J. Cent. South Univ. Technol. (2007)01-0084-04

DOI: 10.1007/s11771-007-0017-0

![]()

Neural network modeling and control of proton exchange membrane fuel cell

CHEN Yue-hua(陈跃华), CAO Guang-yi(曹广益), ZHU Xin-jian(朱新坚)

(Department of Automation, Shanghai Jiaotong University, Shanghai 200030, China)

Abstract:

A neural network model and fuzzy neural network controller was designed to control the inner impedance of a proton exchange membrane fuel cell (PEMFC) stack. A radial basis function (RBF) neural network model was trained by the input-output data of impedance. A fuzzy neural network controller was designed to control the impedance response. The RBF neural network model was used to test the fuzzy neural network controller. The results show that the RBF model output can imitate actual output well, the maximal error is not beyond 20 mΩ, the training time is about 1 s by using 20 neurons, and the mean squared errors is 141.9 mΩ2. The impedance of the PEMFC stack is controlled within the optimum range when the load changes, and the adjustive time is about 3 min.

Key words:

proton exchange membrane fuel cell; radial basis function neural network; fuzzy neural network;

1 IntroductionThe membrane of proton exchange membrane fuel cell (PEMFC) requires water to maintain proton conductivity. A correct water balance must be maintained in the proton exchange membrane in order to guarantee high proton conductivity and an optimum performance of the cell. Drying of the membrane will result in performance degradation, even damage the membrane[1]. On the other hand, flooding of the electrode will obstruct reactant gases to contact catalyst, and result in performance degradation, too[2]. HYUN et al[1] used external humidification method to improve PEMFC efficiency under lower humidity and temperature condition. MALLANT et al[3-6] researched the effects of various humidity, pressure, temperature and gas flow rate on PEMFC performance. FREIRE et al[7] studied the effect of membrane characteristic and humidification conditions on the impedance response of PEMFC. CAUX et al[8] presented a modeling approach to control auxiliaries of a PEMFC and the design of control laws. LUM et al[9] set up a three-dimensional model of PEMFC. SHEN et al[10-11] presented a neural network modeling method to imitate the temperature responses of a fuel cell stack. SCHUMACHER et al[12] presented a fuzzy control strategy which is suitable for miniature PEMFC. YOSHIBA et al[13] designed controllers to control voltage of a MCFC.

In this study, the nonlinear relationship between the impedance and the water content of a PEMFC was analysed and modelled by a radial basis function (RBF) neural network. The fuzzy neural network (FNN) controller was designed to control the impedance of the PEMFC.

2 Descriptions and analysis of PEMFC con- trol system

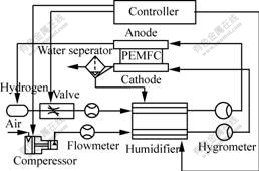

PEMFC control system is composed of the PEMFC stack associated with all the necessary auxiliaries for continuous operation. Fig.1 shows the components in a typical PEMFC control system [3]. The main components are as follows: PEMFC stack; a controller used to control flow rates, temperature and humidity of reactant gases; a compressor used to pressurize PEMFC stack; the humidifier used to humidify reactant gases; a water separator used to obtain hot water from cathode exhaust gas; hygrometers; flowmeters and thermometers.

The PEMFC stack is made up of 32 cells (active area of 128 cm2) and can supply electrical power up to 1 kW at 24 V. Nafion 112 (average thickness of 50 μm) is used to prepare membrane electrode assembly (MEA) [11]. Reactant gases are pre-humidified in the humidifier; water used in the humidifier can be compensated by the water produce in the stack. Usually PEMFC stack is operated at or below 80 ℃ and 0.2-0.3 MPa.

Fig.1 Schematic diagram of PEMFC control system

The conductivity of the membrane in a PEMFC is directly related to its water content, which depends on:

1) The water carried by the humidified reactant gases.

2) The water generated by the cell reaction at the cathode.

3) The electro-osmotic drag, that is, water carried by the protons that were transported from anode to cathode[7].

