文章编号:1004-0609(2009)07-1310-06

Fe-Co-B-Si-Nb-Cr块体非晶合金在纳米压痕过程中的

变形行为

张志纯1, 3,龙志林1, 2, 4,危洪清4,彭 建4,许 福4,李乡安4

(1. 湘潭大学 材料与光电物理学院,湘潭 411105;

2. 湘潭大学 材料设计与制备技术湖南省重点实验室,湘潭 411105;

3. 湘潭大学 能源工程学院,湘潭 411100;

4. 湘潭大学 土木工程与力学学院,湘潭 411105)

摘 要:

利用纳米压痕技术研究直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4块体非晶合金的变形行为以及加载速率对其塑性变形行为的影响规律。结果表明:该块体非晶合金在低加载速率下表现出显著的锯齿流变,而在高的加载速率下表现为连续的塑性变形;在纳米压痕过程中,该块体非晶合金出现室温蠕变现象,且其硬度值随着加载速率的增大而减小。

关键词:

中图分类号:TG 139.8 文献标识码: A

Deformation behaviour of Fe-Co-B-Si-Nb-Cr bulk amorphous alloy during nanoindentation

ZHANG Zhi-chun1, 3, LONG Zhi-lin1, 2, 4, WEI Hong-qing4, PENG Jian4, XU Fu4, LI Xiang-an4

(1. Faculty of Materials Optoelectronics and Physics, Xiangtan University, Xiangtan 411105, China;

2. Key Laboratory of Materials Design and Preparation Technology of Hunan Province,

Xiangtan University, Xiangtan 411105, China;

3. College of Energy Engineering, Xiangtan University, Xiangtan 411100, China;

4. College of Civil Engineering and Mechanics, Xiangtan University, Xiangtan 411105, China)

Abstract: The deformation behaviour of {[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4 bulk amorphous alloy with a diameter of 3 mm and the influence of loading rate on its plastic deformation were investigated by the technique of nanoindentation. The results show that the {[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4 bulk amorphous alloy exhibits prominent serrated flow at low loading rate while the plastic deformation is continuous at high loading rate. During nanoindentation, the room temperature creep of the {[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4 bulk amorphous alloy is observed, and its hardness decreases with the increase of loading rate.

Key words: bulk amorphous alloy; nanoindentation; serrated flow; creep

块体非晶合金优异的力学、物理和化学性能从一出现就引起人们极大的兴趣。自Inoue研究小组首次报道Fe-(Al,Ga)非金属系铁基块体非晶合金以来,人们已经制备出了多种块体非晶合金并对其力学行为进行了研究[1?8],VERDUZCO等[1]如:在Fe77.5?xCrxSi7.5B15 (x=0~8, 摩尔分数,%)非晶中添加少量Cr可以增大其非晶带的抗拉强度;INOUE等[2]制备了[(Fe1?xCox)0.75B0.2Si0.05]96Nb4块体非晶合金,其断裂强度为3 900~4 250 MPa、弹性模量为190~210 GPa;STOICA等[3]利用铜模铸造法制备了2 mm×2 mm×30 mm的Fe66.5Cr4Mo4Ga4P12C5B5.5块体非晶合金,其断裂强度达2.8 GPa,弹性形变达1.9%,而且其断裂行为不同于Zr基、Cu基和Ti基合金。这种断裂行为不是沿着其预定方向扩展,断裂面很不规则,也不像脉状血管式的裂纹[3]。块体非晶合金在室温单轴拉伸或压缩情况下、在没有明显塑性变形的情况下发生的这种断裂行为,限制了块体非晶合金的实际应用[9?13],也导致块体非晶合金的塑性变形机理研究和寻找提高塑性的途径成为块体非晶合金领域研究的热点。一些研究 者[14?15]尝试从其微观组织结构中研究其力学性能,希望建立微观力学性能与宏观力学性能的本构关系,并以此设计出具有较好塑性的铁基块体非晶合金。近20年来用于测量材料微观力学性能的纳米压痕技术,具有省材、高灵敏度、高精确度等特点。GOLOVIN等[14]和SCHUH等[15]把该技术应用到块体非晶合金的研究中,其研究结果表明,该技术很适合研究块体非晶合金这类准脆性材料的微观变形行为。块体非晶合金在纳米压痕过程中可产生显著的塑性变形,为研究其塑性变形机理提供了大量有价值的信息。目前,纳米压痕技术已成为研究块体非晶合金微观力学性能的重要手段,但利用纳米压痕技术研究铁基块体非晶合金微观力学性能的相关报道很少。

