DOI:10.19476/j.ysxb.1004.0609.2019.08.12

粉末高温合金U720Li的热加工行为

吴凯西,谭黎明,何英杰,邓 睿,刘 锋

(中南大学 粉末冶金研究院,长沙 410083)

摘 要:

通过Gleeble-3180热模拟机对具有细晶组织的镍基粉末高温合金U720Li进行高温热压缩变形实验,分析该合金在1000~1150 ℃、0.001~1 s-1应变速率的变形条件下的流变行为。利用采集的应力-应变数据计算材料的热变形激活能,构建材料的本构方程,建立合金的热加工图,并通过微观组织观察对热加工图进行解释。结果表明:失稳区主要位于低温高应变速率区域,合金未发生明显动态再结晶现象,晶界处的应力集中导致沿晶裂纹的产生。在1150 ℃、0.01 s-1条件下,晶粒明显长大;在1100 ℃、0.001 s-1条件下,变形能够获得细小均匀的晶粒组织。

关键词:

文章编号:1004-0609(2019)-08-1676-08 中图分类号:TG132.32 文献标志码:A

镍基粉末高温合金具有晶粒均匀、组织均匀、无宏观偏析、合金化程度高、屈服强度高和疲劳性能优异等优点,因此,被广泛用于制备航空发动机上构件[1-4]。目前,制备粉末高温合金主要流程为“制粉-热等静压-热挤压-等温锻造”,该工艺存在加工步骤多、流程长等问题[5]。其中锻造和热挤压是制备粉末高温合金的重要工艺过程,但在镍基粉末高温合金的热加工过程中,存在变形阻力大、热加工温度区间窄等困难[6-7]。与许多镍基粉末高温合金相比,U720Li合金中含有大量的合金化元素,如Cr、Co、Mo、Al等[8]。由于合金元素质量分数高,在高温下组织控制困难,而合金的性能取决于微观组织,需制定合理的热加工工艺获得细小均匀的晶粒组织。

而流变应力是表征合金的塑性变形特性的最基本参数,决定了塑性变形所需要的载荷和能量。近年来,PRASAD等[9-10]提出的动态加工材料模型(DMM)被认为是一个研究变形机理和优化加工工艺参数的有效途径。利用热加工图能够分析和预测材料在不同区域即不同变形条件下的变形特点和变形机制,如动态回复、动态再结晶、楔形开裂、空洞形成、绝热剪切带等,进而获得热加工的“安全区”和“失稳区”,以获得最佳热加工工艺参数,避免缺陷产生。

目前,对U720Li合金的研究主要集中在变形合金的热处理工艺、拉伸及蠕变性能和热加工行为,而对粉末高温合金U720Li合金的热加工行为研究鲜有报道[11-14]。本实验通过Gleeble-3180热模拟试验机对细晶粉末高温合金U720Li进行等温热压缩,研究了其变形机理,构建了本构方程,同时利用热加工图,确立了该合金最优的高温热加工工艺。采用光学显微镜(Optical microscope, OM)和电子背散射衍射(Electron back scattering diffraction, EBSD)等方法分析了合金不同变形条件的微观组织演化,验证所建立合金的热加工图。

1 实验

本实验采用的U720Li合金的名义成分如表1所示。材料的制备流程为:母合金真空感应熔炼,氩气雾化制粉,装入不锈钢包套后除气封焊,1130 ℃高温热挤压成型,挤压比为16:1。实验前进行了(1050 ℃, 1 h)热处理降低残余应力。最后,通过机械加工获得表面光滑的d 6 mm×9 mm的热压缩试样。

在Gleeble-3180上进行热压缩实验得到应力-应变曲线,利用采集数据计算合金热变形激活能并构建本构方程及其热加工图。实验工程应变为50%,实验温度为1000~1150 ℃,温度间隔为50 ℃,加热速度为5 ℃/s,应变速率为0.001、0.01、0.1和1 s-1;在试样两端采用石墨片润滑减小摩擦阻力的影响,加热到所需温度后保温3 min,变形结束后快速水冷保留高温组织。采用光学显微镜(LEICA-DM4000M)、场发射扫描电镜(FEI Quanta 650)及电子背散射衍(Electron backscatter diffraction,EBSD)分析合金晶粒组织,使用Channel 5软件处理数据,金相试样腐蚀剂为100 mL HCl、100 mL CH3CH2OH和5 g CuCl2。

