DOI: 10.11817/j.issn.1672-7207.2019.07.020

套筒长度对加筋碎石桩复合地基路堤变形和稳定性的影响

陈建峰1,李良勇2, 3,徐超1,冯守中3

(1. 同济大学 地下建筑与工程系,上海,200092;

2. 海南大学 土木建筑工程学院,海南 海口,570228;

3. 武汉广益交通科技股份有限公司,湖北 武汉,430074)

摘 要:

验研究套筒长度对加筋碎石桩复合地基路堤变形和稳定性的影响。研究结果表明:(不加筋)碎石桩复合地基路堤下的桩体主要发生鼓胀变形,导致路堤整体产生显著沉降,但未出现剪切滑移趋势;半长加筋碎石桩复合地基路堤边坡及靠近坡肩下的桩体由于抗弯刚度不足,其在路堤荷载下产生弯曲变形及倾倒,同时位于路堤中心、主要承受竖向荷载的桩体则在加筋套筒底部未加筋部位产生明显的鼓胀变形,从而导致路堤产生很大的沉降,其桩顶和桩间土沉降量是碎石桩复合地基路堤的1.7倍左右;全长加筋碎石桩复合地基路堤边坡下桩体在路堤荷载下向外弯曲,由于其抗弯和抗压刚度较大,路堤沉降较小。在实际应用中,应对桩体采用全长加筋方式,以减小加筋碎石桩复合地基路堤的沉降,提高稳定性。

关键词:道路工程;加筋碎石桩;套筒长度;离心模型试验;变形;稳定性

中图分类号:TU416.1 文献标志码:A 文章编号:1672-7207(2019)07-1662-08

Influence of encasement length on deformation and stability of embankments on composite foundation reinforced with geosynthetic-encased stone columns

CHEN Jianfeng1, LI Liangyong2, 3, XU Chao1, FENG Shouzhong3

(1. Department of Geotechnical Engineering, Tongji University, Shanghai 200092, China;

2. College of Civil Engineering and Architecture, Hainan University, Haikou 570228,China;

3. Wuhan Guangyi Transportation Science and Technology Co. Ltd., Wuhan 430074,China)

Abstract: Influence of encasement length on deformation and stability of embankments on composite foundation reinforced with geosynthetic-encased stone columns (GESCs) was investigated using centrifuge model tests. The results show that for (non-encased) stone column composite foundation, columns under embankment mainly bulge which incurs significant settlement whilst no shear slip occurs. For half-length encased stone column composite foundation, columns under embankment slope and near slope shoulder can bend and tilt due to insufficient bending stiffness of columns. Meanwhile, columns at the center of the embankment are mainly compressed and incur obvious bulging deformation at the junction of the encased and non-encased portions. The above two factors lead to great settlement of half-length encased stone column composite foundation. The settlement at the top of columns and soils for half-length encased stone column composite foundation is about 1.7 times than that of the stone column composite foundation. For the full-length encased stone column composite foundation, columns under embankment slope bend outward but the embankment settlement is small due to the larger bending and compressive rigidity of the columns. In practical application, the stone columns need to be encased in full length to reduce the settlement of embankments on the encased stone column composite foundation and improve their stability.

Key words: road engineering; geosynthetic-encased stone column(GESCs); encasement length; centrifuge model test; deformation; stability