本文作者利用铜模铸造法分别制备直径为2、3、4 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4块体非晶合金,并对其进行XRD测试和DSC检测。在确定直径为3 mm的样品为完全非晶合金后,利用纳米压痕技术研究该块体非晶合金的变形行为,深入研究Fe-Co-B-Si-Nb-Cr块体非晶合金的脆性本质,探讨其塑性不稳定性机理。

1 实验

在高纯氩气保护下,采用纯度大于99.9%的铁、钴、铌、铬、硼、硅为原料,按{[(Fe0.6Co0.4)0.75B0.2- Si0.05]0.96Nb0.04}96Cr4所需摩尔分数配料,将配料放入非自耗式真空电弧炉的铜制坩埚内,将配料多次熔炼至成分均匀的母合金;再将母合金放入真空度小于1.0 Pa的铜模铸造炉的石英管内,熔腔内充入保护氩气,接通高频线圈电源,利用高频线圈产生的巨大热能使母合金熔成液态,在压力差作用下,液态母合金迅速向下喷溅至旋转的单辊铜模表面,并迅速冷却,在结晶温度以下凝固,形成厚度约20 μm的合金薄带样品。将母合金在高压铜模铸造炉内熔化并压入直径约为2、3、4 mm与长约50 mm的铜模中,得到直径约为2、3、4 mm的合金棒样品。利用X射线衍射仪(Cu Kα,λ=0.154 18 nm)分别对合金薄带、棒样品进行X射线 衍射分析;在加热速率为0.67 K/s下,采用差示扫描量热计(DSC)分析其热稳定性;纳米压痕实验选用

TriboIndenter压痕仪、Berkovich压头,通过载荷控制模式,用不同的恒定加载速率(如0.75、1、3和6 mN/s)加载到最大载荷为231 mN后保载10 s,然后以与加载过程相同的速率卸载到0,在每种加载速度下,样品在同样条件下反复测试4个点;利用Digital Instruments NS-3D原子力显微镜观察纳米压痕的形貌。

2 结果

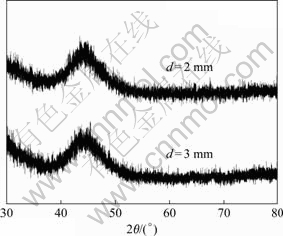

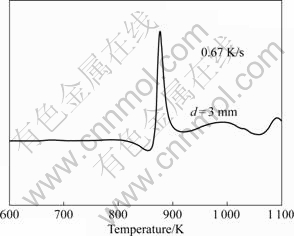

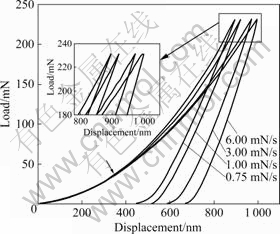

图1所示为直径分别为2、3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4块体合金棒的 XRD谱。由图1可知,XRD谱中没有锐利的晶态衍射峰,而仅在2θ=45?附近有一个弥散的漫射峰,这表明两种直径的合金棒均为完全非晶结构。图2所示为直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4块体非晶合金棒在0.67 K/s加热速率下测量的DSC曲线。 从图2中可看出,直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2- Si0.05]0.96Nb0.04}96Cr4块体非晶合金棒呈现玻璃化转变引起的吸热现象和晶化引起的放热峰,其玻璃转变温度(Tg)、晶化温度(Tx)和过冷液相区温度(ΔTx=Tx?Tg)分别达到833、874和41 K。图3所示为{[(Fe0.6Co0.4)0.75B0.2-Si0.05]0.96Nb0.04}96Cr4块体非晶合金棒在不同加载速率下的纳米压痕试验的荷载—位移曲线。从图3中可见,随着加载速率的增加,该块体非晶合金的变形行为呈现如下特征:1) 在不同的加载速率下,加载曲线有一小段是重合的,直到分叉点(约350 nm处)后出现分离(如图3中箭头所示),而且该段加载曲线光滑连续(没有明显的锯齿流变现象);2) 从分叉点到极限载荷(231 mN)的加载过程中,当加载速率为0.75、1和3 mN/s时,加载曲线上有明显的pop-in现象,当加载速率为6 mN/s时锯齿流变现象基本消失,总体趋势是pop-in现象随着加载速率的增大而减少;3) 在载荷达到最大值后的保载阶段,加载速率为6 mN/s的加载曲线中出现了一个宽约5 nm的蠕变平台,这个蠕变平台的宽度随着加载速率的减小逐渐减小,当加载速率减小到0.75 mN/s时加载曲线中已无明显的蠕变平台;4) 在不同加载速率下从0加载到231 mN,残余深度随加载速率的增加而增大,这反映了合金的硬度随加载速率的增加而减小,硬度从0.75 mN/s时的19.7 GPa逐渐减小到6 mN/s时的14.43 GPa。

