DOI: 10.11817/j.ysxb.1004.0609.2021-36619

Al-Cu-Li系铝锂合金的合金化与微合金化

李劲风,宁 红,刘丹阳,郑子樵

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:

综述了铝锂合金研发历程及成分设计的发展阶段,重点阐述了Al-Cu-Li系铝锂合金中主合金化元素Cu、Li含量对时效析出相类型、力学性能及耐腐蚀性能的影响规律及影响机理,详细论述了微合金化元素Zr、Mn、Mg、Ag、Zn、稀土和In等对Al-Cu-Li系铝锂合金力学性能、耐腐蚀性能及微观组织包括再结晶、时效析出相类型与分布密度的影响。结合笔者课题组研究结果,提出了高强铝锂合金及耐腐蚀铝锂合金两种类型铝锂合金的成分设计思路。

关键词:

文章编号:1004-0609(2021)-02-0258-22 中图分类号:TG146.2 文献标志码:A

引文格式:李劲风, 宁 红, 刘丹阳, 等. Al-Cu-Li系铝锂合金的合金化与微合金化[J]. 中国有色金属学报, 2021, 31(2): 258-279. DOI: 10.11817/j.ysxb.1004.0609.2021-36619

LI Jin-feng, NING hong, LIU Dan-yang, et al. Alloying and micro-alloying in Al-Cu-Li series alloys[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(2): 258-279. DOI: 10.11817/j.ysxb.1004.0609.2021-36619

铝锂合金是指在铝及铝合金中添加Li而形成的一类铝合金。在铝合金中每添加1.0%的Li,可使铝合金密度降低3%,刚度提高6%[1]。新型铝锂合金不仅具有低密度、高弹性模量、高比强度和高比刚度的优点,同时还兼具低疲劳裂纹扩展速率、较好的高温及低温性能等特点[2]。因此,铝锂合金是未来非常有竞争力的一类航空航天材料,欧美及俄罗斯等国均十分重视新型铝锂合金的研制和开发。铝锂合金主要包括Al-Mg-Li及Al-Cu-Li(或Al-Li-Cu)两个系列。Al-Mg-Li系主要为俄罗斯(前苏联)发展的铝锂合金系列,包括1420、1421、1423、1424等铝锂合金,其中Mg和Li均为主合金元素。其他铝锂合金如2197、2195、2050、2055、1460、1469、2090、8090等则基本为Al-Cu-Li系铝锂合金,Cu和Li均为其主合金元素,该系列铝锂合金是现阶段开发新型铝锂合金的主要体系。

铝锂合金的研究和开发至今已有80多年历史,其发展可分为三个阶段,相应的铝锂合金产品也明确划分为三代[2-3],而且第三代铝锂合金在航空及航天工业上已经获得广泛应用。自2010年以来,美国铝业公司(Alcoa)、加拿大铝业公司(Alcan)、美国宇航局(NASA)、空客等铝合金生产企业及应用部门均提出了发展第四代铝锂合金的构想。其中超高强度是第四代铝锂合金的目标性能之一,即在抗疲劳性能、弹性模量基本不降低的前提下,进一步提高其强度和断裂韧性[4]。国内中南大学、航天材料及工艺研究所跟踪了这一发展趋势,已在国家攻关项目的支持下,开发了相应的超高强铝锂合金并进行了工业化试制。

强度提升一直是铝锂合金最主要的发展方向之一。纵观铝锂合金的发展历史,铝锂合金高强化经历了以下三个成分设计阶段。第一个成分设计阶段是高主合金化元素含量阶段,主要采取以下两种方法:1) Li在铝中的固溶度极限为4.2%(约14%),前期主要通过提高主合金化元素Li含量至2%以上甚至更高,增加时效析出相δ′相(Al3Li)的分数[5-6];2) 适当提高Al-Cu-Li系铝锂合金中的Cu含量,析出新的时效强化相T1相(Al2CuLi),产生δ′和T1相的复合强化[7]。

第二个成分设计阶段是Mg+X(X=无、Ag或Zn)微合金化阶段。20世纪80年代末,澳大利亚学者POLMEAR等在Al-4.0Cu-0.3Mg-0.4Ag铝合金中加入不同含量Li(0,0.13%,0.5%,1.0%,2.5%),发现随Li含量增加,其时效硬化效应并不顺序增加;Li含量增加至2.5%,其时效硬化效应下降[8]。之后,Alcoa研究人员在Al-2.6Cu-2.1Li合金中同时添加少量Mg和Zn,发现合金的强度和韧性有较大幅度提高[9]。上述现象的发现标志着铝锂合金的成分设计进入了第二个阶段,即在Al-Cu-Li系铝锂合金中通过Mg/Mg+Ag/Mg+Zn微合金化来实现铝锂合金强度的进一步提升。根据上述原理,Alcoa相继开发了Mg+Ag微合金化的Weldalite 049系列高强铝锂合金,以及Mg+Zn微合金化的2099、2199及2070铝锂合金。国内也于“十一五”、“十二五”期间,由中南大学、北京航空材料研究院、航天材料及工艺研究所、西南铝业(集团)有限责任公司联合开发了Mg+Zn微合金化的2A97铝锂合金。

铝锂合金的第三个成分设计阶段可总结为Mg+Ag+Zn多元复合微合金化阶段。2012年,Alcoa推出了Mg、Ag、Zn共同复合微合金化的2060铝锂合金及2055铝锂合金;其中2055铝锂合金具有超高强度,其典型T8态抗拉强度达到640 MPa。同时,国内中南大学、航天材料及工艺研究所、西南铝业(集团)有限责任公司在Mg+Ag+Zn多元复合微合金化的基础上,通过调整Cu、Li含量,开发了一种新型超高强铝锂合金[10-13]。

1 Al-Cu-Li系铝锂合金中主要时效析出相的强化效果

作为可热处理强化铝合金,Al-Cu-Li系铝锂合金的主要时效强化相包括T1相、δ′相和θ′相 (Al2Cu)。T1相为平衡相,晶体结构为密排六方结构,其晶格常数分别为:a=0.4965 nm,c=0.9345 nm[14]。T1相呈圆盘状,在铝基体{111}Al面析出,与铝基体半共格,其取向关系为:(0001)T1//(111)Al,[1010]T1// [110]Al[14-16]。铝锂合金中T1相在铝基体[112]Al入射方向的选区衍射(SAED)谱及相应透射电镜(TEM)暗场(DF)像照片如图1(a),(b)所示。

θ′相为亚稳相,晶体结构为四方结构,其晶格常数分别为:a=0.404 nm,c=0.58 nm(根据 Silcock 模型)[16]。θ′相呈圆盘状,在铝基体{100}Al面析出,与铝基体半共格,与基体的取向关系为:(100)θ′// (100)Al,[001]θ′//[001]Al[16]。铝锂合金中θ′相在铝基体[100]Al入射方向的SAED谱及相应TEM-DF照片如图1(c),(d)所示。

δ′相为亚稳相,晶体结构为立方超点阵晶体结构(L12),其晶格常数为a=0.405 nm。δ′相为球状相,与铝基体共格,其共格关系为(100)δ′//(100)Al,[001]δ′//[001]Al [16]。铝锂合金中δ′相在铝基体[100]Al入射方向的SAED谱及相应TEM-DF照片如图1(e),(f)所示。

上述三种时效析出相强化机理与强化效果不同。T1相与铝基体半共格,在欠时效时位错可以切过,而峰时效及过时效时主要为绕过强化机制;θ′相与铝基体半共格,欠时效至时效阶段均以绕过强化机制为主;δ′相与铝基体共格,欠时效阶段以切过强化机制为主,但峰时效后δ′相长大,其强化方式转变为绕过机制[17]。

在{111}Al面上析出的直径为D、厚度为T(D>> T)的T1相与交截的{111}Al 滑移面之间的二面角为70.53°,在{111}Al滑移面上T1相的投影及有效间距λ如图2所示。而{100}Al面上析出的直径为D、厚度为T(D>> T)的θ′相与{111}Al滑移面之间的二面角则为54.74°,在{111}Al 滑移面上θ′相的投影及有效间距λ如图3所示[18-19]。

假定球状析出相转变为圆盘状析出相时,单位体积内析出相数密度及单个析出相体积不变,NIE等分别基于切过强化机制和绕过强化机制计算了T1相及θ′相强化效果与球状析出相δ′相强化效果的比值(Dt(plate)/Dt(sphere))随长宽比(Aspect ratio)变化的关系曲线,如图4所示[18-19]。在两种强化机制作用下,T1相及θ′相强化效果均显著大于δ′相,而且T1相及θ′相强化效果均随其长宽比增加而逐渐增大;同时,在相同的长宽比条件下,{111}Al晶面上析出的圆盘状T1相引起的强化效果大于{100}Al晶面上析出的圆盘状θ′相。另外,T1相长宽比通常大于θ′相长宽比。综合而言,铝锂合金主要时效析出相强化效果顺序为:T1相>θ′相>δ′相。