However, water content is very difficult to measure directly or compute out.

The problem of measuring water content can be solved experimentally by measuring inner impedance (Z) of the fuel cell stack. Inner impedance is mainly composed of the protonic resistance of the membrane and the internal contact resistances of the fuel cell stack. The internal contact resistance is constant when fuel cell was produced, so Z is a characteristic variable reflecting the humidification conditions of the fuel cell stack[12]. When operating temperature and pressure are maintained constant, flooding of a cell leads to an abrupt decrease of the corresponding cell voltage and the impedance; on the other hand, drying of the membrane leads to increase of impedance[14]. Flooding problem can be solved by increasing the reactant gases flow rates, which can blow out surplus liquid water in cells. And if the membrane is too dry, the impedance would higher than a specified value, the reactant gases flow rates should be decreased. Based on the sampling data of the impedance of the stack, it can be concluded the impedance Z has nonlinear relations to reactants gases flow rate VR, operating temperature T, and power load P. It can be described as[10-11]:

![]() (1)

(1)

where Ф denotes the nonlinear relation between Z(k) and VR(k), T(k), P(k).

3 RBF neural network modeling method

Neural networks have the capabilities of approximating any nonlinear function and the abilities to learn from experimental data. The radial basis function (RBF) network is used to imitate the dynamic responses of the actual impedance data. RBF network is composing of two layers. The first layer has radial basis function neurons, usually they are chosen as Gaussian functions:

![]() (2)

(2)

where X(k) denotes the input vector; cj and λj are the center parameter and the width parameter of the Gaussian functions, respectively. RBF neurons calculate the Euclidean distances between the centers of Gaussian functions and the network input vector, and pass the results through the Gaussian functions. The second layer has linear neurons, and the RBF network output is calculated as a linear weighted sum of inputs from frontal layer [10]:

![]() (i=1, 2, …, p) (3)

(i=1, 2, …, p) (3)

where ω0,i and ωj,i are the weights. The structure of RBF network is simple and it has a linear layer, so it can offer the advantage of training fast and computing simple. Moreover, if the centers and width parameters of the Gaussian functions are chosen appropriately, RBF network can imitate dynamic curve of sampling data well.

We use the neural networks toolbox in MATLAB 7.0 to perform training and simulation. The training set includes 210 impedance values at different power loads and air flow rates. The data are obtained when the PEMFC stack is operated at 2.5×105 Pa and 80 ℃. Training algorithm of RBF network can increase neurons of RBF layer automatically until the precision require- ment is achieved. The criterion of training a RBF network is to minimize the mean squared errors (MSE) as follows:

![]() (4)

(4)

where n is the number of data points in the training

set; yj(k) and ![]() denote the actual and neural network model output at instance k, respectively.

denote the actual and neural network model output at instance k, respectively.

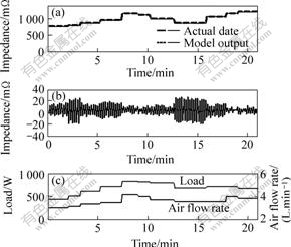

Fig.2 shows the identification result of RBF neural network. It can be seen that RBF network model outputs are in good agreement with the actual data in Fig.2 (a). Fig.2 (b) shows the errors between the model outputs and the actual data. The maximal error is not beyond 27 mΩ, the training time is about 1 s by using 20 neurons, and the MSE obtained is 141.9 mΩ2. The varieties of power load and air flow rates are shown in Fig.2 (c).

4 Fuzzy neural network controller

Based on the RBF network model, a Takagi-Sugeno fuzzy controller is designed. And then, this controller is expressed as a 5-layers feed-forward neural network, whose weight coefficients correspond with the para- meters of the fuzzy controller, however, its weights can be regulated by the studying algorithm of neural network[15]. That is to say, all the parameters of the fuzzy controller can be regulated.

