Tempering microstructure and mechanical properties of pipeline steel X80

NIU Jing(牛 靖)1,2, QI Li-hua(齐丽华)1,2, LIU Ying-lai(刘迎来)1, MA Lei(马 蕾)2,

FENG Yao-rong(冯耀荣)1, ZHANG Jian-xun(张建勋)2

1. Xi’an Tubular Goods Research Center of China National Petroleum Corporation, Xi’an 710065,China;

2. School of Materials Science and Engineering, Xi’an Jiaotong University, Xi’an 710049,China

Received 10 August 2009; accepted 15 September 2009

Abstract:

The tempering microstructure and mechanical properties of X80 steel used for heating-bent pipe were analyzed. The results show that the microstructure of X80 steel tempered at 550 ℃ and 600 ℃ is bainitic ferrite (BF)+granular bainite (GB), and partial ferrite laths in BF merge and broaden. The interior sub-lath boundary of some GB begins to disappear due to merging, the M/A constituent (a mixture of martensite plus retained austenite) in GB is orbicular. At the two tempering temperatures the tested X80 steel shows a certain degree of tempering stability. After being tempered at 650 ℃, the microstructure of X80 steel is GB+quasi-polygonal ferrite(QF), and the original BF laths have merged to form smaller GB crystal grains. The reason is that the steel shows better match of strength and toughness. After being tempered at 700 ℃, the microstructure of X80 steel is composed mainly of QF, which can improve the plasticity but decline severely the yield strength of X80, and the M/A constituent assembles and grows up at the grain boundary of QF, resulting in excellent lower low-temperature toughness of X80.

Key words:

X80 steel; microstructure; tempering temperature; mechanical property;

1 Introduction

X80 steel is often used under rolling condition. Strength and toughness of X80 steel as-rolled are obtained by chemical composition design, controlled rolling and controlled cooling[1-3]. Microstructures of X80 steel are intermediate austenite transformation products like refined acicular ferrite, which have tiny structure and very large specific interfacial area[4]. Since high strength low alloy pipeline steels with acicular ferrite (AF) microstructure were developed in the early 1970s, much work has been done to study this novel microstructure[5-9]. Intermediate transformation products are a kind of metastable microstructure with high volume free energy, which have the tendency of evolution to equilibrium microstructures spontaneously [10]. A significant microstructural change and decrease, not only in the transition temperature, but also in the yield strength, occurred after mother pipe was induction heate[11]. This reduction resulted in a tensile strength below the standard requirements. The subsequent tempering heat treatment is applied to producing an increase in the yield strength to achieve the requirements for this class of steel[12].

The processing technology routine of heating-bent pipe can be divided into two types: tempering-free and quenching + tempering process(Q&T). Tempering can improve the comprehensive properties by the adjustment of microstructure[13-17]. In addition, it can reduce residual stress in pipe body and enhance fracture resistance and safety reliability of bend pipe[18]. So, the process of Q&T is widely used in the manufacture of heating-bent pipe. At present, the second project of west-east gas transmission of China is in significant construction stage. It needs a large number of X80 grade heating-bent pipe. Therefore, the study of tempering influence on the microstructure and mechanical properties of X80 steel is essential to guide production of induction bend pipe. In Refs.[11-12], the effects of the induction hot bending process on the microstructure and the mechanical properties of X80 grade induction bend pipe have been mostly discussed. This study will focus on the tempering microstructure and properties of X80 steel by means of structure analysis and mechanical properties tests.

2 Experimental

The explored material was as-rolled X80 steel,

which was taken from the pipe body of mother pipe. The wall thickness was 22 mm. The chemical composition is listed in Table 1. Previous research showed that the tested X80 steel can get fine structural state if heated up to 950 ℃ and held for 22 min, then cooled in 10% NaCl solution. Fig.1 shows heat treatment process of tested X80 steel.