图1 Al-Cu-Li系铝锂合金SAED谱及时效析出相TEM-DF照片

Fig. 1 SAED patterns and TEM-DF images of Al-Cu-Li alloys

图2 {111}Al面上析出T1相示意图及其在{111}Al滑移面上的投影[18]

Fig. 2 Plate-shaped T1 precipitates at {111}Al plane (a) and their projection on {111}Al slip plane (b)

图3 {100}Al面上析出θ′相示意图及其在{111}α滑移面上的投影[18]

Fig. 3 Plate-shaped θ′ precipitates at {100}Al plane (a) and their projection on {111}Al slip plane (b)[18]

图4 基于切过机制及绕过机制时圆盘状T1相及θ′相强化效果与球状δ′相强化效果的比值(Dt(plate)/Dt(sphere))随长宽比变化的关系曲线[19]

Fig. 4 Variation of ratio (Dt(plate)/Dt(δ′)) with aspect ratio for plate-shaped T1 and θ′ precipitates, calculated assuming (a) shearing mechanism of shearable particles and (b) by-passing mechanism of shear-resistant particles[19]

2 Cu和Li主合金化元素

2.1 Cu、Li含量对Al-Cu-Li系铝锂合金析出相的影响

Cu、Li均为Al-Cu-Li系铝锂合金的主合金元素。铝锂合金中随Cu含量增加,相应地Li含量会有所降低。总体而言,从第二代铝锂合金发展至第三代铝锂合金,其Cu含量从1.0%~2.0%增加至2.5%~4.5%,而Li含量则从2.5%降低至1.5%甚至以下。图5所示为部分典型Al-Cu-Li系铝锂合金Cu、Li含量。

图5 部分典型Al-Cu-Li系铝锂合金的Cu、Li含量

Fig. 5 Cu and Li concentrations of some typical Al-Cu-Li series of alloys

Al-Cu-Li系铝锂合金可能的主要时效强化相包括T1相、δ′相和θ′相,在时效过程中还可能形成GP区、δ′/GP/δ′复合相及δ′/θ′/δ′复合相。然而,Cu、Li含量的差别将导致Al-Cu-Li系铝锂合金析出相组成产生显著差异。

表1所示为不同Cu、Li含量铝锂合金的主要时效析出相组成。当铝锂合金中Cu含量较低 (<2.0%)而Li含量较高时,其主要时效析出相为δ′相,如8090铝锂合金(1.0~1.6Cu,2.2~2.7Li)[20]。随Cu含量增加至2.5~3.0%,在析出δ′相的基础上,还会形成另一种主要时效析出相T1相,此时合金的主要强化相组成为δ′+T1相,如2090铝锂合金(2.4~ 3.0Cu,1.9~2.6Li)[22]。当Cu含量为2.5%~3.0%而Li含量降低至约1.5%~2.0%时,T1相比例增加,而δ′相比例减少,合金的主要强化相组成为T1+δ′,如2099铝锂合金(2.4%~3.0%Cu、1.6%~2.0%Li)[24]。当Cu含量增加而Li含量进一步降低时,合金的主要强化相组成为T1+θ′相,如2195、2050、2198、2055等铝锂合金[25-30]。上述表明Al-Cu-Li系铝锂合金中主要时效析出相组成与其w(Cu)/w(Li)密切相关,高w(Cu)/w(Li)有利于增加T1相和θ′相比例,而低w(Cu)/w(Li)则导致较高的δ′相比例。

表1 不同Cu、Li含量铝锂合金主要时效析出相

Table 1 Main aging precipitates of Al-Li alloys with various Cu and Li concentrations

实际上,当Al-Cu-Li系铝锂合金中Cu、Li含量适当以及特定时效工艺时,其时效强化相组成更加复杂,三种时效析出相T1、θ′及δ′相比例均较高,并可能同时存在大量GP区,形成GP/δ′/GP复合相,如T8态时效含3.1%Cu和2.1%Li的1460铝锂合金(见图6)[23]。

Cu/Li比不同还导致铝锂合金中析出序列的差异。JO等[31]总结了不同w(Cu)/w(Li)铝锂合金T6态时效析出序列,认为在不同w(Cu)/w(Li)铝锂合金中时效析出序列为如下:

w(Cu)/w(Li)>4.0:SSSS→GP区→θ″相→θ′相→θ相;

w(Cu)/w(Li)=2.5~4.0:SSSS→GP区→GP区+δ′相→θ″相+δ′相→θ′相+δ′相→δ′相+T1相→T1相;

w(Cu)/w(Li)=1.0~2.5:SSSS→GP区+δ′相→θ′相+δ′相→δ′相+T1相→T1相;

w(Cu)/w(Li)<1.0:SSSS→δ′相+T1相→T1相。(SSSS指过饱和固溶体)

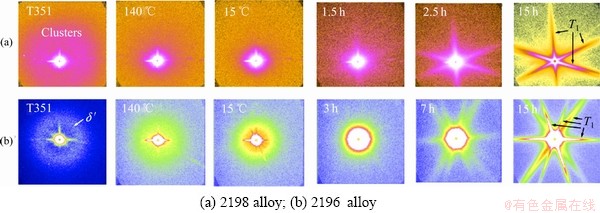

w(Cu)/w(Li)还影响合金铝锂合金T8态时效时最主要强化相T1相析出的孕育期。DECREUS等[32]采用小角度中子散射(Small-angle neutron scattering, SANS)技术研究了2196铝锂合金及2198铝锂合金T8态时效升温及保温(155 ℃)时的析出过程。在Cu/Li比较高的2198铝锂合金中,保温1.5 h时即可观察到T1相析出的第一个各向异性X射线散射条纹(见图7(a)),而Cu/Li比较低的2196铝锂合金保温3~7 h才出现T1相析出的第一个各向异性X射线散射条纹(见图7(b)),即说明Cu/Li比较高时,T1相析出孕育期较短[32]。

图6 T8态时效1460铝锂合金SAED谱及TEM照片[23]

Fig. 6 SAED patterns and TEM images of T8-aged 1460 Al-Li alloy

图7 T351态2198及2196铝锂合金升温及保温不同时间的SAXS图像[32]

Fig. 7 Sequence of SAXS images for 2198 and 2196 Al-Li alloys in T351 temper during heating ramp (at 140 ℃ and 155 ℃) and aging at 155 ℃ for different times, showing formation of characteristic streaks of T1 precipitate

除此之外,w(Cu)/w(Li)不同可导致铝锂合金晶界析出相种类和分布的差异[33]。在高w(Cu)/w(Li)铝锂合金中,晶界可析出较密集的T1相(见图8(a));w(Cu)/w(Li)降低,晶界含Cu的T1相减少(见图8(b))且形成粗大不连续δ相(见图8(c))。

图8 不同Cu、Li含量Al-xCu-yLi-0.4Mg-0.35Mn-0.12Zr合金T6峰时效时晶界区域扫描透射电子显微镜(STEM)照片[33]

Fig. 8 STEM images of grain boundary area in T6 peak-aged Al-xCu-yLi-0.4Mg-0.35Mn-0.12Zr alloys with different Cu and Li concentrations[33]

2.2 Cu、Li含量对Al-Cu-Li系铝锂合金性能的影响

通过改变时效析出相的组成,Cu、Li含量的差异进一步影响其力学性能。研究发现,Al-Cu-Li系铝锂合金强度随Cu含量增加而增加[10-11];但在Cu含量一定时,其硬度、强度并不完全随Li含量增加而顺序提高,甚至可能导致硬度和强度降低[8, 11]。

李劲风等[10-11]采用Cu、Li总摩尔分数结合x(Cu)/x(Li),系统分析了Cu、Li含量对Al-Cu-Li系铝锂合金强度的影响规律。当x(Cu)/x(Li)基本一致时,随Cu、Li总摩尔分数增加,时效析出相分数增加,相应地铝锂合金强度提高。当Cu、Li总摩尔分数基本一致时,铝锂合金强度随x(Cu)/x(Li)增加而提高。如图9所示是在总结作者课题组关于Al-(3.2~4.4)Cu- (0.8~1.5)Li-0.4Mg-0.4Ag-0.4Zn-0.1Zr铝锂合金薄板相同T8态近峰时效拉伸性能结果的基础上,建立的强度(抗拉强度、屈服强度)与Cu、Li总摩尔分数和x(Cu)/x(Li)的关系,图中数字代表相应编号合金的x(Cu)/x(Li)。图9中线段ab左上部分,对应x(Cu)/x(Li)为>0.58,随Cu、Li总摩尔分数增加,铝锂合金强度提高。在线段ab和cd之间部分,对应x(Cu)/x(Li)为0.46~0.55,随Cu、Li总摩尔分数增加,铝锂合金强度提高。在线段cd和ef之间,对应x(Cu)/x(Li)为0.39~0.46,随Cu、Li总摩尔分数增加,铝锂合金强度提高。另外,在Cu、Li总摩尔分数相同(近)时,随x(Cu)/x(Li)例增加,强度有增加的趋势,如7#铝锂合金与9#铝锂合金。

