Properties and forming process of prealloyed powder metallurgy Ti-6Al-4V alloy

WANG Liang(王 亮)1, LANG Ze-bao(郎泽保)1, SHI Hong-pei(史鸿培)1

Aerospace Research Institute of Material and Processing Technology, Beijing 100076, China

Received 15 July 2007; accepted 10 September 2007

Abstract:

The properties and forming process of prealloyed powder metallurgy (PM) Ti-6Al-4V alloy were researched for application of high performance of titanium parts. Hot isostatic press (HIP) technology and two kinds of powders were used in the prealloyed processing to get full density material. Tensile properties, impact toughness and fracture toughness of PM Ti-6Al-4V alloy were studied and discussed. The microstructures were examined with optical microscope and the morphologies of powders were observed by SEM. Forming processes were performed to fabricate PM titanium parts. The experiment results show that the prealloyed PM Ti-6Al-4V alloy has same good properties as wrought material and the complex shape PM parts can be near-net-shaped. Some of the parts have been commercially used. This indicates that the prealloyed process should have bright prospects in making high-performance, complex shape and low-cost titanium alloy parts.

Key words:

titanium alloy; Ti-6Al-4V; powder metallurgy; hot isostatic pressing; microstructure; property; near-net-shape;

1 Introduction

Titanium powder metallurgy can produce high performance and low cost titanium parts. Compared with those by conventional processes, high performance PM titanium parts have many advantages: excellent mechanical properties at least comparable to the level of wrought titanium material, near-net-shape and low cost, being easy to fabricate complex shape parts, full dense material, no inner defect, fine and uniform microstructure, no texture, no segregation, low internal stress, excellent stability of dimension[1-2] and being easy to fabricate titanium based composite parts[3-5]. Powder metallurgy technology of titanium alloy has been commercially used in developed countries[6-15]. Research of utility of PM titanium alloy is performed to meet the increasing need of high performance-to-cost parts[4, 16].

In this work, two kinds of Ti-6Al-4V prealloyed powders are used in PM processing to get full dense titanium alloy. The microstructure and properties of the PM Ti-6Al-4V alloy are studied. The experiments of the near-net-shape process are performed to fabricate PM titanium parts.

2 Experimental2.1 Prealloying process

The prealloying PM process of fabricating titanium alloy and parts is shown in Fig.1. Ti-6Al-4V prealloyed powders that are generally spherical in shape have been produced by the plasma rotating electrode process (PREP) or gas atomization (GA)[17-18]. The packing density of the spherical prealloyed powders can exceed 60% of theoretical density consistently. And prealloyed powders have fine and homogeneous microstructure with the characteristics of rapid solidification. Metal capsule designed and manufactured according to the shape of the product, then powders are poured into the capsule. After that, the capsule is evacuated and sealed. The sealed capsule is put into a HIPing unit and powders are compacted to full density. The HIP parameters are 890-920 ℃, 100 MPa, 1 h.

Two kinds of prealloyed powders are used in the experiment: PREP and GA. Powder morphologies are shown in Fig.2. The chemical composition and powder size are listed in Table 1.

Fig.1 Illustration of steps of prealloying PM process

Fig.2 SEM morphologies of GA and PREP powders: (a) GA powders; (b) PREP powders

Table 1 Chemical composition and powder size of PREP and GA Ti-6Al-4V powder

2.2 Microstructure and mechanical properties

The microstructure, tensile property, impact toughness and fracture toughness of PM Ti-6Al-4V alloy samples are studied. Impact toughness is measured by Charpy impact testing method (U-notch). And the plane strain fracture toughness (KIC) is measured by compact tensile testing method.

2.3 Forming process of parts

Metal capsules and forming models are used in the study of near-net-shape process.

3 Results and discussion3.1 Microstructure

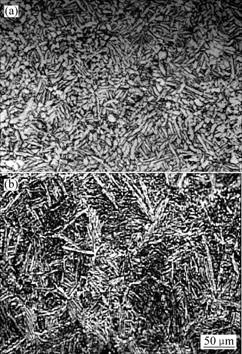

The typical microstructures of prealloyed Ti-6Al-4V alloy are shown in Fig.3. Fig.3(a) shows micrograph of GA powder compact and (b) shows that of PREP powder compact. The microstructures of the two materials are similar, and both are of platelet α and fine transformed β structure, with fine equiaxed α distributed uniformly. The α plate of GA PM alloy is coarser than that of PREP PM alloy. The basket-weave structure is formed and distributed uniformly. The microstructure shows that the PM Ti-6Al-4V alloy has excellent mechanical properties.

3.2 Tensile properties

The typical data of tensile properties of several group of PM Ti-6Al-4V alloy specimens are listed in Table 2, and all of the specimens are in the HIPped state. HIPped state here means the state that the material is cooled in the HIPing unit naturally from HIP temperature (900 ℃) to 300 ℃ or lower. The data in Table 2 show that both GA and PREP PM alloys have excellent tensile properties. Either strength properties (σb, σ0.2) or plasticity properties (δ, ψ) exceed the standard level of wrought bar. According to the data in Table 2, strength of the GA PM Ti-6Al-4V alloy specimens is higher than that of the PREP PM Ti-6Al-4V alloy specimens, and the values of elongation and reduction of area of PREP PM alloy are higher and more uniform.