Table 1 Chemical composition of X80 test steel (mass fraction, %)

Fig. 1 Schematic diagram of heat treatment processing

After heat treatment, mechanical properties test and microstructure observation of the tested X80 steel were performed, respectively. The tensile specimens were cut from the middle of tested plates along wall thickness direction, and separated from transverse direction, then made into standard bar specimens of d12.7 mm. The tensile tests were taken by MTS-880 universal testing machine.

Impact samples with a dimension of 10 mm×10 mm×55 mm were cut from mid-thickness along the transverse direction of the tested plate. V notch in samples was machined along thickness direction. A series of impact tests were carried out by JBC-500 impact testing machine, and the test temperatures were 20, 0, -20, -40, -60 and -80 ℃, respectively. An Axiovert 405M optical microscope and a JEM200CX transmission electron microscope (TEM) were employed to analyze microstructures. JSM-6390A scanning electron microscope(SEM) was used to analyze fracture of impact samples.

3 Results

3.1 Tempering microstructure of X80 steel

The microstructures of X80 steel tempered at four different temperatures are shown in Fig.2. At 550 ℃, the microstructure of X80 consists of bainitic ferrite (BF) + granular bainite (GB) (see Figs.2(a) and (a′)). Original austenite grain boundary is clear, and strip M/A constituent exists at the grain boundary. The interior sub-lath of some of GB began to merge and its boundary disappeared. The M/A constituent in GB is orbicular.

After being tempered at 600 ℃, the microstructure of X80 is still BF+GB (see Figs.2(b) and (b′)). Original austenite grain boundary is not clear, and the M/A constituent on grain boundary is fully decomposed. Bainite ferrite lath merges to form wide laths. Boundaries of laths become fuzzy. The strip M/A constituent between original laths is broken down, refined, leading to exist in the interior of wide laths. Inner substructure of granular bainite disappears, M/A island turns into tiny and spotty particles because of gradual decomposition.

After being tempered at 650 ℃, the microstructure of X80 is GB+QF (quasi-polygonal ferrite), as shown in Figs.2(c) and (c′). The original BF lath merges and recovers to form smaller GB crystal grain, which is basically from a bunch of laths of BF. The microstructure transformation refines the valid grain size. The M/A constituent in original granular bainite is decomposed to form fine M/A island. Ferrite matrix recrystallizes and changes into equiaxed QF. The appearance of grain boundary is redisplayed because there are more M/A constituent particles precipitated at grain boundary of GB and QF which are formed by microstructure transforming.

After being tempered at 700 ℃, as shown in Figs.2(d) and (d′), the microstructure of X80 steel mainly consists of QF. Because of tempering at the higher temperature, non-equilibrium microstructure that is formed by quenching sufficiently converts to QF which has lower free energy. The grains of QF would grow up through grain boundary, and are bigger than those tempered at 650 ℃. Because of the high tempering temperature, M/A constituent assembles, grows up and forms M/A constituent particles with large size at grain boundary of QF, which component with coarse M/A particles would be harmful to the toughness of X80 steel.

3.2 Mechanical properties of tempered X80 steel

Mechanical properties test were performed on X80 steel at different tempering temperatures, and the test results are shown in Table 2 and Fig.3. The results of tensile and impact experiment are average values of three parallel-specimens. Hardness value is mean value of seven points along thickness direction.

In Table 2, it is found that the tensile strength Rm and hardness of explored X80 steel have gradual downward trends with increasing tempering temperature. However,the change of yield strength Rt0.5 has little different from Rm. There is no influence on Rt0.5 when the tempering temperature raises from 550 to 600 ℃. Rt0.5 decreases a little when the temperature increases to 650 ℃, and the decreased amplitude is close to that of Rm. But when the tempering temperature is up to 700 ℃, Rt0.5 has a sharp fall compared with 650 ℃. Below 650 ℃, tempering temperature has little effect on yield ratio Rt0.5/Rm and plastic elongation A of steel used in experiment. At 700℃, X80 steel exhibits a lower yield ratio, only 0.67; and shows good plasticity, A reaches 27.0%.