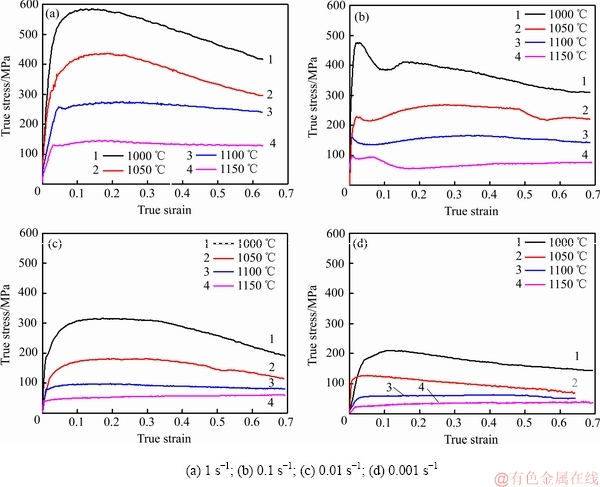

表1 合金名义成分

Table 1 Chemical composition of superalloy (mass fraction, %)

2 结果与讨论

2.1 原始组织观察

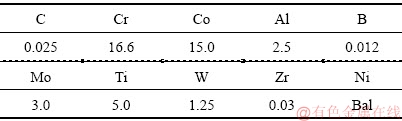

图 1所示为合金原始组织的电子背散射衍射电子像、晶粒统计和晶界取向差分布图。选取500个以上的晶粒进行统计,其平均晶粒直径为8.94 μm,小晶粒所占比例较多,晶粒直径在15 μm以下的比例高达80%,其原始组织小角度晶界(小于10°)比例约为12%,平均晶界取向差 为36.2°,在热挤压过程中,几乎所有晶粒已完成动态再结晶。

为36.2°,在热挤压过程中,几乎所有晶粒已完成动态再结晶。

2.2 应力-应变曲线

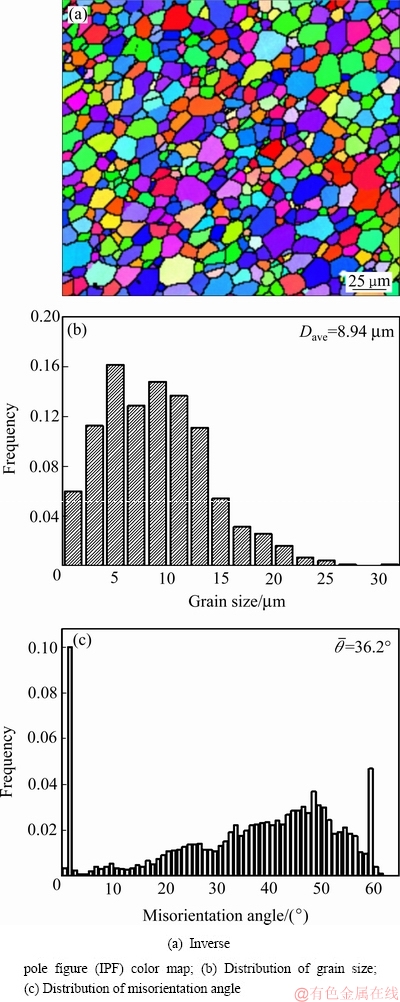

图2所示为合金在不同的温度和应变速率下的应力-应变曲线。一般来说,流变应力显著受到变形温度和应变速率的影响,流变应力随着变形温度的增加和应变速率的减慢而减小。从图2可以看出,合金在不同温度和应变速率下,真应力-应变曲线具有相似的特征,随着应变增加,应力迅速增加,这是因为合金在变形初期,形成大量位错,产生明显加工硬化效果。当流变应力达到峰值时,动态软化与加工硬化第一次达到动态平衡。当应变大于峰值应变时,应力随着应变的增加而降低,呈现出显著的动态软化特征,此时合金发生动态回复或动态再结晶。在变形温度达到1100 ℃以上时,随着应变进一步增加,加工硬化与动态软化达到第二次动态平衡,最终流变应力逐渐趋于稳定[15-17]。