上述强度变化与不同Cu、Li含量改变时效析出相组成及其比例有关。微观组织观察表明(见图10),虽然Cu+Li总摩尔分数较高(17#合金,质量分数为3.45%Cu、1.48%Li),但其x(Cu)/x(Li)比较低,易形成较多δ′相,导致强化效果最好的T1相相对比例降低(见图10(a)和(b));而即使Cu、Li总摩尔分数较低(9#合金,质量分数为4.46%Cu、1.03%Li),但高x(Cu)/x(Li)比使δ′相消失,强化效果更好的T1相和θ′相相对比例增加(见图10(c)和(d))。

另外,不同w(Cu)/w(Li)在影响晶界析出相类型及分布的基础上,将导致其腐蚀性能的差异。研究表明,随w(Cu)/w(Li)降低,其晶间腐蚀(IGC)抗力逐渐提高,如图11所示[33]。

图9 Al-(3.2~4.4)Cu-(0.8~1.5)Li-0.4Mg-0.4Ag-0.4Zn-0.1Zr铝锂合金薄板相同T8态近峰时效强度与Cu、Li摩尔总分数和x(Cu)/x(Li)的关系

Fig. 9 Strength of T8 peak-aged Al-(3.2~4.4)Cu-(0.8~1.5)Li-0.4Mg-0.4Ag-0.4Zn-0.1Zr alloy sheet with different Cu and Li concentrations as function of total Cu and Li mole fraction and x(Cu)/x(Li)

图10 不同Cu、Li含量铝锂合金SAED谱及TEM像

Fig. 10 TEM images of T8 aged Al-Li alloys with different Cu and Li concentrations

图11 时效不同时间Al-xCu-yLi-0.4Mg-0.35Mn-0.12Zr合金晶间腐蚀侧面形貌[33]

Fig. 11 Typical sectional IGC morphologies of Al-xCu-yLi-0.4Mg-0.35Mn-0.12Zr with different Cu and Li concentrations[33]

3 微合金化元素

3.1 Zr、Mn微合金化

Zr是铝合金及铝锂合金中最重要的微合金化元素之一,在Al中的固溶度极限约为0.07%(摩尔分数)。铝合金中添加Zr含量通常为0.05%~0.16% (质量分数),凝固时可形成 Al3Zr初生相粒子,在385~535 ℃退火过程中也可能形成Al3Zr弥散相粒子[34]。Al3Zr粒子与铝基体共格,对铝锂合金晶粒组织控制具有十分重要的作用;660.8 ℃时通过Al3Zr+L (Al)包晶转变,Al3Zr初生相粒子可以作为凝固形核点,提高凝固形核密度,细化铝锂合金铸态晶粒组织;共格的Al3Zr弥散相粒子还能有效阻碍晶界迁移及再结晶过程,并细化再结晶晶粒组织[35-36]。如图12所示为不含Zr和含0.12%Zr元素的Al-4.25Cu-0.85Li-X铝锂合金冷轧薄板固溶处理后的金相照片,不含Zr元素铝锂合金固溶后再结晶晶粒尺寸显著大于含Zr元素的铝锂合金。

(Al)包晶转变,Al3Zr初生相粒子可以作为凝固形核点,提高凝固形核密度,细化铝锂合金铸态晶粒组织;共格的Al3Zr弥散相粒子还能有效阻碍晶界迁移及再结晶过程,并细化再结晶晶粒组织[35-36]。如图12所示为不含Zr和含0.12%Zr元素的Al-4.25Cu-0.85Li-X铝锂合金冷轧薄板固溶处理后的金相照片,不含Zr元素铝锂合金固溶后再结晶晶粒尺寸显著大于含Zr元素的铝锂合金。

Mn在Al铝中的极限固溶度为0.62%,658 ℃通过L (Al)+Al6Mn共晶转变形成Al6Mn粒子。在含Cu的铝合金及Al-Cu-Li系铝锂合金中可形成与基体半共格、呈板条状的Al20Cu2Mn3弥散相粒子,其析出温度区间为300~530 ℃[34]。研究表明,铝锂合金中少量Mn形成的含Mn弥散相粒子可促进再结晶、控制晶粒生长、分散共面滑移,使滑移更加均匀,降低铝锂合金的各向异性[36-37]。

(Al)+Al6Mn共晶转变形成Al6Mn粒子。在含Cu的铝合金及Al-Cu-Li系铝锂合金中可形成与基体半共格、呈板条状的Al20Cu2Mn3弥散相粒子,其析出温度区间为300~530 ℃[34]。研究表明,铝锂合金中少量Mn形成的含Mn弥散相粒子可促进再结晶、控制晶粒生长、分散共面滑移,使滑移更加均匀,降低铝锂合金的各向异性[36-37]。

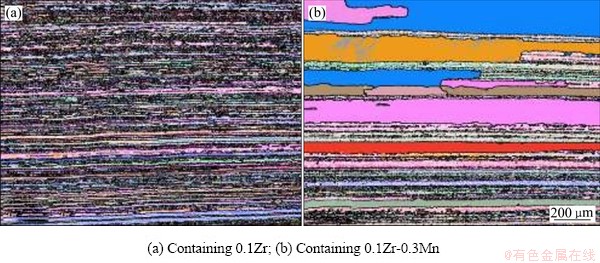

第三代Al-Cu-Li系铝锂合金如2050、2198、2196、2099、2197中通常联合添加微量Zr、Mn,其添加量对再结晶程度具有明显的影响。研究表明,在热轧6 mm厚度2198型铝锂合金中单独添加微量Zr元素时,形成Al3Zr粒子弥散相粒子(见图13(a)中细小白色粒子)阻碍固溶处理时的再结晶,降低其再结晶程度(见图14(a)),相应再结晶机理为SIBM(应变诱发晶界迁移)。而在此基础上添加微量Mn,将形成较粗大的Al20Cu2Mn3弥散相粒子,同时导致Al3Zr粒子数密度降低(见图13(b));热轧时较粗大的Al20Cu2Mn3弥散相粒子增加其边缘基体的变形程度,提高储能进而导致固溶处理时再结晶程度增加(见图14(b)),此时再结晶形核机理以PSN (粒子激发形核)为主[37-39]。

图12 Al-4.25Cu-0.85Li-X铝锂合金冷轧薄板固溶处理后金相照片

Fig. 12 Metallographic images of cold-rolled Al-4.25Cu-0.85Li-X alloy sheets after solutionization

图13 2198-T351铝锂合金6 mm厚度板材STEM-HAADF照片[39]

Fig. 13 STEM-HAADF images of 2198-T351 Al-alloy plates with 6 mm thickness[39]

图14 2198-T351铝锂合金6 mm厚度板材表层EBSD照片[39]

Fig. 14 EBSD maps showing grain structure morphologies at surface layer of 2198-T351 Al-alloy plates with 6 mm thickness[39]

3.2 Mg、Ag、Zn微合金化

3.2.1 Mg、Ag、Zn微合金化元素对时效析出相的影响

Mg是Al-Cu-Li系铝锂合金最主要的微合金化元素之一,大多数第三代铝锂合金均添加一定量的Mg。Ag、Zn是第三代铝锂合金重要的微合金化元素,并通常与Mg同时添加。Mg、Ag、Zn添加显著影响时效强化相的析出,特别是有利于促进T6态时效时T1相的析出。

图15 添加不同微合金化元素Al-3.5Cu-1.0Li-X铝锂合金T6峰时效时TEM照片[40-41]

Fig. 15 TEM images of Al-3.5Cu-1.0Li-X alloys with different micro-alloying elements[40-41]

图15所示分别为Al-3.5Cu-1.0Li-X(X代表Mn、Zr等微合金化元素)合金不添加Mg、单独添加Mg及同时添加Mg+Ag时T6态(175 ℃)峰时效时TEM照片[40-41]。相比不添加Mg(见图15(a)和(b)),单独添加Mg(见图15(c)和(d))及同时添加Mg+Ag(见图15(e)和(f))时均有利于铝锂合金中T1相析出分数增加,同时导致θ′相减少。