图1 直径为2和3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96- Nb0.04}96Cr4块体非晶合金棒的XRD谱

Fig.1 XRD patterns of {[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96- Nb0.04}96Cr4 bulk amorphous alloy rods with diameters of 2 and 3 mm

图2 直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96- Cr4块体非晶合金棒的DSC曲线

Fig.2 DSC curve of {[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4 bulk amorphous alloy rod with diameter of 3 mm

图3 直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4块体非晶合金棒在不同加载速率下的纳米压痕实验的荷载—位移曲线

Fig.3 Typical load—displacement curves measured by nanoindentation experiments for {[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96- Nb0.04}96Cr4 bulk amorphous alloy rod with diameter of 3 mm at different loading rates

3 分析

按照经典弹塑性理论:物体在一定载荷下发生的弹性变形与力的加载路径无关,即在弹性阶段,不同的加载速率得到的载荷—位移曲线是一致的。图3中原点到分叉点(图3中箭头指示位置处)曲线的一致性符合经典弹塑性理论。已报道的Zr基、Pd基、Nd基和La基[14?19]等块体非晶合金系纳米压痕实验加载曲线中也存在锯齿流变现象,且低应变速率下锯齿流变现象显著,随着应变速率的增加,锯齿流变现象逐渐减弱和消失。塑性变形过程中出现这种应力的降落或者跳跃,对于晶体材料而言是由于可动位错和固溶原子的交互作用引起的动态时效过程;对非晶合金来说,由于合金中没有位错等缺陷,过去一般认为是由于非均匀的塑性变形引起的,而SCHUH等[14]认为,锯齿流变与剪切带的形成和扩展密切相关,低应变速率下单一剪切带可以充分扩展,出现明显的锯齿;高应变速率下,多重剪切带同时开动,单一剪切带不能得到充分扩展,锯齿不明显,表现为连续变形。对于直径为3 mm的{[(Fe0.6Co0.4)0.75- B0.2Si0.05]0.96Nb0.04}96Cr4块体非晶合金棒的加载曲线,锯齿流变与应变速率的关系与报道的Zr基、Pd基、Nd基和La基块体非晶[8?13]合金系完全相同,表明锯齿流变行为的转变与这些体系存在相同的机制,即直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96- Nb0.04}96Cr4玻璃合金棒的塑性变形主要集中在少数的剪切带内,压痕过程中的锯齿流变与剪切带的形成和扩展密切相关,其变形过程是一个应力软化的过程。

进一步分析直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2- Si0.05]0.96Nb0.04}96Cr4块体非晶合金棒的载荷—位移曲线还发现,在高加载速率下,当载荷达到最大时,保载阶段有一段蠕变平台,而低加载速率下这种蠕变现象不明显。这一现象的产生与材料的黏弹性和黏性流动相关[20?23]。在高加载速率下,黏弹性和黏性流动在加载过程中受到抑制,而在最大载荷处的保载阶段得到充分发展,表现为最大载荷处的明显蠕变变形;在低加载速率下,黏弹性和黏性流动变形在缓慢的加载过程中已基本完成,最大载荷处的蠕变不明显。

在Zr基和Pd基等体系块体非晶合金的纳米压痕过

程中,硬度与加载速率无关[10?11],Ce基大块非晶合金表现出硬度随加载速率增加而增大的趋势[24],这与Ce基材料的高T/Tg值相关,在接近Tg的温度下,变形行为包含了黏弹性和黏性流动,这两种变形模式都是与时间相关的变形行为。在高加载速率下,黏弹性行为和黏性流动受到抑制,在达到预定载荷时压入的深度较小,从而表现为材料相对较高的硬度;而在较低的加载速率下,黏弹性和黏性流动可以得到充分发生,因而达到预定载荷时压入的深度显著增加,表现为较低的硬度值。而本研究中直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2- Si0.05]0.96Nb0.04}96Cr4块体非晶合金的硬度随着加载速率的增大而减小,这可能与惯性效应和粘度有关。在高加载速率下,大的惯性效应和高加载速率引起的温度升高使粘度下降,使在达到预定载荷时压入深度较大,硬度值随加载速率的增加而减小。

