Trans. Nonferrous Met. Soc. China 23(2013) 3462-3469

Effect of temperature on dielectric property and microwave heating behavior of low grade Panzhihua ilmenite ore

Chen-hui LIU1,2,3, Li-bo ZHANG1,2,3, Jin-hui PENG1,2,3, Bing-guo LIU1,2,3, Hong-ying XIA1,2,3, Xiao-chun GU4, Yi-feng SHI4

1. Yunnan Provincial Key Laboratory of Intensification Metallurgy, Kunming 650093, China;

2. National Local Joint Laboratory of Engineering Application of Microwave Energy and Equipment Technology, Kunming 650093, China;

3. Faculty of Metallurgical and Energy Engineering, Kunming University of Science and Technology, Kunming 650093, China;

4. Yunnan Copper Industry Co., Ltd., Kunming 650093, China

Received 19 October 2012; accepted 31 August 2013

Abstract:

The permittivity of low grade Panzhuhua ilmenite ore at 2.45 GHz in the temperatures from 20 °C up to 100 °C was measured using the technology of open-ended coaxial sensor combined with theoretical computation. The results show that both the real (ε′) and imaginary (ε′′) part of complex permittivity (ε′-jε′′) of the ilmenite significantly increase with temperature. The loss tangent (tan δ) is a quadratic function of temperature, and the penetration depth of ilmenite decreases with temperature increase from 20 °C to 100 °C. The increase of the sample temperature under microwave radiation displays a nonlinear relationship between the temperature (T) and microwave heating time (t). The positive feedback interaction between complex permittivity and sample temperature amplifies the interaction between ilmenite and the microwave radiation. The optimum dimensions for uniform heat deposition vary from 10 cm to 5 cm (about two power penetration depths) in a sample being irradiated from both sides in a 2.45 GHz microwave field when temperature increases from room temperature to 100 °C.

Key words:

dielectric properties; Panzhihua ilmenite low grade; microwave heating; temperature increase;

1 Introduction

Due to the worldwide intensive consumption of rutile resource, ilmenite ore is becoming the major resource for the titanium industry [1]. Many processes are used to upgrade low grade ilmenite ore to produce synthetic rutile or high grade titanium slag for further produce titanium dioxide (TiO2). These processes involve a combination of pyrometallurgy, hydro- metallurgy and electrometallurgy. However, these processes can be highly energy intensive and expensive [2]. Panzhihua ilmenite ore accounts for more than 90% of titanium reserves of China. It contains low grade TiO2 and high content of impurities (especially high content of MgO and CaO), which make it difficult to upgrade the ilmenite ore [3]. Therefore, it is desirable to develop new technology for processing ilmenite ore.

The application of microwave heating in minerals processing and treatment has recently attracted high interests from metallurgical industry. Compared with conventional heating methods, the advantages of microwave heating include rapid and selective heating, uniform distribution, high efficiency, fast switch on and off as well as flexible and modular design [4]. As a result of these advantages, microwave heating has been applied in a variety of mineral processing and extractive metallurgy, such as microwave-assisted ore grinding, microwave-assisted carbothermic reduction and leaching of ilmenite, microwave drying, microwave-assisted roasting and smelting sulfide concentrate, microwave- assisted spent carbon regeneration and microwave- assisted waste management [5-8]. Though the application of microwave heating in the metallurgical industry is promising, further studies on the interaction between microwave radiation and minerals and microwave heating mechanism are highly desired to develop innovative techniques for minerals processing and ore treatment using microwave heating.

In the absence of few ores and minerals have magnetic properties, complex permittivity is the fundamental property that determines the microwave absorption of an ore [9]. Complex permittivity  can be expressed as

can be expressed as

ε=ε′-jε′′ (1)

where  ; the real part (ε′) is often referred as the dielectric constant, which reflects the ability of the material to store electromagnetic energy within its structure; the imaginary part (ε′′) is the dielectric loss factor that characterizes the ability of the material to convert the stored electromagnetic energy into thermal energy.

; the real part (ε′) is often referred as the dielectric constant, which reflects the ability of the material to store electromagnetic energy within its structure; the imaginary part (ε′′) is the dielectric loss factor that characterizes the ability of the material to convert the stored electromagnetic energy into thermal energy.

