J. Cent. South Univ. (2012) 19: 869-874

DOI: 10.1007/s11771-012-1085-3![]()

Influence of cerium on microstructures and mechanical properties of Al-Zn-Mg-Cu alloys

LAI Jian-ping(赖建平)1, JIANG Rong-piao(姜荣票)1, LIU Hua-shan(刘华山)1,

DUN Xiao-long(敦小龙)1, LI Yan-fen(李艳芬)1, LI Xiao-qian(李晓谦)2

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract:

Effect of element cerium (Ce) on microstructure and mechanical properties of Al-Zn-Mg-Cu alloys has been investigated by transmission electron microscopy (TEM), scanning electron microscopy (SEM), differential scanning calorimetry (DSC) and hardness test. The results show that addition of Ce can remarkably refine the as-cast grains and eutectic microstructure. A transformation from Mg(Zn,Cu,Al)2 phase to Al2CuMg phase is observed during homogenization. Furthermore, the Ce addition introduces changes in the precipitation process and consequently in the age-hardening behavior of the alloy. Microstructural measurements reveal that the addition of Ce promotes the precipitation of η' phase, but it also partly retards the precipitation of GP zones. The density of precipitates decreases in a certain degree and rod-like η' precipitates increase when Ce content is from 0.2% to 0.4% (mass fraction).

Key words:

Al-Zn-Mg-Cu alloy; cerium; microstructure; homogenization; precipitation;

1 Introduction

Ultra-high strength Al-Zn-Mg-Cu series alloys are widely used in aerospace industries due to their good combination of high strength and low density [1-2]. Microalloying has been utilized to improve the mechanical properties of aging hardenable aluminum alloys throughout these years [3-5]. Recent investigations have shown that addition of Sc in aluminum alloy is effective due to formation of stable fine Al3(Sc,Zr) particles. However, Sc is too expensive to be used in industrial production.

Of moderate cost, Ce has been considered as one of such alternatives. ZHANG et al [6] found that Ce atoms segregate at grain boundaries of Al-Li alloys and resulted in higher strength. GOVINDARAJU et al [7] observed that mechanical properties of Al-Zn alloy can be improved by adding small amount of Ce. XIAO et al [8] reported that addition of Ce to Al-Cu-Mg-Ag alloy facilitates the precipitation of finer and denser Ω and phases. It was also observed that Ce can decrease the as-cast grain size of Al-Cu–Mg-Ag alloy [9]. Furthermore, WANG et al [10] found that addition of Ce into 2519 alloy can retard the formation of GP zones and promote the precipitation of denser and finer

phase. CHAUBEY et al [11] studied the effect of Ce in 7055 alloy and reported that dendritic structure refined with morphology of precipitates changed from spherical to needle shape when Ce content varied from 0.1% to 0.4% (mass fraction). In brief, addition of Ce can not only effectively modify the as-cast microstructures but also alter the precipitation process for aluminum alloys.

Despite the previous work, the understanding of the rare earth element Ce on aluminum alloys is still limited and especially there is a lack of information available for effect of the element Ce addition in Al-Zn-Mg-Cu alloys. The aim of this work is therefore to study the as-cast and homogenized microstructures and mechanical properties of Ce-containing Al-Zn-Mg-Cu alloys.

2 Experimental

The nominal compositions of the investigated alloys are listed in Table 1. The starting materials include pure Al (99.99%), Mg (99.9%), Zn (99.9%) bulks, Al-Cu (51.98%) and Al-Ce (56.95%) master alloys (mass fraction). The starting materials were melted in a graphic crucible at 780 °C by an electrical resistance furnace. C2Cl6 was used for slag-removing and degassing and then the melt was poured into an iron mold of 2 cm × 10 cm × 17 cm. The obtained ingots were homogenized at 460 °C for 30 h. Subsequently, the homogenized ingots were hot-rolled at 400 °C to plates of about 2 mm in thickness. Finally, the rolled plates were solution- treated at 477 °C for 1 h followed by water-quenching and aged at 120 °C for different durations.