碎石桩处理软土地基主要依靠周围土体提供的侧向约束力,当周围土体强度较低时,桩体容易产生鼓胀破坏[1-3]。采用土工合成材料套筒包裹碎石桩体形成加筋碎石桩(也称为土工织物散体桩),可以大幅度提高碎石桩体的侧限作用,进而提高复合地基承载能力,减少沉降量[4-6]。套筒长度影响加筋碎石桩单桩变形和承载力。MURUGESAN等[7]通过二维数值模拟得出最优套筒长度为2倍桩径。KHABBAZIAN等[8-9]通过三维数值模拟发现最优套筒长度随桩体沉降量的增加而增大,但3倍桩径的套筒长度能够明显减小桩体的沉降量和鼓胀量。MURUGESAN等[10]通过室内模型试验发现碎石桩部分加筋时的性能和全长加筋时较接近,但当荷载超过一定值后,部分加筋的碎石桩会表现出应变软化现象。LEE等[11]通过室内模型试验得出最优加筋长度为2~4倍桩径。HONG等[12]通过室内模型试验发现当筋材刚度较低时,桩体最大鼓胀量发生在距桩顶2.5倍桩径部位,随着筋材刚度的增加,桩体最大鼓胀部位不断加深。陈昌富等[13]引入滑块平衡法,建立加筋碎石桩在深层鼓胀破坏模式下的2种计算模型,发现加筋碎石桩的最优加筋长度约为4倍桩径。套筒长度对加筋碎石桩复合地基变形和稳定性也有很大的影响。RAJESH[14]通过二维数值模拟发现,随着套筒长度的增加,复合地基中超孔隙水压力消散加快,桩土应力比增大。YOO等[15-18]通过三维数值模拟研究加筋碎石桩复合地基路堤变形和稳定性,发现全长加筋桩体有效减少复合地基的沉降。ALI等[19-20]通过模型试验发现部分加筋时,桩体的最大鼓胀变形发生在加筋与未加筋部位交界处。赵明华等[21-22]通过室内模型试验研究套管长度对加筋碎石桩侧向和竖向变形以及破坏模式的影响,发现桩体的最大鼓胀变形多发生于未加筋部位,其破坏模式与多种因素相关。OUYANG等[23]通过模型试验研究加筋碎石桩复合地基的承载变形机理,发现部分加筋时碎石桩最大鼓胀变形发生在未加筋部位,而全长加筋时的最大鼓胀变形发生在距桩顶2~4倍桩径处。DUAN等[24]基于弹塑性理论推导复合地基中加筋碎石桩径向应力解析,发现最优加筋长度与荷载水平、桩体的竖向和径向位移有关。赵明华等[25]基于圆孔扩张理论,获得了可考虑筋材与桩、土协调变形的加筋碎石桩复合地基极限承载力计算方法,发现加筋碎石桩的最优加筋长度随着筋材性能和桩周土体条件的变化而变化。上述研究主要采用数值模拟、1 g(g为重力加速度,1g=9.8 m2/s)相似模型试验和理论分析手段研究套筒长度对加筋碎石桩单桩和复合地基变形、承载力和稳定性的影响,尚缺少现场试验和符合实际应力场、变形场的离心模型试验等方面的研究。因此,本文作者采用土工合成材料套筒对碎石桩体进行全长加筋、半长加筋和不加筋的复合地基路堤离心模型试验,以研究套筒长度对复合地基路堤变形和稳定性的影响。

1 离心模型试验

1.1 试验设备和模拟对象

本次试验所采用的离心设备是同济大学150 g·t容量的复合型土工离心机,其最大离心加速度为200g,有效半径为3 m。所采用的模型箱的有效内部长、宽和高分别为900,700和700 mm。

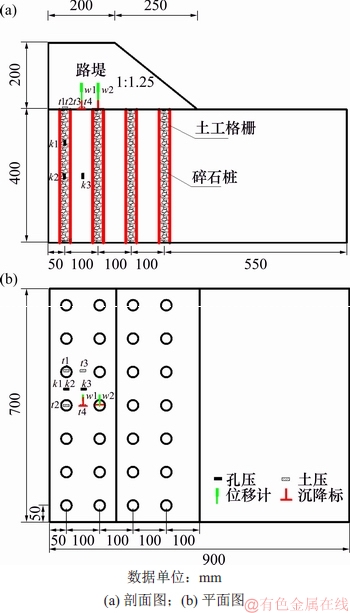

本次试验的模拟对象为高度为5 m,顶宽为5 m,坡率为1:1.25的路堤,路堤下面为10 m厚的软土地基,采用加筋碎石桩进行地基处理,桩长为10 m,桩径为0.8 m,桩间距为2.5 m,正方形布桩。本试验采用的相似比N=25,图1所示为模型尺寸和传感器布设图。本次共开展3组试验,分别采用筋材套筒对碎石桩体进行全长加筋、半长加筋和不加筋试验,其中不加筋碎石桩即为普通的碎石桩。

1.2 模型试验材料

模型地基土由粒径均匀的0.018 mm的商业高岭土制备。液塑限联合试验测得其液限wL=54.2%,塑限wP=34.3%,固结试验测得压缩系数a1-2=0.35 MPa-1,固结不排水剪试验测得有效黏聚力c'=0,有效内摩擦角φ’=27.7°。

