DOI:10.19476/j.ysxb.1004.0609.2017.07.20

含钛冶金熔渣非牛顿流体现象的表征与分析

岳宏瑞1,姜 涛1, 2,薛向欣1, 2

(1. 东北大学 冶金学院 冶金资源与环境工程研究所,沈阳 110819;

2. 东北大学 冶金学院 冶金资源与环境工程研究所 辽宁省冶金资源循环科学重点实验室,沈阳 110819)

摘 要:

以攀钢实际生产高炉渣(CaO-SiO2-Al2O3-MgO-TiO2)为基础,制备不同TiC含量的渣样,研究从1500 ℃到1450 ℃含钛熔渣的触变特性、电流变特性以及爬杆现象等非牛顿流体现象。结果表明:渣样含有8%的TiC,具有明显的触变特性。渣样中不含TiC,剪切应力的上行曲线与下行曲线重合,无触变特性;渣样中TiC质量分数为4%、8%,剪切应力随电场强度的增大而增大,又随电场强度的减小而减小,熔渣具有明显的电流变特性。渣样中TiC质量分数为0时,渣样的剪切应力不随电场强度变化而变化;不同含量TiC的渣样均不具备爬杆现象。

关键词:

文章编号:1004-0609(2017)-07-1485-08 中图分类号:TF01 文献标志码:A

我国的钒钛磁铁矿资源丰富,以攀枝花钢铁,承德钢铁等企业为主,已经实现了高炉冶炼钒钛磁铁矿的稳定生产。然而,由于含钛高炉渣中含有大量的TiO2[1],使得各生产单位在高炉冶炼时,不得不配加30%左右(质量分数)的普通矿以稀释熔渣中TiO2的含量。含钛熔渣中,TiO2在高炉生产的高温、还原条件下,被还原成TiC、TiN以及Ti(C,N)等高熔点固溶体,给高炉冶炼钒钛磁铁矿带来了一系列的生产难题,如铁损大、泡沫渣等[2-5]。为了解决上述问题,实现全钒钛磁铁矿冶炼生产,有必要对含钛熔渣的物理化学性质进行系统研究。

以往的研究中,通常将含钛熔渣视为牛顿流体,极大地简化了含钛熔渣的研究方法,并取得一系列研究成果[6-8]。SAITO等[6]和DONG等[7]认为,TiO2含量增加,黏度随之减小,液相线温度也随之增大。温度或碱度的降低都会使含钛熔渣黏度增大。LIAO等[8]的实验结果表明:两性氧化物TiO2在含钛熔渣中表现为碱性氧化物,TiO2含量增加后,熔渣内部形成更简单硅酸盐结构,流动阻力减小。碱度固定为0.5,TiO2含量从15%增加到30%(质量分数)的过程,黏度随TiO2含量增加而减小。XIE等[9]研究了熔渣黏度在TiO2逐步还原到TiC(TiO2→Ti2O3→TiO→TiC)过程中的变化规律,结果表明:TiO2还原到TiO的过程,熔渣黏度轻微波动,出现TiC后熔渣黏度急剧变化。上述文献在黏度测量时,通常固定剪切速率或取不同剪切速率时黏度的平均值。然而近期的工作[10]发现,熔渣的表观黏度随剪切速率变化而变化,TiC含量大于4%时,熔渣即为非牛顿流体。同时,非牛顿流体具有一些特有的现象,如触变特性、电流变特性以及爬杆现象等。

触变特性流体[11-12]是指非牛顿流体中存在一类流动特性与时间有关的流体。对于这种流体,先逐渐增加剪切速率再逐渐除去剪切速率后,流动剪切应力随剪切速率增加的上行曲线和随剪切速率减小的下行曲线不能重合,形成“滞后回路”,有“滞后回路”的流体即具有触变特性。张先伟等[13]研究了黏土触变过程中强度恢复的微观机理,结果表明:黏土触变过程中的强度恢复主要是颗粒间引力与斥力相互作用的力场变化使结构由分散趋向絮凝发展导致。

电流变效应也称为ER(Electrorheological)效应,是指由于外加电场的作用导致体系的结构和流变性质发生变化,如黏度、屈服应力等。涂福泉等[14]和HAO [15]认为电流变液主要由分散系弥散在绝缘基体中,外加电场后,分散系极化产生链状结构,改变了体系的流动阻力,从而改变了体系的黏度、屈服应力等。姜涛等[16]研究了含钛熔渣黏度在12.5 V/mm直流电场强度下的变化,结果表明:黏度随电场强度的增加而增加。本文作者除通过剪切应力与电场的变化验证文献[16]结论,同时增加电场强度到70 V/mm,并优化了实验流程。