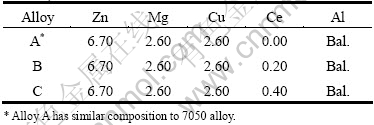

Table 1 Nominal compositions of experimental alloys (mass fraction)

Microstructure analysis was performed on transmission electron microscope (TEM, Tecnai G2 20) and scanning electron microscope (SEM, Sirion 200) with energy dispersive X-ray spectroscope (EDS, GENESIS 60S). The Vickers hardness measurements were conducted with a 29.4 N load and each data given here represent the average of at least five measurements. Phase analysis was performed with X-ray diffractometer (XRD, Rigaku D/max 2500). The scanning speed was 2 (°)/min. Differential scanning calorimetry (DSC, NERZSCH DSC200F) was used to examine the precipitation kinetics of the strengthening phases at a heating rate of 10 °C/min.

3 Results

3.1 As-cast and homogenized microstructures

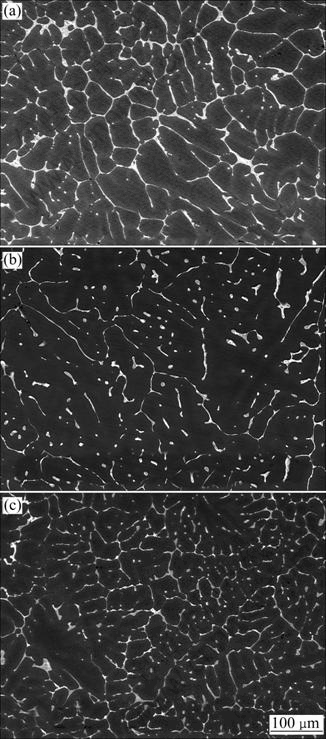

The as-cast microstructures of the alloys with different amounts of Ce are shown in Fig. 1. It can be seen that the eutectic microstructure in the Ce-free alloy (Alloy A) is coarse and continuous, distributing reticularly along the grain boundary. With 0.2% and 0.4% Ce (mass fraction) addition (Alloys B and C), the eutectic microstructure becomes discontinuous and thin and the as-cast grains of the alloys are refined.

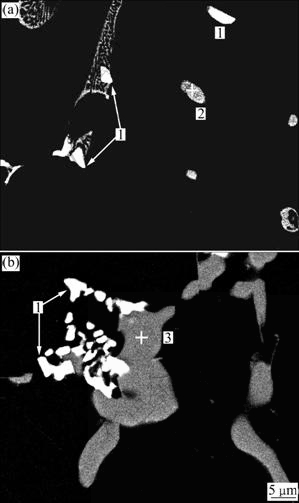

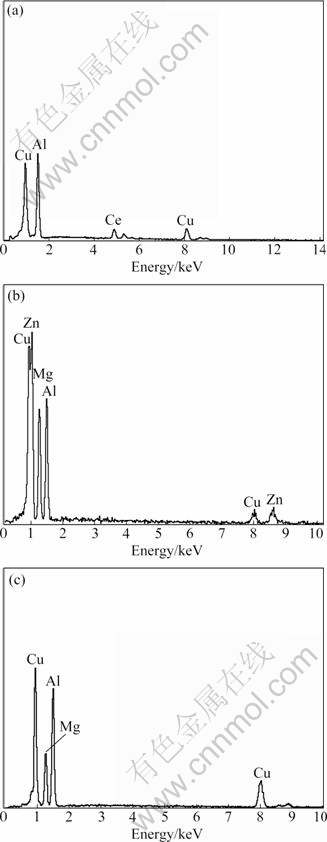

The SEM images of Alloy C are shown in Fig. 2. Energy dispersive X-ray spectroscope is adopted to analyze the particles in the as-cast and homogenized alloy C. The results are demonstrated in Fig. 3 and listed in Table 2. It is known that the bright particles, marked as 1 in Fig. 2(a), are rich in Al, Cu, and Ce, and the molar ratio of Al:Cu:Ce is close to 8:4:1. The gray particles, marked as 2, are composed of Al, Zn, Mg and Cu. Particles, marked as 3, are composed of Al, Cu and Mg, being close to the stoichiometric Al2CuMg phase. Hence, it can be inferred that the bright particles (marked 1) are Al8Cu4Ce phase, the gray phase (marked 2) should be Mg(Zn,Cu,Al)2 phase, and the phase (marked 3) should be Al2CuMg.