Another important parameter is loss tangent that describes how well the material dissipates stored energy into heat at a given frequency and temperature. Loss tangent (tan δ) can be expressed as

(2)

(2)

the permittivities are a function of both temperature and temperature.

Dielectric properties and microwave heating behaviors of Panzhihua ilmenite and ilmenite concentrate have been reported by several previous researchers. HUANG et al [10] studied the microwave absorbing characteristics and temperature increase characteristics of Panzhihua ilmenite concentrate. The results showed that ilmenite concentrate is a good microwave absorbing mineral and the microwave characteristics are largely reduced after the ilmenite concentrate is oxidized. OUYANG et al [11] studied the temperature increase characteristics of different grade of Panzhihua ilmenite ore. The results indicated that the ilmenite increase from room temperature to 500 °C in 6 min under microwave irradiation at 2.45 GHz. The dielectric constant and dielectric loss of synthetic FeTiO3 were measured in the temperature range of 4.2 K to room temperature in the frequency range of 0.1 to 100 kHz [12]. The results indicated that both the dielectric constant and dielectric loss increase with the increase of sample temperature and conductivity due to the electron hopping between Fe2+ and Fe3+ at higher temperatures. VISWANATH and SESHADRI [13] studied the dielectric constant of ilmenite ore in the temperature range of 25-377 °C. The plot of lg ε′ versus 1/T exhibited two linear regimes and the slope changes around 270 °C. At this temperature, a phase transition was observed in the material. CHITEME and MULABA-BAFUBIAND [14] investigated the dielectric properties of natural ilmenite treated with microwave radiation, and found that the dielectric properties of the microwave-treated sample were similar to those of the sample treated by conventional heating techniques. Their experimental results showed a nonlinear relationship between dielectric loss and sample temperature.

To our best knowledge, no reference has been reported regarding on the temperature dependence of dielectric property of low grade Panzhihua ilmenite at the frequency of 2.45 GHz. Therefore, the major objectives of this work are: 1) measure the complex permittivity (dielectric constant ε′ and dielectric loss ε′′) and loss tangent (tan δ) of the ilmenite ore and their variation with sample temperature (from 20 to 100 °C) at the frequency of 2450 MHz; 2) calculate the penetration depth of low grade Panzhihua ilmenite based on the permittivities; and 3) study the characteristics of temperature increase of the ilmenite ore in different time durations of microwave irradiation.

2 Experimental

2.1 Sample preparation

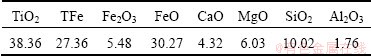

Samples of low grade ilmenite ore were provided by Panzhihua Steel Plant, China. The chemical compositions and grain sizes of the low grade ilmenite are listed in Tables 1 and 2.

Table 1 Chemical components of low grade ilmenite ore (mass fraction, %)

Table 2 Grain size of ilmenite concentrate

As shown in Table 1, titanium dioxide and iron oxides are the main components of the ilmenite ore. Therefore, the dielectric properties of this ore are closely related to that of those components. The original sample was dried at temperature of 105 °C for 24 h in a desiccator.

2.2 Dielectric property measurement system

Several methods have been employed to measure dielectric properties of solid samples including cavity perturbation [15], open-ended coaxial probes [16], waveguide transmission line [17], and free-space [18]. Nevertheless, the open-ended coaxial probe method is currently the most widely used technique for measuring complex dielectric permittivity of materials. It is easy to use and it has a flexible requirement for the sample shape. In addition, this method can take measurements with high accuracy [19].

