Structure and magnetic properties of amorphous and polycrystalline Fe3O4 thin films

TANG Xiao-li(唐晓莉), ZHANG Huai-wu(张怀武), SU Hua(苏 桦), ZHONG Zhi-yong(钟智勇), JING Yu-lan(荆玉兰)

School of Micro-electronics and Solid-state Electronics, University of Electronic Science and Technology of China, Chengdu 610054, China

Received 10 April 2006; accepted 25 April 2006

Abstract:

Half-metallic Fe3O4 films prepared by DC magnetron reactive sputtering with a tantalum(Ta) buffer layer was investigated. Primary emphasis is placed on the structural impact on its magnetic properties. The experimental results show that the amorphous Fe3O4 films exhibit a superparamagnetic response at a large-scale from 20 nm to 150 nm, and the magnetoresistance (MR) isn’t detected. By contrast, the polycrystalline Fe3O4 films possess large saturation magnetization Ms of 420 A/(kg?cm) and a clear magnetoresistance with a field of 40 kA/m. The unusual properties for the amorphous Fe3O4 film are attributed to the existing large density of the similar structure as anti-phase boundaries in the film.

Key words:

half-metal; Fe3O4; spintronic devices; magnetoresistance;

1 Introduction

Half-metallic Fe3O4 films have attracted much research interests since they combine a 100% spin polarization with a high curie temperature of 858 K[1], and become a candidate for future spintronics devices. High-quality Fe3O4 films, especially the epitaxial films on MgO substrates, because of the complete lattice matched, are fabricated by various techniques, such as pulsed laser deposition(PLD)[2], molecular-beam epitaxy(MBE)[3], reactive ion beam deposition (IBD) [4], RF magnetron sputtering with an external inductively coupled RF source[5]. Using the Fe3O4 films in the spintronic devices, such as giant magnetoresistive (GMR) devices with the current- perpendicular- to-plane

(CPP) geometry, current-in-plane(CIP) geometry or magnetic tunneling junctions(MTJ), the practical MR values of a few percent have typically been observed, despite the predicted of high MR values[1,6,7]. The reasons have been in part explained by the coexistence of small amounts of the other phases of iron oxide, such as FeO and Fe2O3[8]. Since the MgO substrate can only confirm the under-layer Fe3O4 to be single crystal, when using Fe3O4 as top-layer or as Fe3O4/normal metal/Fe3O4 configuration [6], it may be amorphous or polycrystalline when fabricated on the metal layer. So, the structure of the Fe3O4 film should be studied carefully to find the influence on the spintronic devices. Otherwise, Fe3O4 films were seldom fabricated by DC magnetron sputtering techniques, due to its fast sputtering rate and not easy to form the single-crystalline Fe3O4 films. However, the DC magnetron sputtering techniques is a conventional and convenient way for fabricating the spintronic device. If the Fe3O4 films fabricated by DC magnetron sputtering also have excellent properties, it may be the easy way to prepare the practical devices. So, in this work we adopt this way to fabricate our films.

2 Experimental

Amorphous and polycrystalline Fe3O4 thin films of varying thickness used in the present study were fabricated on Si (100) substrates by DC magnetron reactive sputtering, which is the traditional way to fabricate the GMR-CPP, GMR-CIP or MTJ, and the samples were annealed in an infrared lamp furnace system under a vacuum to crystallize. Applying Fe3O4films for spintronic devices, it should be noticed that the fabricated temperature should be low (<573 K)[1].

Fe3O4 thin films were fabricated by DC magnetron sputtering a Fe target in Ar+O2 mixture gas. The argon and oxygen flow rates were fixed and only the sputtering powers were changed to find the exact condition for Fe3O4 to form. The base pressure in chamber before sputtering was better than 9×10-6 Pa, which can ensure the film quality, and the working pressure was 0.13 Pa. The optimized deposition condition, which means no other phase existed, was an oxygen flow rate of 1 mL/min, argon 100 mL/min, DC power of 200 W, and the annealing temperature of 300 ℃, which were illustrated in Ref.[9]. In the film prepared procession, a Ta buffer layer was first fabricated to avoid diffusing between the Fe3O4 film and the substrate during the annealing.

Magnetization measurements were performed using a vibrating sample magnetometer system. The structures of the films were characterized by X-ray diffraction (XRD), and the composition and chemical states were analyzed by X-ray photoelectron spectroscopy(XPS).

