J. Cent. South Univ. (2018) 25: 795-804

DOI: https://doi.org/10.1007/s11771-018-3784-x

Effect of magnetite content on Bond work index and preconditioning:Case study on Chadormalu iron ore mine

Hossein INANLOO ARABI SHAD, F SERESHKI, M ATAEI, M KARAMOOZIAN

Department of Mining, Petroleum and Geophysics, Shahrood University of Technology,Shahrood, 3619995161, Iran

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2018

Abstract:

Grinding is one of the most costly operations in the mechanical breaking and mining. Determination of the breakage characteristics and preconditioning is important to increase the grinding efficiency. Investigations of the seismic, mechanical and breakage properties of iron oxides are very important parameters for investigating the rock fragmentation by blasting and comminution processes in iron ore mines. In this paper, at first, geomechanical and seismic properties of the oxide ores (magnetite and hematite) in the Chadormalu iron ore mine were studied. The results showed that the percentage of magnetite has a direct relationship with uniaxial compressive strength, tensile strength and P and S wave’s velocities and has an inverse relationship with Poisson ratio and porosity. Moreover, to study breakage and preconditioning characteristics in the iron ores, two samples with different magnetite percents were blasted by detonation cord. The results showed that with higher percentage of magnetite, the number of fractures induced by blasting increased. Bond work index and magnetite percent were investigated in the 430 blasts in the mine. This investigation not only confirmed the small scale blasting results, but also showed that increasing the magnetite percent up to 50% noticeably reduces Bond work index and energy consumption in the grinding process. Also, the relationship between muck pile fragmentation and magnetite percentage were studied for several blasts that had the same blast pattern parameters and similar geology conditions. These results also confirmed precedents conclusions regarding magnetite percent and preconditioning relationship.

Key words:

iron oxides; geomchanical parameter; preconditioning; magnetite percent; energy consumption;

Cite this article as:

Hossein INANLOO ARABI SHAD, F SERESHKI, M ATAEI, M KARAMOOZIAN. Effect of magnetite percent on Bond work index and preconditioning: Case study Chadormalu iron ore mine [J]. Journal of Central South University, 2018, 25(4): 795–804.

DOI:https://dx.doi.org/https://doi.org/10.1007/s11771-018-3784-x1 Introduction

Iron ore is one of the important materials in mining and steel industrials. MORGAN et al [1] stated that iron includes 32.07% of the Earth’s mass. Also its elemental abundance varies about 5% and as much as 80% of the Earth’s crust and core, respectively. Magnetite, hematite and goethite are three most common iron ore minerals which have cubic, hexagonal (trigonal) and orthorhombic structures, respectively [2]. One of common iron ore minerals in iron ore deposits is magnetite (Fe3O4) which has metasedimentary and magmatic origins. WAYCHUNAS [3] stated that magnetite has an inverse spinel structure and is partly altered to hematite or kenomagnetite in near-surface environments. Commonly in the near-surface environment, hematite (Fe2O3) forms from the oxidation of magnetite. Moreover, OHMOTO [4] demonstrated the application of a pH shift without a redoxreaction on the transformation of magnetite to hematite or vice versa. Goethite (α-FeOOH) is an iron oxyhydroxide that is the most common iron ore mineral in sedimentary and near-surface, altered metasedimentary iron ore deposits [5]. Investigation of the seismic, mechanical and breakage properties of iron oxides are very important parameters for investigating the rock fragmentation by blasting and comminution processes in iron ore mines. MORALES et al [6] demonstrated that the seismic properties of magnetite, hematite and quartz are related to their mineralogy and structures. They also stated that anisotropy is related to crystallographic preferred orientation (CPO). CHICOT et al [2] determined the hardness and elastic properties of pure (crystal) and complex (product of corrosion) iron oxides, magnetite, hematite and goethite using instrumented indentation and molecular dynamics analysis (MDA). Also they found that the hardness and elastic properties are related to the type and structure of minerals. Also, understanding the iron oxides response to implied energy can greatly help in optimizing rock fracturing and the energy consumption of the different stages of mining such as drilling, blasting and mechanical comminution (crushing and grinding). The final step of mining, mineral liberation is completely dependent on achieving the proper rock fracturing in the rock fragmentation by blasting and comminution steps. Also mining costs and throughput optimization can be realized by optimizing rock fracturing processes. Rock fracturing concerns the propagation of cracks and fractures in rocks and the resulting fragmentation [7]. Microfractures and microcracks are small size cracks which, in general, it is not possible to see them through the naked eye as their size is in the range of few millimeters and microns. Micro-cracks can be subdivided into three types, i.e., intragranular, transgranular and intergranular