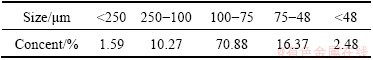

In this work, a hybrid experimental/computational permittivity measuring system developed by the Institute of Applied Electromagnetics in Sichuan University, China, was used to determine the complex permittivity of the ilmenite at different sample temperatures. The schematic diagram of this system is shown in Fig. 1. In the experiment, sample powder is sealed in a resonant cavity (inner diameter of 80 mm, length of 100 mm) made of stainless steel and heated by an electric furnace placed inside the holder cavity. An open ended coaxial sensor (Fig. 2) connected to the Agilent PNA5230 Network Analyzer was used to measure the reflected signals. The probe was placed on the flat surface of a solid sample or inserted into the sample powder for a full contact. The electromagnetic fields around the probe change as the probe contacts with the specimen. The probe receives reflected signals from the sample which contains the information related to the complex dielectric permittivity of the measured sample. The reflected signals were measured by the probe and recorded by the analyzer. A thermocouple was used for temperature measurements. The FDTD method was employed to calculate the distribution of the electromagnetic field around the sensor and the reflection coefficients at different frequencies [20]. Based on the experimental/ computation reflection coefficient, genetic algorithm was used to calculate the complex permittivity of sample [21].

Before the measurements, the network analyzer was warmed for at least 30 min and then calibrated with a load of 50 Ω. The error of the system was around 5% for high-loss materials if a standard calibration process was followed. Permittivity measurements were taken at the frequency of 2.45 GHz. The complex permittivity of the ilmenite sample was measured at 20, 40, 60, 80 and100 °C, respectively.

Fig. 1 Schematic diagram of permittivity measurement system

Fig. 2 Schematic diagram of open-ended coaxial sensor

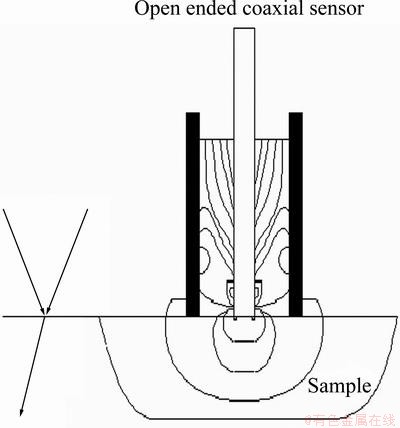

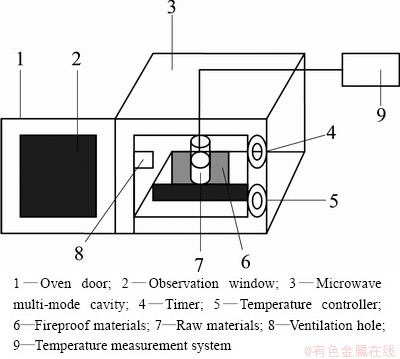

2.3 Microwave heating equipment

Microwave heating equipment was made by the Key Laboratory of Unconventional Metallurgy, has the ability to alter power intensity in the range of 0-3000 W at the frequency of 2.45 GHz. The microwave system consists of two magnetrons, a waveguide and a multi-mode cavity. It is equipped with a water-cooled condenser and a temperature controller to adjust the microwave power level for a preset temperature. The schematic diagram of the microwave heating equipment is shown in Fig. 3. A ceramic crucible container with an inner diameter of 100 mm and a length of 200 mm was located at the center of the stainless steel oven. A thermocouple pyrometer was used to measure the sample temperature. The measurements were recorded by a designated computer.

Fig. 3 Schematic diagram of microwave heating system

To investigate the behavior of microwave heating, a sample of 500 g ilmenite ore was dried at 105 °C for 2 h and then was placed in the crucible. The thermocouple pyrometer was inserted into the center of the sample for taking temperature measurements. Microwave radiation was imposed on the sample. After a preset residence time, the microwave irradiation was stopped and temperature was recorded.

3 Results and discussion

3.1 Real and imaginary permittivity

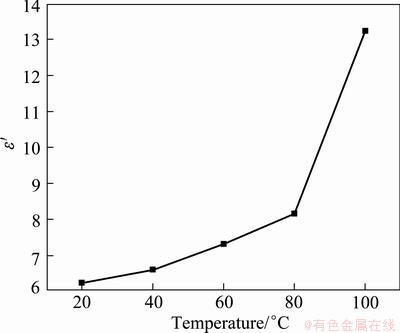

The real permittivity of Panzhihua ilmenite ore variation with the temperature increase at 2.45 GHz is shown in Fig. 4. The real permittivity increased with the increasing of temperature. The real permittivity slightly increased from room temperature to 40 °C. However, it rapidly increased with the increase of sample temperature with a rate of 0.04/°C when temperature was above 40 °C. When above about 80 °C, the increase rate of real permittivity with temperature became extremely high. Although the temperature limit in the measurement was 100 °C, the real permittivity of ilmenite which increased with the increasing of temperature had the same trend with the dielectric constant of nickeliferous laterite ores and kaolin ores [22]. Compared with other ores and minerals, the low grade ilmente ore has a higher value.