爬杆现象也称Weissenberg现象[17-19]。在一只装有流体的烧杯里插入并旋转转杆,对于牛顿流体,由于离心的作用,液面将呈凹形。而对于黏弹性流体,流体向中心运动,且沿转杆向上爬,即爬杆现象。产生爬杆现象的机理是液体内存在法向应力差,法向应力使得流体克服离心力和重力分别向中心和向上聚拢。

鉴于以上结论,本文作者在五元渣系(CaO-SiO2-Al2O3- MgO-TiO2)中添加不同含量的TiC,使用自行改造设备,在得到含钛熔渣为非牛顿流体的基础上,借鉴非牛顿流体研究方法,通过熔渣黏度、剪切应力、外加电场、熔渣液面等之间的关系,研究了含钛熔渣的触变特性、电流变特性和爬杆现象。并对TiC含量、恒温温度、剪切速率等对含钛熔渣非牛顿流体现象的影响进行分析讨论。

1 实验

1.1 渣样

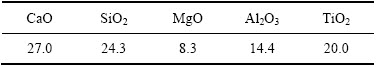

以攀钢实际生产高炉渣[20-21](见表1)为基础,采用化学纯试剂(供应商:国药集团化学试剂有限公司)经混料、烘干处理后,配制不同TiC含量的渣样如表2所列,其中TiC粒度分布如图1所示,TiC粉末的粒度分布在3.18~33.43 μm,平均粒度为14.1 μm。配置好的渣样经1550 ℃恒温1 h化渣、冷却、粉碎后称取140 g备用。

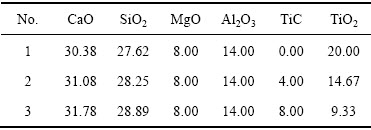

表1 攀枝花钢铁转炉炉渣化学组成

Table 1 Chemical composition of BF slag from Panzhihua iron and steel corporation (mass fraction, %)

表2 实验渣样的成分

Table 2 Experimental composition of slag examples (mass fraction, %)

图1 TiC 粉末的粒度分布

Fig. 1 Grain size distribution of TiC powder

1.2 实验设备及流程

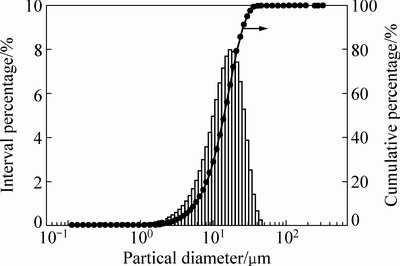

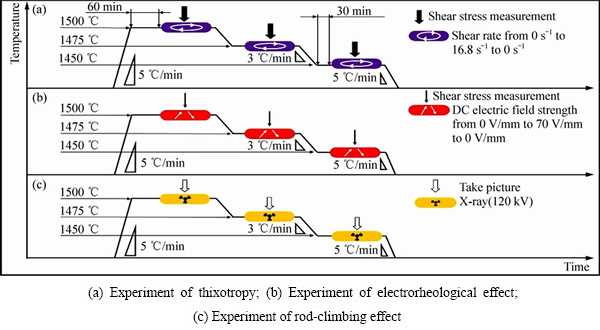

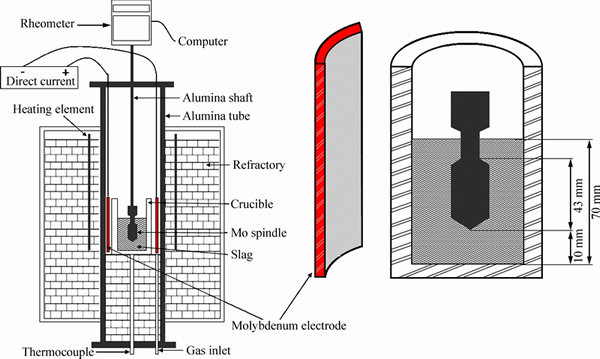

在研究含钛熔渣触变特性时,主要应用的设备如图2所示。实验过程为:将上述140 g渣样放入内衬钼片的石墨坩埚(内径:d40 mm×90 mm)内,加热到1500 ℃,恒温60 min使熔渣反应均匀,插入钼质转子,打开流变仪(Brookfield DV-Ⅲ),剪切速率从0增大至16.8 s-1后又减小至0,测定此过程熔渣的剪切应力变化。测定结束后,降温至1475 ℃,恒温30 min,重复上述测量过程。温度再次降低到1450 ℃,恒温30 min,重复测量后取出转杆,降温结束实验。实验流程示意图如图3(a)所示。