选取灰色的尼龙窗纱作为本次模型试验的筋材。将尼龙窗纱制作成圆筒状,接缝处重叠1 cm,采用小型缝纫机来回缝纫4道,然后采用502胶水将缝线和尼龙灰窗纱进行胶结,保证接缝处的强度不低于尼龙窗纱的强度。通过宽条拉伸试验测得其极限抗拉强度为2.5 kN/m,5%拉伸率时的强度为0.9 kN/m,筋材刚度(即5%拉伸率时拉伸力与拉伸率之比)为18 kN/m,乘以相似比25后对应原型筋材的强度和刚度分别为63 kN/m和450 kN/m,与现有商业土工格栅力学性质接近。

采用平均粒径为2.64 mm的石英砂模拟桩体材料,其干密度为1.60~1.85 g/cm3。制备的模型桩桩体密度为1.75 g/cm3。

采用平均粒径为1.23 mm的铁矿砂模拟路堤填土,其干密度为1.80~2.40 g/cm3。模型路堤分层填筑,其密度为2.20 g/cm3。

图1 模型尺寸及传感器布设图

Fig. 1 Model size and arrangement of instruments

1.3 地基制备过程

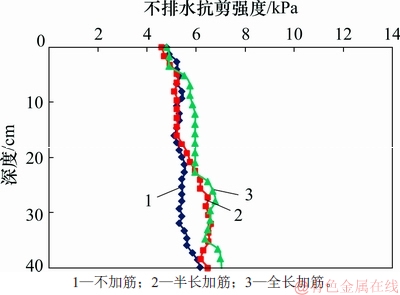

图2 地基土不排水抗剪强度随深度变化曲线

Fig. 2 Relationship between undrained shear strength and depth of foundation soil

图3 成桩及填筑路堤后的复合地基

Fig. 3 Composite foundation with the columns and embankment constructed

1) 将完全饱和的高岭土泥浆在25g离心加速度下固结3 h,而后采用陈建峰等[26]特制的小型静力触探仪对地基土体进行静力触探试验,测得的地基土不排水抗剪强度随深度的变化曲线如图2所示。从图2可以看出:3组试验地基土的不排水抗剪强度相近,约为6 kPa。

2) 将厚度为2 cm的钻有桩位孔的定位板置于地基土上方,将外径与桩径相等的空心薄壁钢管从桩位孔中缓慢压入地基土内,然后取出空心钢管内的土体。

3) 采用全长加筋工况时,将缝制好的全长加筋窗纱套筒放入钢管内,之后通过中空的PVC击实杆贯入石英砂,每贯入5 cm左右用击实杆击实40次,然后分段拔管,保证石英砂顶面与套管底面有2 cm左右的重合段。采用半长加筋工况时,清孔完毕后直接灌入石英砂,分段拔管至20 cm高度后放入缝制好的半长加筋窗纱套筒,然后灌入石英砂分段拔管。

4) 重复步骤3直至所有桩体均打设完毕,然后修剪高出地基土表面的桩体,使得桩体与地基表面平齐,最后分层填筑路堤。图3所示为成桩及填筑路堤后的复合地基。

1.4 传感器布置

如图1所示,为了测量作用于桩顶和桩间土上的压力,在路堤中心线附近桩顶和桩间土上分别布置2个土压力计。在地基土中埋设3个孔隙水压力计测量超孔隙水压力。在桩顶和桩间土上各埋设1个沉降标,然后,在沉降标上布设差动式位移计测量桩顶和桩间土沉降。