Fig.2 RBF neural network identifying results

(a) Comparison between actual data and model outputs;(b) Model output error; (c) Variety of load and air flow rate

Two linguistic variables, Ze and ΔZ, are introduced as the input vectors of the fuzzy controller[12]:

1) For stable operation, the stack impedance Z should be kept within a specified range [Zll Zul], where Zll and Zul are the lower and upper limits of the optimum impedance range, respectively. For example, at 80 ℃ the impedance should be controlled within the range [1 020 mΩ 1 080 mΩ]. Ze is the deviation of impedance from the optimum range:

(5)

(5)

2) The linguistic variable ΔZ represents the variety of Z:

![]() (6)

(6)

The output of controller is proportional to ΔZ, so ΔZ is introduced for preventing the controller from tending to oscillate.

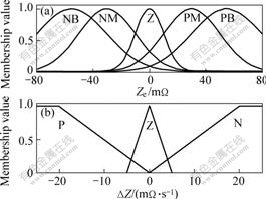

The initial membership function of the linguistic variable Ze and ΔZ are shown in Fig.3, where Gauss membership functions are chosen for Ze and triangular-shaped membership functions for ΔZ. In Fig.3, NB, NM, Z, PM, PB, P and N are fuzzy linguistic values, which denote negative big, negative middle, zero, positive middle, positive big, positive and negative, respectively.

The Takagi-Sugeno fuzzy inference system (FIS) is comprised of 15 initial fuzzy rules. For example, one rule reads:

Fig.3 Membership functions of linguistic variables Ze and ΔZ

(a) Membership functions of Ze; (b) Membership functions of ΔZ

if (Ze=PB) and (ΔZ=P) then U=p0+p1Ze+p2ΔZ

where U is the controller output; p0, p1 and p2 are weights of rules. The parameters in the FIS needed to be adjusted including the centers and the widths of Gaussian membership functions, and the weights of Taskagi-Sugeno fuzzy rules. Studying algorithm of

weight coefficients![]() , centers cij and widths σij are given as below[15]. The cost function is defined as:

, centers cij and widths σij are given as below[15]. The cost function is defined as:

![]() (7)

(7)

where yi and ![]() denote sample output value and RBF model output value, respectively.

denote sample output value and RBF model output value, respectively.

![]() (8)

(8)

Then ![]() can be obtained by:

can be obtained by:

![]()

![]() (9)

(9)

After receiving ![]() , we can choose cij and σij as:

, we can choose cij and σij as:

![]() (10)

(10)

![]() (11)

(11)

![]() (12)

(12)

And then:

![]() (13)

(13)

![]() (14)

(14)

![]() (15)

(15)

![]() (16)

(16)

where β is learning rate, β>0

5 Simulation results

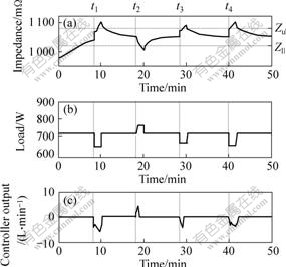

In simulations, the RBF neural network model is used to test the fuzzy neural network (FNN) controller. The impedance responses at 80 ℃ are shown in Fig.4(a), and the varieties of power load and controller output are shown in Figs.4(b) and 4(c), respectively.

Fig.4 Simulation of FNN controller at 80 ℃

(a) Impedance response; (b) Variety of power load;(c)Variety of controller output

In the tests, the power load is decreased at times t1, t3 and t4. The electrochemistry reaction is slow down and water production rate is decreased, leading to a decrease of the water content of the membrane, so the impedance is increased. When the impedance exceeds Zul, the FNN controller decreases air flow rate, after about 3 min, the impedance is decreased to the optimum range. Load is increased manually at t2, then the impedance is lower than Zll, the FNN controller increases air flow rate to adjust impedance to the specific range.

From Fig.4, it can be seen that at different external loads, the proposed controller can regulate and control the inner impedance of PEMFC to change smoothly and quickly to its optimum range. Therefore it is feasible to use this proposed controller for PEMFC system.