Fig.2 Micrographs of X80 steel tempered at 550 ℃ (a) and(a′), 600 ℃ (b) and(b′), 650 ℃ (c) and (c′), 700 ℃ (d) and (d′)

Table 2 Mechanical properties of X80 steel at different tempering temperatures

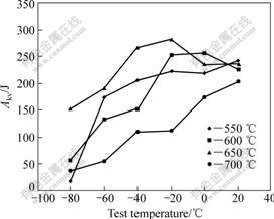

Fig.3 Toughness-test temperatures curves of X80 steel at different tempering temperatures

As shown in Fig.3, impact energy Akv of X80 steel tempered at a series of test temperatures shows complex changing tendency. When tempered at 550 ℃ and 600 ℃, impact energies at different test temperatures are similar to each other, and the changing tendency does not change as the test temperature declines. When tempered at 700 ℃, impact energy of X80 steel linearly decreases as the test temperature declines, and all are smaller than those under other tempering conditions. At lower than -20 ℃, impact energy of X80 steel which was tempered at 650 ℃ is higher than that tempered at other tempering temperatures, though the impact energy declines with the decreased of test temperature, the decreased amplitude is small, even tested at -80 ℃, the impact energy is still more than 150 J. So, it is concluded that X80 steel tempered at 650 ℃ has good toughness, particularly excellent low temperature toughness.

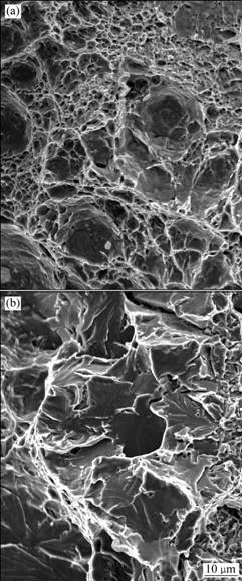

SEM observations of the fracture of X80 impact specimens at four tempering temperatures indicate that impact fracture of X80 steel tempered at 650 ℃ presents dimple mode, and becomes smaller and shallower with the decrease of test temperature. While tempered at 700 ℃, impact fracture of the tested steel shows mainly cleavage mode at test temperature lower than -20 ℃. When tempered at 550 ℃ and 600 ℃, it mainly presents dimple mode, it shows cleavage mode only when test temperature is -80 ℃. Impact fracture appearance of X80 steel tempered at 650 ℃ and 700 ℃ is shown in Fig.4.

Fig.4 SEM fractographs of impact specimens fractured at -20 ℃ for X80 steel: (a) 650 ℃; (b) 700 ℃

There is obviously different for the two impact fracture morphologies. Impact fracture shape of X80 tempered at 650 ℃ is dimple of which size is not uniform (see Fig.4(a)). When tempered at 700 ℃, the fracture appearance is cleavage, the size of cleavage surface has accordance with grain of quasi-polygonal ferrite, as shown in Figs.2(d) and (d′). There are tearing ridge among cleavage surfaces, showing a certain capability of deformation (see Fig.4(b)). So, it is easy to conclude that cleavage crack of X80 steel whose microstructure is mainly quasi-polygonal ferrite (tempered at 700 ℃) once it initiates and propagates fast along some cleavage surface, to form cleavage surface whose size is almost grain size. Of course, the big particles of M/A constituent that exists in grain boundary of quasi-polygonal ferrite would cause cleavage initiate. But to the X80 steel tempered at 650 ℃, the reason of dimple fracture is that tiny and uniform microstructure is formed in it. Tiny and uniform granular bainite grains have a good deformation capability under dynamic load. The M/A constituent distributed uniformly affects spreading dynamic stress, thereby decreases the stress concentration in grain, to make X80 steel get better toughness. And also, because of the existence of M/A, it is easy to form dimple by the root of granular M/A constituent. Ultimately, propagating of impact crack is carried on by the way of joining dimple. So, it shows good toughness, and presents dimple morphology as shown in Fig.4(a).