图2 触变现象实验设备的示意图

Fig. 2 Schematic diagram of experimental apparatus of thixotropy

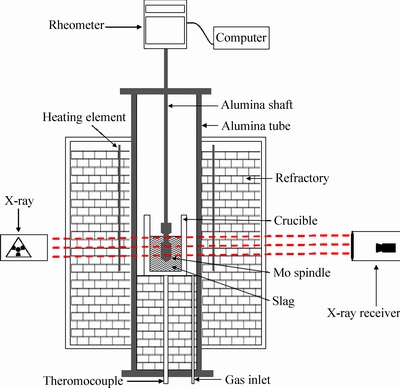

在研究含钛熔渣电流变特性时,在图2所示的设备上进行改造,改造后的设备示意图如图4所示,详细信息参考专利[22],实验过程为:将140 g渣样放入刚玉坩埚(内径:d40 mm×90 mm)内,加热到预设温度1500 ℃后,恒温60 min,打开流变仪与直流电源, 剪切速率固定为5.6 s-1,电场强度从0 V/mm增加至70 V/mm后又降低到0 V/mm,测量不同电场强度下熔渣的剪切应力,随后降温重复上述测量过程。实验流程示意图如图3(b)所示。

在研究含钛熔渣爬杆现象时,在图2所示的设备上进行改造,改造后的设备示意图如图5所示,详细信息参考专利[23],实验过程为:将140 g渣样加放入内衬钼片的石墨坩埚(内径:d40 mm×90 mm)内,加热到预设温度1500 ℃后,恒温60 min,插入钼质转子,其中转子与液面接触部分直径为3 mm,打开流变仪与X射线发生装置,曝光电压为120 kV,剪切速率从0 s-1增至16.8 s-1,采集熔渣液面变化影像,随后降温重复上述过程。实验流程示意图如图3(c)所示。

1.3 改造后的设备测试结果与文献和FactSage结果对比

研究熔渣电流变性和爬杆现象所用的实验装置,经过自行改造,改造后测得渣样1在1500 ℃下的黏度值均为0.142 Pa·s。将所得黏度值与文献和FactSage热力学软件预测结果对比如表3所列。实验所得黏度略小于参考文献中所得黏度值和FactSage计算值,其中主要原因是所使用黏度测量设备、转子形状、尺寸不同,同时所列参考文献未考虑剪切速率对熔渣黏度的影响。

图3 实验流程的温度-时间示意图

Fig. 3 Temperature-time schedule of experiments

图4 电流变效应实验设备的示意图

Fig. 4 Schematic diagram of experimental apparatus of electrorheological effect

表3 本文黏度测量结果与FactSage和参考文献结果的对比总结

Table 3 Summary of viscosities of Ti-bearing slag obtained by present work, FactSage and reported in references

图5 爬杆现象实验设备的示意图

Fig. 5 Schematic diagram of experimental apparatus of rod-climbing effect

2 结果与讨论

2.1 TiC含量对含钛熔渣触变特性的影响

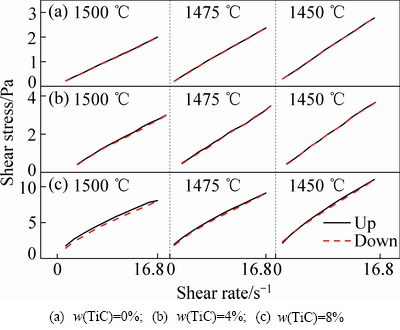

图6所示为不同TiC含量熔渣的剪切应力与剪切速率之间的关系。剪切速率从0 s-1增加到16.8 s-1后,立即降低到0 s-1。熔渣中TiC质量分数为0,温度范围为1500 ℃到1450 ℃时,剪切应力的上行曲线与下行曲线重合,熔渣体系剪切应力无滞后现象;熔渣中TiC质量分数为4%,温度为1500 ℃时,下行曲线低于上行曲线,形成了“滞后回路”,温度为1475 ℃和1450 ℃时,下行曲线与上行曲线之间滞后现象不明显;熔渣中TiC质量分数为8%,温度从1500 ℃降低到1450 ℃,下行曲线滞后于上行曲线,尤其温度为1500 ℃时,滞后现象更加明显,熔渣体系具有明显的触变特性。