图1 热挤压后微观组织

Fig. 1 Microstructure of as-extruded specimen

2.3 本构方程的建立

图2 不同应变速率下的流变应力-应变曲线

Fig. 2 Strain–stress curves under various temperatures at strain rates

在变形过程中,流变应力与变形温度和应变速率存在密切的关系。在高温热塑性变形中,变形速率受热激活能控制,因此,采用双曲正弦型Arrhenius方程构建研究中合金的本构关系模型,其表达式如式(1)所示[18]:

(1)

(1)

式中: 为应变速率;T为变形温度;

为应变速率;T为变形温度; 为流变应力;Q为热变形激活能;n为应力指数;A和

为流变应力;Q为热变形激活能;n为应力指数;A和 为材料常数;R为摩尔气体常数。热变形激活能Q如式(2)所示:

为材料常数;R为摩尔气体常数。热变形激活能Q如式(2)所示:

(2)

(2)

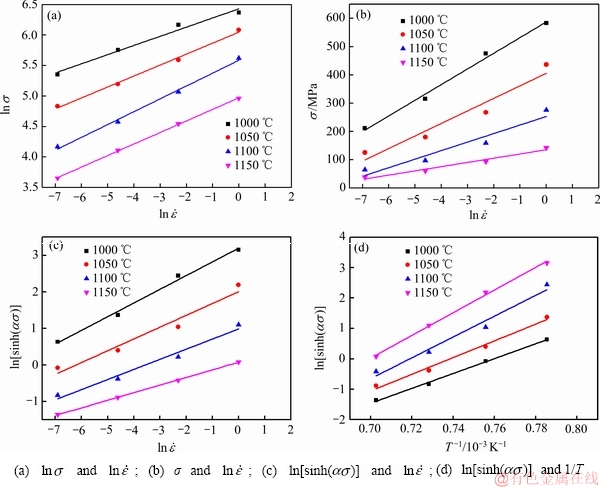

取不同变形温度和应变速率下的峰值应力,峰值应力自然对数 与

与 关系如图3(a)所示,峰值应力

关系如图3(a)所示,峰值应力 与

与 关系如图3(b)所示,通过线性拟合来确定

关系如图3(b)所示,通过线性拟合来确定 -

- 和

和 -

- 最优斜率;通过计算可得

最优斜率;通过计算可得 为0.0066。

为0.0066。 -

- 和

和 -1/T的拟合曲线分别如图3(c)和(d)所示,可求出热变形激活能Q为867.88 kJ/mol。

-1/T的拟合曲线分别如图3(c)和(d)所示,可求出热变形激活能Q为867.88 kJ/mol。

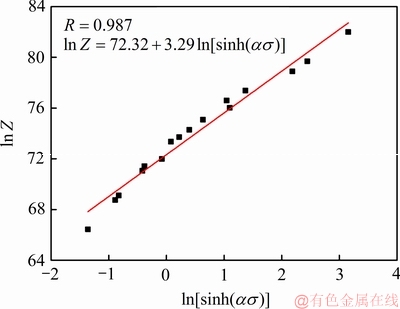

ZENER-HOLLOMON等[19]提出了温度补偿应变速率的本构方程,将材料变形过程各参数之间相关联,即Zener-Hollomon (Z)参数的概念,其表达式为

(3)

(3)

两侧去自然对数可得

(4)

(4)

对 和

和 进行线性拟合计算得到n为3.29413和A为2.5657×1031,本构方程如式(5)所示:

进行线性拟合计算得到n为3.29413和A为2.5657×1031,本构方程如式(5)所示:

(5)

(5)

