Microstructure and mechanical behavior of cold-rolled CMnAlSi TRIP-aided steel sheets

JING Cai-nian(景财年)1,2, WANG Ming-gang(王明刚)1, WANG Zuo-cheng(王作成)2,

TAN Qi-zhong(谭启忠)1, Sung-Joon KIM3

1. School of Materials Science and Engineering, Shandong Jianzhu University, Ji’nan 250101, China;

2. School of Materials Science and Engineering, Shandong University, Ji’nan 250061, China,

3. Korea Institute of Machinery and Materials, Changwon 641010, Korea

Received 10 August 2009; accepted 15 September 2009

Abstract:

The microstructure, mechanical properties and retained austenite stability of CMnAlSi-TRIP steels were investigated. Optical microscopy and X-ray diffractometry were used to analyze the microstructure, volume fraction and carbon concentration of retained austenite, while the tensile tests were performed to study the retained austenite stability against strain-induced martensitic transformation. The results show that the mechanical properties of the CMnAlSi cold-rolled TRIP-aided steels fabricated by proper heat treatment display good combination of strength and ductility after isothermal bainitic transformation (IBT) treatment at 420-450 ℃ for 60-120 s. The austenite transformation kinetics is influenced significantly by the IBT temperature, and the high mechanical stability of retained austenite, governed by its carbon concentration, and determines high strain hardening during deformation.

Key words:

transformation induced plasticity(TRIP); isothermal bainitic transformation (IBT); mechanical properties; retained austenite stability;

1 Introduction

Transformation induced plasticity (TRIP) steels have complex multiphase microstructure composed of ferrite, bainite and retained austenite[1]. These metastable retained austenite can transform into martensite during plastic deformation, which generates a TRIP effect resulting in excellent combination of high strength and ductility at high strength level[2-5]. Conventional low carbon TRIP steels (C-Mn-Si) contain large amount of Si to retard cementite nucleation during the isothermal bainitic transformation(IBT) because of its insolubility in cementite, then the retained austenite is carbon enriched and maintained at room temperature[6-7]. However, in the processing of hot rolling or annealing, complex oxides will form on surface in the high Si (>1.5%, mass fraction) TRIP steels, which causes poor wettability and deteriorates hot dip galvanizing property[5, 8]. Thus, A1[9-10], P[11-13] and Cu[14-15] are fully or partially substituted with Si with similar function of inhibiting carbide precipitation.

Many studies of TRIP-steels have been concerned on the mechanical properties and the heat-treatment parameters of CMnSi TRIP-steels[3-4, 6]. There are few studies focused on the microstructure and mechanical properties of CMnAlSi TRIP-steels. Also, the effects of mechanical stability of retained austenite and the heat-treatment conditions on the resulting mechanical properties have not been investigated sufficiently. Therefore, in this work, the microstructure and the mechanical properties of low alloyed 0.15C-1.5Mn- 1.5Al-03.Si TRIP-steel added with 0.1%P and 0.5%Cu is investigated. The relationship between mechanical properties and mechanical stability of retained austenite is also discussed.

2 Experimental

The steel investigated is a CMnAlSi-TRIP steel, with the chemical compositions (mass fraction, %) of 0.15C, 1.5Mn, 1.5Al, 0.3Si, 0.5Cu and 0.1P. 25 kg cast ingots were vacuum melted and were hot-rolled by classical procedure to 4 mm. After pickling, the steel slabs were finally cold-rolled to 1 mm in thickness. ASTM E-8 standard was used for the tensile sample,

with 50 mm in gauge length and 12.5 mm in gauge width. The tensile axis was prepared parallel to the rolling direction of the cold-rolled sheets. The two-step heat treatment schedule, simulated by two salt baths, was used. Firstly, the samples were intercritically annealed at 820 ℃ for 120 s, then were fast moved to another salt bath for bainitic transformation and followed by air-cooling to room temperature. The IBT temperature was designed as 400, 420, 450, and 500 ℃, with the soaking time of 6-300 s. Tensile testing was performed at ambient temperature with a constant crosshead speed of 2 mm/min. Mechanical properties were got from these tensile curves. The mechanical stability of retained austenite was also investigated under different strains.