Fig.3 Optical micrographs of prealloyed PM Ti-6Al-4V alloy: (a) GA; (b) PREP

Table 2 Typical tensile properties of prealloyed PM Ti-6Al-4V alloy at room temperature

Morphologies of GA and PREP powders are similar, all are spherical. But there are differences between the two kinds of powders. In Fig.2, it can be seen that most accompanied of the particles of the two kinds of powders are in good ‘spherical shape’, but there are some ‘satellitic particles’ accompanied with GA powder while little in PREP powder. Commonly, ‘satellitic particles’ have influence on the properties of PM alloy. There are ‘crack-like’ morphologies on the GA powder surface while the surface of PREP powder is rather smooth, as shown in Fig.4. According to the producing process, the cooling rate of GA powder is more rapid, that means more fine and uniform microstructure. GA and PREP powders have their own characteristics. Both the two kinds of powders can be compacted to PM titanium alloy with excellent properties in the research.

Fig.4 Surface morphologies of Ti-6Al-4V prealloyed powders: (a) GA; (b) PREP

3. 3 Impact toughness of PM titanium alloy

The impact toughness at room temperature of PM Ti-6Al-4V specimens with PREP powder is studied. The typical data are listed in Table 3. The average impact toughness value of the specimens is 60.8 J/cm2, and the standard minimum value for wrought bar is 40 J/cm2. The impact toughness of PM Ti-6Al-4V alloy is about one and a half times of the standard value of wrought bar. PM Ti-6Al-4V alloy shows excellent impact property.

Table 3 Impact toughness of PREP PM Ti-6Al-4V alloy at room temperature

3.4 Fracture toughness of PM titanium alloy

The plane strain fracture toughness (KIC) at room temperature of PM Ti-6Al-4V specimens with PREP powder is studied. The typical data are listed in Table 4. The typical value of KIC of wrought parts is about 75 MPa?m1/2, and the average value of PM alloy is 105.7 MPa?m1/2. The fracture property of PM Ti-6Al-4V alloy is better than that of wrought parts.

Table 4 Fracture toughness of PREP PM Ti-6Al-4V alloy in room temperature

3.5 Forming of PM titanium alloy parts

Prealloyed near-net-shape processes of PM titanium alloy parts are studied. By using metal capsules or metal capsule and forming modal, a lot of near-net-shape PM parts are prepared and produced. The design of capsules and forming models is important because of the different shrinkage of different shape of parts[19-20]. Some PM Ti-6Al-4V alloy parts are shown in Fig.5.

Fig.5(a) shows a kind of PM titanium alloy structure part with thin gridding wall. The thin gridding wall is in net shape and needn’t to be machined. The part has been in commercial use. Fig.5(b) shows a big dimension thin wall integrity PM titanium alloy cabin with adapting flanges, which is d 445 mm×372 mm with the wall thickness of 5 mm. The cabin is a high performance and low cost product with no defect, which has been commercially used in a pressure vessel. Fig.5(c) shows a PM titanium alloy connector, with a little machining at necessary position of fitting. Fig.5(d) shows high performance PM titanium alloy connecting rods for the automobile engine. The properties of the PM parts can entirely meet the demands of the engine.

Fig.5 Near-net-shape PM Ti-6Al-4V alloy parts: (a) PM titanium alloy structure part with thin gridding wall; (b) Big dimension thin wall integrity PM titanium alloy cabin; (c) PM titanium alloy connector; (d) PM titanium alloy connecting rod

4 Conclusions

1) The mechanical properties of the prealloyed PM Ti-6Al-4V alloy are excellent and the microstructure is fine and uniform. The tensile properties, impact toughness and fracture toughness of PM Ti-6Al-4V alloy are at least equivalent to the levels of wrought material.

2) Though there are differences between GA and PREP Ti-6Al-4V powders, both kinds of powders can be compacted to PM titanium alloy with excellent properties.

3) The complex shape PM titanium alloy parts can be formed by near-net-shape process. Titanium alloy powder metallurgy technology has been commercially used.

4) The prealloyed process should have bright prospects in making high-performance, complex shape and low-cost titanium alloy parts.

References

[1] EYLON D, FROES F H, PARSONS L D. Titanium PM components for advanced aerospace applications[J]. Met Powder Rep, 1983, 38(10): 567-571.

[2] FROES F H. Prealloyed titanium powder metallurgy-barriers to use[J]. Int J Powder Metall, 1987, 23(4): 267-269.

[3] FROES F H, HEBEISEN J. Emerging and future applications for HIPing of titanium based materials[C]//LI Cheng-gong, CHEN Hong-xia, MA Fu-kang. Hot Isostatic Pressing Conference Proceedings, HIP’99. Beijing: International Academic Publishers, 1999: 1-24.