2.4 热加工图建立与分析

图3 不同变量之间的线性拟合

Fig. 3 Relationships between different variables

图4 合金变形过程 参数与

参数与 的关系

的关系

Fig. 4 Relationship between  and

and

热加工性能指的是材料在塑性变形过程中不发生破坏的变形能力,PRASAD等[9]根据功率耗散理论认为总能量P可分为耗散量和耗散协量两部分,其数学定义为

(6)

(6)

式中:G为材料发生塑性变形所消耗的能量;J为材料变形过程中组织演变所耗散的能量。 如式(7)所示:

如式(7)所示:

(7)

(7)

式中:m为应变速率敏感因子;k为常数。m由式(8)所确定:

(8)

(8)

当0<m<1时,J可以表示为

(9)

(9)

当m =1时,材料处于理想线性耗散状态,耗散能量J达到最大值Jmax,即

(10)

(10)

由式(9)和式(10)可得到1个功率耗散因子η:

(11)

(11)

η反映了不同变形温度、不同应变速率下合金的组织演变过程,即η越大,微观组织变化越大,通常来说动态再结晶相关的效率为0.3~0.5[20]。

热加工过程中有些材料可能会发生失稳过程,导致变形缺陷,如流变应力集中、绝热剪切变形、空洞和开裂等。单凭耗散图不足区分安全的加工区域和失稳的加工区域。PRASAD等[21]以大应变塑性变形不可逆热力学的极值原理为基础,提出合金在高温变形流变失稳判据为

<0 (12)

<0 (12)

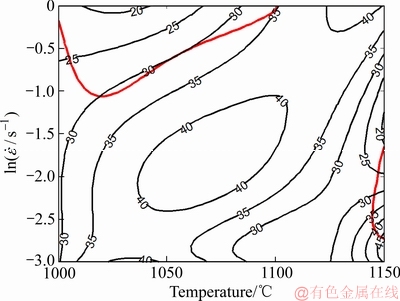

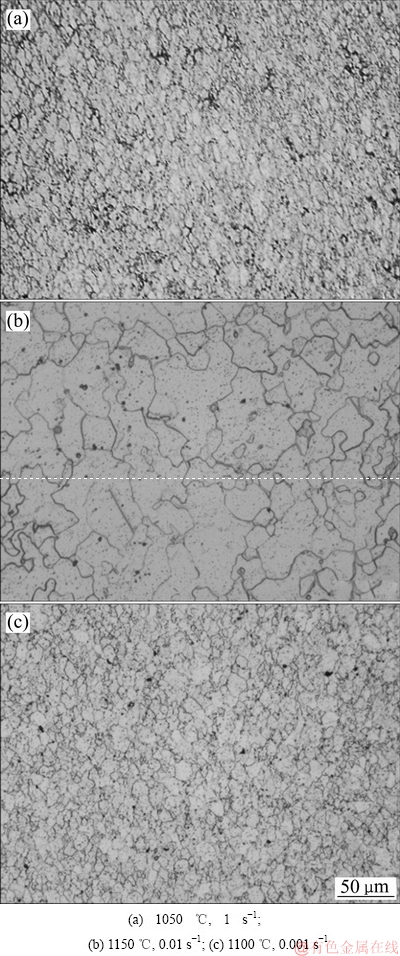

当 为负值时,发生塑性流变失稳,将加工失稳图叠加在功率耗散图上即为热加工图,结果如图5所示。图5中热加工图等值线上的数字表示功率耗散因子的百分数,功率耗散因子的峰值区域主要集中在低应变速率区域,安全区域η越高代表材料的热加工性能越好,可能是热加工最佳区域,而红色线条所围区域为热加工过程中失稳区。当真应变为0.6时,存在2个失稳区,第1个失稳区温度为1000~1090 ℃、应变速率为0.1~1 s-1,发现功率耗散因子η较低,说明材料大部分能量用于塑性变形。通过对1050 ℃、1 s-1变形条件下的微观组织观察发现,晶粒被拉长且具有明显的方向性,变形组织没有得到消除,合金未发生明显的动态再结晶,晶界处的应力集中导致沿晶裂纹的产生(见图6(a))。第2个失稳区温度为1140~1150 ℃、应变速率为0.003~0.04 s-1。观察在1150 ℃、0.01 s-1变形条件下微观组织,发现晶粒在高温的作用下急剧长大(见图6(b)),在加工U720Li合金时应避免这种情况的发生。当变形温度为1100 ℃、应变速率为0.001 s-1时,合金已经完全再结晶,晶粒为细小的等轴晶组织(见图6(c))。