The samples for microstructure observation were mechanically polished and chemically etched in a 10% sodium metabisulfite solution, and then observed by optical microscope. For XRD testing, samples were prepared by mechanical grinding and finally chemical etching to get a half thickness around of 0.5 mm in solution of hydrofluoric acid and hydrogen peroxide. Retained austenite was measured using a Rigaku X-ray diffractometer with Mo Kα radiation operated at 50 kV and 40 mA. The volume fraction of retained austenite φγ was calculated through the integrated intensity of (211)α peak and (220)γ, (311)γ peaks and the retained austenite peaks were also used to calculate the carbon concentration(wC) using the following equation[16]:

a0=3.578+0.033×wC (1)

where a0 is the lattice parameter of retained austenite.

3 Results and discussion

3.1 Microstructure

Fig.1 shows the typical microstructure of the investigated steels after IBT at 450 ℃ for 60 s. In the present etching method, ferrite shows in gray, bainite and martensite in black and retained austenite in white. Optical microstructure investigations show that most retained austenite is mainly located at the ferrite grain

Fig.1 Optical microstructure of ample after IBT treatment at 450 ℃ for 60 s

and others is imbedded in ferrite matrix. The content of retained austenite ranges from 6% to 17% in the samples IBT treated at 400-500 ℃ for 6-300 s. The variation content of retained austenite is clearly affected by IBT temperature and soaking time.

3.2 Mechanical properties

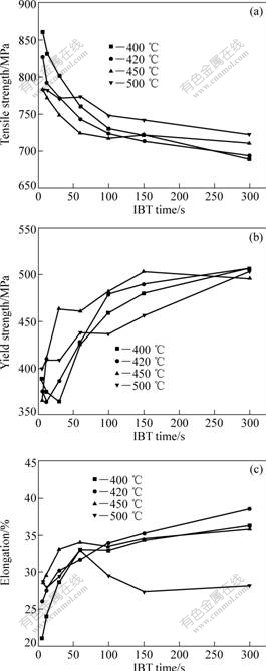

Fig.2 shows the mechanical properties as a function of IBT time. Although the solid solution strength of Al is less than that of Si, the investigated steels show excellent combination of mechanical properties and ductility, with the strength-ductility balance (σb?δ) of 220-270 MPa. The reason is that the addition of P and Cu can obviously improve the tensile strength. According to the previous data[11, 13], the addition of 0.1% P in the steels can bring 67 MPa to the mechanical properties, and addition Cu can also strengthen the ferrite matrix[15]. As a result, the steel held for 60 s at 450 ℃ has tensile strength of 730 MPa. The total elongation is in the range of 22%-36% for the steels in spite of the P and Cu additions deteriorate the ductility[11, 15]. The best combination of strength-ductility balance is obtained for holding time of 60-120 s at a bainitic temperature of 420-450 ℃, showing the proper heat treatment parameters to fabricate this kind of steel.

Fig.2 Mechanical properties of samples after different IBT procedures: (a) Tensile strength; (b) Yield strength; (c) Elongation

Fig.2 indicates clearly the tendency that the tensile strength decreases with increasing IBT time, while the yield strength and the total elongation increase up to 100 s. After holding for 100 s, the variation of mechanical properties is not clear. In the IBT process, the Al and P additions effectively suppress the cementite formation and expel the carbon from bainite to austenite[5]. The remaining austenite can be carbon enriched enough to withstand the further cooling and exited at room temperature. For short IBT time, the partly bainite transformation produces remaining austenite with low carbon concentration, which transforms to martensite in the final cooling. Consequently, the mechanical properties show high tensile strength, low yield strength and elongation. With increasing IBT time, the volume fraction of retained austenite increases accompanied with high carbon concentration; meanwhile, bainite and retained austenite substitute the martensite. These determine the mechanical properties of reduced tensile strength, increased yield strength and elongation.

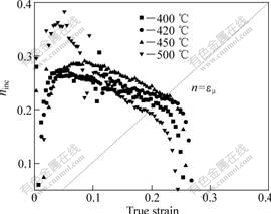

Fig.3 shows the differential incremental strain hardening exponent as a function of true strain for the specimens treated for 60 s. The strain hardening exponent is calculated as

ninc=dlnσ/dlnε (2)

where σ is the true stress and ε is the true strain. The specimens all show high strain hardening exponent greater than 0.2 and high uniform elongation before necking. But the obvious variation appears that the uniform elongation of samples treated at 420-450 ℃ is larger than that of others. The elongation of samples treated at 500 ℃ increases at the early straining and decreases at the later straining, showing the variation of transformation of retained austenite to martensite. This indicates the different mechanical stability of retained austenite.