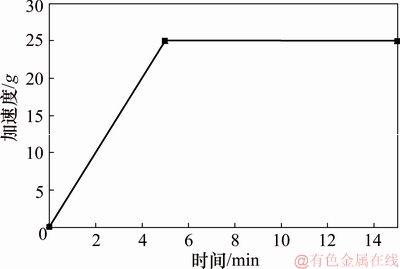

3组试验的加载过程相同,图4所示为加载过程中加速度曲线。由图4可见:在5 min内加速到25g,而后稳定10 min。

图4 加载过程中加速度曲线

Fig. 4 Acceleration curves during loading

2 试验结果

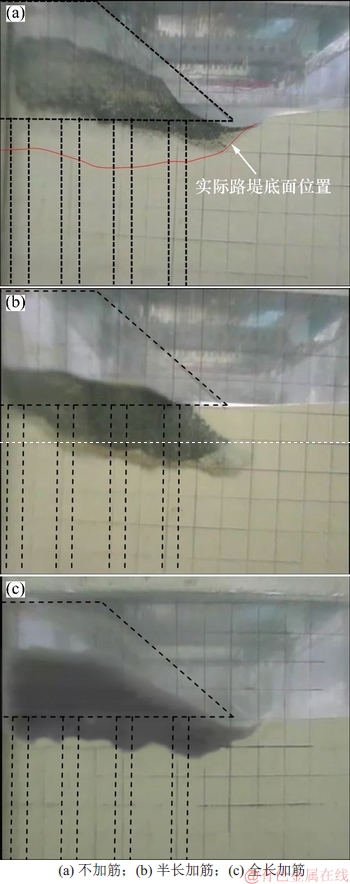

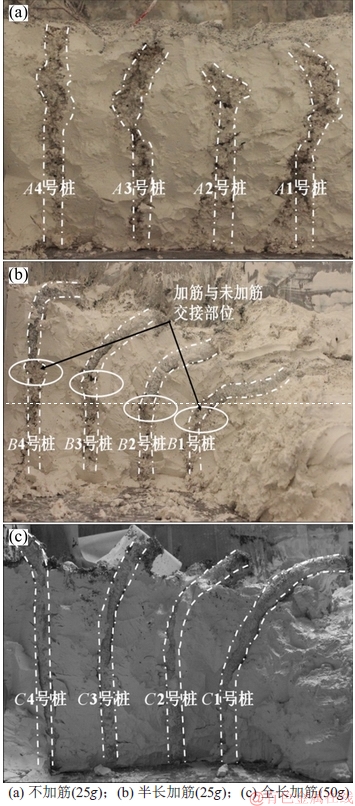

2.1 路堤变形

图5为加速度达到25g后,休止期末时3组试验的路堤变形形态,图5中虚线框为离心模型运转前路堤和桩体的轮廓线。不加筋的复合地基路堤填土呈倾斜状,这是由于模型箱侧壁高岭土向上翻浆遮住了路堤底部填土,但根据试验结束后挖除土体所得到的变形后实际路堤底面位置如图5(a)所示,可见其实际沉降量显著。由图5(b)可见:半长加筋的复合地基路堤产生了很大的沉降,路堤几乎全部陷入地基土中,这是由于边坡及靠近坡肩下的半长加筋桩体在路堤荷载下弯曲变形;全长加筋的复合地基路堤沉降较小且相对比较均匀。

图5 25g末时复合地基路堤变形形态

Fig. 5 Deformed shape of composite foundation embankments at the end of 25g

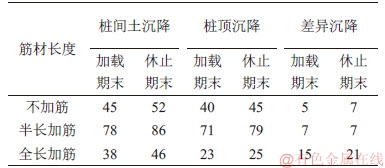

图6所示为3组试验桩顶和桩间土沉降随时间变化曲线图。由图6可见:半长加筋的桩顶和桩间土沉降量较不加筋和全长加筋大很多。表1所示为桩顶和桩间土沉降,在休止期末,半长加筋、不加筋和全长加筋的桩间土沉降量分别约为86,52和46 mm,桩顶沉降量分别约为79,45和25 mm,半长加筋的桩顶和桩间土沉降量为不加筋的1.7倍左右。将半长加筋的桩间土和桩顶沉降量乘以离心模型率N=25而还原成原型,则分别高达2 150和1 975 mm。

全长加筋的桩顶和桩间土之间的差异沉降明显,而半长加筋和不加筋的差异沉降基本一致。由表1可见:在休止期末全长加筋、半长加筋和不加筋时桩顶和桩间土之间的差异沉降,分别约为21,7和7 mm。

图6 桩顶和桩间土沉降随时间变化曲线

Fig. 6 Settlement at the top of columns and soil varied with time

表1 桩顶和桩间土沉降

Table 1 Settlement at the top of columns and soilmm

2.2 超孔隙水压力

图7所示为3组试验3个测点处超孔隙水压力与时间的关系曲线。由图7可见:3个测点的超孔隙水压力变化规律相似,其在加载阶段迅速上升,而在休止阶段则较快速地消散;对同一加筋长度的桩体,k1,k2和k3测点测得的超孔隙水压力依次增大,原因是k1测点较k2和k3测点埋深浅,排水路径短,而k3点位于4根桩中间,其比同一埋深的k2测点排水路径远;在同一测点,半长加筋的超孔隙水压力要大于不加筋的超孔隙水压力,全长加筋的超孔隙水压力最小。这是由于全长加筋桩体的刚度大,导致荷载向桩顶集中,从而作用于桩间土上的荷载减小,超孔隙水压力减小,而半长加筋桩体由于发生弯曲变形,导致作用于桩间土上的荷载增加,其产生的超孔隙水压力较不加筋时更大。