cracks. Intragranular microcracks are confined to the interior of a single grain; Transgranular microcracks cross more than one grain; and intergranular micro-cracks are formed along a grain-boundary [8]. The rock fracturing is directly related to all stages of mining operations. Although the comminution processes are the most expensive operations in mining, the extent of pre-existent cracks and the breakage and geomechanical characteristics of minerals can influence and increase the crushing and the milling efficiency and decrease the costs of them. However, fewer investigations are available that deal with the seismic, mechanical and breakage properties of the iron oxides. The purpose of this study is to examine the geomechanical, seismic and breakage properties of the iron oxides and the influence of them on comminution process.

2 Research method

2.1 Materials

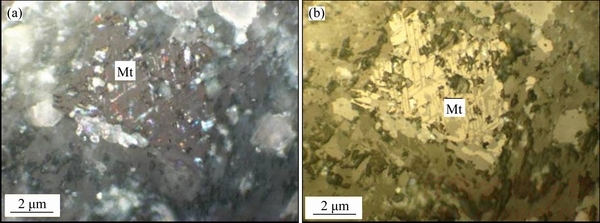

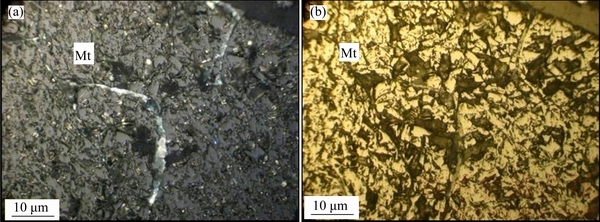

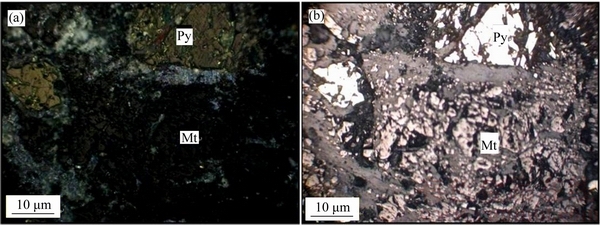

Chadormalu iron ore mine is located 165 km west of Yazd city in Iran. From geological and tectonics point of view, this mine is one of the most complicated areas of Iran. The Chadormalu iron ore mine comprises the magmatic northern and southern orebodies and its geological reserve is 400 million tons and the minable reserve is 330 million tons that more than 90% of Chadormalu deposit is located in the northern orebody. The ore minerals consist predominantly of magnetite and hematite. Bladed hematite crystals are shown in Figure 1. Figures 2 and 3 show magnetite crystals which have a cubic structure and three cleavage sets. Subordinate amounts of apatite, pyrite, quartz and feldspar may also be observed (Figures 4 and 5). In these figures, different lighting and magnifying were used. Country rocks of the orebodies are Precambrian metamorphic rocks, and Cambrian subvolcanic intrusive “syenite”, gabbro-diorite, volcanic rocks (predominantly rhyolite) with intercalations of siliceous dolomite, and pyroclastic breccias. Due to contact metamorphism by the resurgent Sorkh granite (Chadormalu granite), portions of the country rocks have been converted to hornfels [9].