含钛熔渣的内部结构复杂,渣中含有细小的TiC等固溶体[26]时,会以固溶体为晶核核心形成复杂的组织结构。如图6(c) 所示,随剪切速率的逐渐增大,剪切应力逐渐增大,熔渣内部结构被破坏。剪切速率逐渐撤除后,剪切应力又逐渐减小,但未能恢复到上行曲线的程度,进而形成了“滞后回路”。上行曲线是熔渣受到外力结构被破坏的过程,下行曲线是熔渣内部结构逐渐恢复的过程,渣中TiC颗粒间的引力与斥力相互作用,重新排列,调整结构,形成了相对的亚稳定状态。若将图6(c)中1500 ℃的曲线斜率近似为熔渣的黏度,可得到熔渣黏度随剪切速率增加而减小的结论。进一步说明此时熔渣具有剪切稀化现象。通过热力学软件FactSage分析发现,对于渣样1来说,温度从1500 ℃逐渐降温的过程中,在1412.83 ℃时,第一个固相钙钛矿开始析出,所以在1500~1450 ℃之间,TiC应为渣样2和3内的唯一固相。因此,上述不同渣样之间滞后曲线的差异可归功于TiC含量的影响。

图6 渣样1、2、3的剪切应力与剪切速率之间的关系

Fig. 6 Relationship of shear stress and shear rate of slag sample 1, 2 and 3

2.2 TiC含量对含钛熔渣电流变特性的影响

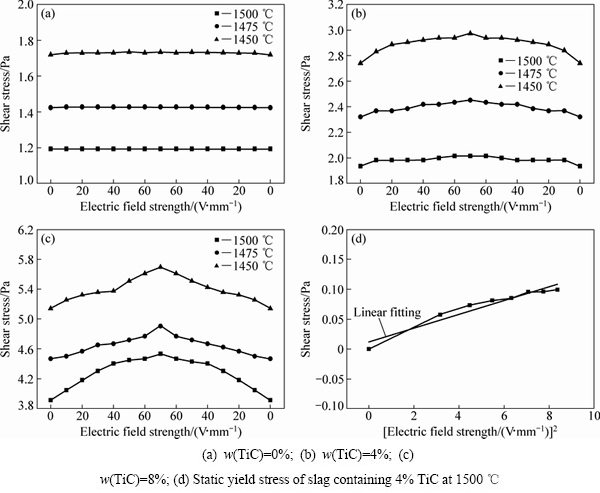

图7所示为不同TiC含量渣样在电场强度下剪切应力的变化。熔渣中TiC含量为0%,温度范围为1500 ℃到1450 ℃时,随电场强度的先增加后减小,剪切应力没有变化。熔渣中TiC含量为4%和8%,温度为1500 ℃到1450 ℃时,熔渣的剪切应力随电场强度的增加而增加,又随电场强度的减小而减小。且8%TiC渣系的剪切应力对电场强度的敏感度比4%TiC渣系的大。

相关文献[27-28]表明,TiC分散在橡胶等基体中,具有显著的电流变特性。当施加电场时,TiC被极化,固相间的相互作用加强,并沿着电场方向聚集成纤维状结构,从而提高了电流变液的抗剪切能力。在足够强的外电场作用下,电流变流体产生一个明显的电诱导屈服应力。因此,只有当外力大于屈服应力时,电流变流体才会发生流动[29-30]。从上述结论可知,含TiC的熔渣应为介电性电流变液,在无电场作用时,熔渣中的TiC颗粒呈无规则分布。施加电场后,弥散在熔渣中的TiC固体颗粒极化后相互吸引,沿电场方向形成了链状结构,熔渣内部出现静态屈服应力,从而使熔渣的剪切应力增大。在极化模型中,电场所产生的应力按如方程(1)计算[31]:

(1)

(1)

式中:k为常数;εm为基体介电常数;r为粒子半径;β为有效极化系数,可计算如下:

(2)

(2)

式中:σ为电导率;p和m分别代表固相和液相;v为电场频率;vc为Maxwell-Wagner弛豫频率,vc可计算为:

(3)

(3)

在本研究中,电场频率v为0,β2和电场应力Felec可分别计算为:

(4)

(4)

(5)

(5)