4 Analysis and discussion

When the tempering temperature changes, mechanical properties of the X80 steel used in the experiments change accordingly. It is mainly due to the impact of microstructure on X80 steel. By analyzing microstructure of X80 at different tempering temperatures, there are two changes: one change is ferrite phase and the other is M/A constituent. In general, the ferrite phase was ductile, but the M/A constituent was brittle[19-20]. As far as ferrite phase concerned, its shape and interior structure are different as the X80 steel is tempered at different temperatures.

As shown in Figs.5(a) and (b), after tempering at 550 ℃ and 600 ℃, internal ferrite of X80 steel is mainly lath structure, high density dislocation distributes in interior, and the dislocation has the package configuration due to the temperature. WU et al[21] concerned that dislocation within bainite lath into two types. One type is high-density dislocation which tangles with each other, the precipitates can be seen in dislocation, and it is difficult to make dislocation disappeared by tempering. The other type of dislocation is well distributed and arrayed basically paralleled to each other, they do not tangle with each other and precipitates cannot be seen in it. This kind of dislocations is easy to slip out of grain boundary and disappear. Although ferrite laths of X80 steel as-tempered have began to merge, large numbers of dislocation package still exist in laths. It can be deduced that this dislocation in ferrite laths belongs to the first type. Due to the existence of such dislocation, X80 steel has a good tempering stability when tempered at 550 ℃ and 600 ℃, and displays similar mechanical properties, as shown in Table 2 and Fig.3. Compared with tempered at 550 ℃, ferrite laths of X80 tempered at 600 ℃ present the appearance of combining, M/A constituent strip existing at interface of laths converges to block and intermittently locates in the interior of combined wide ferrite laths, but the regularity of their distribution still can be seen. M/A constituent is a kind of brittle mixture, its size and shape have great effect on the toughness of steel[20]. M/A constituent converging to block is beneficial to the improvement of toughness compared with M/A strip.

It can be seen from Fig.5(c), when tempering temperature increases to 650 ℃, ferrite laths merge further and interface of lath disappears, there are a large number of dislocation packages and tiny M/A in the interior of combined laths. Combination of ferrite laths take place between laths with little angle grain boundaries, which are interior of lath bunch. Because of the high tempering temperature, crystal grains originated from ferrite lath bunch basically form. The interface of inner laths is hard to distinguish, and the original ferrite lath could be distinguished partly. Recrystallization of ferrite seems to happen, and transforms to equiaxial grain. There are still high density dislocation packages in the interior of grain which is formed by ferrite lath. This dislocations belong to the first dislocation mentioned before. As shown in Fig.5(c), the mergence of ferrite lath is characterized by disappearance of some interfaces among laths, simultaneously the M/A constituent at the interfaces of laths partly decomposes, ultimately forms little M/A constituent particles, distributing dispersively in the ferrite matrix. In Figs.2(c) and (c′), the boundaries of sub-structure in granular bainite which are transformed from ferrite laths are twisted, intermittent and high density dislocation packages exist in sub-structure, as shown in Fig.5(c). The existence of sub-structure and the dispersively distributed fine M/A constituent are the essential reason that X80 steel temped at 650 ℃ obtains good match of strength and toughness.

After tempering temperature reaches 700 ℃, the microstructure of the test X80 steel has important change, a mass of QF form, and typical morphology is shown in Fig.5(d). The interior of QF grain is clean, and dislocation density is lower, a few precipitates (maybe carbonitride of Nb) can be seen in QF. There are large blocks of M/A at grain boundary of QF. The QF matrix is a kind of plastic phase, which makes X80 steel possess excellent plasticity and low yield strength. Due to the existence of strengthen phase M/A constituent, the decline of tensile strength of this steel is not obvious. Of course, blocky M/A constituent is also a kind of brittle phase. As the X80 steel bearing kinetic is loaded at low temperature, impact cracks is easy to initiate in blocky M/A constituent, propagate rapidly along the weakness surface in QF to grain boundary. Finally, cleavage morphology is formed on the fractograph, as shown in Fig.4(b). At the same time, the X80 steel presents low impact toughness, as shown in Fig.3.