图16所示为不含Zn及含0.75%Zn的Al-2.7Cu- 1.7Li-0.4Mg-X铝锂合金T6峰时效时[100]Al SAED谱及TEM-DF照片[42]。合金主要时效析出相均为δ′相及T1相。但添加0.75%Zn合金中T1相析出密度增加,同时δ′相尺寸减小。

研究表明,Mg+Ag+Zn三元复合添加具有更大的促进T1相析出的效果,是超高强铝锂合金微合金化成分设计的主要方向[43-44]。综合文献分析表明,Mg、Mg+Ag、Mg+Zn、Mg+Ag+Zn微合金化均能显著促进Al-Cu-Li系铝锂合金中T6态时效时主要强化相T1相析出,其中以Mg+Ag+Zn三元复合添加效果最好,Mg+Ag和Mg+Zn效果次之。需要说明的是,T8态时效时预变形产生的位错能促进T1相形核,将部分减弱上述微合金化效果[44]。

对于Mg+X(X=Ag、Zn)微合金化促进T1相时效析出机理,研究人员进行了如下总结。

T1相与铝基体半共格,为减少形核阻力,T1相将于位错、晶界、亚晶界等处优先析出,层错及铝基体{111}Al面上形成的GP区也是其重要的优先形核位置[45-46]。合金中添加微量Mg后,由于Mg原子与空位(V)之间的结合能高,大量过饱和空位在固溶淬火过程中易被Mg原子俘获形成Mg-V对,并形成大量的Mg-Cu-V团簇,为时效过程提供大量有效的可动空位,从而促进GP区的形成,继而促进T1相形核析出[46]。同时,Mg能显著降低铝合金的层错能,有利于层错形成,为T1相提供更多形核位置,促进T1相的形核析出[46]。

图16 不含Zn及含0.75%Zn的Al-2.7Cu-1.7Li-0.4Mg-X铝锂合金T6峰时效时[100]Al SAED谱及TEM-DF照片[42]

Fig. 16 SAED patterns and TEM-DF images of T6 peak-aged Al-2.7Cu-1.7Li-0.4Mg-X alloys with different micro-alloying elements[42]

当联合添加Mg+Ag元素后,检测到Mg、Ag元素可存在于T1相内部[47](见图17(a)),也可偏聚与T1相与基体的界面部位[48](见图17(b))。根据上述现象及原子之间的相互作用趋势,提出的Mg+Ag复合添加促进T1相析出的机理如下:由于Mg、Ag原子间的强相互作用,在淬火及时效早期,合金中形成了Mg-Ag原子团簇;在随后的时效过程中,Mg、Ag原子与Cu、Li原子的相互作用促使Cu、Li原子扩散到团簇周围,且Cu原子不断替代Ag,使团簇溶解形成更加稳定的三元T1相。即Mg、Ag原子在时效前期将作为桥梁促进T1相形核,但在时效过程中Mg、Ag原子将逐渐排除出T1相[47]。

关于Mg+Zn微合金化作用机理还有待进一步探索。有研究认为Mg+Zn微合金化作用与Mg+Ag类似,并在Mg+Zn微合金化的2099铝锂合金T1 相内部发现Mg、Zn原子的富集[49]。作者课题组也发现在2099铝锂合金T1相内部发现Mg、Zn的同时富集(见图17(c))。然而,也有研究认为Zn原子进入T1相,占据T1相中Cu原子位置,即Zn元素取代T1相中Cu元素位置[50]。

图17 不同微合金化Al-Cu-Li合金T1相中元素分布

Fig. 17 Element distribution through T1 precipitates in Al-Cu-Li alloy with different microalloying elements

3.2.2 Mg、Ag、Zn微合金化元素对性能的影响

通过促进T1相形核,加速时效响应过程,Mg、Ag、Zn微合金化将显著影响铝锂合金的力学性能。表2所示为不添加Mg、单独添加Mg及复合添加Mg+Ag的Al-3.5Cu-1.0Li-X(X代表Mn、Zr等微合金化元素)铝锂合金冷轧薄板T6态(175 ℃)及T8态近峰时效时的拉伸性能。相比不添加Mg元素时,合金中单独添加Mg时,T6峰时效时强度大幅度提高;同时添加Mg+Ag时,其强度进一步大幅度提高。T8时效时强度变化表现出类似规律,但强度提高幅度明显降低[40-41]。

表3所示为单独添加0.25Mg及复合添加0.25Mg+0.75Zn的Al-2.6Cu-1.7Li-X(X代表Mn、Zr等微合金化元素)铝锂合金挤压棒材T6态(175 ℃)及T8态近峰时效时的拉伸性能[51]。复合添加Mg+Zn时,对应峰时效抗拉强度和屈服强度均有所提高。

表4所示为Al-3.7Cu-1.2Li-X(X代表Mn、Zr等微合金化元素)中分别少量添加Mg+Ag、Mg+Zn及Mg+Ag+Zn后T6(175 ℃)及T8峰时效时的拉伸性能[43-44]。综合而言,Mg+X(X=无、Ag或/和Zn)微合金化通过促进T1相析出,能有效提高T6态时效时Al-Cu-Li系铝锂合金强度,其微合金强化效果呈现如下规律:Mg+Ag+Zn>Mg+Ag>Mg+Zn>Mg。另外,T8态时效时呈现相似的强化规律,但微合金强化效果部分减弱。

Ag、Zn微合金化对铝锂合金腐蚀性能表现出不同的影响效果。在铝锂合金腐蚀过程中,晶界同时含Cu、Li析出相T1及T2相在腐蚀过程中存在电化学极性转换机制。T1及T2相电位较负,作为阳极先发生腐蚀,其中活泼元素Li优先溶解后,导致腐蚀后的T1相和T2相产生Cu元素富集并转化为阴极,进而促进其边缘铝基体的阳极溶解[52-54]。铝锂合金中添加的Zn元素可进入晶界含Cu、Li析出相(晶界T1相及晶界其他含Cu相),代替其部分Cu元素(见图18(a)),降低析出相中不活泼元素Cu的含量,在腐蚀过程中减弱上述电化学极性转换后促进边缘铝基体阳极溶解的效果,进而提高其耐蚀性能[55-58]。Ag元素同样可进入晶界含Cu、Li析出相(见图18(b))[59],然而由于Ag元素电化学活性低于Cu元素,将进一步加剧上述电化学极性转换后促进其边缘铝基体阳极溶解的效果,进而降低其耐蚀性能。

表2 Mg、Ag微合金化Al-3.5Cu-1.0Li-X铝锂合金薄板T6、T8态峰时效时拉伸性能[41]

Table 2 Tensile properties of T6 and T8 peak-aged Al-3.5Cu-1.0Li-X alloy sheets with micro-alloying elements of Mg and Ag[41]

表3 Mg、Zn微合金化Al-2.6Cu-1.7Li-X铝锂合金挤压棒材T6及T8峰时效拉伸性能[51]

Table 3 Tensile properties of T6 and T8 peak-aged Al-2.6Cu-1.7Li-X alloy bars with micro-alloying elements of Mg and Zn[51]

表4 Mg、Ag、Zn微合金化Al-3.7Cu-1.2Li-X铝锂合金冷轧薄板T6、T8态峰时效时拉伸性能[43]

Table 4 Tensile properties of T6 and T8 peak-aged Al-3.7Cu-1.2Li-X alloy sheets with micro-alloying elements of Mg, Ag and Zn[43]

3.3 稀土微合金化

研究表明,稀土(RE)元素在铝合金中有细化晶粒、阻碍再结晶、提高韧性及强度的效果,如Sc在Al-Mg系及Al-Zn-Mg系铝合金中具有细晶强化、Al3(Sc,Zr)第二相强化及亚结构强化的作用[60-61]。然而有不少研究发现,Sc、Ce、Er等稀土元素在不同Al-Cu-Li系铝锂合金中具有不同的作用效果,既可能提高铝锂合金强度,但也可能导致其强度降低,如表5所示。

图18 HAADF-STEM照片及晶界析出相元素面扫描照片

Fig. 18 HAADF-STEM images and scanning element analysis mapping of grain boundary precipitates

