DOI: 10.11817/j.issn.1672-7207.2015.10.017

飞秒激光共振吸收对掺Pr-Nd硅玻璃烧蚀阈值的影响

罗志,孙小燕,周江夏子,银恺,谭超,邓旺,段吉安

(中南大学 高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘 要:

共振吸收在飞秒激光烧蚀加工中对靶材烧蚀阈值的影响,针对具有特定吸收光谱的掺Pr-Nd硅玻璃(Pr-Nd玻璃)和无特定吸收的石英玻璃,分别采用共振吸收波长585,807 nm和非共振吸收波长720,775 nm对2种靶材进行烧蚀加工,并基于烧蚀轮廓,提出一种靶材烧蚀阈值的计算方法。研究结果表明:在烧蚀阈值附近,靶材的初始种子电子产生方式主要为多光子电离;Pr-Nd玻璃在共振波长585 nm和807 nm的作用下,多光子电离较为剧烈,烧蚀轮廓长度较石英玻璃分别增长19.8%和6.8%,且对于加工波长807 nm,烧蚀阈值较石英玻璃降低12.3%;而对于非共振波长720 nm和775 nm的烧蚀加工,共振烧蚀效应消失,2种靶材的烧蚀轮廓长度和烧蚀阈值基本一致。

关键词:

中图分类号:TN249 文献标志码:A 文章编号:1672-7207(2015)10-3676-06

Influence of femtosecond laser resonant absorption on ablation threshold fluency of Pr-Nd doped silicate glass

LUO Zhi, SUN Xiaoyan, ZHOU Jiangxiazi, YIN Kai, TAN Chao, DENG Wang, DUAN Jian

(State Key Laboratory of High Performance and Complex Manufacturing,

Central South University, Changsha 410083, China)

Abstract: In order to further understand the influence of resonant absorption on ablation threshold fluency of femtosecond laser ablating target, two kinds of wavelength (resonant wavelengths 585 nm and 807 nm, and nonresonant wavelengths 720 nm and 775 nm) were adapted to process Pr-Nd doped silicate glass (Pr-Nd Glass), which owned special absorption spectrum, and ordinary fused silica. Based on ablating profiles, a computing method for calculating ablation threshold fluency was put forward. The results show that the approach of producing initial seed electron is mainly multiphoton ionization near ablation threshold fluencies of the two targets, and the multiphoton ionization is extremely strong when Pr-Nd Glass is ablated by the resonant wavelengths 585 nm and 807 nm. Compared with fused silica, the lengths of ablation profiles increase respectively by 19.8% and 6.8% ablated with these two wavelengths. For wavelength 807 nm, the ablation threshold fluency decreases by 12.3% compared with that of fused silica. However, the resonant ablation efficiencies fade away ablated with the nonresonant wavelengths 720 nm and 775 nm, and there are substantial agreement for the lengths of ablation profiles and the ablation threshold fluencies of the two targets.

Key words: resonant absorption; femtosecond laser; ablation threshold fluency; multiphoton ionization

随着微纳加工领域的飞速发展,脉冲激光烧蚀加工已逐渐成为一种较为成熟的加工方式[1-2]。基于共振吸收的激光加工以其高灵敏性和高选择性越来越受化学[3]、生物[4]和物理[5]等不同领域的青睐。共振激光烧蚀是一种通过调节波长使光子能量与原子或分子能级差匹配,从而达到高烧蚀效率或降低材料烧蚀阈值的加工手段,主要应用于金属[6]、半导体[7]、聚合物[8]和介质[9]等材料。目前,对于共振激光烧蚀的较多研究主要集中于纳秒激光[6]和皮秒激光[7, 10],由于它们聚焦后的加工功率密度较低,因而电子对光子的非线性吸收不够明显。飞秒激光以其极高功率密度的特性,使其与材料的作用机制有了本质的变化[11-12],尤其是非线性吸收效应的显著体现,使得激光与材料的作用过程更为复杂,因而对于飞秒激光共振烧蚀的研究越来越受到学术各界的显著关注。尽管有些小组对于飞秒激光共振烧蚀阈值的研究已开展部分工作[13-14],并从各自的角度对实验结果进行了合理解释,但所得结论并不完全统一,如同一种材料烧蚀阈值的不一致性,对材料去除机理解释也存在部分差异等,因而进一步开展共振吸收对材料烧蚀阈值的影响等方面的工作,为飞秒激光与材料相互作用的研究提供更多的数据基础具有重要意义。本文作者以具有一定吸收特性的Pr-Nd玻璃为实验对象,讨论飞秒激光共振烧蚀对其烧蚀阈值的影响,以及烧蚀阈值光强附近材料所对应的电离机制。