Fig. 1 SEM images of as-cast microstructures of three alloys: (a) Alloy A; (b) Alloy B; (c) Alloy C

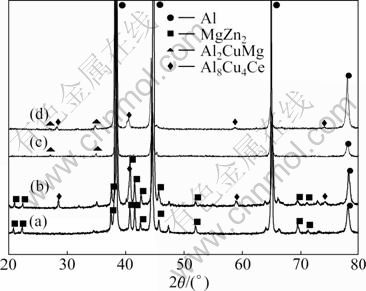

Compared with the as-cast alloy, the XRD patterns of Al8Cu4Ce in homogenized state are much weaker, indicating that Al8Cu4Ce particles have dissolved into α-Al matrix during homogenization (Fig. 4). Besides, MgZn2 disappears and large isolated Al2CuMg phase forms after homogenization. So, it can be concluded that Mg(Zn,Cu,Al)2 may transform into Al2CuMg phase during homogenization, which is in agreement with the results in Refs. [12-13].

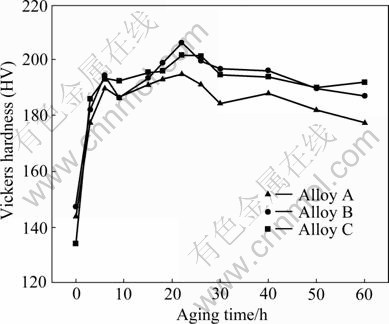

3.2 Hardness curves

The precipitation hardening responses of the alloys are revealed by Vickers hardness curves, which come from the sample after solution treatment at 477 °C for 1 h, hot-rolling and aged at 120 °C (Fig. 5). With the increase of Ce addition, the peak-aging hardness increases from HV195 (Alloy A) to HV206 (Alloy B) and then decreases to HV202 (Alloy C). It is worth emphasizing that the peak-aging condition is achieved after approximately the same time at 22 h, independent of Ce content.

Fig. 2 SEM images of as-cast and homogenized micro- structures of alloy C: (a) As-cast condition; (b) Homogenized condition

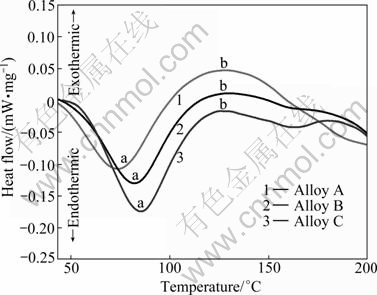

3.3 DSC analysis

Figure 6 shows the DSC curves of the samples after solution treated at 477 °C for 1 h, water quenched and natural aging for 6 h. In light of earlier investigations [14-16] and taking into account the peak temperatures and their sequence, the first endothermic Peak a can be attributed to the reversion of GP zones, and the strong exothermic Peak b corresponds to the formation of η' phase. On one hand, the position of Peak a has been shifted to a higher temperature in Ce-containing alloys, which indicates that Ce addition might suppress the precipitation reaction; On the other hand, the position of the Peak b almost does not change with the Ce content, which indicates that Ce addition does not delay or promote the precipitation process of η' phase formation. The results are in agreement with the hardness data.