3.3 Stability of retained austenite

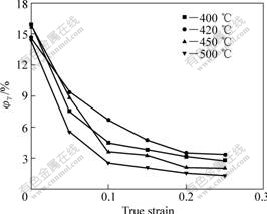

Fig.4 shows the variation of volume fraction of retained austenite as a function of applied strain, after the samples were treated for 60 s at different IBT temperatures. The martensite transformation rate of samples treated at 500 ℃ is greater than that of samples treated at other temperatures, and the volume fraction of retained austenite fleetly decreases at the early straining, in contrast, the others are more gradual.

Fig.3 Instantaneous strain hardening exponent values for samples held for 60 s at different IBT temperatures

Fig.4 Variation of volume fraction of retained austenite as function of true strain

A fast transformation of retained austenite to martensite would lead to the increase of n value[11], and the results fit well with the strain hardening exponent results observed in Fig. 3. The transformation of retained austenite to martensite produces higher ductility to TRIP steel. The TRIP effect generates free dislocations and dilatational deformation in the surrounding ferritic matrix, which increases the strain hardening exponent in the further straining and finally brings higher uniform and total elongation to the sample[3, 5].

In order to quantify the kinetics of the strain-induced martensite transformation as a function of strain, the Ludwigson and Berger relation was used[17]:

![]() (3)

(3)

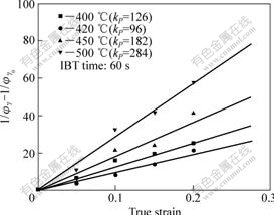

where φγ is the volume fraction of retained austenite; ![]() is the initial volume fraction of retained austenite; kP is a constant showing the stability of retained austenite against strain; P is the strain exponent of autocatalytic effect and is 1 for TRIP steel. The lower kP value denotes the higher retained austenite stability that retards the martensite transformation during strain. Fig.5 shows the change of

is the initial volume fraction of retained austenite; kP is a constant showing the stability of retained austenite against strain; P is the strain exponent of autocatalytic effect and is 1 for TRIP steel. The lower kP value denotes the higher retained austenite stability that retards the martensite transformation during strain. Fig.5 shows the change of ![]() as a function of true strain. When P is supposed to be 1, and kP values for samples treated at 400-500 ℃ are 126, 96, 182, 284, respectively. The different kP values mean the different retained austenite stabilities against strain-induced martensite transformation, i.e., the retained austenite stability of samples treated at 420 ℃ is higher than that of other samples.

as a function of true strain. When P is supposed to be 1, and kP values for samples treated at 400-500 ℃ are 126, 96, 182, 284, respectively. The different kP values mean the different retained austenite stabilities against strain-induced martensite transformation, i.e., the retained austenite stability of samples treated at 420 ℃ is higher than that of other samples.

Fig.5 Fitting curves of Ludwigson and Berger relation to data of strain-induced martensite transformation

This difference of retained austenite stability can be interpreted through the carbon concentration. From the XRD data, we know that steel treated at 420 ℃ has the higher carbon concentration of retained austenite. Many researches demonstrate that the carbon concentration of retained austenite is the crucial factor that governs the retained austenite stability against straining[11, 18]. The higher carbon concentration improves the mechanical driving force and suppresses the strain-induced martensite transformation[5]. Thus, the retained austenite with higher carbon concentration shows high mechanical stability, which gradually transforms into martensite during whole straining, and then the sample exhibits high ductility.

4 Conclusions

1) CMnAlSi-TRIP steel with P and Cu additions strengthens the ferrite matrix without losing ductility, showing an excellent combination of mechanical properties (σb?δ) of 220-270 MPa through proper heat treatment.

2) After holding for 60-120 s at 420-450 ℃, tensile strength around 730 MPa and elongation around 32% are obtained for the investigated steel.

3) The high mechanical stability of retained austenite determines best strain hardening during deformation, and the mechanical stability of retained austenite is governed by its carbon concentration enriched during IBT heat treatment.

References

[1] RAY A, DHUA S K. Microstructural manifestations in color: Some applications for steels [J]. Materials Characterization, 1996, 37(1): 1-8.