1 实验

1.1 加工靶材

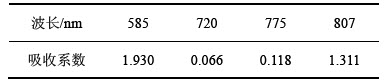

本文所选加工靶材为Pr-Nd玻璃(PNB586,中国江苏省海安县汇虹光电仪器厂),其吸收光谱测试结果如图1所示。实验所选加工波长分别为585,720,775和807 nm,其中720 nm和775 nm为非共振波长;585 nm(最强吸收峰值点)为共振波长,对应于Nd3+能级谱图的2个能级分别是:基态4I9/2,激发态4G5/2;807 nm(第2强吸收峰值点)为另一共振波长,对应于Nd3+能级谱图的2个能级分别是:基态4I9/2,激发态4F5/2+2H9/2。4种加工波长所对应的吸收系数如表1所示。此外,还选用了透明石英玻璃作为另一种靶材,用于实验对比。在400~1 000 nm波段,石英玻璃对任何波长都表现为透射特性,因而其吸收光谱为一条近乎过原点的水平直线。

图1 Pr-Nd玻璃的吸收光谱

Fig. 1 Absorption spectrum of Pr-Nd Glass

表1 Pr-Nd玻璃在不同波长处的吸收系数

Table 1 Absorption rate of Pr-Nd Glass at different wavelengths

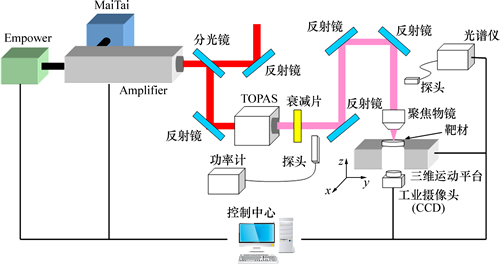

1.2 实验方法

实验中所用激光器为钛宝石飞秒激光器(美国光谱物理公司),其中心波长为800 nm,脉宽为120 fs,重复频率为1 kHz。实验加工装置示意图如图2所示,激光器出射激光首先通过分束镜分光,一束用于800 nm激光的直接加工,另一束通过反光镜导入到激光参数放大器(TOPAS)中,其可以在240~1 640 nm范围内对波长进行调节,精度为0.01 nm。经过TOPAS调节的激光束再通过衰减片将激光功率调节到实验所需5 mW,然后再通过一组反光镜将一定功率的光束导入到物镜中进行聚焦,且聚焦光束传播方向垂直于靶材表面。靶材置于三维运动平台(XMS, 美国理波公司)上,可随三维运动平台在空间范围(长×宽×高)为160 mm×50 mm×25 mm内精确定位和任意方向直线或曲线运动,精度可达5 nm。此外,图中光谱仪用于实时监控不同波长光谱的稳定性,工业摄像头(CCD)用于检测不同波长的空间光强分布模式。加工过程中,首先将靶材置于离聚焦点足够远的地方,以使焦点不足以加工靶材表面;然后使靶材以0.06 mm/s的速度靠近焦点(z方向),同时沿y方向以0.12 mm/s的速度移动;直到焦点进入靶材体内,且表面不足以被损伤为止。