3 Results and discussionAll the Fe3O4 films of varying thickness (20-150 nm) used in the study were fabricated under identical conditions for comparison. Fig.1 shows the X-ray diffraction patterns of Fe3O4 films with thickness of 150 nm for different annealing temperature. Fig.2 shows the typical Fe2p core spectrum of Fe3O4 films.

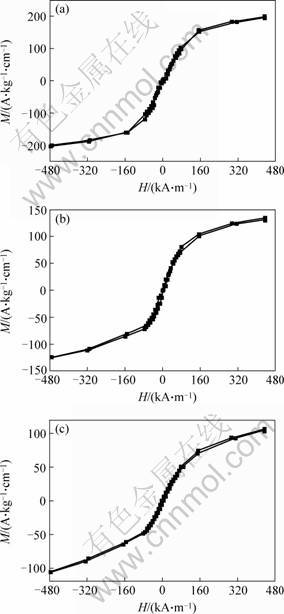

From magnetization measurements by vibrating sample magnetometer system, the amorphous and polycrystalline Fe3O4 thin films displayed different magnetic properties. Fig.3 shows the hysteresis-loops for Fe3O4 amorphous films with thickness of 20, 70 and 150 nm. In the wide thickness range, S-shaped hysteresis-loops with zero coercive force (Hc) were observed, which suggests that the films are superparamagnets.

This finding was quite surprising, because only magnetic nanoclusters in the form of an ultrafine powder, three-dimensional islands or small particles were known to exhibit supermagnetism. The reason is attributed to the thermal energy, which becomes larger than the magnetic anisotropy energy. On the other hand, the amorphous Fe3O4 films do not consist of islands or small clusters. In Refs.[11-13], the superparamagnetic property was also observed in the ultrathin epitaxial Fe3O4 film with thickness below 5 nm. This was attributed to the ultrathin Fe3O4 films containing a high density of antiphase boundaries (APBs), at which an antiferromagnetic (AF) exchange interaction can be present to frustrate the interdomain interaction. The APBs were natural growth

Fig.1 XRD patterns of Fe3O4 films with thickness of 150 nm annealed at different temperatures: (a) 0 ℃; (b) 300 ℃

Fig.2 Typical XPS measurement of Fe2p core spectrum of Fe3O4 films

defects, resulting from the fact that the lattice constant of Fe3O4 is twice as large as the one of MgO and causes the octahedral (B) sites to shift in and out-of the plane. The amorphous Fe3O4 films, due to its disorder growth, but exist some nanocrystalline. The reason may be attributed to the similar structures as APBs existing in the films. The density of the APBs may be larger than that existing in the single-crystal films, and increases with the film thickness. Therefore, in a wide thickness range, the amorphous films are superparamagnetic. It may be one

Fig.3 Hysteresis curves of amorphous Fe3O4 films with different thicknesses: (a)—20 nm; (b)—70 nm; (c)—150 nm

of the reasons for our Fe3O4/Cu/Fe3O4 spin valves absence of GMR signal, because the top-layer Fe3O4 is amorphous.

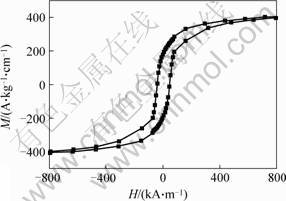

By contrast, rapid annealing the films at 300 the polycrystalline Fe3O4 thin films were fabricated, shown as Fig.1. Its hysteresis-loop is displayed in Fig.4.

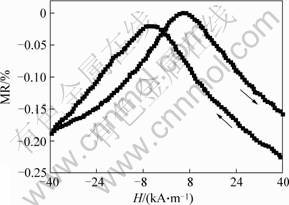

It is evident from Fig.4 that the polycrystalline Fe3O4 films possess large saturation magnetization Ms (420 A/(kg?cm)) and a clear magnetoresistance, shown in Fig.5. The MR curves present negative magnetoresis-tance effect, which is one of the important properties for Fe3O4 films[14]. Therefore, the polycrystalline Fe3O4 films, which are easier to form than the single-crystal films, can be used in fabricating the spintronic devices.

Fig. 4 Hysteresis curves of 150 nm polycrystalline Fe3O4 films

Fig.5 Parallel MR measured at room temperature for polycrystalline Fe3O4 films

4 Conclusions

The growth structure of the Fe3O4 films are very important for them using in spintronic devices. Based on research, the amorphous Fe3O4 film exhibit a superparamagnetic response at a large-scale from 20 nm to 150 nm, and no magnetoresistance was detected. The reason was attributed to the similar structure as APBs. Therefore the amorphous Fe3O4 film is not suitable for using in spintronic devices. In addition, annealing the film at 300 ℃, high quality polycrystalline Fe3O4 film can be fabricated, and it possesses large saturation magnetization Ms (420 A/(kg?cm)) and a clear magnetoresistance. Therefore, crystallize is the primary condition for the half-metallic Fe3O4 being used in spintronic devices.