Figure 1 Photomicrographs of bladed hematite crystals with crossed polarized light (a) and plane polarized light (b) (Hm: Hematite)

Figure 2 Photomicrographs of magnetite cubic crystals with crossed polarized light (a) and plane polarized light (b)(Mt: Magnetite)

Figure 3 Photomicrographs of magnetite cubic crystals with crossed polarized light (a) and plane polarized light (b) (Mt: Magnetite)

Figure 4 Photomicrographs of anhedral pyrite in magnetite ore with crossed polarized light (a) and plane polarized light (b) (Mt: Magnetite; Py: Pyrite)

2.2 Effect of magnetite and hematite ore on geomechanical and seismic properties

In this research, the cores of iron ore were collected with different percentages of magnetite and hematite without gangue. As mentioned earlier, the geomechanical and seismic properties of the ore is influenced by comprised minerals. Thus, the geomechanical and seismic tests based on the percentage of magnetite were conducted on samples in the rock mechanic laboratory. These tests included uniaxial compressive strength, tensile strength, elastic modulus (E), Poisson ratio (n), porosity, water absorption, P wave velocity and S wave velocity.

Figure 5 Photomicrographs of anhedral pyrite in magnetite ore with crossed polarized light (a) and plane polarized light (b) (Mt: Magnetite; Py: Pyrite)