表5 微量稀土对Al-Cu-Li系铝锂合金强度的影响

Table 5 Influence of small addition of RE elements on Al-Cu-Li alloy strength

微观组织分析表明,在添加微量Sc、Ce、Er等RE元素的Al-(3.5-4.3)Cu-1.2Li-X铝锂合金(X代表其它微合金元素)中,T1相和θ′相数量减少,即含Cu时效强化相T1相及θ′相析出分数降低[68-71]。在低Li含量Al-Cu-Li系铝锂合金(w(Cu)>3.0%)中,强化相以T1相和θ′相为主;添加微量Sc、Ce、Er等RE元素后,RE元素与Cu元素结合,在凝固及退火过程中即分别形成Al8Cu4Sc、Al8Cu4Ce及Al8Cu4Er等第二相(见图19)[69],不能有效地形成Al3Sc(或Al3(Sc,Zr))等弥散粒子,减弱其细化晶粒、阻碍再结晶及弥散强化的效果(见图20(a));同时,难溶相Al8Cu4Sc、Al8Cu4Ce及Al8Cu4Er粒子含较多Cu元素且固溶处理时不能溶解至固溶体基体中,导致过饱和固溶体基体中Cu含量降低,相应时效后析出的含Cu强化相T1相及θ′相减少,时效强化效果降低。

若铝锂合金中w(Cu)/w(Li)降低,合金强化相以δ′相为主,T1相比例下降。同时,能更有效的形成Al3(Sc,Zr)等弥散粒子,发挥阻碍再结晶的效果(见图20(b))[72],因而在低w(Cu)/w(Li)铝锂合金中微量RE元素具有有效的阻碍再结晶、提高强度的作用。

在一定w(Cu)/w(Li)铝锂合金中,强化相以δ′相为主,但同时存在一定量T1相时,微量RE元素如0.1%Sc可以形成一定的Al3(Sc,Zr)弥散粒子,并弥补形成Al8Cu4Sc粒子的负面影响效果;但当RE元素如Sc含量增加至0.2%以上时,将导致形成更多的难溶Al8Cu4Sc粒子,Al3(Sc,Zr)弥散粒子的有益作用并不能弥补形成较多Al8Cu4Sc粒子产生的负面影响,结果导致铝锂合金强度降低[63]。综上所述,RE元素在Al-Cu-Li系铝锂合金中的微合金化作用效果与其Cu、Li含量密切相关,高Cu含量铝锂合金中应控制Sc、Ce、Er等RE元素的添加。

图19 Al-3.4Cu-1.2Li-X-0.082Sc铝锂合金固溶处理后SEM背散射照片及难溶相粒子EDS分析[69]

Fig. 19 SEM back scattered image (a) and EDS analysis of residual particles (b) of solutionized Al-3.4Cu-1.2Li-X-0.082Sc alloy[69]

图20 含Sc铝锂合金冷轧薄板固溶后金相照片[72]

Fig. 20 Metallographic images of Sc containing Al-Li alloy sheet after solutionization[72]

3.4 In元素微合金化

研究表明,Al-Cu合金中添加微量In、Sn、Cd元素,这些原子偏聚在析出相与基体的界面上,降低界面能,从而加速θ′相的析出,提高Al-Cu合金的时效响应速度。同时,In和Sn等微量元素所形成的富In和富Sn粒子先于θ′相形成,可作为θ′相非均匀形核的位置,从而促进θ′相的析出。另外,微量In、Sn的添加还能抑制θ′相的粗化,提高Al-Cu合金的过时效性能[73-75]。

鉴于微量In在Al-Cu合金中有益的微合金化效果,研究人员进行了In元素在Al-Cu-Li系铝锂合金中的微合金化效果研究。PAN等[76-78]发现0.2%~ 0.5%In微合金化的Al-3.3Cu-0.8Li铝锂合金T6态时效(175 ℃)时大量析出一种均匀分布的、与铝基体共格的稳定立方相χ相(Al5Cu6Li2),并促进θ′相析出,提高铝锂合金强度。同时,由于In 与空位间的强相互作用使其在淬火态或时效早期捕捉了大量空位,减少T1相形核所需的位错环,从而延缓 T1 相形核析出;另外,该立方相χ相同时含Cu和Li原子,与T1相析出呈竞争关系,χ相大量析出相应地减少了T1相析出分数[4]。

GILMORE等[79]发现Al-4.2Cu-1.2Li-0.16Zr合金中添加0.09%In可促进T6态时效时θ″相和T1相析出,提高铝锂合金强度。WOO等则发现在低Cu高Li含量的Al-2.5Cu-1.8Li合金中添加0.18%In时,160 ℃进行T6态时效时可促进T1相和θ′相,而抑制δ′相析出,提高铝锂合金强度[80]。上述研究表明,In可以促进Al-Cu-Li合金T6态时效时θ′相和θ″相析出;但如果形成立方相χ相(Al5Cu6Li2),则抑制T1相析出;反之则促进T1相析出。但总体而言,关于In在铝锂合金中的微合金化作用机理,尚待进一步深入研究。

另外,在添加微合金化元素Mg的基础上再添加微量In,其微合金化作用并无叠加效果[77-78]。而且T8态时效时,In的微合金化作用效果明显减弱[77-78]。

4 总结

从20世纪70年代以来,以成分设计为目的的铝锂合金的合金化及微合金化研究已取得了长足的进步,特别是现代先进检测手段的发展,铝锂合金的微合金化研究工作取得了更大的进展。综合国内外研究文献,结合笔者课题组成分设计研究成果,可以总结以下两种类型铝锂合金成分设计思路。

1) 对于高强铝锂合金的成分设计,可在采用Mg+Ag、Mg+Zn或Mg+Ag+Zn复合微合金化的基础上,保证较高Cu、Li总摩尔分数的同时,提高x(Cu)/x(Li),通过增加T1相和θ′相析出密度和比例,达到铝锂合金高强度的目的。

2) 对于耐腐蚀铝锂合金的成分设计,一方面应降低铝锂合金中x(Cu)/x(Li)或w(Cu)/w(Li),减少晶界含Cu析出相分数;另一方面,添加微合金化元素Zn,减少晶界含Cu析出相中的Cu含量,减弱腐蚀过程中晶界析出相电化学极性转换后促进边缘基体阳极溶解的作用。

航空工业和航天工业的飞速发展,对轻质高强铝合金材料提出了迫切需求,可以预计我国将迎来轻质铝锂合金的研究高潮。这些研究既包括成形、焊接、热处理等方面的应用技术研究,也包括基于不同应用背景和性能要求的成分设计研究。虽然铝锂合金的合金化和微合金化研究已取得重要进展,但基于未来铝锂合金成分设计发展的需要,笔者认为Al-Cu-Li系铝锂合金还应该在以下几个方面开展更深入的研究。① 针对航空工业对耐损伤铝锂合金的需求,系统深入地开展(微)合金化元素对铝锂合金耐损伤性能的影响规律及机理研究,开发高耐损伤铝锂合金。② 进一步深入开展复合微合金化,特别是Mg+Zn复合微合金化的作用效果及机理研究。③ 开展稀土元素在不同成分铝锂合金中的作用效果研究,包括力学性能、耐损伤性能,充分发挥稀土元素的有益作用,并摒弃其有害作用。

REFERENCES

[1] EL-ATY A A, XU Y, GUO X Z, et al. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review[J]. Journal of Advanced Research, 2018, 10: 49-67.

[2] RIOJA R J, LIU J. The evolution of Al-Li base products for aerospace and space applications[J]. Metallurgical Materials Transaction A, 2012, 43(9): 3325-3337.

[3] 李劲风, 郑子樵, 陈永来, 等. 铝锂合金及其在航天工业上的应用[J]. 宇航材料工艺, 2012, 42(1): 13-19.

LI Jin-feng, ZHENG Zi-qiao, CHEN Yong-lai, et al. Al-Li alloys and their application in aerospace industry[J]. Aerospace Materials and Technology, 2012, 42(1): 13-19.

[4] 郑子樵, 李劲风, 陈志国, 等. 铝锂合金的合金化与微观组织演化[J]. 中国有色金属学报, 2011, 21(10): 2337-2351.

ZHENG Zi-qiao, LI Jin-feng, CHEN Zhi-guo, et al. Alloying and microstructural evolution of Al-Li alloys[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2337-2351.

[5] CHEN T R, HUANG J C, LIAUO J M, et al. Effects of lubrication on superplastic forming of 8090 Al-Li sheets[J]. Scripta Metallurgica et Materialia, 1994, 31(3): 309-314.

[6] McDARMAID D S. Effect of natural aging on the tensile properties of the Al-Li alloys 8090, 8091 and 2091[J]. Materials Science and Engineering A, 1988, 101: 193-200

[7] DERVENIS C P, MELETIS E I, HOCHMAN R F. Corrosion fatigue in Al-Li alloy 2090[J]. Materials Science and Engineering A, 1988, 102(2): 151-160.

[8] POLMEAR I J, CHESTER R J. Abnormal age hardening in an Al-Cu-Mg alloy containing silver and lithium[J]. Scripta Metallurgical, 1989, 23: 1213-1218.

[9] RIOJIA R J, BRETZ P E. Aluminum-Lithium alloys having improved corrosion resistance containing Mg and Zn. United States Patent 4961792[P]. 1990-10-09.