图2 实验加工装置示意图

Fig. 2 Schematic diagram of experimental processing device

2 结果与分析

2.1 烧蚀阈值计算方法

材料的激光烧蚀阈值是指在给定实验条件下,对指定靶材能产生足够强非线性电离的最小脉冲激光能量密度,宏观表现为能破坏靶材表面的最小脉冲激光能量密度。为了精确的计算烧蚀阈值,首先对空间高斯激光束进行如下分析,基模高斯光束的空间光强分布可表述为:

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

其中:r为垂直于光轴的径向位移;z为沿光传播方向的轴向位移;λ为入射激光波长;I0=I(0,0)为束腰ω0中心点处的激光功率密度,其值可通过对I(0, 0)在整个横截面内积分求出,如式(3)所示;P为入射激光总功率;S为入射激光的横截面;ωz为场振幅减小到中心值的1/e或光强降低到中心值的1/e2时的光斑半径,其与束腰半径的关系如式(2)所示;ω0为束腰半径,由于对I(r,z)在光斑半径ωz范围内的积分结果只与输入激光功率有关,如式(4)所示,因而若用一个针孔在横截面内去截激光,并使其轴线与光轴重合,调节针孔在激光传播方向上的位置,使得通过针孔的激光功率为原激光功率的86.466%,则针孔的半径即为该位置的光斑半径ωz ,测量2个不同位置处的光斑半径,即可通过式(5)求出束腰半径ω0。

依据以上分析,若靶材的烧蚀阈值已知,对于给定的加工光路系统,则可以模拟出激光光强在空间的烧蚀阈值包络,其形状如同2个枣胡的轴向叠加,沿光轴方向的截面如图3所示(假设波长为807 nm,靶材烧蚀阈值为1.2 J/cm2);反之,若通过烧蚀加工得到图3所示的包络,则亦可求出对应的靶材烧蚀阈值。

图3 空间高斯分布的烧蚀阈值包络

Fig. 3 Ablation threshold profile of spatial Gaussian distribution

2.2 共振吸收对烧蚀阈值的影响

不同波长的飞秒激光烧蚀加工结果如图4所示,其中图4(a)对应的靶材为Pr-Nd玻璃,图4(b)对应的靶材为石英玻璃;4条烧蚀轮廓对应的波长分别为585,720,775和807 nm。

图4 不同波长的飞秒激光烧蚀加工轮廓

Fig. 4 Profiles ablated by femtosecond laser with different wavelengths

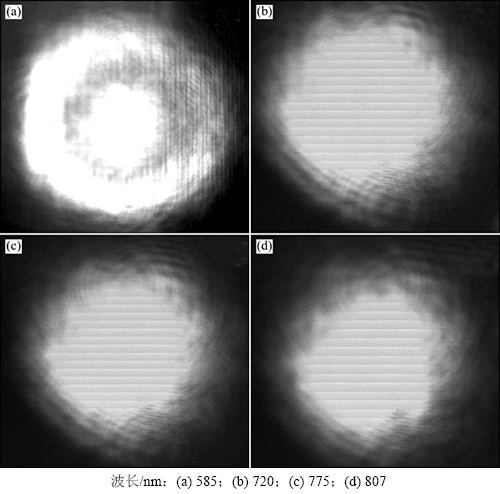

对比图3和4可以看出:波长720,775和807 nm的实验加工图形基本与理论计算结果图形一致,而585 nm波长的实验加工结果偏差很大,通过CCD观测各波长出射激光的空间光强分布模式,发现585 nm波长为旋转对称的高斯横模TEM10分布,而720,775和807 nm 3个波长为较理想的高斯基模TEM00分布,如图5所示。为了基于以上方法计算各波长对应的靶材烧蚀阈值,选用720,775和807 nm波长的实验加工结果作进一步分析。