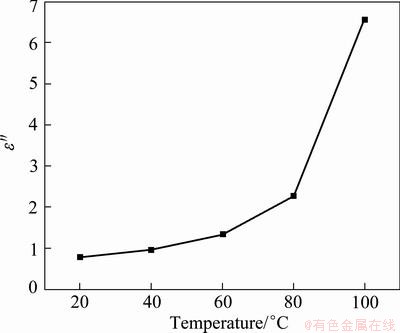

Figure 5 shows the imaginary permittivity of Panzhihua ilmenite ore variation with the temperature increase at 2.45 GHz. The imaginary permittivity was lower than the real part in the range of tested temperatures, while the trend of temperature increase was similar with that of real permittivity. In the temperatures between 20 and 60 °C, the imaginary permittivity slightly increased with temperature. This increase became more rapidly when the temperature was above 60 °C and this quick increase was maintained in the temperature range of 60-100 °C.

Fig. 4 Variation of real part of complex permittivity with sample temperature

Fig. 5 Variation of imaginary part of complex permittivity with sample temperature

The real part of anatase TiO2 powder is 2.9±0.29 and the imaginary part is (6.2±2.1)×10-3 in the microwave frequency regime between 2.9 and 3.2 GHz [23]. The low grade ilmenite has higher values of ε′ and ε′′ than anatase TiO2 powder at room temperature, especially the values of ε′′, which indicates that ilmenite ore is very good at absorbing microwave radiation. DERVOSE et al [23] measured the dielectric properties of high temperature sintered pure TiO2powder at room temperature and between 20 kHz and 1000 Hz, and the result showed that dielectric constant of rutile has the similar trend with the Panzhihua ilmenite ore. But the dielectric constant is easily affected by microwave frequency and it is instability. The ilmenite in our work is an ion crystal and has complex minerals. On the interfaces between various compounds a large number of ions and electrons exist, most ions and electrons will produce relaxation phenonmenon under microwave field. The imaginary of permittivity of a dielectric is directly proportional to the conductivity. The number of ions and electrons of ilmenite will increase with increasing of temperature, making loss factor of ilmenite increase with temperature increasing. Ilmenite will absorb more electromagnetic energy and convert it into thermal energy, and thermal energy makes ilmenite generate temperature increase.

Pervious studies on ilmenite showed that the increase in conductivity of ilmenite at higher temperatures is due to the increase in the number of pairs of (Fe2+, Fe3+) and (Ti3+, Ti4+) [24]. When ilmenite is heated with microwave radiation at the frequency of 2.45 GHz, orientation (dipolar) polarization is the dominant polarization and the associated relaxation phenomena constitute the loss mechanisms [25]. At room temperature, the Ti4+ ion has the minimum potential. Therefore, it is off-centered and gives rise to electric dipoles. The energy levels of Ti4+ rapidly increase with temperature. At a large scale, this feature makes the dielectric constant of ilmenite expeditiously increase with temperature, while it triggers a fast ionic relaxation process at a micro scale. Due to the relationship between ε′′ and conductivity σ, more microwave energy is converted into thermal energy with the increase of ε′′, which leads to a quick increase in ilmenite temperature [26].

3.2 Loss tangent and penetration depth

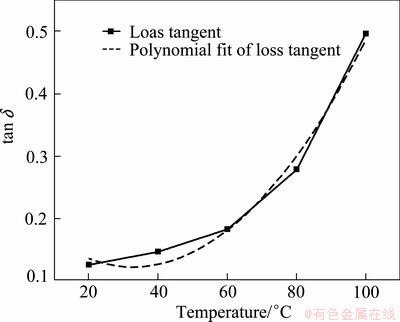

The values of loss tangent of the ilmenite ore at the frequency of 2.45 GHz were calculated using Eq. (2) and the results are shown in Fig. 6.