6 Conclusions

1) Compared with the complex mathematical or mechanism modeling method, RBF neural network modeling method is more quick and accurate for specific object, therefore it is suitable to apply to control system of fuel cells.

2) The FNN controller can regulate the parameters of membership functions and fuzzy rules, so it can overcome the limitations of the traditional fuzzy controller. In simulation, the FNN controller can adjust impedance quickly to the optimum range when load is varied.

References[1] HYUN D, KIM J. Study of external humidification method in proton exchange membrane fuel cell[J]. Journal of Power Sources, 2004, 126(1/2): 98-103.

[2] YI Bao-lian. Fuel Cell[M]. Beijing: Chemistry Industry Press, 2003: 239-243. (in Chinese)

[3] MALLANT R K A M. PEMFC systems: the need for high temperature polymers as a consequence of PEMFC water and heat management[J]. Journal of Power Sources, 2003, 118(1/2): 424-429.

[4] FRANCESCO M D, ARATO E, COSTA P. Transport phenomena in membranes for PEMFC applications: an analytical approach to the calculation of membrane resistance[J]. Journal of Power Sources, 2004, 132(1/2): 127-134.

[5] SHAN Y, CHOE S Y. A high dynamic PEM fuel cell model with temperature effects[J]. Journal of Power Sources, 2005, 145(1): 30-39.

[6] YOSHIBA F, ONO N, IZAKI Y, et al. Numerical analyses of the internal conditions of a molten carbonate fuel cell stack: comparison of stack performances for various gas flow types[J]. Journal of Power Sources, 1998, 71(1/2): 328-336.

[7] FREIRE T J P F, GONZALEZ E R. Effect of membrane characteristics and humidification conditions on the impedance response of polymer electrolyte fuel cells[J]. Journal of Electroanalytical Chemistry, 2001, 503: 57-68.

[8] CAUX S, LACHAIZE J, FADEL M, et al. Modeling and control of a fuel cell system and storage elements in transport application [J]. Journal of Process Control, 2005, 15(4): 481-491.

[9] LUM K W, MCGUIRK J J. Three-dimensional model of a complete polymer electrolyte membrane fuel cell—model formulation, validation and parametric studies[J]. Journal of Power Sources, 2005, 143(1/2): 103-124.

[10] SHEN Cheng, CAO Guang-yi, ZHU Xin-jian. Nonlinear modeling and adaptive fuzzy control of MCFC stack [J]. Journal of Process Control, 2002, 12(8): 831-839.

[11] SUN Tao, CAO Guang-yi, ZHU Xin-Jian. Nonlinear modeling of PEMFC based on neural networks identification[J]. Journal of Zhejiang University: Science, 2005, 6A(5): 365-370.

[12] SCHUMACHER J O, GEMMAR P, DENNE M, et al. Control of miniature proton exchange membrane fuel cells based on fuzzy logic[J]. Journal of Power Sources, 2004, 129(2): 143-151.

[13] YOSHIBA F, IZAKI Y, WATANABE T. Wide range load controllable MCFC cycle with pressure swing operation[J]. Journal of Power Sources, 2004, 137(2): 196-205.

[14] YAN Wei-mon, CHEN Fa-lin, WU Huang-yi, et al. Analysis of thermal and water management with temperature-dependent diffusion effects in membrane of proton exchange membrane fuel cells[J]. Journal of Power Sources, 2004, 129(2): 127-137.

[15] SUN Zeng-qi. Intelligent Control Theory and Technology[M]. Beijing: Tsinghua University Press, 1997: 177-181.(in Chinese)

(Edited by YANG You-ping)

Foundation item: Project(2003AA517020) supported by the National High Technology Research and Development Program of China

Received date: 2006-04-30; Accepted date: 2006-06-28

Corresponding author: CHEN Yue-hua, Doctoral candidate; Tel: +86-21-27975676; E-mail: chenqi78@sjtu.edu.cn

- Neural network modeling and control of proton exchange membrane fuel cell