在纳米压痕实验中计算材料的硬度通常使用的是Oliver-Pharr方法,接触深度hc是通过卸载曲线利用下式计算:

![]()

式中:h为压入深度,P为对应位移处的载荷,ε为与压头类型有关的常数(对Berkovich压头是0.75),S为卸载曲线的斜率(即接触刚度):

S=dP/dh (2)

再根据接触面积函数A=fhc确定,有时也称为形状函数。对于理想的Berkovich压头:

Ac=24.56hc2 (3)

材料的硬度可以表示为

![]()

由于用Oliver-Pharr方法只能得到最大位移处的卸载曲线斜率,所以也只能算出最大位移处的硬度值。要得到H—h关系,则必须得到S—h关系。一般材料的S—h关系是线性的[25],可用下式描述:

S=a+bh (5)

式中:a和b都是常数,任意两个不同压入深度的S值决定了整个S—h关系,将式(5)代入式(1)可得hc—h关系,再将该hc—h关系代入式(3)就能算出Ac—h的关系。这样,也就能从式(4)计算出H—h关系。

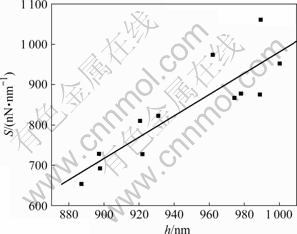

使用最小二乘法对不同速率的卸载曲线的接触刚度(S)及压入深度(h)拟合(如图4)。由图4可知:

S=?1662.90318+2.6439h (6)

(7)

(7)

图4 不同速率的卸载曲线中接触刚度(S)与压入深度(h)的实验数据和拟合关系曲线

Fig.4 Experimental data and fitting curve of contact stiffness vs displacement at different loading rates

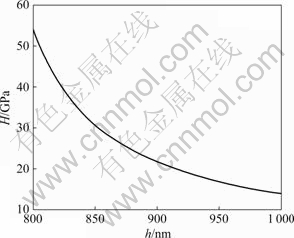

将P=231 mN代入式(7),可得H—h关系(见图5)。由图5可知,随着压入深度的增加合金硬度值减小。

图5 最大载荷为231 mN时硬度与压入深度的关系

Fig.5 Relationship between hardness and displacement at maximum load of 231 mN

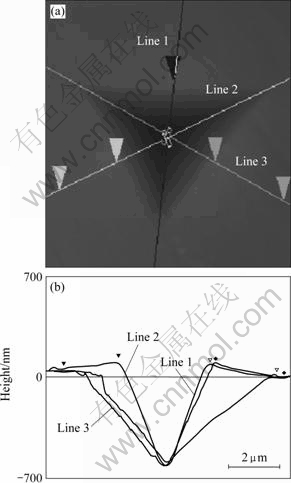

图6所示为利用Digital Instruments NS-3D原子力

图6 0.75 mN/s加载速率下{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96- Nb0.04}96Cr4 块体非晶合金纳米压痕的AFM形貌(a)及其横线高度分布(b)

Fig.6 AFM morphology (a) and cross-section profile (b) of indent after nanoindentation for {[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96- Nb0.04}96Cr4 bulk amorphous alloy at loading rate of 0.75 mN/s

显微镜(AFM)观测的压痕表面形貌。图中压痕是直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4块体非晶合金棒样品在加卸载速率均为0.75 mN/s的纳米压痕实验中形成的。从图6(a)可以看出,在加载速率为0.75 mN/s下的压痕边缘表面附近有不同程度的突起,且图6(b)清楚地显示了突起高度差,最大达到99.662 nm。这进一步表明直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4块体非晶合金棒在低载速率下有明显的锯齿流变现象。

4 结 论

1) 在对直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2- Si0.05]0.96Nb0.04}96Cr4块体非晶合金的制备与纳米压痕加载过程中,通过DSC检测获得其玻璃转变温度、晶化温度和过冷液相区温度分别达到833、874和41 K。