[2] ZACKAY V F, PARKER E R, DFAHR D, BUSCH R. The enhancement of ductility on high strength steels [J]. Trans of ASM, 1967, 60(2): 252-259.

[3] JACQUES P J. Transformation-induced plasticity for high strength formable steels [J]. Current Opinion in Solid State and Materials Science,2004, 8(3/4): 259-265.

[4] ZAREI H A, YUE S. Ferrite formation characteristics in Si-Mn TRIP steels [J]. ISIJ Int, 1997, 37(6): 583-589.

[5] de COOMAN B C. Structure–properties relationship in TRIP steels containing carbide-free bainite [J]. Current Opinion in Solid State and Materials Science, 2004, 8(3/4): 285-303.

[6] SAKUMA Y, MATSUMURA O, TAKAKECHI, H. Mechanical properties and retained austenite in intercritically heat-treated bainite transformed steel and their variation with Si and Mn additions [J]. Metallurgical Transactions A, 1991, 22A(2): 489-498.

[7] SCOTT C P, DRILLLET J. A study of the carbon distribution in retained austenite [J]. Scripta Materialia,2007, 56(6): 489-492.

[8] JACQUES P J, GIRAULT E, MERTENS A, VERLINDEN B, VANHUMBEECK J, DELANNAY F. The developments of cold-rolled TRIP-assisted multiphase steels [J]. ISIJ Int, 2001, 41(9): 1068-1074.

[9] de MEYER M, van DERSCHUEREN D, de COOMAN B C. The influence of the substitution of Si by Al on the properties of cold rolled C-Mn-Si TRIP steels [J]. ISIJ Int, 1999, 39(8): 813-822.

[10] SRIVASTAVA A K, BHATTACHARJEE D, JHA G, GOPE N, SINGH S B. Microstructural and mechanical characterization of C-Mn-Al-Si cold-rolled TRIP-aided steel [J]. Mater Sci Eng A, 2007, 445/446: 549-557.

[11] JING C N, SUH D W, OH C S, WANG Z C, KIM S J. Effects of phosphorous addition on mechanical properties and retained austenite stability of 0.15C-1.5Mn-1.5Al TRIP-aided cold rolled steels [J]. Metals and Materials International, 2007, 13(1): 13-19.

[12] BARBE L, VERBEKEN K, WETTINCK E. Effect of the addition of P on the mechanical properties of low alloyed TRIP steels [J]. ISIJ Int, 2006, 46(8): 1251-1257.

[13] CHEN H C, ERA H, SHIMIZU M. Effect of phosphorus on the formation of retained austenite and mechanical properties in Si-containing low-carbon steel sheet [J]. Metallurgical Transactions A, 1989, 20A(3): 437-445.

[14] LEE H, KOH H J, SEO C H, KIM N J. Microstructure and tensile properties of hot-rolled Fe-C-Mn-Si-Cu multiphase steel [J]. Scripta Materialia, 2008, 59(1): 83-86.

[15] KIM S J, LEE C G, LEE T H, OH C S. Effect of Cu, Cr and Ni on mechanical properties of 0.15%C TRIP-aided cold rolled steels [J]. Scripta Materialia, 2003, 48(5): 539-544.

[16] ONINK M, BRAKMAN C M, TICHELAAR F D, MITTERMEIJER E J, VANDERZWA A G S, ROOT J H, KONYER N B. The lattice parameters of austenite and ferrite in Fe-C alloys as functions of carbon concentration and temperature [J].Scripta Metallurgica et Materialia, 1993, 29(8): 1011-1016.

[17] ITAMI A, TAKAHASHI M, USIHIODA K. Plastic stability of retained austenite in the cold-rolled 0.14%C-1.9%Si-1.7%Mn sheet steel [J]. ISIJ Int, 1995, 35(9): 1121-1127.

[18] WANG J, VANDERZWAAG S. Stabilization mechanisms of retained austenite in transformation-induced plasticity steel [J]. Metallurgical and Materials Transactions A, 2001, 32(6): 1527-1539.

(Edited by YANG Bing)

Foundation item: Project(2008BS04023) supported by the Science Foundation for Excellent Young Scientist of Shandong Province, China

Corresponding author: JING Cai-nian; Tel: +86-531-86367285; E-mail: jcn@sdjzu.edu.cn