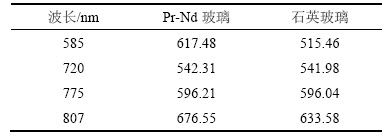

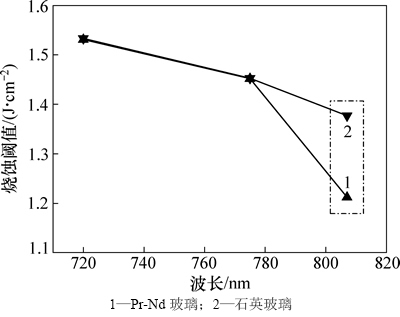

对于波长720,775和807 nm,可以通过测量烧蚀轮廓的尺寸,根据以上理论分析,计算出对应条件下靶材的烧蚀阈值。为了减小测量误差对计算结果的影响,选择测量烧蚀轮廓的长度来计算对应的烧蚀阈值。表2给出了Pr-Nd玻璃和石英玻璃上烧蚀轮廓的长度测量结果。由表2可见:对于非共振波长720 nm和775 nm,2种靶材上的烧蚀长度基本相等;而对于共振波长807 nm,Pr-Nd玻璃上的烧蚀长度较石英玻璃上的烧蚀长度增长了6.8%;计算各个长度对应的烧蚀阈值,对比结果如图6所示,相应的对于非共振波长720 nm和775 nm,2种靶材的烧蚀阈值基本一致;而对于共振波长807 nm,石英玻璃的烧蚀阈值为1.38 J/cm2,Pr-Nd玻璃的烧蚀阈值为1.21 J/cm2,降低了12.3%。尽管共振波长585 nm的加工结果无法推算出准确的烧蚀阈值,但对比2种靶材上的烧蚀轮廓长度(Pr-Nd玻璃上的烧蚀长度较石英玻璃上的烧蚀长度增长了19.8%)可以反映出:对于共振波长585 nm(最强吸收峰值点),Pr-Nd玻璃的烧蚀阈值较石英玻璃的烧蚀阈值有更大的降低。

图5 飞秒激光器在Pr-Nd玻璃4个特征波长处的出射激光空间高斯模式

Fig. 5 Spatial Gaussian modes of incident femtosecond laser at four characteristic wavelengthes of Pr-Nd Glass

表2 不同波长飞秒激光对Pr-Nd玻璃和石英玻璃的烧蚀加工长度

Table 2 Ablation lengthes of Pr-Nd Glass and fused silica ablated by femtosecond laser with different wavelengthes μm

图6 飞秒激光烧蚀加工Pr-Nd玻璃和石英玻璃,不同波长对应的烧蚀阈值

Fig. 6 Ablation threshold fluency at different wavelengthes with femtosecond laser ablating Pr-Nd Glass and fused silica

2.3 多光子电离对共振烧蚀的影响

飞秒激光烧蚀加工介质材料,主要是通过大量光子的激发使靶材局部产生大量自由电子,进而达到瞬时的库仑力失衡并发生库仑爆炸,从而实现局部材料的去除。其中激发大量自由电子的基本过程为:大量光子辐照到靶材表面,使外层价带电子主要通过雪崩电离和碰撞电离机制被激发到导带,从而产生大量自由电子;然后雪崩电离和碰撞电离所需的种子电子来源于初始阶段的光致电离(包括多光子电离和隧道电离2种机制)[15]。在飞秒激光与材料的相互作用过程中,多光子电离和隧道电离共同存在,所占比例取决于Keldysh因子γ[16],该因子主要与材料的属性及入射激光功率密度有关:

(6)

(6)

(7)

(7)

式中:IP为电离势;UP为有质动力势;I为入射激光的功率密度;ω为入射激光角频率。当γ>1时,多光子电离占主导;当γ<1时,隧道电离占主导[14, 17]。对于靶材Pr-Nd玻璃和石英玻璃,在共振波长807 nm处,烧蚀阈值对应的Keldysh因子分别为:γPr-Nd=2.707,γfused silica=2.537,都大于1,因而对于2种靶材,初始种子电子的产生方式主要为多光子电离。