图7 超孔隙水压力随时间变化曲线

Fig. 7 Excess pore water pressures varied with time

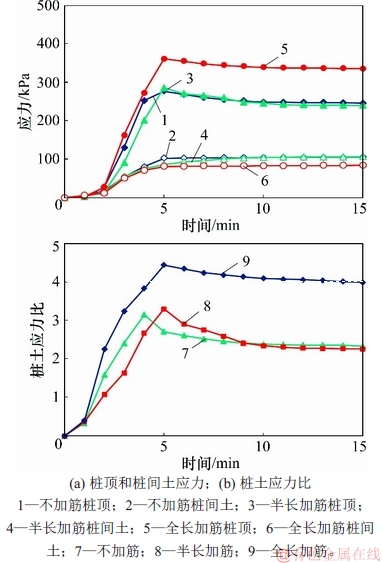

2.3 桩顶和桩间土应力

图8所示为3组试验桩顶和桩间土应力以及桩土应力比随时间变化曲线。由图8(a)可见:三者桩顶应力均明显高于桩间土应力;全长加筋的桩顶应力较半长加筋和不加筋情况偏大,休止期末全长加筋、半长加筋和不加筋三者的桩顶应力分别约为335,239和245 kPa;而全长加筋时的桩间土应力较半长加筋和不加筋时略小,休止期末三者桩间土应力分别为84,106和105 kPa。

由图8(b)可见:三者桩土应力比变化规律基本一致,在加载阶段桩土应力比不断增大,而在休止阶段桩土应力比逐渐减小并趋于稳定。这是由于加载阶段荷载向刚度较大的桩体集中,导致桩土应力比增加;而在休止阶段随着超孔隙水压力的消散,桩间土体固结,土体模量增大,导致部分荷载转移到土体,桩土应力比减小。休止期末,全长加筋、半长加筋和不加筋的桩土应力比分别约为4.0,2.2和2.3,全长加筋的桩土应力比约为后两者的1.8倍。

图8 桩顶和桩间土应力及桩土应力比随时间的变化

Fig. 8 Stress on columns and soil as well as stress concentration ratio varied with time

2.4 桩体变形及路堤稳定性

由于25g下套筒全长加筋碎石桩复合地基的沉降较不加筋和半长加筋情况明显偏小,为进一步探讨其稳定性,故对该组试验继续加至50g,而后休止10 min。50g时休止期末的桩间土和桩顶沉降分别为65和35 mm,介于不加筋和半长加筋的桩间土和桩顶沉降。试验结束后,挖除桩周土体观测这3组试验的桩体变形,如图9所示。

图9 桩体变形图

Fig. 9 Deformations of columns

由图9(a)可见:(不加筋)碎石桩桩体其碎石挤入周围软土中,其以鼓胀变形为主,使得路堤产生了显著沉降;坡脚下的A1号桩上部虽然产生了弯曲变形,但复合地基并没有出现滑移的趋势。尽管碎石桩桩体抗弯刚度很低,然而,当桩体产生鼓胀变形并引起路堤整体较大沉降后,路堤自身的水平荷载也降低,同时桩间土由于固结其强度有所提高,故软土中的碎石桩复合地基路堤不一定出现剪切滑移破坏,而会因桩体鼓胀变形而引起路堤过大沉降。

由图9(b)可见:半长加筋时,坡脚下的B1号桩其半长加筋桩体沿着加筋套筒底部加筋与未加筋交接部位向外倾倒,B2号桩以及靠近坡肩下的B3号桩其半长加筋桩体则发生了弯曲变形,原因应是半长加筋桩体其抗弯刚度不足,在路堤边坡所产生的水平荷载下桩体发生弯曲变形甚至倾倒。而路堤中心的B4号桩体主要承受路堤的竖向荷载,在加筋套筒底部未加筋部位发生明显的鼓胀变形,原因是桩顶应力通过加筋桩体传递至未加筋部位,且软土的侧限能力低,导致未加筋部位的碎石向外挤出而产生鼓胀,所得现象与ALI等[19-20]的一致。可见,半长加筋桩体的抗压刚度也偏小。上述2个因素导致半长加筋碎石桩复合地基路堤产生很大的沉降。