将所得电场中剪切应力与剪切速率之间的曲线回归到剪切速率为0时,即得到熔渣的静态屈服应力。图7(d)所示为TiC质量分数4%、温度1500 ℃时熔渣的静态屈服应力随电场强度的平方变化关系。由图7(d)可知,静态屈服应力与电场强度的平方近似于线性关系,即满足上述方程(5),为此可判断含有4%TiC的熔渣所表现出的电流变性质,满足上述极化模型。本研究与文献[16]中所用的电场强度与传统电流变研究[26-27]中的千伏级电场相比都较小。所以,剪切应力或黏度变化幅度都较小,实验结果受其他因素影响无法完全忽略,如黏度会随恒温时间增长而增大等。故本文作者采用电场强度先增加后减小的实验流程,以确定电场对剪切应力变化的主导作用。

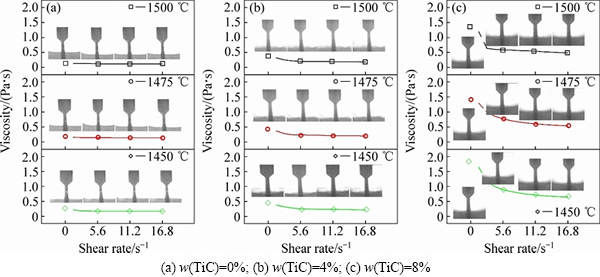

2.3 TiC含量对含钛熔渣爬杆现象的影响

图8所示为不同TiC含量渣样液面随转杆转动的变化情况。由图8可知,TiC质量分数为0%时,熔渣黏度在剪切速率从0 s-1到16.8 s-1的范围内波动很小,熔渣可视为牛顿流体。剪切速率为0、5.6、11.2和16.8 s-1时,熔渣的液面不随转杆转动而向中心聚集或沿杆上爬。TiC质量分数增到4%后,熔渣黏度随剪切速率增加而减小,表现出剪切稀化现象,熔渣不再为牛顿流体,但熔渣液面仍不随转杆转动而变化。TiC质量分数为8%时,熔渣的黏度随温度的降低而增加,且剪切稀化现象更加明显,熔渣的液面不随转杆转动而变化,即不存在爬杆现象。

非线性黏弹性力学理论表明,在剪切应力作用下,黏弹性材料将产生法向应力。法向应力差N1、N2如下所示:

(6)

(6)

(7)

(7)

式中:nxx、nyy、nzz 为3个方向的法向应力分量;A、B是材料常数;γ为剪切速率。当第一法向应力差N1远远大于第二方向应力差N2时,通常会出现爬杆现象。黏弹性材料的各向异性决定了不同法向应力分量的大小不同,转杆在材料中旋转时,应力使黏弹性材料“咬住”转杆并沿杆运动,黏弹性流体的弹性成分越大,其法向应力就越大,爬杆现象就越明显。由上述理论可判断,本实验中的渣样缺少黏弹性流体的弹性,不是黏弹性流体。关于爬杆现象的研究,相关文献多聚焦于爬杆现象的建模[19, 32],直观观察爬杆现象的报道并不多见,关于爬杆现象的实现条件,还需要进一步系统地研究。另外,从图8中可以发现,TiC质量分数为0%时,液面较光滑,TiC质量分数为4%和8%时,熔渣液面变得粗糙,这种现象也应加以关注。

图7 直流电场对渣样1、2、3剪切应力的影响

Fig. 7 Effect of direct current electric field on shear stress of slag sample 1, 2 and 3

图8 转杆转动对熔渣渣样面的影响

Fig. 8 Effect of shaft rotating on liquid level of molten slag samples

3 结论

1) 五元渣系(CaO-SiO2-Al2O3-MgO-TiO2)加入质量分数为4%的TiC,温度为1500℃,剪切速率先增后减,相应的剪切应力上行曲线和下行曲线不能完全重合,熔渣表现出触变特性,TiC增加到8%,温度为1500 ℃到1450 ℃时,“滞后回路”变得更加明显。

2) 含钛熔渣中TiC质量分数为4%和8%时,熔渣的剪切应力随电场的强度增大而增大,随后又随电场强度的减小而减小。含钛熔渣为基础五元渣系时,熔渣的剪切应力不随电场强度变化而变化。

3) 含钛熔渣中TiC质量分数为0%到8%,温度为1500 ℃到1450 ℃,剪切速率为0 s-1到16.8 s-1时,熔渣未表现出爬杆现象,可初步判断实验中渣样不是黏弹性流体。

REFERENCES

[1] 雷雪飞, 薛向欣, 杨 合, 朱祥剑, 李振朋. 酸浸浓度对高钛酸浸渣光催化活性的影响[J]. 中国有色金属学报, 2015, 25(6): 1640-1647.

LEI Xue-fei, XUE Xiang-xin, YANG He, ZHU Xiang-jian, LI Zhen-peng. Effects of leaching concentration on photocatalytic activity of acid leaching residue of high titanium slag[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(6): 1640-1647.