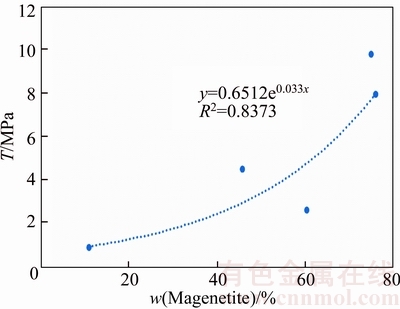

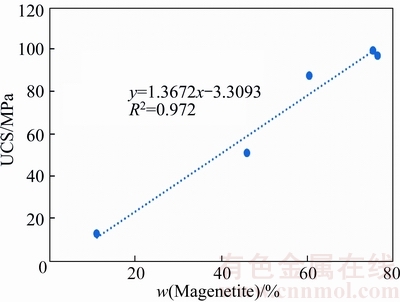

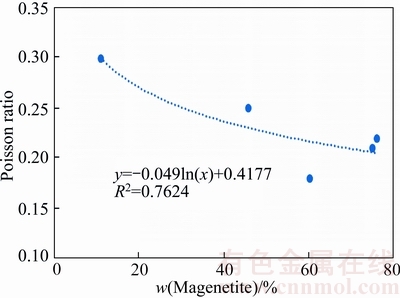

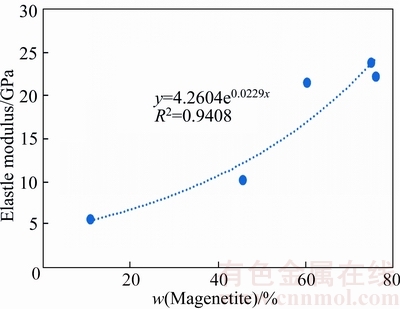

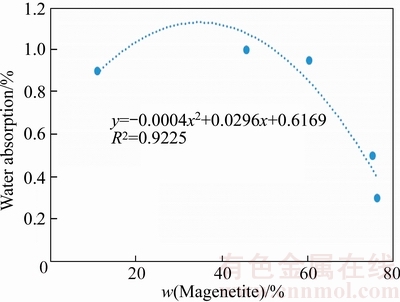

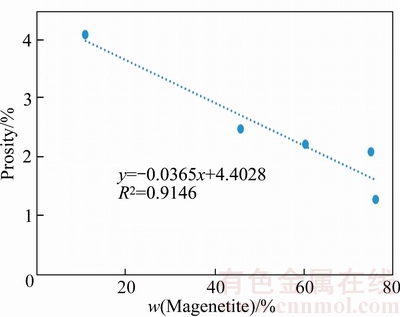

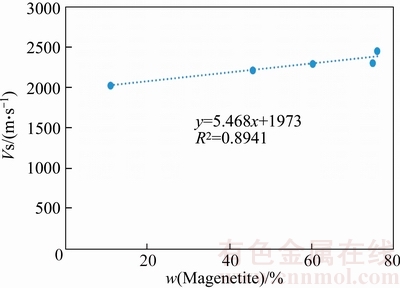

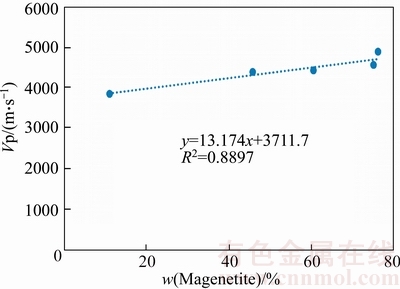

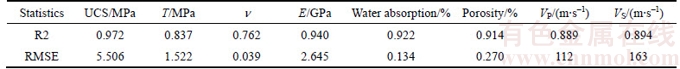

Figures 6 to 13 show the relations between the percentage of magnetite and the different parameters using regression analysis. Table 1 presents determination factor and root mean square error for equations between the percentage of magnetite and geomechanical parameters. The results show that the percentage of magnetite has an influence on the seismic and geomechanical parameters. Among of these parameters, the uniaxial compressive strength, porosity and P wave velocity (VP) and S wave velocity (VS) have a linear relation with the percentage of magnetite. In additional, the uniaxial compressive strength (UCS), tensile strength (T), P wave velocity (VP) and S wave velocity (VS) have a direct relationship with the percentage of magnetite and Poisson ratio and porosity have an inverse relationship with the percentage of magnetite.

Figure 6 Relation between tensile strength and magnetite percentage

Figure 7 Relation between UCS and magnetite percentage

Figure 8 Relation between Poisson ratio and magnetite percentage

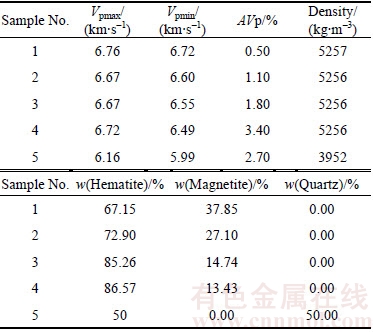

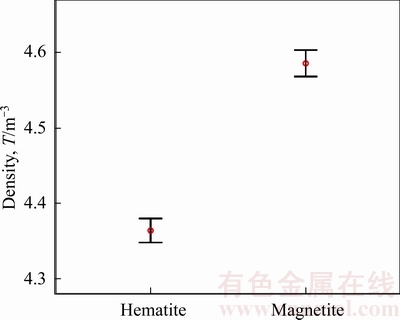

MORALES et al [6] determined the LPO (lattice preferred orientations)-derived seismic properties of iron ores in samples with contrasting mineralogy (hematite, magnetite and quartz) and deformed under different conditions. They demonstrated that the magnitudes of the P wave velocity of magnetite are higher than hematite (Tables 2 and 3). These results support the obtained results in Chadormalu iron ore mine concerning the relation between magnetite percentage and P wave velocity. MORALES et al [6] also found that an absent or weak crystallographic preferred orientation (CPO), the high modal content of magnetite (the anisotropy of cubic minerals (magnetite) is usually lower than that of non-cubic minerals) and the relatively weak anisotropy of elastic stiffness of hematite single crystals cause the tested samples are seismically quasi-isotropic or weakly anisotropic. They also stated that the magnitudes of P and S-wave velocities derived of hematite CPO are lower than the values experimentally determined in iron ores. Furthermore, the magnetite cubic crystals reduce porosity and increase density in the ore mineral. Figure 14 shows maximum, average and minimum of the hematite and magnetite densities for 627 data sets in Chadormalu iron ore mine. In Figure 14, the samples with magnetite higher than 30% is defined as magnetite ore and the samples with magnetite lower than 30% is defined as hematite.