由图9(c)可见:全长加筋时,在离心加速度50g下路堤边坡下的桩体发生了弯曲变形,但由于全长加筋桩体的抗弯刚度高,桩体的弯曲变形程度仍较25g下半长加筋时小。然而,离心模型试验证实了陈建峰等[27-28]采用1g模型试验和三维数值模拟所得出的结果,即加筋碎石桩桩体在路堤荷载下易发生弯曲变形而不易被剪切破坏。

由上所述,套筒加筋长度对加筋碎石桩复合地基路堤变形和稳定性影响显著。半长加筋桩体其抗弯刚度不足,而路堤水平荷载又较碎石桩路堤大,导致路堤沉降更大,稳定性更低,其半长加筋的效果还不如碎石桩的效果。另外,半长加筋碎石桩加筋长度是其桩径的6.25倍,而对加筋碎石桩单桩沉降和承载力研究得出的最优加筋长度为2~4倍桩径的结论,显然不可应用于复合地基中的加筋碎石桩。

在实际应用中,由于路堤自身产生较大水平荷载以及软土本身的侧限能力低,应对碎石桩桩体采用全长加筋方式,以减小加筋碎石桩复合地基路堤的沉降,提高稳定性。

3 结论

1) 对于(不加筋)碎石桩复合地基路堤下的桩体,由于碎石挤入软土中,其主要发生鼓胀变形,导致路堤整体产生显著沉降,但未出现剪切滑移的趋势。

2) 半长加筋碎石桩复合地基路堤边坡及靠近坡肩下的桩体由于抗弯刚度不足,其在路堤荷载下发生弯曲变形及倾倒,同时位于路堤中心、主要承受竖向荷载的桩体则在加筋套筒底部未加筋部位产生明显鼓胀变形,导致路堤产生很大的沉降,其桩顶和桩间土沉降量为碎石桩复合地基路堤的1.7倍左右。

3) 全长加筋碎石桩复合地基路堤边坡下桩体在路堤荷载下向外弯曲,但由于全长加筋的桩体抗弯和抗压刚度较大,路堤沉降较小。

4) 在实际应用中,应对桩体采用全长套筒加筋方式,以减小加筋碎石桩复合地基路堤的沉降及提高稳定性。

5) 后续研究工作将基于离心模型试验,采用三维有限元程序ZSoil建立加筋碎石桩复合地基路堤流固耦合数值模型,进一步研究不同参数对加筋碎石桩复合地基路堤变形及稳定性的影响。

参考文献:

[1] HUGHES J M O, WITHERS N J. Reinforcing of soft cohesive soils with stone columns[J]. Ground Engineering, 1974, 7(3): 42-49.

[2] HUGHES J M O, WITHERS N J, GREENWOOD D A. A field trial of the reinforcing effect of a stone column in soil[J]. Géotechnique, 1975, 25(1): 31-44.

[3] MADAV M R, MIURA N. Soil improvement panel report on stone columns[C]//Proceedings of the 13th International Conference on Soil Mechanical and Foundation Engineering, New Delhi, India. 1994: 163-164.

[4] ALEXIEW D, BROKEMPER D, LOTHSPEICH S. Geotextile encased columns (GEC): load capacity, geotextile selection and pre-design graphs[C]// Proceedings of the Geo-frontiers Conference. Austin, Texas, USA. ASEC, 2005: 497-510.

[5] RAITHEL M, KIRCHNER A, SCHADE C, et al. Foundation of constructions on very soft soils with geotextile encased columns – state of the art[C]// Proceedings of Geo-frontiers Conference, Austin, Texas. ASEC, USA. 2005: 1-11.

[6] 陈建峰, 李良勇, 徐超, 等. 路堤荷载下土工织物散体桩复合地基离心模型试验[J]. 岩土工程学报, 2018, 40(5): 932-938.

CHEN Jianfeng, LI Liangyong, XU Chao, et al. Centrifugal model tests on composite foundation reinforced by geosynthetic-encased stone columns under embankment loads[J]. Chinese Journal of Geotechnical Engineering, 2018, 40(5): 932-938.

[7] MURUGESAN S, RAJAGOPAL K. Geosynthetic-encased stone columns: Numerical evaluation[J]. Geotextiles and Geomembranes, 2006, 24(6): 349-358.