为负值时,发生塑性流变失稳,将加工失稳图叠加在功率耗散图上即为热加工图,结果如图5所示。图5中热加工图等值线上的数字表示功率耗散因子的百分数,功率耗散因子的峰值区域主要集中在低应变速率区域,安全区域η越高代表材料的热加工性能越好,可能是热加工最佳区域,而红色线条所围区域为热加工过程中失稳区。当真应变为0.6时,存在2个失稳区,第1个失稳区温度为1000~1090 ℃、应变速率为0.1~1 s-1,发现功率耗散因子η较低,说明材料大部分能量用于塑性变形。通过对1050 ℃、1 s-1变形条件下的微观组织观察发现,晶粒被拉长且具有明显的方向性,变形组织没有得到消除,合金未发生明显的动态再结晶,晶界处的应力集中导致沿晶裂纹的产生(见图6(a))。第2个失稳区温度为1140~1150 ℃、应变速率为0.003~0.04 s-1。观察在1150 ℃、0.01 s-1变形条件下微观组织,发现晶粒在高温的作用下急剧长大(见图6(b)),在加工U720Li合金时应避免这种情况的发生。当变形温度为1100 ℃、应变速率为0.001 s-1时,合金已经完全再结晶,晶粒为细小的等轴晶组织(见图6(c))。

2.5 微观组织分析

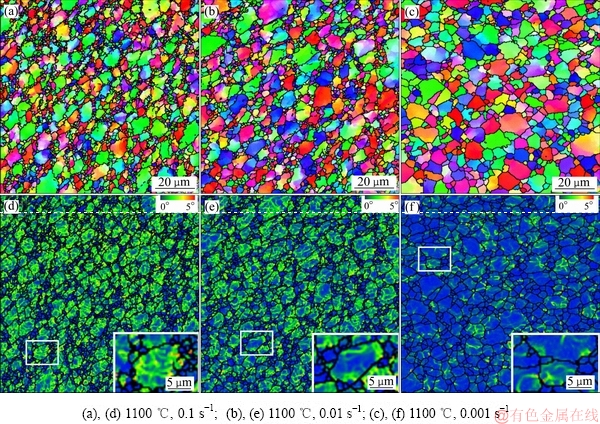

图7(a)~(c)所示为在变形温度为1100 ℃下不同应变速率下试样纵切面组织显微图。由图7(a)可见,在变形条件为1100 ℃、0.1 s-1时,由于应变速率较快,使得位错密度增加和产生绝热升温,使再结晶发生速率加快,在变形晶粒附近出现了较多细小的再结晶晶粒组织,而动态再结晶晶粒因变形时间太短来不及长大,与变形晶粒构成“项链组织”,项链组织的出现通常被认为是再结晶大面积触发的标志之一[22]。在热加工过程中,项链组织是由应变导致形成锯齿形或弓起的晶界,而这种锯齿型或弓起的晶界处成为潜在的动态再结晶形核点。随着应变速率的降低到0.001 s-1,合金有充足的时间进行动态再结晶的形核与长大,呈现出等轴晶晶粒组织(见图7(c))。LI等[23]报道了大面积发生动态再结晶都具有较高的功耗效率,合金在变形温度为1100 ℃时功率耗散因子基本上大于0.3,这证明了热加工图的可靠性。

图5 应变为0.6时U720Li的热加工图

Fig. 5 Hot processing map at strain of 0.6 for U720Li (Values on figure line are efficiency of power dissipation, %)

图6 不同变形条件下试样的微观组织形貌

Fig. 6 Optical microstructures of fine grained at true strain of 0.69 and deformation conditions