The microstructure of quenched X80 steel is lath bainite + granular bainite. Among all kinds of microstructures in micro-alloy steel, quasi-polygonal ferrite is the most stable, followed by granular bainite, and the most unstable is the lath bainite, the end of microstructure evolution should be equilibrium structure and quasi-polygonal ferrite[22]. Above analysis shows

Fig.5 TEM micrographs of X80 steel tempered at 550 ℃ (a), 600 ℃ (b), 650 ℃ (c) and 700 ℃ (d)

that as the tempering temperature increases, microstructure of test X80 steel transforms to equilibrium state step by step. If tempering at lower temperature, quasi-steady structure like granular bainite would form in it. The results of microstructure analysis and properties study on the X80 steel indicate that tempered at lower temperature than 600 ℃, the X80 steel has certain tempering stability, while tempered at 650℃, it can get better match of strength and toughness due to good microstructure.

5 Conclusions

1) When tempered at 550 ℃ and 600 ℃, the microstructure of X80 steel is BF+GB. Partial ferrite laths merge and become thicker than before. The interior sub-lath boundary of some of GB begins to disappear, and the M/A constituent in GB is orbicular. At the two tempering temperatures the tested X80 steel shows a certain degree of tempering stability.

2) When tempered at 650 ℃, the microstructure of X80 steel is GB+QF, the original BF lath merges to form fine GB crystal grain, which is the reason that the steel shows better match of strength and toughness.

3) When tempering temperature up to 700 ℃, the microstructure of X80 steel is mainly QF, which can improve the plasticity but decrease severely the yield strength of the X80 steel. The M/A constituent assembling and growing up in the grain boundary of QF results in lower cold temperature toughness.

References

[1] KONG Jun-hua, ZHEN Lin, GUO Bin, LI Ping-he, WANG Ai-hua, XIE Chang-sheng. Influence of Mo content on microstructure and mechanical properties of high strength pipeline steel [J]. Materials and Design, 2004, 25: 723-728.

[2] JUN H J, KANG J S, SEO D H, KANG K B, PARK C G. Effects of deformation and boron on microstructure and continuous cooling transformation in low carbon HSLA steels [J]. Mater Sci and Eng A, 2006, 422: 157-162.

[3] RODRIGUES P C M, PERELOMA E V, STANTOS D B. Mechanical properties of an HSLA bainitic steel subjected to controlled rolling with accelerated cooling [J]. Mater Sci and Eng A, 2000, 283: 136-143.

[4] DHUA S K, AMITAVA RAY, SAMA D S. Effect of tempering temperatures on the mechanical properties and microstructure of HSLA-100 type copper baring steels [J]. Mater Sci and Eng A, 2001, 318: 197-210.

[5] THOMPSON S W, COLVIN D J, KRAUSS G. On the bainitic structure formed in a modified A710 steel [J]. Scripta Metallurgica, 1988, 22(7): 1069-1074.

[6] COLDREN A P, SMITH Y E, CRYDERMAN R L. Processing and properties of low carbon steel [C]//American Institute of Mining, Metallurgical and Petroleum Engineers. New York, 1973: 163-189.

[7] WANG Wei, SHAN Yi-yin, YANG Ke. Study of high strength pipeline steels with different microstructures [J]. Mater Sci and Eng A, 2009, 502: 38-44.

[8] ZHAO Y T, SHANG C J, YANG S W, WANG X M, HE X L. The metastable austenite transformation in Mo-Nb-Cu-B low carbon steel [J]. Mater Sci and Eng A, 2006, 433: 169-174.