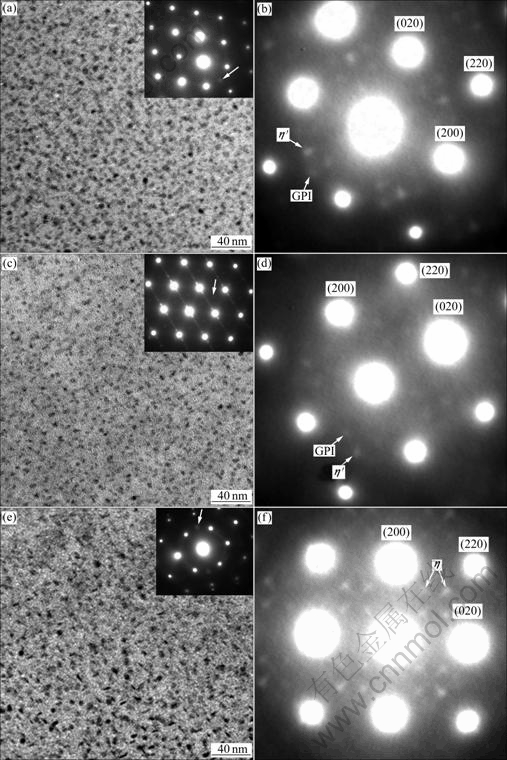

3.4 TEM investigations

Difference in the aging response among the three alloys can be understood by comparing their microstructures. Figure 7 shows the bright field images of precipitate microstructure of the three alloys in á011? zone axis after aging at 120 °C for 22 h. Corresponding to diffraction features of GPI zone and η' phase [11-12], weak diffractions observed at {1, (2n+1)/4, 0} positions and at 1/3 and 2/3{220} positions in the á001?Al projection confirm that the precipitates consist of GPI zones and η′ phase. The η′ precipitates are dominant phases, due to the stronger diffraction spots from η' phase, which are in agreement with recent investigations [17-18]. It can be seen that finer and denser precipitates are observed in the Ce-containing alloys. In addition, the density of precipitates decreases and more rod-like η' precipitates are observed when Ce content increases from 0.2% to 0.4%. It might be attributed to the retardation of GP zones, which can be confirmed by diffraction features from á001?Al projection. Compared with the Ce-free alloy, the diffraction spots from GP zones are weaker in Ce-containing alloys. This result is consistent with the work of CHAUBEY et al [11], which suggests that Ce addition promotes the precipitation of η' precipitates and retards the formation of GP zones.

Fig. 3 EDS patterns of second phase: (a) Phase 1 in Fig. 2(a); (b) Phase 2 in Fig. 2(a); (c) Phase 3 in Fig. 2(b)

Table 2 Results of EDS analysis of compounds in alloy C (molar fraction, %)

Fig. 4 XRD patterns of as-cast specimens: (a) Alloy A (as-cast); (b) Alloy C (as-cast); (c) Alloy A (homogenized); (d) Alloy C (homogenized)

Fig. 5 Vickers hardness curves of alloys aged at 120 °C

Fig. 6 DSC curves of alloys in as-quenched condition

4 Discussion

The present work shows that the Ce addition affects the microstructures and mechanical properties of Al-Zn-Mg-Cu alloys. With Ce addition, the as-cast grains are finer and eutectic microstructures along grain boundaries become discontinuous and thin (Fig. 1). Besides, a transformation of primary particle from Mg(Zn,Cu,Al)2 to S phase Al2CuMg is observed during homogenization.

The influence of Ce addition on the precipitation process during aging is investigated. Firstly, denser and finer precipitates are found in the Ce-containing alloys. And with Ce addition from 0.2% to 0.4%, the density of precipitates decreases, resulting in lower hardness response (Fig. 5). Secondly, more rod-like precipitates are observed while adding Ce content from 0 to 0.4%, which may be due to the retardation of GP zones during aging. This conclusion can be confirmed by DSC and diffraction features from á001?Al projection. The mechanism of Ce enhancing the precipitation of η' phase may be attribute to the larger atom size and high vacancy binding energy. It is reported that atoms considerable larger than Al can affect the nucleation of precipitates [10]. When Ce atoms enter the Al matrix, it inevitably causes the distortion of crystal lattices and raises system energy, due to the larger diameter of Ce atom (0.27 nm) than that of Al atom (0.182 nm). There might be much oversaturated vacancies aggregating around Ce atoms to keep the system at low level of energy. Because of the high vacancy binding energy [19], the Ce atoms would be relatively mobile and able to aggregate to nucleate η' phase. EMBURY and NICHOLSON [20] called it “amoeba-like” movement. Many vacancies are bound to Ce atoms to form Ce-vacancy clusters due to its high vacancy binding energy. And large Ce atoms with accompanying vacancies could reduce the misfit at the edges of η' and hence reduce the interfacial energy. As a result, nucleation of η' precipitate is promoted by Ce addition, which is in close agreement with recent study [10].