Figure 9 Relation between elastic modulus and magnetite percentage

Figure 10 Relation between water absorption and magnetite percentage

Figure 11 Relation between porosity and magnetite percentage

Figure 12 Relation between S wave velocity and magnetite percentage

Figure 13 Relation between P wave velocity and magnetite percentage

Table 1 Determination factor and root mean square error (RMSE) for equations between percentage of magnetite and geomechanical parameters

Table 2 P wave velocities and anisotropies of compressional (Vp) in hematite, magnetite and quartz single crystals [6]

Table 3 P wave velocities and anisotropies of compressional (Vp) determined from crystallographic orientation of hematite, magnetite and quartz within iron ore specimen [6]

Reviewing the literature concerning the relation between UCS and P wave velocity shows that these two parameters have a direct and in most cases linear relation [10-15]. These results confirm the direct relation between the UCS and magnetite percentage in the tested samples.

2.3 Effect of iron ore mineral on preconditioning

Generally, ore minerals are classified based on grade, geology and chemical characteristics and do not take into account the breakage and preconditioning characteristics. Preconditioning is defined as “The alteration of the rock physical properties magnitudes after blasting, due to the creation and extension of cracks and micro cracks” [16, 17]. The main factors which affect the breakage and preconditioning characteristics include: induced stress, type and structure of mineral, texture, rock elastic and mechanical properties and natural porosity or pre-existing cracking [8, 18–21].

Figure 14 Maximum, average and minimum densities in magnetite and hematite, Chadormalu iron ore

KESSON et al [8] and LIU et al [21] stated that mineralogy and texture are important factors in the generating microcracks induced by stress. Their results showed that the mineralogy and texture can control the stress preconditioning in the rock materials.

KESSON et al [8] and LIU et al [21] stated that mineralogy and texture are important factors in the generating microcracks induced by stress. Their results showed that the mineralogy and texture can control the stress preconditioning in the rock materials.

JERN [19] also stated that grain boundary strength, grain boundary symmetry, grain size, cleavage planes and stiffness have an influence on the preconditioning.

OZKAHRAMAN [22] stated that the number of fractures inside the fragments induced by blasting have a direct relationship with preconditioning and size of the particles.

Measuring fractures and effect of them on run of mine, energy consumption and overall cost of mining are important factors in the preconditioning studies. During comminution, the preconditioning causes a reduction in energy consumption and an increase of throughput because of a reduction in fragment strength. Some indirect techniques such as P-wave and S-wave velocity measurements, Bond work index tests and drop weight tests have been applied to measuring fracturing based on measuring relative changes in mechanical and/or elastic properties.

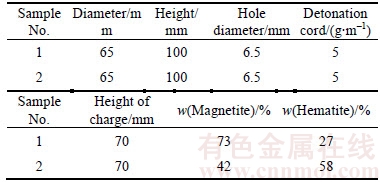

To study the propagation of microcracks in the iron ores, two iron ore cores with different percentages of magnetite and hematite were blasted by 5 g/m detonating PETN cord. The samples were covered by an elastic material with thickness of 7 mm. This is due to the effect of boundary conditions and tensile reflections. The specificities of samples and the explosive type used are given in the Table 4 and Figure 15.

Table 4 Specifics of samples and explosive type

Figure 15 Experimental set up of samples

After blasting of samples, the results showed that the sample with higher percentage of magnetite was fragmented more than the simple with lower percentage of magnetite (the numbers of generated fragments were compared) (Figures 16 and 17). The reason of this behaviour is high hardness in the magnetite ore. The hardness of a material is related to its resistance to plastic deformation usually by indentation. CHICOT et al [2] demonstrated that the hardness of magnetite is higher than hematite and goethite and the magnetite ore has higher resistance to plastic deformation than the hematite ore. Another reason might be the cubic structure of magnetite that increases the isotropy of elastic properties compared to non-cubic minerals (hematite) MORALES et al [6]. These reasons may increase magnetite brittleness and increasing the number of fractures induced by blasting in the magnetite ore. A material is brittle if, when subjected to stress, it breaks without significant plastic deformation (strain). Brittle materials (even those of high strength) absorb relatively little energy prior to fracture.