对于普通石英玻璃,价带电子电离所需穿越的带隙宽度为9 eV,由于585 nm和807 nm对应的单光子能量分别为2.119 eV和1.536 eV,因而价带电子需要至少同时分别吸收5个或6个光子才能被激发到导带成为自由电子。但对于Pr-Nd玻璃,光子可以通过共振吸收的方式被价带电子所吸收,使得在飞秒激光与靶材作用过程中,束缚电子对光子的吸收强度得以显著增强,能更容易地电离产生种子电子,从而较普通多光子电离,共振吸收多光子电离能为随后的雪崩电离和碰撞电离提供更多的种子电子。所以在共振波长585 nm和807 nm飞秒激光的作用下,Pr-Nd玻璃的烧蚀轮廓长度较石英玻璃有较明显的增长,烧蚀阈值有所降低,且对于807 nm波长,烧蚀阈值降低了12.3%;而在非共振波长720 nm和775 nm飞秒激光的作用下,无此共振烧蚀效应。

3 结论

1) 依据高斯光束的空间光强分布规律,模拟仿真了靶材的烧蚀阈值轮廓线,并提出了一种基于烧蚀轮廓的靶材烧蚀阈值计算方法。

2) 在相同实验条件下,共振波长585 nm和807 nm飞秒激光在Pr-Nd玻璃上的烧蚀轮廓长度较石英玻璃上的烧蚀轮廓长度分别增长了19.8%和6.8%,且对于807 nm波长,Pr-Nd玻璃的烧蚀阈值较石英玻璃的烧蚀阈值降低了12.3%;而对于非共振波长720 nm和775 nm,2种靶材的烧蚀轮廓长度和烧蚀阈值基本一致。

3) 在多光子电离的情况下,Pr-Nd玻璃在共振吸收波长585 nm和807 nm的作用下,能更容易激发出更多的初始种子电子,使得随后的雪崩电离和碰撞电离更为剧烈,从而实现Pr-Nd玻璃烧蚀阈值的降低。

参考文献:

[1] Reinhardt C, Passinger S, Chichkov B N, et al. Restructuring and modification of metallic nanorod arrays using femtosecond laser direct writing[J]. Applied Physics Letters, 2005, 89: 231117-1-3.

[2] Akichika K, Takeo O, Ryota S, et al. Growth processes of lithium titanate thin films deposited by using pulsed laser deposition[J]. Applied Physics Letters, 2012, 101: 123103-1-4.

[3] Bubb D M, Horwitz J S, Mcgill R A, et al. Resonant infrared pulsed-laser deposition of a sorbent chemoselective polymer[J]. Applied Physics Letters, 2001, 79(17): 2847-2849.

[4] Calvin M, Adam M S, David J R, et al. Laser ablation with resonance-enhanced multiphoton ionization time-of-flight mass spectrometry for determining aromatic lignin wolatilization products from biomass[J]. Review of Scientific Instruments, 2011, 82: 033104-1-10.

[5] Kovaleski S D, Gilgenbach R M, Ang L K, et al. Dynamics of electron beam ablation of silicon dioxide measured by bye laser resonance absorption photography[J]. Applied Physics Letters, 1998, 73(18): 2576-2578.

[6] Allen T M, Kelly P B, Anderson J E, et al. Depth profiling of copper thin films by resonant laser ablation[J]. Applied Physics A, 1995, 61: 221-225.

[7] Wagner M, Schneider H, Winnerl S, et al. Resonant enhancement of second order sideband generation for intraexcitonic transitions in GaAs/AlGaAs multiple quantum wells[J]. Applied Physics Letters, 2009, 94: 241105-1-3.