[10] 李劲风, 陈永来, 张绪虎, 等. Cu、Li含量对Mg、Ag、Zn复合微合金化铝锂合金力学性能及微观组织的影响[J]. 宇航材料工艺, 2015, 45(2): 24-28.

LI Jin-feng, CHEN Yong-lai, ZHANG Xu-hu, et al. Influence of Cu and Li contents on mechanical properties and microstructures of Mg-, Ag- and Zn-microalloyed Al-Li alloys[J]. Aerospace Materials and Technology, 2015, 45(2): 24-28.

[11] LI Jin-feng, LIU Ping-li, CHEN Yong-lai, et al. Mechanical properties and microstructures of Mg, Ag and Zn mult-microalloyed Al-(3.2~3.8)Cu-(1.0~1.4)Li alloys[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(7): 2103-2112.

[12] 李劲风, 陈永来, 张绪虎, 等. 一种新型超高强铝锂合金板材的组织与力学性能[J]. 稀有金属材料与工程, 2017, 46(12): 3715-3720.

LI Jin-feng, CHEN Yong-lai, ZHANG Xu-hu, et al. Structures and mechanical properties of a super-high strength Al-Li alloy[J]. Rare Metal Materials and Engineering, 2017, 46(12): 3715-3720.

[13] 程 彬, 郑子樵, 范春平, 等. 时效制度对新型 Al-Cu-Li 合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(7): 926-933.

CHENG Bin, ZHENG Zi-qiao, FAN Chun-ping, et al. Effect of aging treatments on microstructures and properties of new Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1833-1842.

[14] Lü Ke-xin, ZHU Chen-yang, ZHENG Jing-xu, et al. Precipitation of T1 phase in 2198 Al-Li alloy studied by atomic-resolution HAADF-STEM[J]. Journal of Materials Research, 2019, 34(20): 3535-3544.

[15] HUANG J C, ARDELL A J. Crystal structure and stability of T1 precipitates in aged AI-Li-Cu alloys[J]. Materials Science and Technology, 1987, 3: 176-188.

[16] WANG S C, STARINK M J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg-(Li) based alloys[J]. International Materials Reviews, 2005, 50(4): 193-215.

[17] NIE J F, MUDDLE B C. On the form of the age-hardening response in high strength aluminium alloys[J]. Materials Science & Engineering A, 2001, 319/321: 448-451.

[18] NIE J F, MUDDLE B C, POLMEAR I J. The effect of precipitate shape and orientation on dispersion strengthening in high strength aluminium alloys[J]. Materials Science Forum, 1996, 217/222: 1257-1262.

[19] NIE J F, MUDDLE B C. Microstructural design of high- strength aluminum alloys[J]. Journal of Phase Equilibria, 1998, 19(6): 543-551

[20] LIU Yu-lin, ZHANG Yun, ZHAO Hong-en, et al. Microstructure and mechanical properties of 8090 Al-Li alloy[J]. Acta Metallurgica Sinica (English Letters), 1992, 5(2): 89-94.

[21] GHOSH K S, DAS K, CHATTERJEE U K. Studies of retrogression and reaging behavior in a 1441 Al-Li-Cu-Mg-Zralloy[J]. Metallurgical and Materials Transactions A, 2005, 36: 3477-3487.

[22] ZHAO Zhi-long, LIU Lin, CHEN Zheng. Co-strengthening contribution of δ′ and T1 precipitates in Al-Li alloys 2090 and 2090+Ce[J]. Rare Metals, 2006, 25(3): 197-201

[23] LI Jin-feng, YE Zhi-hao, LIU Dan-yang, et al. Influence of pre-deformation on aging precipitation behavior of three Al-Cu-Li alloys[J]. Acta Metallurgica Sinica (English Letters), 2017, 30(2): 133-145.

[24] LIN Y, LU C, WEI C Y, et al. Effect of aging treatment on microstructures, tensile properties and intergranular corrosion behavior of Al-Cu-Li alloy[J]. Materials Characterization, 2018, 141: 163-168.

[25] 魏修宇, 郑子樵, 潘峥嵘, 等. 预变形对 2197 铝锂合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1996-1999.

WEI Xiu-yu, ZHENG Zi-qiao, PAN Zheng-rong, et al. The role of plastic deformation on microstructure and mechanical properties of 2197 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1996-1999.

[26] CHEN Bin, GUO Ming-feng, ZHENG Jing-xu, et al. The effect of thermal exposure on the microstructures and mechanical properties of 2198 Al-Li alloy[J]. Advanced Engineering Materials, 2016, 18(7): 1225-1233.

[27] YE Zhi-hao, CAI Wen-xin, LI Jin-feng, et al. Impact of annealing prior to solution treatment on aging precipitates and intergranular corrosion behavior of Al-Cu-Li alloy 2050[J]. Metallurgical and Materials Transactions A, 2018, 49: 2471-2486.

[28] LI Jin-feng, LIU Dan-yang, NING Hong, et al. Experimental quantification of “hardenability” of 2195 and 2050 Al-Li alloys by using cold-rolled sheets[J]. Materials Characterization, 2018, 137: 180-188.

[29] BALDUCCI E, CESCHINI L, MESSIERI S, et al. Effects of overaging on microstructure and tensile properties of the 2055 Al-Cu-Li-Ag alloy[J]. Materials Science and Engineering A, 2017, 707: 221-231.

[30] 李劲风, 郑子樵, 蔡 彪. 一种铝锂合金搅拌摩擦焊的接头力学性能及微观组织研究[J]. 宇航材料工艺, 2013, 43(3): 71-76.

LI Jin-feng, CAI Biao, ZHENG Zi-qiao. Mechanical property and microstructure of friction stir welding (FSW) joint of an Al-Li alloy[J]. Aerospace Materials and Technology, 2013, 43(3): 71-76.

[31] JO Hyung-Ho, HIRANO Ken-ichi. Precipitation processes in Al-Cu-Li alloys by DSC[J]. Materials Science Forum, 1987, 13/14: 377-382.

[32] DECREUS B, DESCHAMPS A, GEUSER F De, et al. The influence of Cu/Li ratio on precipitation in Al-Cu-Li-X alloys[J]. Acta Materialia, 2013, 61: 2207-2218.

[33] LIU Dan-yang, LI Jin-feng, LIN Yong-cheng, et al. Cu/Li ratio on the microstructure evolution and corrosion behaviors of Al-xCu-yLi-Mg alloys[J]. Acta Metallurgica Sinica (English Letters), 2020, 33(9): 1201-1216.

[34] 桑冯建, 郑子樵, 王海金. Mn 在 2297 铝锂合金中的微合金化作用[J]. 稀有金属材料与工程, 2018, 47(3): 871-877.

SANG Feng-jian, ZHENG Zi-qiao, WANG Hai-jin. Micro-alloying effects of Mn in 2297 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2018, 47(3): 871-877.

[35] GUO Zhan-ying, ZHAO Gang, CHEN C G. Effects of homogenization treatment on recrystallization behavior of 7150 aluminum sheet during post-rolling annealing[J]. Materials Characterization, 2016, 114: 79-87.

[36] YANG Shou-jie, DAI Sheng-long, SU Bin. Influence of alloying elements on mechanical properties of Al-Li plates[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(2): 321-324.

[37] TSIVOULAS D, PRANGNELL P B. The effect of Mn and Zr dispersoid-forming additions on recrystallization resistance in Al-Cu-Li AA2198 sheet[J]. Acta Materialia, 2014, 77: 1-16.

[38] TSIVOULAS D, PRANGNELL P B. Comparison of the effect of individual and combined Zr and Mn additions on the fracture behavior of Al-Cu-Li alloy AA2198 rolled sheet[J]. Metallurgical and Materials Transactions A, 2014, 45: 1338-1351.

[39] TSIVOULAS D. Effects of combined Zr and Mn additions on the microstructure and properties of AA2198 sheet[D]. Manchester: University of Manchester, UK, 2010.

[40] 王瑞琴, 郑子樵, 陈圆圆, 等. Ag, Mg合金化对Al-Cu-Li合金时效特性和显微组织的影响[J]. 稀有金属材料与工程, 2009, 38(4): 622-626.

WANG Rui-qin, ZHENG Zi-qiao, CHEN Yuan-yuan, et al. Effects of Ag, Mg micro-alloying on aging characteristics and microstructure of Al-Cu-Li alloy[J]. Rare Metal Materials and Engineering, 2009, 38(4): 622-626.

[41] 王瑞琴. 2050合金微合金化及其组织和性能的研究[D]. 长沙: 中南大学, 2009.

WANG Rui-qin. Microalloying, structures and properties of 2050 alloy[D]. Changsha: Central South University, 2009.