Fig. 7 TEM images in á011? zone axis of Al matrix and selected area diffraction patterns from á001? projection of peak-aged alloys: (a), (b) Alloy A; (c), (d) Alloy B; (e), (f) Alloy C

5 Conclusions

1) The eutectic structures in the as-cast Ce- containing alloys are identified as α-Al, Mg(Zn,Cu,Al)2 and coarse Al8Cu4Ce particles. A transformation of primary particle from Mg(Zn,Cu,Al)2 to S phase (Al2CuMg) is observed during homogenization.

2) Denser and finer precipitates are observed in Ce-containing alloys, resulting in higher hardness of Ce-containing alloys. But the density of precipitates decreases to a certain degree while the Ce content is from 0.2% to 0.4%, leading to the decrease in hardness. More rod-like precipitates observed with Ce addition may be due to the retardation of GP zones

Acknowledgement

One of the authors, LIU Hua-shan, would like to thank the support from the Scientific Center for Phase Diagrams and Materials Design, Central South University, China.

References

[1] HEINZ A, HASZLER A, KEIDEL C, MOLDENHAUER S, BENEDICTUS R. Recent development in aluminum alloys for aerospace applications [J]. Materials Science and Engineering A, 2000, 280: 102-107.

[2] WILLIAMS J C, STARKE E J A. Progress in structural materials for aerospace systems [J]. Acta Mater, 2003, 51(19): 5775-5799.

[3] SENATORAVA O G, UKSUSNIKOV A N, LEQOSHINA S F, FRIDLYANDER I N, ZHENQINA I P. Influence of different minor additions on structure and properties of high-strength Al-Zn-Mg-Cu alloy sheets [J]. Materials Science Forum, 2000, 331: 1249-1254.

[4] SENKOV O N, BHAT R B, SENKOVA S V, SCHLOZ J D. Microstructure and properties of cast ingots of Al-Zn-Mg-Cu alloys modified with Sc and Zr [J]. Metallurgical and Materials Transactions A, 2005, 36(8): 2115-2126.

[5] SENKOV O N, SHAGIEV M R, SENKOVA S V, MIRACLE D B. Precipitation of Al3(Sc,Zr) particles in an Al-Zn-Mg-Cu-Sc-Zr alloy during conventional solution heat treatment and its effect on tensile properties [J]. Acta Materialia, 2008, 56(15): 3723-3738.

[6] ZHANG Min-gang, CHANG Zhi-liang, YAN Jun-min, HAO Jin-zhi. Investigation of the behaviour of rare earth element cerium in aluminum-lithium alloys by the method of internal friction [J]. Journal of Materials Processing Technology, 2001, 115(3): 294-297.

[7] GOVINDARAJU H K, JAYARAJ T, SADANANDARAO P R, VENKATESHA C S. Evaluation of mechanical properties of as-cast Al-Zn-Ce alloy [J]. Materials and Design, 2010, 31(1): S24-S29.

[8] XIAO D H, WANG J N, DING D Y, YANG H L. Effect of rare earth Ce addition on the microstructure and mechanical properties of an Al-Cu-Mg-Ag alloy [J]. Journal of Alloys and Compounds, 2003, 352(1/2): 84-88.

[9] SONG Min, CHEN Kang-hua, HUANG Lan-ping. Effect of Ce and Ti on the microstructures and mechanical properties of an Al-Cu-Mg-Ag alloy [J]. Rare Metals, 2007, 26: 28-32.