[8] KHABBAZIAN M, MEEHAN C L, KALIAKIN V N. Numerical study of effect of encasement on stone column performance[C]// GeoFlorida 2010: Advances in Analysis, Modeling & Design. USA, ASCE, 2010: 184-193.

[9] KHABBAZIAN M, KALIAKIN V N, MEEHAN C L. Numerical study of the effect of geosynthetic encasement on the behaviour of granular columns[J]. Geosynthetics International, 2010, 17(3): 132-143.

[10] MURUGESAN S, RAJAGOPAL K. Model tests on geosynthetic-encased stone columns[J]. Geosynthetics International, 2007, 14(6): 346-354.

[11] LEE D, YOO C, PARK S. Model tests for analysis of load carrying capacity of geogrid encased stone column[C]// The Seventeenth International Offshore and Polar Engineering Conference. Lisbon, Portugal. International Society of Offshore and Polar Engineers, 2007: 1632-1635.

[12] HONG Yungshan, WU Chosen, YU Yisheng. Model tests on geotextile-encased granular columns under 1-g and undrained conditions[J]. Geotextiles and Geomembranes, 2016, 44(1): 13-27.

[13] 陈昌富, 吴梦婷. 基于滑块平衡法顶部加箍碎石桩承载力计算方法[J]. 岩土工程学报, 2013, 35(7): 1253-1260.

CHEN Changfu, WU Mengting. Computational method for bearing capacity of upper geosynthetic-encased stone columns based on block limit equilibriun method[J]. Chinese Journal of Geotechnical Engineering, 2013, 35(7): 1253-1260.

[14] RAJESH S. Time-dependent behaviour of fully and partially penetrated geosynthetic encased stone columns[J]. Geosynthetics International, 2017, 24(1): 60-71.

[15] YOO C, KIM S B. Numerical modeling of geosynthetic-encased stone column-reinforced ground[J]. Geosynthetics International, 2009, 16(3): 116-126.

[16] YOO C. Performance of geosynthetic-encased stone columns in embankment construction: numerical investigation[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2010, 136(8): 1148-1160.

[17] YOO C. Settlement behavior of embankment on geosynthetic-encased stone column installed soft ground – A numerical investigation[J]. Geotextiles and Geomembranes, 2015, 43(6): 484-492.

[18] 陈建峰, 童振湄, 柳军修, 等. 竖向荷载下加筋碎石桩复合地基数值分析[J]. 岩土力学, 2013, 34(S2): 393-399.

CHEN Jianfeng, TONG Zhenmei, LIU Junxiu, et al. Numerical analyses of composite foundation of geosynthetic-encased stone columns subjected to vertical loading[J]. Rock and Soil Mechanics, 2013, 34(S2): 393-399.

[19] ALI K, SHAHU J T, SHARMA K G. Model tests on geosynthetic-reinforced stone columns: a comparative study[J]. Geosynthetics International, 2012, 19(4): 292-305.

[20] ALI K, SHAHU J T, SHARMA K G. Model tests on single and groups of stone columns with different geosynthetic reinforcement arrangement[J]. Geosynthetics International, 2014, 21(2): 103-118.

[21] 赵明华, 顾美湘, 张玲, 等. 竖向土工加筋体对碎石桩承载变形影响的模型试验研究[J]. 岩土工程学报, 2014, 36(9): 1587-1593.

ZHAO Minghua, GU Meixiang, ZHANG Ling, et al. Model tests on influence of vertical geosynthetic-encasement on performance of stone columns[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(9): 1587-1593.

[22] GU Meixiang, ZHAO Minghua, ZHANG Ling, et al. Effects of geogrid encasement on lateral and vertical deformations of stone columns in model tests[J]. Geosynthetics International, 2016, 23(2): 100-112.

[23] OUYANG Fang, ZHANG Jianjing, Liao Weiming, et al. Characteristics of the stress and deformation of geosynthetic-encased stone column composite ground based on large-scale model tests[J]. Geosynthetics International, 2016, 24(3): 1-13.

[24] DUAN Yuanyu, ZHANG Yiping, CHAN D, et al. Theoretical elastoplastic analysis for foundations with geosynthetic-encased columns[J]. Journal of Zhejiang University SCIENCE A, 2012, 13(7): 506-518.