[9] SHIN S Y, HWANG B, LEE S, KIM N J, AHN S S. Correlation of microstructure and charpy impact properties in API X70 and X80 line-pipe steels [J]. Mater Sci and Eng A, 2007,458: 281-289.

[10] ZHOU Gui-feng, WEN Mu-bing, LI Ping-he, WANG Xue-min, HE Xin-lai. Research on microstructure and mechanical properties of ultra-low carbon bainitic steel ULCB600 [J]. Iron & Steel, 2000, 35(12): 47-49. (in Chinese)

[11] BATISTA G Z, NASCHPITZ L, HIPPERT E, BOTT I S. Induction hot bending and heat treatment of 20’’ API 5L X80 pipe [J]. ASME, 2006(3): 89-98.

[12] ISHIKAWA N, ENDO S, KONDO J, TAKAGISHI M. Development of X80 grade induction bend pipe [J]. ASME, 2002(3): 121-128.

[13] SHANG Cheng-jia, YANG Shan-wu, WANG Xue-min, HOU Hua-xing, YU Gong-li, WANG Wen-zhong. Microstructure and mechanical properties of low carbon bainitic steel [J]. Iron & Steel, 2005, 40(4): 62-65, 82. (in Chinese)

[14] BIERMANN K, KAUCKE C, PROBST-HEIN M, KOSCHLIG B. Alloying concept for high-strength seamless heavy-wall line pipe suitable for sour service applications [J]. ASME, 2004(3): 1789-1795.

[15] ARAI Y, KONDO K, HAMADA M, HISAMUNE N, MURAO N, OSAKO H, MURASE T. Development of high-strength heavy-wall sour-service seamless line pipe for deep water by applying inline heat treatment [J]. ASME, 2004(3): 1797-1804.

[16] ARAI Y, KONDO K, HIRATA H, HAMADA M, HISAMUNE N, HITOSHIO K, MURASE T. Metallurgical design of newly developed material for seamless pipes of X80-X100 Grades [J]. ASME, 2007(4): 37-44.

[17] KONDO K, ARAI Y, HIRATA H, HAMADA M, KITOSHIO K, HISAMUNE N, MURASE T. Development of high strength heavy wall seamless pipes of X80-X100 grade for ultra-deep water application [J]. ASME, 2008(3): 49-59.

[18] LIU Wei, LI Guo-xing, FENG Yao-rong. Exploration of technical conditions for induction heating bent pipes [J]. Technology Supervision in Petroleum Industry, 2002, 18(12): 6-8. (in Chinese)[19] FANG Hong-sheng, LIU Dong-yu, XU Guang-ping, BAI Bing-zhe, YANG Zhi-gang. The ways to improve strength and toughness of bainitic steel [J]. Materials for Mechanical Engineering, 2001, 25(6): 1-5, 41. (in Chinese)

[20] YU Shao-fei, QIAN Bai-nian. Local brittleness of X70 pipeline steel [J]. Chinese Journal of Material Research, 2004, 18(4): 405-411. (in Chinese)

[21] WU Hui-bin, SHANG Cheng-jia, YANG Shan-wu, HOU Hua-xing, MA Yu-pu, YU Gong-li. Tempering microstructures and mechanical properties of an ultra-fine low carbon bainitic steel [J]. Acta Metallurgica Sinica, 2004, 40(11): 1143-1150. (in Chinese)

[22] XU Zu-yao. Principles of phase transformation [M]. Beijing: Science Press, 2000: 124. (in Chinese)

(Edited by LI Xiang-qun)

Foundation item: Project(6990-HT-XEX-03-(2008)-0137) supported by the Major Special Project of Science and Technology of China National Petroleum Corporation

Corresponding author: NIU Jing; Tel: +86-29-88726178; E-mail: niuj@tgrc.org