Figure 16 Fractures in sample with 73% magnetite

Figure 17 Fractures in sample with 42 % magnetite

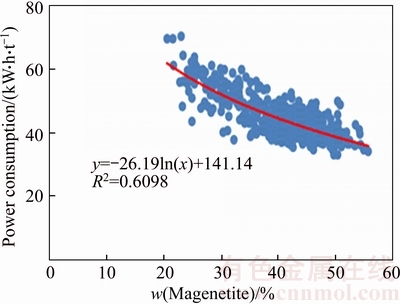

For validating the results of two small scale tests, indirect technique was used. It is possible to study the effect of magnetite percent on preconditioning and power consumption in the comminution process using Bond work index. Figure 18 shows the relation between Bond work index and magnetite percent for 430 sets of data. As it can be seen from Figure 18, increasing the percentage of magnetite will decrease the Bond work index. This result demonstrates that increasing the magnetite percentage increases magnetite brittleness and the number of fractures are induced by blasting. On the other hand, the significant correlation between the percentage of magnetite and Bond work index confirms the results from blasted samples.

Figure 18 Relation between bond work index and magnetite percent

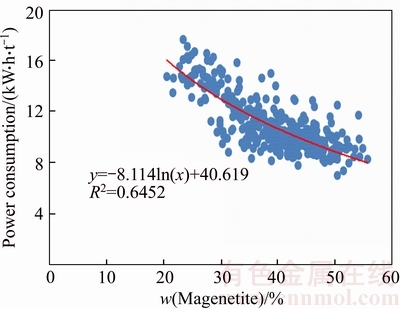

Also, as can be seen from Figure 18, when the percentage of magnetite increases, the Bond work index will decrease. Reducing the Bond work index causes a reduction of energy consumption during comminution and therefore the processing costs will be decreased. Figure 19 shows that increasing magnetite percentage in Chadormalu iron mine will decrease the power consumption in this mine. These results show that if the percentage of magnetite in mill feed increases from 25% to 50%, the power consumption will decrease from 70 kW·h/t to 40 kW·h/t.

Figure 19 Relation between power consumption and magnetite percentage

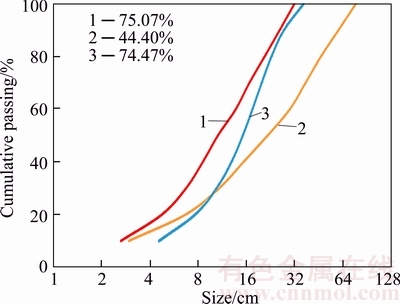

Furthermore, the relationship between muck pile fragmentation and magnetite percentage was studied for several blasts that had the same blast pattern parameters and similar geology conditions (Figure 20). As it can be seen from Figure 20, rock fragmentation shows a direct relationship with magnetite percentage. These results also confirm precedents conclusions regarding magnetite percent and preconditioning relationship.

Figure 20 Relation between rock fragmentation and percentage of magnetite

3 Conclusions

The effect of magnetite percent on Bond work index and preconditioning was studied in Chadormalu iron mine. At first, geomechanical parameters of iron oxides such as uniaxial compressive strength, tensile strength, elastic modulus, Poisson ratio, porosity, water absorption, P wave velocity and S wave velocity were measured and compared with percentage of magnetite. Then, two small scale tests were carried out on the cores of diameters 65 mm, blasted with detonation cord of 5 g/m charged in holes of 6.5 mm. The obtained results were compared with magnetite percent. Finally, to validate the small scales tests results, magnetite percent was plotted versus Bond work indices. The following remarks are to note:

1) The percentage of magnetite has a direct relationship with uniaxial compressive strength, tensile strength and P and S wave’s velocities. The percentage of magnetite has an inverse relationship with Poisson ratio and porosity.

2) The small scale test with higher percentage of magnetite was fragmented more than the simple with lower percentage of magnetite.

3) The comparing between percentage of magnetite and Bond work indices showed that increasing the percentage of magnetite will decrease the Bond work index.

4) Increasing fragmentation and decreasing the Bond work index with increasing percentage of magnetite might be due to the cubic structure and hardness of magnetite.

6) Increasing the percentage of magnetite in feed of process factory from 25% to 50%, decreases the power consumption from 70 kW·h/t to 40 kW·h/t.