[25] 赵明华, 何玮茜, 衡帅, 等. 基于圆孔扩张理论的筋箍碎石桩承载力计算方法研究[J]. 岩土工程学报, 2017, 39(10): 1785-1792.

ZHAO Minghua, HE Weixi, HENG Shuai, et al. Calculation method of geogrid-encased stone columns' bearing capacity based on cavity expansion theory[J]. Chinese Journal of Geotechnical Engineering, 2017, 39(10): 1785-1792.

[26] 陈建峰, 柳军修, 马君. 实验室用小型单桥静力触探探头的标定[J]. 同济大学学报(自然科学版), 2012, 40(4): 549-552, 588.

CHEN Jianfeng, LIU Junxiu, MA Jun. Calibration of a miniature cone penetrometer for geotechnical model test[J]. Journal of Tongji University(Natural Science), 2012, 40(4): 549-552, 588.

[27] 陈建峰, 王波, 魏静, 等. 加筋碎石桩复合地基路堤模型试验[J]. 中国公路学报, 2015, 28(9): 1-8.

CHEN Jianfeng, WANG Bo, WEI Jing, et al. Model test of embankment on composite foundation reinforced with geosynthetic-encased stone columns[J]. China Journal of Highway and Transport, 2015, 28(9): 1-8.

[28] CHEN Jianfeng, LI Liangyong, XUE Jianfeng, et al. Failure mechanism of geosynthetic-encased stone columns in soft soils under embankment[J]. Geotextiles and Geomembranes, 2015, 43(5): 424-431.

(编辑 秦明阳)

收稿日期: 2018 -08 -18; 修回日期: 2018 -10 -20

基金项目(Foundation item):国家自然科学基金资助项目(41572266);上海市浦江人才计划项目(14PJD032) (Project(41572266) supported by the National Natural Science Foundation of China; Project(14PJD032) supported by Shanghai Pujiang Program)

通信作者:李良勇,博士,讲师,从事加筋土结构与边坡支护研究;E-mail:liliangyong200@163.com

摘要:采用离心模型试验研究套筒长度对加筋碎石桩复合地基路堤变形和稳定性的影响。研究结果表明:(不加筋)碎石桩复合地基路堤下的桩体主要发生鼓胀变形,导致路堤整体产生显著沉降,但未出现剪切滑移趋势;半长加筋碎石桩复合地基路堤边坡及靠近坡肩下的桩体由于抗弯刚度不足,其在路堤荷载下产生弯曲变形及倾倒,同时位于路堤中心、主要承受竖向荷载的桩体则在加筋套筒底部未加筋部位产生明显的鼓胀变形,从而导致路堤产生很大的沉降,其桩顶和桩间土沉降量是碎石桩复合地基路堤的1.7倍左右;全长加筋碎石桩复合地基路堤边坡下桩体在路堤荷载下向外弯曲,由于其抗弯和抗压刚度较大,路堤沉降较小。在实际应用中,应对桩体采用全长加筋方式,以减小加筋碎石桩复合地基路堤的沉降,提高稳定性。

[6] 陈建峰, 李良勇, 徐超, 等. 路堤荷载下土工织物散体桩复合地基离心模型试验[J]. 岩土工程学报, 2018, 40(5): 932-938.

[13] 陈昌富, 吴梦婷. 基于滑块平衡法顶部加箍碎石桩承载力计算方法[J]. 岩土工程学报, 2013, 35(7): 1253-1260.

[18] 陈建峰, 童振湄, 柳军修, 等. 竖向荷载下加筋碎石桩复合地基数值分析[J]. 岩土力学, 2013, 34(S2): 393-399.

[21] 赵明华, 顾美湘, 张玲, 等. 竖向土工加筋体对碎石桩承载变形影响的模型试验研究[J]. 岩土工程学报, 2014, 36(9): 1587-1593.

[25] 赵明华, 何玮茜, 衡帅, 等. 基于圆孔扩张理论的筋箍碎石桩承载力计算方法研究[J]. 岩土工程学报, 2017, 39(10): 1785-1792.

[26] 陈建峰, 柳军修, 马君. 实验室用小型单桥静力触探探头的标定[J]. 同济大学学报(自然科学版), 2012, 40(4): 549-552, 588.

[27] 陈建峰, 王波, 魏静, 等. 加筋碎石桩复合地基路堤模型试验[J]. 中国公路学报, 2015, 28(9): 1-8.