图7(d)~(f)所示为与之相对应的局部取向差面分布图,局部取向差图只考虑取向差在5°以内的所有像素点。由图7(d)可见,当应变速率为0.1 s-1时,出现局部取向差较大的区域一般位于变形晶界附近,而晶内的局部取向差较小,表明在热变形过程中,晶界处优先发生变形,晶界附近的应力应变集中区域,其应变储能较晶内的大,位错密度较高。而新形成的再结晶晶粒局部取向差很小,这表明新形成的晶粒为无畸变的晶粒。随着应变速率的降低,局部取向差明显降低,再结晶晶核有足够的时间吸收变形区域附近的位错及变形储能进一步长大,消耗体系内大量的位错及畸变储能(见图7(f))。

图7 合金在变形温度为1100 ℃下不同应变速率的IPF和局部取向差分布图

Fig. 7 IPF maps of microstructures and local misorientaion maps under different deformation conditions

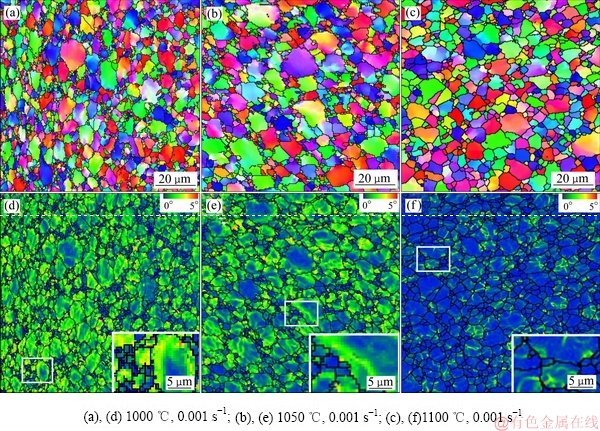

图8 合金在应变速率为0.001 s-1下不同变形温度的IPF和局部取向差分布图

Fig. 8 IPF maps of microstructures and local misorientaion maps under different deformation conditions

变形温度能够显著影响合金再结晶行为,图8(a)~(c)所示为应变速率为0.001 s-1、不同变形温度下的微观组织。在1000 ℃时,晶粒在变形作用下沿着垂直于压缩方向被拉长,在变形晶粒晶界处为应力、应变集中区(见图8(d)),变形晶粒附近出现了细小的再结晶晶粒组织。当温度升高至1050 ℃时,再结晶晶粒长大,高温能够促进再结晶的快速形核并加强晶界的迁移能力,在高温变形时再结晶的晶粒更容易长大(见图8(e))。当变形温度为1100 ℃时,可以看到合金的微观组织呈现等轴状态的完全再结晶晶粒。表明合金的动态再结晶被完全触发,得到细小等轴晶组织,此时变形晶粒被新生的无畸变再结晶晶粒所取代,导致体系内的局部取向差下降(见图8(f))。

3 结论

1) 在变形初期,随着应变的增加,流变应力迅速增加到峰值。在达到峰值应力后,流变曲线表现出明显的低软化现象,主要与动态回复和动态再结晶等微观结构演化有关。

2) 镍基粉末高温合金U720Li的热变形激活能为867.88 kJ/mol,合金热压缩变形时的本构方程为

3) 构建了粉末高温合金U720Li在1000~1150 ℃,0.001~1 s-1的热加工图,失稳区主要位于低温高应变速率区域,合金未发生明显动态再结晶现象,晶界处的应力集中导致沿晶裂纹的产生;在1150 ℃、0.01 s-1变形条件下,晶粒明显长大,应避免此加工条件。

4) 在1100 ℃、0.001 s-1变形条件下能够得到均匀、细小的再结晶晶粒组织,此条件为最佳的热加工参数。

REFERENCES

[1] PRZYBYLA C P, MCDOWELL D L. Microstructure- sensitive extreme value probabilities for high cycle fatigue of Ni-base superalloy IN100[J]. International Journal of Plasticity, 2010, 26(3): 372-394.