Fig. 6 Variation of loss tangent with sample temperature

From Eq. (2), an increase in tan δ is a result of more rapid increase in ε′′ than that in ε′. The experimental results revealed that the variation of tan δ with sample temperature had a similar pattern with that of ε′ and ε′′. The values of tan δ increased with a rate of 0.0014/°C from room temperature to 60 °C. The increase rate was about 0.01/°C when temperature was above 60 °C. At room temperature, tan δ was only 0.12, but it rapidly increased to 0.5 when the sample was heated to 100°C. The variation of loss tangent with temperature at 2450 MHz can be expressed as follows when the temperature was between 20 and 100 °C:

tan δ=0.2104-0.00533T+0.00008T2 (3)

The values of loss tangent of ilmenite are much higher than that of pure TiO2 powder, limonite ore and goethite ore. Panzhihua ilmenite has not only the similar high dielectric constant as pure TiO2 powder but also the high loss factor, indicating that Panzhihua ilmenite has strong ability to absorb microwave energy and transform the thermal energy.

The power penetration depth (Dp) is defined as the depth where the strength of microwave field is reduced to 1/e of its surface value and is expressed with the following equation:

(4)

(4)

where λ0 is the wavelength, λ0=12.24 cm in 2.45 GHz; π is a constant. The penetration depth of Panzhihua ilmenite ore can be calculated by Eq. (4) based on the measured results of dielectric properties.

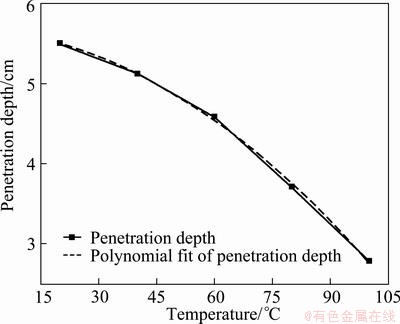

Figure 7 shows the variation of penetration depth of ilmenite ore with temperature at 2.45 GHz. Second order polynomial equation was used to fit the curve of temperature dependence of penetration depth, the result was shown as

Dp=5.6806-0.00368T-2.5464e-4T2 (5)

The R2 value is 0.99846. A high correlation value and low deviations indicate this equation can be used for prediction.

Fig. 7 Variation of penetration depth of sample with temperature and polynomial fitting curve

As shown in Fig. 7, the optimum dimensions for uniform heat deposition in a sample being irradiated from both sides in a 2.45 GHz microwave field vary from 10 to 5 cm (about two power penetration depths) when temperature increases from room temperature to 100 °C. The deposited microwave energy can be relatively uniformly distributed by double-sided irradiation according to the penetration depth, and rapidly relatively uniform temperature increase can be achieved. In a larger sample, there will be obvious temperature gradients. In a smaller sample, a central hot spot may be produced by surface cooling. The accurate determination of penetration depth helps to optimize the load size in the microwave applicator.

3.3 Microwave heating behavior

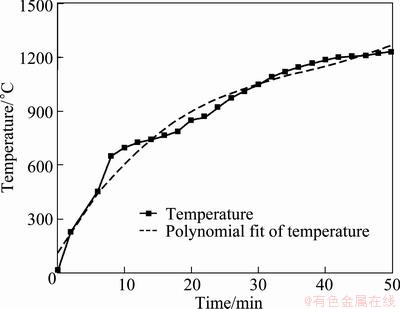

The temperature variation of the Panzhihua low grade ilmenite with microwave heating time was shown in Fig. 8. The sample temperature nonlinearly increased with heating time. Figure 8 shows that the sample temperature increased from room temperature to 1230 °C within 60 min, which indicates that ilmenite ore has strong ability to absorb microwave energy and convert it into heat.