[4] WANG Liang, SHI Hong-pei, LANG Zhe-bao. Research of technologies of manufacturing high performance PM titanium alloy and titanium based composite parts[C]//Annual Academic Conference of the 13th Professional Information System of China Aerospace. Urumchi: 2003: 230-235. (in Chinese)

[5] TAMIRISAKANDALA S, BHAT R B, RAVI V A, MIRACK D B. Powder metallurgy Ti-6Al-4V-xB alloys: Processing, microstructure, and properties[J]. JOM, 2004, 56(5): 60-63.

[6] ANOSHKIN N F. General results of HIP development and new arising problems[C]//MIYAMOTO Y, BUEKENHOUT L, FUJIKAWA T. Proceedings of International Conference on Hot Isostatic Pressing, HIP’02. Moscow: JSC “All-Russia Institute of Light Alloy”(VILS), 2003: 7-14.

[7] RACHUK V S, GONCHAROV N S, MARTYNYENKO Y A, BARINSHTEIN B M, SCIORELLI F A. Design, development, and history of the oxygen/hydrogen engine RD-0120. AIAA 95-2540[R]. Washington: American Institute of Aeronautics and Astronautics, 1995.

[8] FROES F H, EYLON D. Developments in titanium powder metallurgy[J]. J Met, 1980(4): 47-54.

[9] SHEINKER A A, CHANANIC G R, BOHLEN J W. Evaluation and application of prealloyed titanium P/M parts for airframe structures[J]. Int J Powder Metall, 1987, 23(3): 171-179.

[10] DEMCHENKOV G G. Progress trend of titanium granules metallurgy—A perspective technology for manufacture of super-sophisticated aerospace components[J]. Titan, 2003, 13(2): 35-41.

[11] GUICHARD D, RAISSON G, PIERONNER M. Cost effective production of Ti alloy net-shape parts by the isoprec powder metallurgy process[C]//MIYAMOTO Y, BUEKENHOUT L, FUJIKAWA T. Proceedings of International Conference on Hot Isostatic Pressing, HIP’02. Moscow: JSC “All-Russia Institute of Light Alloy”(VILS), 2003: 103-107.

[12] VALJUKHOW S G, SCOPOV J V, AZAROV A F, BOBILJOV P I, KOROTKOVA A I. Development of complex-shaped impellers with small flow sections made from titanium alloy powders by HIP[C]//MIYAMOTO Y, BUEKENHOUT L, FUJIKAWA T. Proceedings of International Conference on Hot Isostatic Pressing, HIP’02. Moscow: JSC “All-Russia Institute of Light Alloy”(VILS), 2003: 108-110.

[13] ZENG Han-ming. Essentials of advanced materials for high technology[M]. Beijing: Science and Technology Publishers of China, 1993: 119-123. (in Chinese)

[14] GOIRAND B, ALLIOT P, BARTHOULOT J L. Testing the first fuel turbopump of the Vinci engine. AIAA 2003-5069[R]. Alabama: American institute of Aeronautics and Astronautics, 2003.

[15] WHITTAKER D, GINTY B, HOPKINS B, UNWIN P, PENFOLD G, ASHWORTH M, WARD M. Finding pathways to future titanium success[J]. Metal Powder Report, 2005, 60(10): 27-31.

[16] WANG Liang, SHI Hong-pei. Research of high performance titanium alloy powder metallurgy technology[J]. Aerospace Materials & Technology, 2003, 33(3): 42-44. (in Chinese)

[17] LEYENS C, PETER M. Titanium and titanium alloys[M]. CHENG Zhen-hua. Beijing: Chemical Industry Press, 2005: 229-231. (in Chinese)

[18] FROES F H, MASHL S J, MOXSON V S, HEBEISEN J C, DUZ V A. The technologies of titanium powder metallurgy[J]. JOM, 2004, 56(11): 46-48.

[19] ANOCHINA A, GOLOVESCHKIN V, SAMAROV V, SELIVERSTOV D, RAISSON G, GUICHARD D. Mathematical model for simulation of hot isostatic pressing of complex shape parts with periodical structure of inserts[C]//MIYAMOTO Y, BUEKENHOUT L, FUJIKAWA T. Proceedings of International Conference on Hot Isostatic Pressing, HIP’02. Moscow: JSC “All-Russia Institute of Light Alloy”(VILS), 2003: 48-54.

[20] KATORGIN B I, DERKACH G G, KASHKAROV A M, GROMYKO B M, ZHELEZNIAK O N, KOZYKOV B A, ZAITZEV M V. Creation of critical parts of powerful LRE on the basis of HIP technology of granulated nickel alloys[C]//MIYAMOTO Y, BUEKENHOUT L, FUJIKAWA T. Proceedings of International Conference on Hot Isostatic Pressing, HIP’02. Moscow: JSC “All-Russia Institute of Light Alloy”(VILS), 2003: 71-83.

Corresponding author: WANG Liang; Tel: +86-10-68380666; E-mail: wliangsh@sohu.com