[2] VISWANATHAN G B, SAROSI P M, WHITIS D H, MILLSA M J. Deformation mechanisms at intermediate creep temperatures in the Ni-base superalloy René 88 DT[J]. Materials Science & Engineering A, 2005, 400(1): 489-495.

[3] NGANBE M, HEILMAIER M. High temperature strength and failure of the Ni-base superalloy PM 3030[J]. International Journal of Plasticity, 2009, 25(5): 822-837.

[4] LI H Y, SUN J F, HARDY M C, EVANS H E, WILLIAMS S J, DOEL T J A, BOWEN P. Effects of microstructure on high temperature dwell fatigue crack growth in a coarse grain PM nickel based superalloy[J]. Acta Materialia, 2015, 90: 355-369.

[5] HE Guo-ai, TAN Li-ming, LIU Feng, HUANG Lan, HUANG Zai-wang, JIANG Liang. Revealing the role of strain rate during multi-pass compression in an advanced polycrystalline nickel base superalloy[J]. Materials Characterization, 2017, 128: 123-133.

[6] HE Guo-ai, LIU Feng, HUANG Lan, JIANG Liang. Hot deformation behaviors of a new hot isostatically pressed nickel based powder metallurgy superalloy[J]. Journal of Materials Research, 2016, 31(22): 3567-3579.

[7] CHEN Xiao-min, LIN Y C, WEN Dong-xu, ZHANG Jin-long, HE Min. Dynamic recrystallization behavior of a typical nickel-based superalloy during hot deformation[J]. Materials and Design, 2014, 57: 568-577.

[8] MONAJATI H, JAHAZI M, BAHRAMI R, YUE S. The influence of heat treatment conditions on γ′ characteristics in Udimet 720[J]. Materials Science and Engineering A, 2004, 373(1/2): 286-293.

720[J]. Materials Science and Engineering A, 2004, 373(1/2): 286-293.

[9] PRASAD Y V R K, GEGEL H L, DORAIVELU S M, MALAS J C, MORGAN J T, LARK K A, BARKER D R. Modeling of dynamic material behavior in hot deformation: Forging of Ti-6242[J]. Metallurgical Transactions A, 1984, 15(10): 1883-1892.

[10] PRASAD Y V R K. Author’s reply: Dynamic materials model: Basis and principles[J]. Metallurgical and Materials Transactions A, 1996, 27(1): 235-236.

[11] CHEN Jia-yu, DONG Jian-xin, ZHANG Mai-cang, YAO Zhi-hao. Deformation mechanisms in a fine-grained Udimet 720Li nickel-base superalloy with high volume fractions of γ′ phases[J]. Materials Science and Engineering A, 2016, 673: 122-134.

[12] LIU Fang-fang, CHEN Jia-yu, DONG Jian-xin, ZHANG Mai-cang, YAO Zhi-hao. The hot deformation behaviors of coarse, fine and mixed grain for Udimet 720Li superalloy[J]. Materials Science & Engineering A, 2016, 651: 102-115.

[13] GOPINATH K, GOGIA A K, KAMAT S V, BALAMURALIKRISHNAN R, RAMAMURTY U. Tensile properties of Ni-based superalloy 720Li: Temperature and strain rate effects[J]. Metallurgical & Materials Transactions A, 2008, 39(10): 2340-2350.

[14] YUAN Y, GU Y F, CUI C Y, OSADA T, TETSUI T, YOKOKAWA T, HARADA H. Creep mechanisms of U720Li disc superalloy at intermediate temperature[J]. Materials Science and Engineering A, 2011, 528(15): 5106-5111.

[15] LIU Yan-hui, NING Yong-quan, YANG Xue-mei, YAO Ze-kun, GUO Hong-zhen. Effect of temperature and strain rate on the workability of FGH4096 superalloy in hot deformation[J]. Materials & Design, 2016, 95: 669-676.

[16] JIANG He, DONG Jian-xin, ZHANG Mai-cang, ZHENG Lei, YAO Zhi-hao. Hot deformation characteristics of Alloy 617B nickel-based superalloy: A study using processing map[J]. Journal of Alloys and Compounds, 2015, 647: 338-350.