References[1] TAKAHASHI H, SOVEYA S, HAYAKAWA J, ITO K, KIDA A, YAMAMOTO C, ASANO H, MATSUI M. Fabrication and magnetoresistive effect of current perpendicular to plane devices using half-metallic Fe3O4 thin films on metallic films [J]. J Appl Phys, 2003, 93: 8029-8031.

[2] KRASNIKOV S A, VINOGRADOV A S, HALLMEIER K H, H?HNEC R, ZIESE M, ESQUINAZI P, CHASS? T, SZARGAN R. Oxidation effects in epitaxial Fe3O4 layers on MgO and MgAl2O4 substrates studied by X-ray absorption, fluorescence and photoemission [J]. Mater Sci Eng B, 2004, 109: 207-212.

[3] KIM W, KAWAGUCHI K, KOSHIZAKI N, SOHMA M, MASUMOTO T. Fabrication and magnetoresistance of tunnel junctions using half-metallic Fe3O4 [J]. J Appl Phys, 2003, 93: 8032-8034.

[4] LAI Chih-huang, HUANG Po-hsiang, WANG Yu-jen, HUANG R T. Room-temperature growth of epitaxial Fe3O4 films by ion beam deposition [J]. J Appl Phys, 2004, 95: 7222-7224.

[5] HONG J P, LEE S B, JUNG Y W, LEE J H, YOON K S, KIM K W, KIM C O, LEE C H, JUNG M H. Room temperature formation of half-metallic Fe3O4 thin films for the application of spintronic devices [J]. Appl Phys Lett, 2003, 83: 1590-1592.

[6] DIJKEN S V, FAIN X, WATTS S M, NAKAJIMA K, COEY J M D. Magnetoresistance of Fe3O4/Au/Fe3O4 and Fe3O4/Au/Fe spin-valve structures [J]. J Magn Magn Mater, 2004, 280: 322-326.

[7] AOSHIMA K I, WANG S X. Fe3O4 and its magnetic tunneling junctions grown by ion beam deposition [J]. J Appl Phys, 2003, 93: 7954-7956.

[8] SCHEDIN F, van der LAAN G, THORNTON G. Magnetic properties of stoichiometric and nonstoichiometric ultrathin Fe3O4 (111) films on Al2O3 (0001) [J]. J Appl Phys, 2004, 96: 1165-1169.

[9] TANG Xiao-li, ZHANG Huai-wu, SU Hua, ZHONG Zhi-yong. Study of the buffer-layer and annealing temperature impact on fabrication of polycrystalline Fe3O4 film for the application of spintronic devices [J]. J Vac Sci Technol B, 2005, 23(6): 2314-2318.

[10] LIU H, JING E Y, BAI H L, ZHENG. R K. Structure and magnetotransport properties of Fe3O4-SiO2 composite films reactively sputtered at room temperature [J]. J Appl Phys, 2004, 95: 5661-5665.

[11] VOOGT F C, PALSTRA T T M, NIESEN L, ROGOJANU O C, JAMES M A, HIBMA T. Superparamagnetic behavior of structural domains in epitaxial ultrathin magnetic films [J]. Phys Rev B, 1998, 57: R8107-R8110.

[12] EERENSTEIN W, HIBMA T, CELOTTO S. Mechanism for superparamagnetic behavior in epitaxial Fe3O4 films [J]. Phys Rev B, 2004, 70: 184404-184409.

[13] HIBMA T, VOOGT F C, NIESEN L, van der HEIJDEN P A A, de JONGE W J M, DONKERS J J T M, van derr ZAAG P J. Anti-phase domains and magnetism in epitaxial magnetite layers [J]. J Appl Phys, 1999, 85: 5291-5293.

[14] LIU H, JIANG E Y, BAI H L, ZHENG R K, WEI H L, ZHANG X X. Large room-temperature spin-dependent tunneling magnetoresistance in polycrystalline Fe3O4 films [J]. Appl Phys Lett, 2004, 83: 3531-3533.

Foundation item: Project (90306015) supported by the National Natural Science Foundation of China, and the Youths’ Teacher Supporting Project of University of Electronic Science and Technology of China (UESTC).

Corresponding author: TANG Xiao-li; Tel: +86-28-83201440; Fax: +86-28-83201810; E-mail: tangtang1227@163.com