(5)

Then Rgb can be estimated. It can be seen from the impedance plot that Rg is about 5Ω, while Rgb is about 20kΩ, which indicates that the grain boundary effects play an important role in Ba0.65Sr0.35TiO3 ceramics.

From Fig.2(c) the relaxation time τ can also be calculated according to the formulation ωmaxτ=1 at the maximum of the imaginary part of the impedance. The relaxation time of grain boundary τ1 and that of grain τ2 can be calculated from the frequency of the peak imaginary as 7×10-3s and 3.1×10-6s, respectively. This indicates that the movement of the dipole in the grain boundary is more difficult than in the grains.

3.3 Ferroelectric properties

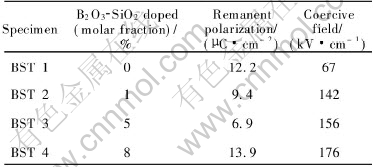

The remanent polarization and the coercive field of BST ceramics are listed in Table 1. It can be seen that the coercive field increases with the increase of the doping glass content, while the remanent polarization decreases with the increase of the doping glass content when the doping content is lower than 8%. B2O3-SiO2 has no ferroelectricity, so that the content increases, the ferroelectricity of the ceramics decreases and the remanent polarization decreases. At the same time, as B2O3-SiO2 content increases the grain size decreases and the ratio of the grain boundary in the ceramics increases, so the movement of the domain becomes more difficult, which causes the increase of the coercive field. In Table 1, its very clear that when the content of B2O3-SiO2 reaches 8%, the remanent polarization increases abruptly. It may be caused by a new material formed in the ceramics. The typical P—E hysteresis loop of Ba0.65Sr0.35TiO3 ceramics in Fig.3(a) is slimmer than that of 8% B2O3-SiO2 (molar fraction) doped ceramics in Fig.3(b), which is also confirmed in Table 1.

Table 1 Remanent polarization and coercive field of BST ceramics

Fig.2 Typical impedance plot and its equivalent circuit

Fig.3 Typical hysteresis loops of BST ceramics

4 CONCLUSIONS

The sintering temperature of BST ceramics prepared by conventional solid-state reaction method is decreased by adding B2O3-SiO2. Investigation of the effects of glass doping shows that the dielectric constant and the dielectric loss of B2O3-SiO2 doped Ba0.65Sr0.35TiO3 ceramics decrease as the glass content increases. From the typical impedance plot of BST ceramics at 355℃, the resistances of grain and grain boundary can be calculated as 5Ω and 20kΩ, respectively. The relaxation time of grain boundary and gain can also be calculated from the frequency dependence of imaginary part of impedance as 7×10-3s and 3.1×10-6s, respectively. The coercive field increases, while the remanent polarization decreases with the increase of the doping glass content, which indicates that doping B2O3-SiO2 decreases the ferroelectricity of Ba0.65Sr0.35TiO3 ceramics.

REFERENCES

[1]ZHAI Ji-wei, YAO Xi, CHENG Xiao-gang, et al. Direct-current field dependence of dielectric properties in B2O3-SiO2 glass doped Ba0.6Sr0.4TiO3 ceramics [J]. Mater Sci, 2002, 37: 3739-3745.

[2]Tsai M S, Tseng T Y. Effect of bottom electrodes and dielectric relaxation and defect analysis of (Ba0.47Sr0.53)TiO3 thin film capacitors [J]. Mater Chem & Phys, 1998, 57: 47-56.

[3]SU B, Holmes J E, CHENG B L, et al. Processing effects on the microstructure and dielectric properties of barium strontium titanate (BST) ceramics [J]. J Electroceram, 2002, 9: 113-118.

[4]Szymczak L, Ujima Z, Handerek J, et al. Sintering effects on dielectric properties of (Ba, Sr)TiO3 ceramics [J]. Ceramics International, 2004, 30: 1003-1008.

[5]Thakur O P, Prakash C, Agrawal D K. Dielectric behavior of Ba0.95Sr0.05TiO3 ceramics sintered by microwave [J]. Mater Sci & Eng, 2002, B96: 221-225.

[6]Weiliou J, Chiou B S. Analysis of the dielectric characteristics for polycrystalline Ba0.65Sr0.35TiO3 (Ⅰ)—frequency dependence in the paroelectric state [J]. J Mater Sci, 2000, 11: 637-643.