2) 在不同的加载速率下,加载位移从0增加到约350 nm内加载曲线光滑连续(没有明显的锯齿流变现象);当加载位移继续增加至最大值的过程中,表现出不连续的塑性变形即锯齿流变现象,且随着加载速率的增大锯齿流变现象逐渐消失;在以6 mN/s的加载速率加卸载曲线中的保载阶段,观察到5 nm的蠕变平台,当加载速率减少到0.75 mN/s 后蠕变平台消失。

4) 在0.75~6 mN/s的加载速率中,合金硬度随加载速率的增加而减小,即硬度值由19.7 GPa降低到14.43 GPa,这表明铁基块体非晶合金的塑性变形包括黏性流动等因素。

[1] VERDUZCO J A, BETANCOURT I, SAAVEDR F, REYNOSO E. Mechanical properties of amorphous Fe-based melt spun ribbons with Cr additions[J]. J Non-cryst Solids, 2003, 329: 163?166.

[2] INOUE A, SHEN B L, CHANG C T. Super-high strength of over 4 000 MPa for Fe-based bulk glassy alloys in [(Fe1?xCox)0.75B0.2Si0.05]96Nb4 system[J]. Acta Materialia, 2004, 52: 4093?4099.

[3] STOICA M, ECKERT J, ROTH S, ZHANG Z F, SCHULTZ L, WANG W H. Mechanical behavior of Fe65.5Cr4Mo4Ga4P12C5B5.5 bulk metallic glass[J]. Intermetallics, 2005, 13: 764?769.

[4] LONG Z L, SHAO Y, DENG X H, ZHANG Z C, JIANG Y, ZHANG P, SHEN B L, INOU E A. Cr effects on magnetic and corrosion properties of Fe-Co-Si-B-Nb-Cr bulk glassy alloys with high glass-forming ability[J]. Intermetallics, 2007, 15: 1453?1458.

[5] LONG Z L, SHEN B L, SHAO Y, CHANG C T, ZENG Y Q, INOUE A. Corrosion solutions[J]. Materials Transactions, 2006, 47: 2566?2570.

[6] LONG Z L, CHANG C T, DING Y H, SHAO Y, ZHANG P, SHEN B L, INOUE A. Corrosion behavior of Fe-based ferromagnetic (Fe, Ni)-B-Si-Nb bulk glassy alloys in aqueous electrolytes[J]. Journal of Non-Crystalline Solids, 2008, 354: 4609?4613.

[7] LONG Z L, WEI H Q, DING Y H, ZHANG P, XIE G Q, INOUE A. A new criterion for predicting the glass-forming ability of bulk metallic glasses[J]. Journal of Alloys and Compounds, 2009, 475: 207?219.

[8] LONG Z L, XIE G Q, WEI H Q, SU X P, PENG J, ZHANG P, INOUE A. On the new criterion to assess the glass-forming ability of metallic alloys[J]. Mater Sci Eng A, 2009, 509: 23?30.

[9] INOUE A. Stabilization of metallic supercooled liquid and bulk amorphous alloys[J]. Acta Materialia, 2000, 48: 279?306.

[10] 杨元政, 董振江, 仇在宏, 陈小祝, 谢致薇, 白晓军. 块体非晶合金Cu58Zr20Ti20Mo2 的形成与力学性能[J]. 中国有色金属学报, 2007, 17(7): 1090–1095.

YANG Yuan-zheng, DONG Zheng-jiang, QIU Zai-hong, CHEN Xiao-zhu, XIE Zhi-wei, BAI Xiao-jun. Formation and mechanical properties of Cu58Zr20Ti20Mo2 bulk metallic glass[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(7): 1090–1095.

[11] MUKAI T, NIEH T G, KAWAMURA Y, INOUE A, HIGASHI K. Dynamic response of a Pd40Ni40P20 bulk metallic glass in tension[J]. Scripta Materialia, 2002, 46: 43–47.

[12] LONG Z L, SHAO Y, XIE G Q, ZHANG P, SHEN B L, INOUE A. Enounced soft-magnetic and corrosion properties of Fe-based bulk glassy alloys with improved plasticity through the addition of Cr[J]. Journal of Alloy and Compounds, 2008, 462: 52–59.

[13] GOLOVIN Y I, IVOLGIN V I, KHONIK V A, KITAGAWA K, TYURIN A I. Serrated plastic flow during nanoindentation of a bulk metallic glass[J]. Scripta Materialia, 2001, 45: 947–952.