[2] 谢洪恩. 攀钢高炉炉渣性能分析[J]. 中国冶金, 2011, 11(21): 22-25.

XIE Hong-en. Analysis of properties of blast furnace slag at Pangang[J]. China Metallurgy, 2011, 11(21): 22-25.

[3] NAGASAKA T, HINO M, BAN-YA S. Interfacial kinetics of hydrogen with liquid slag containing iron oxide[J]. Metallurgical and Materials Transactions B, 2000, 31(5): 945-955.

[4] PARK H, PARK J Y, KIM G H, SOHN I. Effect of TiO2 on the viscosity and slag structure in blast furnace type slags[J]. Steel Research International, 2012, 83(2): 150-156.

[5] 王振阳, 张建良, 邢相栋, 刘征建. 钒在高钛渣系与铁液间分配行为与热力学分析[J]. 中国有色金属学报, 2015, 25(5): 1355-1361.

WANG Zhen-yang, ZHANG Jian-liang, XING Xiang-dong, LIU Zheng-jian. Distribution behaviors and thermodynamic analysis of vanadium between molten iron and high titanium slag[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(5): 1355-1361.

[6] SAITO N, HORI N, NAKASHIMA K, MORI K. Viscosity of blast furnace type slags[J]. Metallurgical and Materials Transactions B, 2003, 34B: 509-516.

[7] DONG X J, SUN H Y, SHE X F, XUE Q G, WANG J S. Viscosity and viscosity estimation model of fully liquid slags in TiO2-Al2O3-CaO-SiO2 and TiO2-Al2O3-CaO-SiO2-MgO systems with high TiO2 concentration and low mass ratio of CaO to SiO2[J]. Ironmaking and Steelmaking, 2014, 41(2): 99-105.

[8] LIAO J L, LI J, WANG X D, ZHANG Z T. Influence of TiO2 and basicity on viscosity of Ti-bearing slag[J]. Ironmaking and Steelmaking, 2012, 39(2): 133-139.

[9] XIE D, MAO Y, ZHU Y. Viscosity and flow behaviour of TiO2-containing blast furnace slags under reducing conditions[C]//VII Int. Conf. on Molten Slags Fluxes and Salts. Cape Town, South Africa: The South African Mining and Metallurgy, 2004: 43-50.

[10] JIANG T, LIAO D M, ZHOU M, ZHANG Q Y, YUE H R, YANG S T, DUAN P N, XUE X X. Rheological behavior and constitutive equations of heterogeneous titanium-bearing molten slag[J]. Int J Miner Metall Mater, 2015, 22(8): 804-810.

[11] RINALDI V A,  J J Jr. Time dependent stress-strain behavior of bentonite slurries; effect of thixotropy[J]. Powder Technology, 2016, 291: 311-321.

J J Jr. Time dependent stress-strain behavior of bentonite slurries; effect of thixotropy[J]. Powder Technology, 2016, 291: 311-321.

[12] MA Jun-yi, LIN Yan-bin, CHEN Xiang-ling, ZHAO Bao-tang, ZHANG Ji. Flow behavior, thixotropy and dynamical viscoelasticity of sodium alginate aqueous solutions[J]. Food Hydrocolloids, 2014, 38(4): 1407-1413.

[13] 张先伟, 孔令伟, 李 俊, 杨爱武. 黏土触变过程中强度恢复的微观机理[J]. 岩土工程学报, 2014, 36(8): 1944-1950.

ZHANG Xian-wei, KONG Ling-wei, LI Jun, YANG Ai-wu. Microscopic mechanism of strength increase of clay during thixotropic process[J]. Chinese Journal of Geotechnical Engineering, 2014, 36(8): 1944-1950.

[14] 涂福泉, 刘小双, 毛 阳, 胡良智. 电流变液的研究现状及其应用进展[J]. 材料导报, 2014, 6(28): 66-68.

TU Fu-quan, LIU Xiao-shuang, MAO Yang, HU Liang-zhi. Recent progress and application of electrorheological fluids[J]. Materials Review, 2014, 6(28): 66-68.

[15] HAO T. The Interfacial polarization-induced electroogical effect[J]. Journal of Colloid and Interface Science, 1998, 206(1): 240-246.

[16] 姜 涛, 张 璐, 廖德明, 薛向欣. 低电场强度下非均相含钛冶金熔渣的流变特性[J]. 中国有色金属学报, 2015, 25(1): 227-232.