[7]Liou J U, Chiou B S. Analysis of the dielectric characteristics for polycrystalline Ba0.65Sr0.35TiO3(Ⅱ)—d.c. field dependence with a modified bias equation [J]. J Mater Sci, 2000, 11: 645-651.

[8]Garcia S, Font R, Portelles J, et al. Effect of Nb doping on (Sr,Ba)TiO3 ceramics samples [J]. J Electroceram, 2001, 2: 101-108.

[9]WU Long, CHEN Yih-chien, HUANG Cheng-liang, et al. Direct-current field of dielectric properties in alumina-doped barium strotium titanate [J]. J Am Ceram Soc, 2000, 83(7): 1713-1719.

[10]Yoo J H, Gao W. Pyroelectric and dielectric bolometer properties of Sr modified BaTiO3 ceramics [J]. J Mater Sci, 1999, 34: 5361-5369.

[11]WU Bin, ZHANG Liang-ying, YAO Xi. The effect of Zn-B-Si-O addition on Ba0.7Sr0.3TiO3 by sol-gel process [J]. Ceramics International, 2004, 30: 1753-1756.

[12]HUANG Cheng-liang, WENG Min-hung, LION Cioutizer, et al. Low temperature sintering and microwave dielectric properties of Ba2Ti9O20 ceramics using glass additions [J]. Materials Research Bulletin, 2000, 35: 2445-2456.

[13]WANG Sea-Fue, CHIANG Chuang-chung, WANG Chai-Hui. Effects of B2O3 on the phase formation of Ba2Ti9O20 ceramics [J]. Mater Chem & Phys, 2003, 79: 256-260.

[14]WU J M, HUANG H L. Effect of crystallization on microwave dielectric properties of stoichimetric cordierite glasses containing B2O3 and V2O5 [J]. J Mater Res, 2000, 15: 222-227.

[15]Rhim S M, Hong S, Bak H, et al. Effects of B2O3 addition on the dielectric and ferroelectric properties of Ba0.7Sr0.3TiO3 ceramics [J]. J Am Soc, 2000, 83(5): 1145-1148.

[16]Rhim S M, Bak H, Hong S, et al. Effects of heating rate on the sintering behavior and the dielectric properties of Ba0.7Sr0.3TiO3 ceramics prepared by boron containing liquid-phase sintering [J]. J Am Soc, 2000, 83(12): 3009-3013.

[17]Yamamoto H, Koga A, Shibagaki S, et al. Low-temperature firing of MgTiO3-CaTiO3 microwave dielectric ceramics modified with B2O3 and V2O3 [J]. J Ceram Soc Jpn, 1998, 106: 355-359.

[18]Jo Wook, Chung Ui-Jin, Hwang Nong-Moon, et al. Temperature dependence of the coarsening behavior of (Ba, Sr)TiO3 grains dispersed in a SiO2-rich liquid matrix [J]. J Europ Ceram Soc, 2003, 23: 1565-1569.

[19]Senthil Mrugan G, Varma K B R. Microstructure, dielectric, pyroelectric and ferroelectrics studies on partially grain-oriented SrBi2Ta2O9 ceramics [J]. Electroceram, 2002, 8: 37-48.

[20]LI Biao-rong. Theory of Electroceramics Processing [M]. Wuhan: Huazhong University of Science & Technology Press, 1994. 79-80.

[21]TANG Xiao-feng, TANG Zi-long, ZHOU Zhi-gang. Complex impedance spectra of BaTiO3 based PTCR ceramics [J]. Inorg Mater, 2000, 12: 1037-1042.

[22]Abram E J, Sinclair D C, West A R. A strategy for analysis and modeling of impedance spectroscopy data of electroceramics: doped lanthanum gallate [J]. J Electroceram, 2003, 10: 165-177.

[23]Vyunov O I, Kovalnko L L, Belous A G. The effect of isovalent substitutions and dopant of 3d-metals on the properties of ferroelectrics-semiconductors [J]. Condensed Matter Physics, 2003, 6: 213-220.

Foundation item: Project(50372017/E0204) supported by the National Natural Science Foundation of China

Received date: 2004-12-01; Accepted date: 2005-01-18

Correspondence: ZHANG Tian-jin, Professor, PhD; Tel: +86-27-88661682; E-mail: zhangtj@hubu.edu.cn