Acknowledgements

The authors would like to thank and acknowledge Prof. F. Ouchterlony, Chair of Mining Engineering and Mineral Economics of Montanuniversitaet Leoben. Furthermore, special thanks to Mr. K. Moazami, management of Kani Kavan Shargh Consultant Co. and Mr. S. M. Abrishami, management of Chadormalu Mining and Industrial Complex Co. for their cooperation in conducting the field trials and permission to publish these results.

References

[1] MORGAN J W, ANDERS E. chemical composition of earth, venus, and mercury [J]. National Academy of Sciences of the United States of America, 1980, 77: 6973–6977.

[2] CHICOT D, MENDOZA J, ZAOUI A, LOUIS G, LEPINGLE V, ROUDET F, LESAGE J. Mechanical properties of magnetite (Fe3O4), hematite (α-Fe2O3) and goethite (α-FeO·OH) by instrumented indentation and molecular dynamics analysis [J]. Materials Chemistry and Physics, 2011, 129: 862–870.

[3] WAYCHUNAS G A. Crystal chemistry of oxides and oxyhydroxides [J]. Reviews in Mineralogy and Geochemistry, 1991, 25: 11–68.

[4] OHMOTO H. Nonredox transformations of magnetite- hematite in hydrothermal systems [J]. Economic Geology, 2003, 98: 299–304.

[5] CLOUT J M F, MANUEL J R. Iron ore: Mineralogy, processing and environmental sustainability [M]. Elsevier Ltd, 2015.

[6] MORALES L F G, LAGOEIRO L E, ENDO I. First results on the LPO-derived seismic properties of iron ores from the Quadrilátero Ferrífero region, southeastern Brazil [J]. Tectonophysics, 2008, 460(1–4): 21–33.

[7] KIM K. Rock fracturing & mine to mill optimization [D]. Arizona: University of Arizona, 2012.

[8]  KESSON U, HANSSON J, STIGH J. Characterisation of microcracks in the Bohus granite, western Sweden, caused by uniaxial cyclic loading [J]. Engineering Geology, 2004, 72: 131–142.

KESSON U, HANSSON J, STIGH J. Characterisation of microcracks in the Bohus granite, western Sweden, caused by uniaxial cyclic loading [J]. Engineering Geology, 2004, 72: 131–142.

[9] TORAB F M. Geochemistry and metallogeny of magnetite- apatite deposits of the BAFQ mining district, central Iran [D]. Clausthal-Zellerfeld: Clausthal University of Technology, 2008.

[10] GOKTAN R M. Theoretical and practical analysis of rock rippability [D]. Istanbul: Istanbul Technical University, 1988.

[11]  A, ZARIF I. Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey [J]. Engineering Geology, 1999, 51: 303–317.

A, ZARIF I. Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey [J]. Engineering Geology, 1999, 51: 303–317.

[12] YASAR E, ERDOGAN Y. Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks [J]. International Journal of Rock Mechanics & Mining Sciences, 2004, 41: 871–875.

[13] SHARMA P K, SINGH T N. A correlation between Schmidt hammer rebound numbers with impact strength index, slake durability index and P-wave velocity [J]. International Journal of Earth Sciences, 2011, 100:189–195.

[14] DIAMANTIS K, GARTZOS E, MIGIROS G. Study on uniaxial compressive strength, point load strength index, dynamic and physical properties of serpentinites from Central Greece: Test results and empirical relations [J]. Engineering Geology, 2009, 108:199–207.

[15] KHANDELWAL M, SINGH T N. Correlating static properties of coal measures rocks with P-wave velocity [J]. International Journal of Coal Geology, 2009, 79: 55–60.

[16] ELORANTA J. The efficiency of blasting verses crushing and grinding [C]// Proceeding of the 23th annual general conference on explosives and blasting technique. Las Vegas, USA, International Society of Explosives Engineers: ISEE,1997: 157–163.