JIANG Tao, ZHANG Lu, LIAO De-ming, XUE Xiang-xin. Rheological properties of heterogeneous phase titanium-bearing metallurgical slag under low electric field intensity[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 227-232.

[17] WEISSENBERG K. A continuum theory of rheological phenomena[J]. Nature, 1947, 159(4035): 310-311.

[18] BEAVERS G S, JOSEPH D D. The rotating rod viscometer[J]. J Fluid Mech, 1975, 69(3): 475-511.

[19] LUO X L. Numerical simulation of Weissenberg phenomena-the rod-climbing of viscoelastic fuids[J]. Comput Methods Appl Mech Engrg, 1999, 180(3/4): 393-412.

[20] QIU G B, CHEN L, Zhu J Y,  X W, BAI C G. Effect of Cr2O3 addition on viscosity and structure of Ti-bearing blast furnace slag[J]. ISIJ Int, 2015, 55(7): 1367-1376.

X W, BAI C G. Effect of Cr2O3 addition on viscosity and structure of Ti-bearing blast furnace slag[J]. ISIJ Int, 2015, 55(7): 1367-1376.

[21] 隋丽丽, 翟玉春. 硫酸氢铵焙烧高钛渣提取TiO2[J]. 中国有色金属学报, 2014, 24(3): 826-830.

SUI Li-li, ZHAI Yu-chun. Extraction of TiO2 from high titanium slag through roasting by ammonium bisulfate[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 826-830.

[22] 姜 涛, 岳宏瑞, 薛向欣, 段培宁, 张乔祎. 一种测定含钛熔渣电流变特性的装置: 中国, CN205209915U[P]. 2016-5-4.

JIANG Tao, YUE Hong-rui, XUE Xiang-xin, DUAN Pei-ning, ZHANG Qiao-yi. An equipment of electrorheological effect testing of titanium-bearing slag: China, CN205209915U[P]. 2016-5-4.

[23] 姜 涛, 岳宏瑞, 薛向欣, 段培宁. 一种观测含钛熔渣爬杆现象的装置: 中国,CN205209992U[P]. 2016-5-4.

JIANG Tao, YUE Hong-rui, XUE Xiang-xin, DUAN Pei-ning. An equipment of rod-climbing effect testing of titanium-bearing slag: China, CN205209992U[P]. 2016-5-4.

[24] ZHANG S F, ZHANG X, LIU W,  X W, BAI C G, WANG L. Relationship between structure and viscosity of CaO-SiO2-Al2O3-MgO-TiO2 slag[J]. J Non-Cryst Solids, 2014, 402: 214-222.

X W, BAI C G, WANG L. Relationship between structure and viscosity of CaO-SiO2-Al2O3-MgO-TiO2 slag[J]. J Non-Cryst Solids, 2014, 402: 214-222.

[25] REN S, ZHANG J L, WU L S, LIU W J, BAI Y N, XING X D, SU B X, KONG D W. Influence of B2O3 on viscosity of high Ti-bearing blast furnace slag[J]. ISIJ Int, 2012, 52(6): 984-991.

[26] CHEN De-sheng, ZHAO Long-sheng, QI Tao, HU Guo-ping, ZHAO Hong-xin, LI Jie, WANG Li-na. Desilication from titanium-vanadium slag by alkaline leaching[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(10): 3076-3082.

[27] WANG Y, LUO F, ZHOU W C, ZHU D M. Dielectric and electromagnetic wave absorbing properties of TiC/epoxy composites in the GHz range[J]. Ceram Int, 2014, 40(7): 10749-10754.

[28] YUAN X Y, CHENG L F, ZHANG L T. Influence of temperature on dielectric properties and microwave absorbing performances of TiC nanowires/SiO2 composite[J]. Ceram Int, 2014, 40(10): 15391-15397.

[29] KLINGENBERG D J, VANSWOL F, ZUKOSKI C F. The small shear rate response of electrorheological suspensions.Ⅱ.extension beyond the point-dipole limit[J]. Journal of Chemical Physics, 1991, 94(9): 6170-6178.

[30] KLINGENBERG D J, ZUKOSKI C R. Studies on the steady-shear behavior of electrorheological suspensions[J]. Langmuir, 1990, 6(1): 15-24.

[31] PARTHASARATHY M, KLINGENBERG D J. Electrorheology: Mechanisms and models[J]. Materials Science & Engineering R-Reports, 1996, 17(2): 57-103.