[8] Johnson S L, Schriver K E, Haglund R F, et al. Effects of the absorption coefficient on resonant infrared laser ablation of poly (ethylene glycol)[J]. Journal of Applied Physics, 2009, 105: 024901-1-6.

[9] Ang L K, Lau Y Y, Gilgenbach R M. Resonant absorption of a short-pulse laser in a doped dielectric[J]. Applied Physics Letters, 1999, 74(20): 2912-2914.

[10] Kolev V Z, Duering M W, Luther-davies B, et al. Compact high-power optical source for resonant infrared pulsed laser ablation and deposition of polymer materials[J]. Optics Express, 2006, 14(25): 12302-12309.

[11] Mangirdas M, Albertas Z, Gabija B, et al. Mechanisms of three-dimensional structuring of photo-polymers by tightly focused femtosecond laser pulses[J]. Optics Express, 2010, 18(10): 10209-10221.

[12] Balling P, Schou J. Femtosecond-laser ablation dynamics of dielectrics: basics and applications for thin films[J]. Reports on Progress in Physics, 2013, 76: 036502-1-39.

[13] 赵清亮, 姜涛, 董志伟, 等. 飞秒激光加工SiC的烧蚀阈值及材料去除机理[J]. 机械工程学报, 2010, 46(21): 172-177.

ZHAO Qingliang, JIANG Tao, DONG Zhiwei, et al. Ablation threshold and material removal mechanisms of SiC processed by femtosecond laser[J]. Chinese Journal of Mechanical Engineering, 2010, 46(21): 172-177.

[14] ZHAO Yadong, JIANG Lan, FANG Juqiang, et al. Resonant effects in nonlinear photon absorption during femtosecond laser ablation of Nd-doped silicate glass[J]. Applied Optics, 2012, 51(29): 7039-7045.

[15] Mao S S, Quere F, Guizard S, et al. Dynamics of femtosecond laser interactions with dielectrics [J]. Applied Physics A, 2004, 79: 1695-1709.

[16] Keldysh L V. Ionization in the field of a strong electromagnetic wave[J]. Soviet Physics JETP, 1965, 20(5): 1945-1957.

[17] Turker T, Francis R. Dichotomy between and multiphoton ionization in atomic photoionization: Keldysh parameter versus scaled frequency[J]. Physical Review A, 2012, 86: 053407-1-10.

(编辑 陈爱华)

收稿日期:2015-03-11;修回日期:2015-06-24

基金项目(Foundation item):国家重点基础研究发展规划(973计划)项目(2011CB013000);国家自然科学基金资助项目(51005250,91123035)(Project (2011CB013000) supported by the National Basic Research Program of China (973 Program); Projects (51005250, 91123035) supported by the National Natural Science Foundation of China)

通信作者:孙小燕,博士,副教授,从事激光加工研究;E-mail:Sunxy@csu.edu.cn

摘要:为了进一步研究共振吸收在飞秒激光烧蚀加工中对靶材烧蚀阈值的影响,针对具有特定吸收光谱的掺Pr-Nd硅玻璃(Pr-Nd玻璃)和无特定吸收的石英玻璃,分别采用共振吸收波长585,807 nm和非共振吸收波长720,775 nm对2种靶材进行烧蚀加工,并基于烧蚀轮廓,提出一种靶材烧蚀阈值的计算方法。研究结果表明:在烧蚀阈值附近,靶材的初始种子电子产生方式主要为多光子电离;Pr-Nd玻璃在共振波长585 nm和807 nm的作用下,多光子电离较为剧烈,烧蚀轮廓长度较石英玻璃分别增长19.8%和6.8%,且对于加工波长807 nm,烧蚀阈值较石英玻璃降低12.3%;而对于非共振波长720 nm和775 nm的烧蚀加工,共振烧蚀效应消失,2种靶材的烧蚀轮廓长度和烧蚀阈值基本一致。