[10] WANG Wen-tao, ZHANG Xin-ming, GAO Zhi-guo, JIA Yu-zhen, YE Ling-ying, ZHENG Da-wei, LIU Ling. Influences of Ce addition on the microstructures and mechanical properties of 2519A aluminum alloy plate [J]. Journal of Alloys and Compounds, 2010, 491(1/2): 366-371.

[11] CHAUBEY A K, MOHAPATRA S, JAYASANKAR K, PRADHAN S K, SATPATI B, SAHAY S S, MISHRA B K, MUKHERJEE P S. Effect of cerium addition on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy [J]. Transactions of The Indian Institute of Metals, 2009, 62(6): 539-543.

[12] MONDAL C, MUKHOPADHYAY A K. On the nature of T(Al2MgZn3) and S(Al2CuMg) phases present in as-cast and annealed 7055 aluminum alloy [J]. Materials Science and Engineering A, 2005, 391(1/2): 367-376.

[13] FAN Xi-gang, JIANG Da-min, MENG Qing-chang, ZHONG Li. Microstructural evolution of an Al-Zn-Mg-Cu alloy during homogenization [J]. Materials Letters, 2006, 60(12): 1475-1479.

[14] DESCHAMPS A, LIVET F, BRECHET Y. Influence of predeformation on aging in an Al-Zn-Mg alloy: I. Microstruture evolution and mechanical properties [J]. Acta Mater, 1999, 47(1): 281-292.

[15] JIANG X J, NOBLE B, HANSEN V, TAFTO J. Influence of zirconium and copper on the early stages of aging in Al-Zn-Mg alloys [J]. Metallurgical and Materials Transactions A, 2001, 32(5): 1063-1073.

[16] BUHA J, LUMELY R N, CROSKY A G. Secondary ageing in an aluminum alloy 7050 [J]. Materials Science and Engineering A, 2008, 492(1/2): 1-10.

[17] SHA G, CEREZO A. Early-stage precipitation in Al-Zn-Mg-Cu alloy [J]. Acta Materialia, 2004, 52(15): 4503-4516.

[18] CHEN Jun-zhou, ZHEN Liang, YANG Shou-jie, SHAO Wen-zhu, DAI Sheng-long. Investigation of precipitation behavior and related hardening in AA7055 aluminum alloy [J]. Materials Science and Engineering A, 2009, 500(1/2): 34-42.

[19] RAMAN K S, DAS E S S, VASU K I. Values of solute-vacancy energy in aluminum matrix for Ag, Be, Ce, Dy, Fe, Li, Mn, Nb, Pt, Sb, Si, Y and Yb [J]. Scripta Metallurgica, 1970, 4(4): 291-293.

[20] EMBURY J D, NICHOLSON R B. The nucleation of precipitates: The system Al-Zn-Mg [J]. Acta Metallurgica, 1965, 13(4): 403-417.

(Edited by HE Yun-bin)

Foundation item: Project(2010CB731706) supported by the National Basic Research Program of China

Received date: 2011-02-25; Accepted date: 2011-06-23

Corresponding author: LIU Hua-shan, Professor, PhD; Tel: +86-731-88876735; E-mail: hsliu@mail.csu.edu.cn

Abstract: Effect of element cerium (Ce) on microstructure and mechanical properties of Al-Zn-Mg-Cu alloys has been investigated by transmission electron microscopy (TEM), scanning electron microscopy (SEM), differential scanning calorimetry (DSC) and hardness test. The results show that addition of Ce can remarkably refine the as-cast grains and eutectic microstructure. A transformation from Mg(Zn,Cu,Al)2 phase to Al2CuMg phase is observed during homogenization. Furthermore, the Ce addition introduces changes in the precipitation process and consequently in the age-hardening behavior of the alloy. Microstructural measurements reveal that the addition of Ce promotes the precipitation of η' phase, but it also partly retards the precipitation of GP zones. The density of precipitates decreases in a certain degree and rod-like η' precipitates increase when Ce content is from 0.2% to 0.4% (mass fraction).