[17] SHI Zhao-xia, YAN Xiao-feng, DUAN Chun-hua. Characterization of hot deformation behavior of GH925 superalloy using constitutive equation, processing map and microstructure observation[J]. Journal of Alloys and Compounds, 2015, 652: 30-38.

[18] BRUNI C, FORCELLESE A, GABRIELLI F. Hot workability and models for flow stress of NIMONIC 115 Ni-base superalloy[J]. Journal of Materials Processing Technology, 2002, 125/126: 242-247.

[19] PARK N K, YEOM J T, NA Y S. Characterization of deformation stability in hot forging of conventional Ti-6Al-4V using processing maps[J]. Journal of Materials Processing Technology, 2002, 130(2): 540-545.

[20] RAVICHANDRAN N, PRASAD Y V R K. Dynamic recrystallization during hot deformation of aluminum: A study using processing maps[J]. Metallurgical Transactions A, 1991, 22(10): 2339-2348.

[21] SOMANI M C, MURALEEDHARAN K, PRASAD Y V R K, SINGH V. Mechanical processing and microstructural control in hot working of hot isostatically pressed P/M IN-100 superalloy[J]. Materials Science and Engineering A, 1998, 245(1): 88-99.

[22] PONGE D, GOTTSTEIN G. Necklace formation during dynamic recrystallization: Mechanisms and impact on flow behavior[J]. Acta Materialia, 1998, 46(1): 69-80.

[23] LI H Z, WANG H J, LI Z, LIU C M, LIU H T. Flow behavior and processing map of as-cast Mg-10Gd-4.8Y- 2Zn-0.6Zr alloy[J]. Materials Science and Engineering A, 2010, 528(1): 154-160.

Hot deformation behavior of P/M superalloy U720Li

WU Kai-xi, TAN Li-ming, HE Ying-jie, DENG Rui, LIU Feng

(Research Institute of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Hot deformation on a fine-grained P/M superalloy U720Li was performed at 1000-1150 ℃ and strain rate of 0.001-1 s-1 by the Gleeble-3180 simulator. The deformation activity energy and constitutive equations were established by the true stress and true strain data. Processing maps for hot working were established on the basis of the variations of power dissipation efficiency, and related them with the microstructure observation. The results show that the major instability domain locates at low temperature and the high strain rate region, which is mainly caused by intergranular cracks, and the dynamic recrystallization doesn’t occurred. The grain growth is remarkably triggered under 1150 ℃, 0.01 s-1. Optimum hot working condition for U720Li is determined as 1100 ℃ and 0.001 s-1, where the refined and uniform grains are observed.

Key words: nickel-based powder superalloy; constitutive model; hot processing map; microstructure

Foundation item: Project(2016YFB0701404) supported by the National Basic Research Development Program of China; Project(91860105) supported by the National Natural Science Foundation of China

Received date: 2018-09-19; Accepted date: 2019-07-05

Corresponding author: LIU Feng; Tel: +86-18607324887; E-mail: liufeng@csu.edu.cn

(编辑 龙怀中)

基金项目:国家重点研究计划资助项目(2016YFB0701404);国家自然科学基金资助项目(91860105)

收稿日期:2018-09-19;修订日期:2019-07-05

通信作者:刘 锋,副教授,博士;电话:18607324887;E-mail:liufeng@csu.edu.cn

摘 要:通过Gleeble-3180热模拟机对具有细晶组织的镍基粉末高温合金U720Li进行高温热压缩变形实验,分析该合金在1000~1150 ℃、0.001~1 s-1应变速率的变形条件下的流变行为。利用采集的应力-应变数据计算材料的热变形激活能,构建材料的本构方程,建立合金的热加工图,并通过微观组织观察对热加工图进行解释。结果表明:失稳区主要位于低温高应变速率区域,合金未发生明显动态再结晶现象,晶界处的应力集中导致沿晶裂纹的产生。在1150 ℃、0.01 s-1条件下,晶粒明显长大;在1100 ℃、0.001 s-1条件下,变形能够获得细小均匀的晶粒组织。