Fig. 8 Variation of sample temperature with microwave heating time

Temperature increase rate of the ilmenite under microwave irradiation between 25-700 °C, 700-900 °C, 900-1120 °C are 67.9, 15.8, 20 and 6.94 °C/min, respectively. This result is in good agreement with the dielectric properties of the ilmenite. At lower temperatures, the ilmenite ore can absorb only a small fraction of microwave radiation energy imposed to it because of the low ε′ and ε′′ values. Consequently, only a small portion of the radiation energy was converted to thermal energy and the sample temperature increased slowly. When temperature was above 60 °C, the values of ε′ and ε′′ increased swiftly that induced a fast increase in sample temperature in a short time. This positive feedback interaction between dielectric property and sample temperature explains the mechanism that the ilmenite ore can be heated to a very high temperature in a short time by the application of microwave radiation because the material can absorb a much larger fraction of radiation energy at higher temperatures. In the temperature range from 700 up to 900 °C, the temperature increase rate of the sample was lower than that in the temperature range between 100 and 700 °C. The sample kept a high temperature increase rate from 900 up to 1120 °C, with the growing effect of conductivity of sample, the temperature increase rate of sample decreased with time, making the sample keep a constant temperature. This result suggests that one of the differences between conventional heating and microwave heating is that the process of microwave heating is nonlinear because the heating starts inside. Regression analysis shows that the relation between the sample temperature and microwave heating time can be expressed by the following equation:

T=111.7214+62.32872t-1.4069t2+0.01247t3 (4)

With an R2 of 0.97357, Eq. (4) is a good representation of microwave heating behavior of the low grade ilmenite. This result agrees well with the previous studies of CHITEME et al [14]. This phenomenon also occurred in other minerals and ores such as nickeliferous limonitic laterite ores and oil shall [9]. ZHANG et al [27] investigated microwave absorbing properties of high titanium slag, and the results showed that the temperature of high titanium slag can increase from room temperature to 1050 °C in 5 min, indicating a higher temperature increase rate than Panzhihua ilmenite ore [27]. High titanium slag has more content of TiO2 and less impurities. Dielectric properties of high content of TiO2 makes that the high titanium slag has a quicker temperature increase rate. Different dielectric phases are commonly contained in minerals. When heated by microwave radiation, components of high dielectric constant and high dielectric loss can absorb more electromagnetic energy from microwave radiation and cause increase in temperature. This temperature increase induces the change in dielectric properties. On the other hand, components of low dielectric constant cannot be well heated by microwave radiation. In these materials, mass and heat transfer is the key factor of temperature changes. Some minerals have very low dielectric constants and hardly absorb microwave radiation at low temperatures. However, the dielectric constants of these minerals appear to be high at higher temperatures. In this case, materials of high dielectric constant can be added to those minerals for effective microwave heating. Since different components of an ore have different dielectric properties, stress discrepancy occurs on the surface of a lump sample of such ore, and such discrepancy generates cracks and crackles on the surface. Therefore, the grinding time of microwave-pretreated minerals can be significantly shorter than that without microwave pretreatment.

4 Conclusions

1) The real and imaginary parts of complex permittivity of low grade Panzhihua ilmenite significantly vary with temperature. Loss tangent is related to sample temperature by a quadratic function between 20 and 100 °C. With the temperature increase, the imaginary part increases rapidly, and therefore, the coupling of microwave radiation with the ilmenite ore is dramatically improved.

2) The optimum dimensions for uniform heat deposition vary from 10 to 5 cm (about two power penetration depths) in a sample being irradiated from both sides in a 2.45 GHz microwave field when temperature increases from room temperature to 100 °C.

3) The increase in sample temperature triggers the increase in conductivity of some ions at grain boundaries, which leads to an increase in the dielectric loss factor, in turn, speeds up the increase of temperature. This positive feedback interaction between complex permittivity and sample temperature makes the ilmenite ore absorb a much larger fraction of microwave radiation and converts the electromagnetic energy into thermal energy more effectively.

References

[1] CHACHULA F, LIU Q. Upgrading a rutile concentrate produced from Athabasca oil sands tailings [J]. Fuel, 2003, 82(8): 929-942.

[2] ZHANG Wen-sheng, ZHU Zhao-wu, CHEN Chu-yong. A literature review of titanium metallurgical process [J]. Hydrometallurgy, 2011, 108(3-4): 177-188.

[3] ZHANG Li, HU Hui-ping, WEI Liang-ping, CHEN Qi-yuan, TAN Jun. Hydrochloric acid leaching behaviour of mechanically activated Panxi ilmenite (FeTiO3) [J]. Separation and Purification Technology, 2010, 73(2): 173-178.