[32] DABBAUT B, HOCQ B. On the numerical simulation of axisymmetric swirling flows of differential viscoelastic liquids: the rod climbing effect and the Quelleffekt[J]. J Non-Newtonian Fluid Mech, 1992, 43(1): 103-126.

Expression and analysis of non-Newtonian fluid behaviors of titanium-bearing metallurgical slag

YUE Hong-rui1, JIANG Tao1, 2, XUE Xiang-xin1, 2

(1. School of Metallurgy, Northeastern University, Shenyang 110819, China;

2. Liaoning Key Laboratory of Metallurgical Resources Recycling Science, Shenyang 110819, China)

Abstract: Slag samples were based on the on-site slag (CaO-SiO2-Al2O3-MgO-TiO2) of Panzhihua Iron and Steel Corporation. Non-Newtonian behaviors, thixotropy, electrorheological effect and rod-climbing effect were investigated from 1500 ℃ to 1450 ℃. The result shows that the slag sample containing 8% TiC has an obvious thixotropy. While for the slag sample without TiC, the up line of shear stress coincides with the down line which means no thixotropy is observed. A remarkably electrorheological response is observed in slag system with 4%TiC and 8%TiC, and the shear stress increases with increasing the electric field and decreases with decreasing the electric field. For the slag sample without TiC, the shear stress is not altered by the electric field. Neither the slag system containing TiC or not containing TiC shows a rod-climbing effect.

Key words: titanium-bearing slag; non-Newtonian fluid; thixotropy; electrorheological effect; rod-climbing effect

Foundation item: Projects (51174051, 51090383) supported by the National Natural Science Foundation of China

Received date: 2016-03-28; Accepted date: 2016-10-25

Corresponding author: JIANG Tao; Tel: +86-24-83670467; E-mail: jiangt@smm.neu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51174051,51090383)

收稿日期:2016-03-28;修订日期:2016-10-25

通信作者:姜 涛,教授,博士;电话:024-83670467;E-mail:jiangt@smm.neu.edu.cn

摘 要:以攀钢实际生产高炉渣(CaO-SiO2-Al2O3-MgO-TiO2)为基础,制备不同TiC含量的渣样,研究从1500 ℃到1450 ℃含钛熔渣的触变特性、电流变特性以及爬杆现象等非牛顿流体现象。结果表明:渣样含有8%的TiC,具有明显的触变特性。渣样中不含TiC,剪切应力的上行曲线与下行曲线重合,无触变特性;渣样中TiC质量分数为4%、8%,剪切应力随电场强度的增大而增大,又随电场强度的减小而减小,熔渣具有明显的电流变特性。渣样中TiC质量分数为0时,渣样的剪切应力不随电场强度变化而变化;不同含量TiC的渣样均不具备爬杆现象。

[1] 雷雪飞, 薛向欣, 杨 合, 朱祥剑, 李振朋. 酸浸浓度对高钛酸浸渣光催化活性的影响[J]. 中国有色金属学报, 2015, 25(6): 1640-1647.

[2] 谢洪恩. 攀钢高炉炉渣性能分析[J]. 中国冶金, 2011, 11(21): 22-25.

[5] 王振阳, 张建良, 邢相栋, 刘征建. 钒在高钛渣系与铁液间分配行为与热力学分析[J]. 中国有色金属学报, 2015, 25(5): 1355-1361.

[13] 张先伟, 孔令伟, 李 俊, 杨爱武. 黏土触变过程中强度恢复的微观机理[J]. 岩土工程学报, 2014, 36(8): 1944-1950.

[14] 涂福泉, 刘小双, 毛 阳, 胡良智. 电流变液的研究现状及其应用进展[J]. 材料导报, 2014, 6(28): 66-68.

[16] 姜 涛, 张 璐, 廖德明, 薛向欣. 低电场强度下非均相含钛冶金熔渣的流变特性[J]. 中国有色金属学报, 2015, 25(1): 227-232.

[18] BEAVERS G S, JOSEPH D D. The rotating rod viscometer[J]. J Fluid Mech, 1975, 69(3): 475-511.

[21] 隋丽丽, 翟玉春. 硫酸氢铵焙烧高钛渣提取TiO2[J]. 中国有色金属学报, 2014, 24(3): 826-830.

[22] 姜 涛, 岳宏瑞, 薛向欣, 段培宁, 张乔祎. 一种测定含钛熔渣电流变特性的装置: 中国, CN205209915U[P]. 2016-5-4.

[23] 姜 涛, 岳宏瑞, 薛向欣, 段培宁. 一种观测含钛熔渣爬杆现象的装置: 中国,CN205209992U[P]. 2016-5-4.