[42] 魏修宇. 高性能中强耐损伤铝锂合金的组织结构、热处理和性能关系研究[D]. 长沙: 中南大学, 2010.

WEI Xiu-yu. Relationship between microstructure, heat treatment and properties of doderate strength, high damage tolerant Al-Li alloy[D]. Changsha: Central South University, 2010.

[43] 罗先甫, 郑子樵, 钟继发, 等. Mg、Ag、Zn对一种新型铝锂合金时效行为的影响[J]. 中国有色金属学报, 2013, 23(7): 1833-1842.

LUO Xian- fu, ZHENG Zi -qiao, ZHONG Ji- fa, et al. Effects of Mg, Ag and Zn multi alloying on aging behavior of new Al Cu Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1833-1842.

[44] 罗先甫. 新型Al-Cu-Li合金的时效组织与力学性能研 究[D]. 长沙: 中南大学, 2013.

LUO Xian- fu. Study of the structure and mechanical properties of new Al-Cu-Li alloy[D]. Changsha: Central South University, 2013.

[45] NOBLE B, THOMPSON G E. T1(Al2CuLi) precipitation in aluminum-copper-lithium alloys[J]. Metal Science Journal, 1972, 6: 167-174.

[46] ITOH G, CUI Q, KANNO M. Effects of a small addition of magnesium and silver on the precipitation of T1 phase in an Al-4%Cu-1.1%Li-0.2%Zr alloy[J]. Materials Science & Engineering A, 1996, 211(1/2): 128-137.

[47] GAULT B, GEUSER F De, BOURGEOIS L, et al. Atom probe tomography and transmission electron microscopy characterization of precipitation in Al-Cu-Li-Mg-Ag alloy[J]. Ultramicroscopy, 2011, 111: 683-689.

[48] MURAYAMA M, HONO K. Role of Ag and Mg on precipitation of T1 phase in an Al-Cu-Li-Mg-Ag alloy[J]. Scripta Materialia, 2001, 44(4): 701-706.

[49] GUINEL M J F, BRODUSCH N, SHA G, et al. Microscopy and microanalysis of complex nanosized strengthening precipitates in new generation commercial Al-Cu-Li alloys[J]. Journal of Microscopy, 2014, 255(3): 128-137.

[50] GUMBMANN E,LEFEBVRE W,GEUSER F De,et al.The effect of minor solute additions on the precipitation path of an Al-Cu-Lialloy[J]. Acta Materialia, 2016, 115: 104-114.

[51] 朱小辉. 新型铝锂合金(2099和2196合金)挤压材组织与性能的研究[D]. 长沙: 中南大学, 2009.

ZHU Xiao-hui. Structures and properties of new Al-Li alloy (2099 and 2196) ertusions[D]. Changsha: Central South University, 2009.

[52] LI Jin-feng, ZHENG Zhi-qiao, LI Shi-chen, et al. Simulation study on function mechanism of T1(Al2CuLi) in localized corrosion of Al-Cu-Li alloy[J]. Transactions of Nonferrous Metal Society of China, 2006, 16(6): 1268-1273.

[53] LI J F, LI C X, PENG Z W, et al. Corrosion mechanism associated with T1 and T2 precipitates of Al-Cu-Li alloys in NaCl solution[J]. Journal of Alloys and Compounds, 2008, 460: 688-693.

[54] LI J F, ZHENG Z Q, LI S C, et al. Simulation study on function mechanism of some precipitates in localized corrosion of Al alloy[J]. Corrosion Science, 2007, 49(6): 2436-2449.

[55] LI Jin-feng, XU Long, CAI Chao, et al. Mechanical property and intergranular corrosion sensitivity of Zn-free and Zn micro-alloyed Al-2.7Cu-1.7Li-0.3Mg alloys[J]. Metallurgical and Materials Transactions A, 2014, 45(12): 5736-5748.

[56] LI J F, BIRBILIS N, LIU D Y, et al. Intergranular corrosion of Zn-free and Zn micro-alloyed Al-xCu-yLi alloys[J]. Corrosion Science, 2016, 105: 44-57.

[57] LIU D Y, LI J F, MA Y L, et al. A closer look at the role of Zn in the microstructure and corrosion of an Al-Cu-Li alloy[J]. Corrosion Science, 2018, 45: 220-231.

[58] LIU Dan-yang, MA Yun-long, LI Jin-feng, et al. The influence of Zn addition on microstructure of an Al-1.7 Cu-4.0 Li-0.4 Mg alloy[J]. Journal of Materials Research and Technology, 2020, 9(2): 2423-2439.

[59] LIU Dan-yang, WANG Jie-xia, LI Jin-feng, et al. The effect of Ag element on the microstructure characteristic evolution of an Al-Cu-Li-Mg alloy[J]. Journal of Materials Research and Technology, 2020, 9(5): 11121-11134.

[60] PENG Y Y, LI S, DENG Y, et al. Synergetic effects of Sc and Zr microalloying and heat treatment on mechanical properties and exfoliation corrosion behavior of Al-Mg-Mn alloys[J]. Materials Science & Engineering A, 2016, 666: 61-71.

[61] LIU J, YAO P, ZHAO N Q, et al. Effect of minor Sc and Zr on recrystallization behavior and mechanical properties of novel Al-Zn-Mg-Cu alloys[J]. Journal of Alloys and Compounds, 2016, 657: 717-725.

[62] 张海锋, 郑子樵, 林 毅, 等. 微量Sc对2099铝锂合金组织与性能的影响[J]. 中南大学学报(自然科学版), 2014, 45(5): 1420-1427.

ZHANG Hai-feng, ZHENG Zi-qiao, LIN Yi, et al. Effects of small addition of Sc on microstructure and properties of 2099 Al-Li alloy[J]. Journal of Central South University (Science and Technology), 2014, 45(5): 1420-1427.

[63] MA J, YAN D S, RONG L J, et al. Effect of Sc addition on microstructure and mechanical properties of 1460 alloy[J]. Progress in Natural Science-Materials International, 2014, 24(1): 13-18.

[64] JIA M, ZHENG Z Q, LUO X F. Influence of AlCuSc ternary phase on the microstructure and properties of a 1469 alloy[J]. Materials Science Forum, 2014, 794/796: 1057-1062.

[65] 梁文杰, 潘青林, 朱朝明, 等. 含钪Al-Cu-Li-Zr合金的组织与性能[J]. 材料科学与工艺, 2007, 15(2): 154-157.

LIANG Wen-jie, PAN Qing-lin, ZHU Zhao-ming, et al. Microstructure and properties of A l-Cu-Li-Zr alloys containing Sc[J]. Materials Science and Technology, 2007, 15(2): 154-157.

[66] 陈志国,郑子樵,王芝秀,等. Al-4.0Mg-1.5Cu-1.0Li合金中Sc的微合金化行为[J]. 中国有色金属学报, 2004, 14(3): 372-377.

CHEN Zhi-guo, ZH ENG Zi-qiao, WANG Zhi-xiu, et al. Microstructural evolution and ageing behaviour of Al-4.0Mg-1.5Cu-1.0Li-(0.2Sc) alloys[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 372-377.

[67] YU Xin-xiang, YIN Deng-feng, YU Zhi-ming. Effects of Cerium and Zirconium microalloying addition on the microstructures and tensile properties of novel Al-Cu-Li alloys[J]. Rare Metal Materials and Engineering, 2016, 45(8): 1917-1923.

[68] LIU Dan-yang, WANG Jie-xia, LI Jin-feng. The microstructures evolution and mechanical properties disparity in 2070 Al-Li alloy with minor Sc addition[J]. Transactions of Nonferrous Metal Society of China, 2018, 28(11): 2151-2161.

[69] MA Yun-long, LI Jin-feng. Variation of aging precipitates and strength of Al-Cu-Li alloys caused by small addition of rare earth elements[J]. Journal of Materials Engineering and Performance, 2017, 26(9): 4329-4339.

[70] 潘 波, 李 睿, 李劲风, 等. Ce微合金化对一种Al-Cu-Li系高强铝锂合金薄板组织及拉伸性能的影响[J]. 中国有色金属学报, 2018, 28(1): 21-30.

PAN Bo, LI Rui, LI Jin-feng, et al. Effect of Ce on structures and tensile properties of high-strength Al-Cu-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 21-30.

[71] 李劲风, 刘丹阳, 郑子樵, 等. Er微合金化对2055铝锂合金力学性能及微观组织的影响[J]. 金属学报, 2016, 52(7): 821-830.

LI Jin-feng, LIU Dan-yang, ZHENG Zi-qiao, et al. Effect of Er micro-alloying on mechanical properties and microstructures of 2055 Al-Li alloy[J]. Acta Metallurgica Sinica, 2016, 52(7): 821-830.