[4] CHEN Guo, CHEN Jin, GUO Sheng-hui, LI Jun, SRINIVASAKANNAN C, PENG Jin-hui. Dissociation behavior and structural of ilmenite ore by microwave irradiation [J]. Applied Surface Science, 2012, 258(10): 4826-4829.

[5] GUO Sheng-hui, CHEN Guo, PENG Jin-hui, CHEN Jin, LI Dong-bo, LIU Li-jun. Microwave assisted grinding of ilmenite [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 2122-2126.

[6] LI Yu, LEI Ying, ZHANG Li-bo, PENG Jin-hui, LI Chang-long. Microwave drying characteristics and kinetics of ilmenite [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(1): 202-207.

[7] PENG Jin-hui, YANG Jing-jing, HUANG Ming, HUANG Meng-yang. Microwave-assisted reduction and leaching process of ilmenite [C]//Antennas, Propagation and EM Theory, 2008. ISAPE 2008. 8th International Symposium. IEEE, 2008: 1383-1386.

[8] PICKLES C A. Microwave in extractive metallurgy: Part 2. A review of applications [J]. Minerals Engineering, 2009, 22(13): 1112-1118.

[9] PICKLES C A. Microwave in extractive metallurgy: Part 1. Review of fundaments [J]. Minerals Engineering, 2009, 22(13): 1102-1111.

[10] HUANG Meng-yang, PENG Jin-hui, LEI Ying, HUANG Ming, ZHANG Shi-min. The temperature rise and microwave-absorbing characteristics of ilmenite concentrate in microwave field [J]. Journal of Sichuan University: Engineering Science Edition, 2007, 39(2): 111-115. (in Chinese).

[11] OUYANG Hong-yuan, YANG Zhi, XIONG Xue-liang, WANG Kang-hai. Study on elevated temperature curve and fluidization leaching behaviour of illmenite in microwave field [J]. Mining and Metallurgical Engineering, 2010, (2): 73-75. (in Chinese)

[12] IWAUCHI K, KIYAMA M,NAKAMURA T. Dielectric properties of FeTiO3 [J]. Physica Status Solidi, 1991, 127(2): 567-575.

[13] VISWANTH R P, SESHSDRI A T. The ferroelectric characteristics in Fe-Ti-O system [J]. Solid State Communications, 1991, 92(10): 831-842.

[14] CHITEME C, MULABA-BAFUBIANDI A F. An investigation on electric properties of microwave treated natural ilmenite [J]. Journal of Materials Science, 2006, 41(8): 2365-2372.

[15] MATTHEW K T, RAVEENDRANATH U. Cavity perturbation techniques for measuring dielectric parameters of water and other allied liquids [J]. Sensors Update, 2000, 7(1): 185-210.

[16] NELSON S O, BARTLEY P G Jr. Measuring frequency- and temperature-dependent dielectric properties of food materials [J]. IEEE Transactions on Instrumentation and Measurement, 2002, 51(4): 589-592.

[17] DESHPANDE M D, REDDY C J, TIEMSIN P I, CRAVEY R. A new approach to estimate complex permittivity of dielectric materials at microwave frequencies using waveguide measurements [J]. IEEE Transactions on Microwave Theory and Technology, 1997, 45(3): 359-365.

[18] SEO I S, CHIN W S, LEE D G. Characterization of electromagnetic properties of polymeric composite materials with free space method [J]. Composite Structures, 2004, 66(1-4): 533-542.

[19] SHEEN N I, WOODHEAD I M. An open-ended coaxial probe for broad-band permittivity measurement of agricultural products [J]. Journal of Agricultural Engineering Research, 1999, 74(2): 193-202.

[20] FRANCOIS T, BERNARD J. Complete FDTD analysis of microwave heating processes in frequency-dependent and temperature-dependent media [J]. IEEE Transactions on Microwave Theory and Technology, 1997, 45(1): 108-117.

[21] HUANG Ka-ma, CAO Xue-jun, LIU Chang-jun, XU Xiao-bang. Measurement/computation of effective permittivity of dilute solution in saponification reaction [J]. IEEE Transactions on Microwave Theory and Technology, 2003, 51(10): 2106-2111.