[17] MICHAUX S, DJORDJEVIC N. Influence of explosive energy on the strength of the rock fragments and SAG mill throughput [J]. Mineral Engineering, 2005, 18: 439–448.

[18] KERN H, WENK H R. Preferred orientation in deformed metal and rocks [M]. Elsevier, 1985.

[19] JERN M. Micro and macro crack growth as a result of blasting [C]// Proceeding of the 7th International Symposium on Rock Fragmentation by Blasting. Beijing, China: Metallurgical Industry Press, 2002: 155–161.

[20] TAKEMURA T, GOLSHANI A, ODA M, SUZUKI K. Preferred orientations of open microcracks in granite and their relation with anisotropic elasticity [J]. International Journal of Rock Mechanics & Mining Sciences, 2003, 40(4): 443–454.

[21] LIU S, FAISAL ANWAR A H M, CHEOL KIM B, ICHIKAWA Y. Observation of microcracks in granite using a confocal laser scanning microscope [J]. International Journal of Rock Mechanics & Mining Sciences, 2006, 43: 1293–1305.

[22] OZKAHRAMAN H T. Breakage mechanisms and an encouraging correlation between the Bond parameters and the friability value [J]. The Journal of the South African Institute of Mining and Metallurgy, 2010, 110: 153–159.

(Edited by HE Yun-bin)

中文导读

磁铁矿含量对邦德功指数和预处理的影响:以Chadormalu铁矿为例

摘要:研磨是机械回采和采矿中成本最高的工序。确定破碎特征和预处理对提高研磨效率非常重要。氧化铁的抗震、力学和破碎性能是研究铁矿石爆破和破碎过程中岩石碎块的重要参数。本文研究了Chadormalu铁矿中氧化物矿石(磁铁矿和赤铁矿)的抗震和岩土力学性能。结果表明:磁铁矿含量与单向压缩强度,拉伸强度,P和S波速率呈正相关关系,而与泊松比和孔隙率呈负相关关系。为研究铁矿石的破碎和预处理性能,对含有不同磁铁矿含量的样品进行导索爆破实验。结果表明,高磁铁矿含量的样品爆破碎片数较多。研究了矿区430次爆破的邦德功和磁铁矿含量。结果表明,随着磁铁矿含量增加至50%,爆破范围减小,邦德功和能量消耗也降低。此外,通过研究多次具有相同爆破参数和相似地质条件的爆破,研究石碓碎片和磁铁矿含量的关系。结果与前述磁铁矿与预处理的关系一致。

关键词:铁矿石;岩土力学性能;预处理;磁铁矿含量;能量消耗

Received date: 2017-02-14; Accepted date: 2017-05-06

Corresponding author: Hossein INANLOO ARABI SHAD, PhD; Tel: +98-9124756725; E-mail: h.inanloo@shahroodut.ac.ir

Abstract: Grinding is one of the most costly operations in the mechanical breaking and mining. Determination of the breakage characteristics and preconditioning is important to increase the grinding efficiency. Investigations of the seismic, mechanical and breakage properties of iron oxides are very important parameters for investigating the rock fragmentation by blasting and comminution processes in iron ore mines. In this paper, at first, geomechanical and seismic properties of the oxide ores (magnetite and hematite) in the Chadormalu iron ore mine were studied. The results showed that the percentage of magnetite has a direct relationship with uniaxial compressive strength, tensile strength and P and S wave’s velocities and has an inverse relationship with Poisson ratio and porosity. Moreover, to study breakage and preconditioning characteristics in the iron ores, two samples with different magnetite percents were blasted by detonation cord. The results showed that with higher percentage of magnetite, the number of fractures induced by blasting increased. Bond work index and magnetite percent were investigated in the 430 blasts in the mine. This investigation not only confirmed the small scale blasting results, but also showed that increasing the magnetite percent up to 50% noticeably reduces Bond work index and energy consumption in the grinding process. Also, the relationship between muck pile fragmentation and magnetite percentage were studied for several blasts that had the same blast pattern parameters and similar geology conditions. These results also confirmed precedents conclusions regarding magnetite percent and preconditioning relationship.