[72] PENG Zhuo-wei, LI Jin-feng, SANG Feng-jian, et al. Structures and tensile properties of Sc-containing 1445 Al-Li alloy sheet[J]. Journal of Alloys and Compounds, 2018, 747: 471-483.

[73] GABLE B M, MUDDLE B C. Factors influencing the heterogeneous nucleation of θ' in Al-Cu-In alloys[J]. Materials Science Forum, 2006, 519-521: 585-590.

[74] 舒 军, 陈志国, 李世晨, 等. 微量 Sn和In对Al-3.5%Cu合金时效行为及微观组织演变的影响[J]. 中国有色金属学报, 2012, 22(9): 2486-2491.

SHU Jun, CHEN Zhi-guo, LI Shi-chen, et al. Effect of trace Sn(In) addition on ageing behaviour and microstructure evolution of Al-3.5%Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2486-2491.

[75] 潘峥嵘, 郑子樵, 李世晨, 等. In对Al-3.5Cu合金析出过程的影响[J]. 稀有金属材料与工程, 2011, 40(6): 1079-1083.

PAN Zheng-rong, ZHENG Zi-qiao, LI Shi-chen, et al. Effect of In addition on precipitation process of Al-3.5Cu alloy[J]. Rare Metal Materials and Engineering, 2011, 40(6):1079-1083.

[76] PAN Zheng-rong, ZHENG Zi-qiao, LIAO Zhong-quan, et al. New cubic precipitate in Al-3.5Cu-1.0Li-0.5In (wt.%) alloy[J]. Materials Letters, 2010, 64: 942-944.

[77] PAN Zheng-rong, ZHENG Zi-qiao, LIAO Zhong-quan, et al. Effects of Indium on precipitation in Al-3.3Cu-0.8Li alloy[J]. Acta Metallurgica Sinica (English Letters), 2010, 23(4): 285-292.

[78] MA Yun-long, LI Jin-feng, LIU Dan-yang, et al. Influence of small Indium (In) addition on microstructures and tensile properties of Al-Cu-1.0Li-(Mg) alloy[J]. Rare Metal Materials and Engineering, 2009, 48(1): 1-8.

[79] GILMORE D L, STARKE E A Jr. Trace element effects on precipitation processes and mechanical properties in an Al-Cu-Li alloy[J]. Metallurgical and Materials Transactions A, 1997, 28: 1399-1415.

[80] WOO K D, KIM S W. The mechanical properties and precipitation behavior of an Al-Cu-Li-(In,Be) alloy[J]. Journal of Materials Science, 2002, 37: 411-416.

Alloying and micro-alloying in Al-Cu-Li series alloys

LI Jin-feng, NING hong, LIU Dan-yang, ZHENG Zi-qiao

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The research process of Al-Li alloys and their composition design development stages are summarized. The influence and corresponding mechanism of contents of main alloying elements Cu and Li on the aging precipitate types, mechanical properties and corrosion resistance of Al-Cu-Li series alloys are emphatically expounded. The effects of micro-alloying elements Zr, Mn, Mg, Ag, Zn, Rare earth (RE) and Indium (In) on the mechanical properties, corrosion resistance and micro-structures, such as recrystallization, type and population density of aging precipitates, are discussed in detail. Based on the reported literatures and the research results of our research group, the composition design ideas of two kinds of Al-Li alloys, high strength Al-Li alloys and corrosion resistant Al-Li alloys, are proposed.

Key words: Al-Li alloy; alloying; micro-alloying; mechanical property; corrosion; microstructure

Foundation item: Project(2013AA032401) supported by Key National High-tech Research and Development Program of China

Received date: 2020-10-11; Accepted date: 2020-12-28

Corresponding author: LI Jin-feng; Tel: +86-13278861206; E-mail: lijinfeng@csu.edu.cn

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2013AA032401)

收稿日期:2020-10-11;修订日期:2020-12-28

通信作者:李劲风,教授,博士;电话:13278861206;E-mail:lijinfeng@csu.edu.cn

摘 要:综述了铝锂合金研发历程及成分设计的发展阶段,重点阐述了Al-Cu-Li系铝锂合金中主合金化元素Cu、Li含量对时效析出相类型、力学性能及耐腐蚀性能的影响规律及影响机理,详细论述了微合金化元素Zr、Mn、Mg、Ag、Zn、稀土和In等对Al-Cu-Li系铝锂合金力学性能、耐腐蚀性能及微观组织包括再结晶、时效析出相类型与分布密度的影响。结合笔者课题组研究结果,提出了高强铝锂合金及耐腐蚀铝锂合金两种类型铝锂合金的成分设计思路。

[3] 李劲风, 郑子樵, 陈永来, 等. 铝锂合金及其在航天工业上的应用[J]. 宇航材料工艺, 2012, 42(1): 13-19.

[4] 郑子樵, 李劲风, 陈志国, 等. 铝锂合金的合金化与微观组织演化[J]. 中国有色金属学报, 2011, 21(10): 2337-2351.

[10] 李劲风, 陈永来, 张绪虎, 等. Cu、Li含量对Mg、Ag、Zn复合微合金化铝锂合金力学性能及微观组织的影响[J]. 宇航材料工艺, 2015, 45(2): 24-28.

[12] 李劲风, 陈永来, 张绪虎, 等. 一种新型超高强铝锂合金板材的组织与力学性能[J]. 稀有金属材料与工程, 2017, 46(12): 3715-3720.

[13] 程 彬, 郑子樵, 范春平, 等. 时效制度对新型 Al-Cu-Li 合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(7): 926-933.

[25] 魏修宇, 郑子樵, 潘峥嵘, 等. 预变形对 2197 铝锂合金显微组织和力学性能的影响[J]. 稀有金属材料与工程, 2008, 37(11): 1996-1999.

[30] 李劲风, 郑子樵, 蔡 彪. 一种铝锂合金搅拌摩擦焊的接头力学性能及微观组织研究[J]. 宇航材料工艺, 2013, 43(3): 71-76.

[34] 桑冯建, 郑子樵, 王海金. Mn 在 2297 铝锂合金中的微合金化作用[J]. 稀有金属材料与工程, 2018, 47(3): 871-877.

[40] 王瑞琴, 郑子樵, 陈圆圆, 等. Ag, Mg合金化对Al-Cu-Li合金时效特性和显微组织的影响[J]. 稀有金属材料与工程, 2009, 38(4): 622-626.

[41] 王瑞琴. 2050合金微合金化及其组织和性能的研究[D]. 长沙: 中南大学, 2009.

[42] 魏修宇. 高性能中强耐损伤铝锂合金的组织结构、热处理和性能关系研究[D]. 长沙: 中南大学, 2010.

[43] 罗先甫, 郑子樵, 钟继发, 等. Mg、Ag、Zn对一种新型铝锂合金时效行为的影响[J]. 中国有色金属学报, 2013, 23(7): 1833-1842.

[44] 罗先甫. 新型Al-Cu-Li合金的时效组织与力学性能研 究[D]. 长沙: 中南大学, 2013.

[51] 朱小辉. 新型铝锂合金(2099和2196合金)挤压材组织与性能的研究[D]. 长沙: 中南大学, 2009.

[62] 张海锋, 郑子樵, 林 毅, 等. 微量Sc对2099铝锂合金组织与性能的影响[J]. 中南大学学报(自然科学版), 2014, 45(5): 1420-1427.

[65] 梁文杰, 潘青林, 朱朝明, 等. 含钪Al-Cu-Li-Zr合金的组织与性能[J]. 材料科学与工艺, 2007, 15(2): 154-157.

[66] 陈志国,郑子樵,王芝秀,等. Al-4.0Mg-1.5Cu-1.0Li合金中Sc的微合金化行为[J]. 中国有色金属学报, 2004, 14(3): 372-377.

[70] 潘 波, 李 睿, 李劲风, 等. Ce微合金化对一种Al-Cu-Li系高强铝锂合金薄板组织及拉伸性能的影响[J]. 中国有色金属学报, 2018, 28(1): 21-30.

[71] 李劲风, 刘丹阳, 郑子樵, 等. Er微合金化对2055铝锂合金力学性能及微观组织的影响[J]. 金属学报, 2016, 52(7): 821-830.

[74] 舒 军, 陈志国, 李世晨, 等. 微量 Sn和In对Al-3.5%Cu合金时效行为及微观组织演变的影响[J]. 中国有色金属学报, 2012, 22(9): 2486-2491.

[75] 潘峥嵘, 郑子樵, 李世晨, 等. In对Al-3.5Cu合金析出过程的影响[J]. 稀有金属材料与工程, 2011, 40(6): 1079-1083.