[14] SCHUH C A, NIEH T G A. Nanoindentation study of serrated flow in bulk metallic Glasses[J]. Acta Materialia, 2003, 51: 87–99.

[15] WEI B C, ZHANG T H, LI W H, SUN Y F, WANG Y R. Serrated plastic flow during nanoindentation in Nd-based bulk metallic glasses[J]. Intermetallics, 2004, 12: 1239–1243.

[16] NIEH T G, SCHUH C, WADSWORTH J, LI Y. Strain rate-dependent deformation in bulk metallic glasses[J]. Intermetallics, 2002, 10: 1177–1182.

[17] YANG F Q, GENG K, LIAW P K, FAN G J, CHOO H. Deformation in a Zr57Ti5Cu20Ni8Al10 bulk metallic glass during nanoindentation[J]. Acta Materialia, 2007, 55: 321?327.

[18] MUKHOPADHYAY N K, BELGER A, PAUFLER P, KIM D H. Nanoindentation studies on Cu-Ti-Zr-Ni-Si-Sn bulk metallic glasses[J]. Mater Sci Eng A, 2007, 449/451: 954?957.

[19] DROZDZ D, KULIK T, FECHT H J. Nanoindentation studies of Zr-based bulk metallic glasses[J]. Journal of Alloys and Compounds, 2007, 441: 62?65.

[20] WEI B C, ZHANG T H, ZHANG L C, XING D M, LI W H, LIU Y. Plastic deformation in Ce-based bulk metallic glasses during depth-sensing indentation[J]. Mater Sci Eng A, 2007, 449/451: 962?965.

[21] ZHANG L C, WEI B C, XING D M, ZHANG T H, LI W H, LIU Y. The characterization of plastic deformation in Ce-based bulk metallic glasses[J]. Intermetallics, 2007, 15: 791?795.

[22] LI W H, SHIN K, LEE C G, WEI B C, ZHANG T H, HE Y Z. The characterization of creep and time-dependent properties of bulk metallic glasses using nanoindentation[J]. Mater Sci Eng A, 2008, 478: 371?375.

[23] 彭 建, 龙志林, 危洪清, 李乡安, 张志纯. 铁基块体晶合金在纳米压痕过程中的蠕变行为研究[J]. 物理学报, 2009, 58(6): 4059?4065.

PENG J, LONG Z L, WEI H Q, LI X A, ZHANG Z C. Creep behavior of a Fe-based bulk amorphous alloy using nanoindentation[J]. Acta Physica Sinica, 2009, 58(6): 4059?4065

[24] 张凌晨, 邢冬梅, 张泰华, 魏炳忱, 李维火, 王育人. Ce基大块非晶合金在纳米压人过程中的变形行为[J]. 科学通报, 2006, 51(11): 1349?1352.

ZHANG Ling-chen, XING Dong-mei, ZHANG Tai-hua, WEI Bing-chen, LI Wei-huo, WANG Yu-ren. The behavior of deformation in Ce-based bulk metallic glasses during nanoindentation[J]. Chinese Science Bulletin, 2006, 51(11): 1349?1352.

[25] 谭孟曦. 利用纳米压痕加载曲线计算硬度-压入深度关系及弹性模量[J]. 金属学报, 2005, 41(10): 1020?1024.

TAN Meng-xi. Extracting hardness-displacement relations and elastic moulus using nanoindentation loading curves[J]. Acta Metallurgica Sinica, 2005, 41(10): 1020?1024.

基金项目:湖南省自然科学基金资助项目(09JJ6069);湖南省科技厅计划资助项目(2008FJ3095);湖南省教育厅资助科研项目(09A088, 08C880, 08C893)

收稿日期:2008-03-27;修订日期:2009-02-15

通讯作者:龙志林,教授,博士;电话:0731-58298287;E-mail: longzl@xtu.edu.cn

(编辑 李向群)

摘 要:利用纳米压痕技术研究直径为3 mm的{[(Fe0.6Co0.4)0.75B0.2Si0.05]0.96Nb0.04}96Cr4块体非晶合金的变形行为以及加载速率对其塑性变形行为的影响规律。结果表明:该块体非晶合金在低加载速率下表现出显著的锯齿流变,而在高的加载速率下表现为连续的塑性变形;在纳米压痕过程中,该块体非晶合金出现室温蠕变现象,且其硬度值随着加载速率的增大而减小。