[22] PICKLES C A. Microwave heating behaviour of nickeliferous limonitic laterite ores [J]. Minerals Engineering, 2004, 17(6): 775-784.

[23] DERVOSC T, THIRIOS E, NOVACOVICH, J, VASSILIOU P. Permittivity properties of thermally treated TiO2 [J]. Materials Letters, 2004, 58(9): 1502-1507.

[24] JONSCHER A K. Dielectric relaxation in solids [J]. Journal of Physics D: Applied Physics, 1999, 32(14): R57-R70.

[25] METAXAS A C. Microwave heating [J]. Power Engineering Journal, 1991, 5(5): 237-247.

[26] WRIGHT, R A, COCKS F H, VANIMAN D T, BLAKE R D, MEEK T T. Thermal processing of ilmenite and titania-doped haematite using microwave energy [J]. Journal of Materials Science, 1989, 24(4): 1337-1342.

[27] ZHANG Li-bo, CHEN Guo, PENG Jin-hui, CHEN Jin, GUO Sheng-hui, DUAN Xin-hui. Microwave absorbing properties of high titanium slag [J]. Journal of Central South University of Technology, 2009, 16(4): 588-593.

温度对低品位攀枝花钛铁矿的介电性能和微波加热行为的影响

刘晨辉1,2,3,张利波1,2,3,彭金辉1,2,3,刘秉国1,2,3,夏洪应1,2,3,顾晓春4,史谊峰4

1. 云南省特种冶金重点实验室,昆明 650093;

2. 微波能工程应用及装备技术国家地方联合工程实验室,昆明 650093;

3. 昆明理工大学 冶金与能源工程学院,昆明 650093;

4. 云南铜业股份有限公司,昆明 650093

摘 要:采用实验和理论计算相结合的同轴探头反射法测定低品位钛铁矿粉末在2.45 GHz频率下和20~100 °C之间的介电特性,并测定钛铁矿在微波场下的升温特性。结果表明:低品位钛铁矿的复介电常数的实部和虚部都随着矿物温度的升高而显著增大;矿物的损耗角正切和温度有二次函数关系;矿物的穿透深度随温度的升高而不断降低。微波场下钛铁矿的升温曲线表明温度和微波辐射时间具有非线性关系。复介电常数与温度的相互作用关系使微波能和钛铁矿的相互作用不断增强,矿物产生更多热量并产生温升,进一步加剧微波能和矿物的耦合作用。当2.45 GHz的微波从两侧加热钛铁矿时,随着温度从室温上升到100 °C,优化的物料厚度是从10 cm逐渐降低到5 cm。

关键词:介电特性;攀枝花钛铁矿;微波加热;温升

(Edited by Chao WANG)

Foundation item: Projects (51090385, 5114703) supported by the National Natural Science Foundation of China; Project (2012DFA70570) supported by the International S&T Cooperation Program of China; Project (2011FZ038) supported by the Applied Basic Research Project of Yunnan Province

Corresponding author: Li-bo ZHANG; Tel: +86-0871-5191046; E-mail: lbzhang@kmust.edu.cn

DOI: 10.1016/S1003-6326(13)62889-7

Abstract: The permittivity of low grade Panzhuhua ilmenite ore at 2.45 GHz in the temperatures from 20 °C up to 100 °C was measured using the technology of open-ended coaxial sensor combined with theoretical computation. The results show that both the real (ε′) and imaginary (ε′′) part of complex permittivity (ε′-jε′′) of the ilmenite significantly increase with temperature. The loss tangent (tan δ) is a quadratic function of temperature, and the penetration depth of ilmenite decreases with temperature increase from 20 °C to 100 °C. The increase of the sample temperature under microwave radiation displays a nonlinear relationship between the temperature (T) and microwave heating time (t). The positive feedback interaction between complex permittivity and sample temperature amplifies the interaction between ilmenite and the microwave radiation. The optimum dimensions for uniform heat deposition vary from 10 cm to 5 cm (about two power penetration depths) in a sample being irradiated from both sides in a 2.45 GHz microwave field when temperature increases from room temperature to 100 °C.