DOI: 10.11817/j.issn.1672-7207.2021.04.024

半高导叶对离心泵压力脉动影响的数值模拟与试验研究

江伟1, 2,朱相源2,田辉3,李国君2,王玉川1

(1. 西北农林科技大学 水利与建筑工程学院,陕西 杨凌,712100;

2. 西安交通大学 热流科学与工程教育部重点实验室,陕西 西安,710049;

3. 承德石油高等专科学校 机械工程系,河北 承德,067000)

摘 要:

-ω湍流模型对不同半高导叶叶片高度时离心泵内部流场进行非稳态数值分析。通过数值模拟与试验方法探讨半高导叶对离心泵压力脉动性能的影响规律。研究结果表明:随着导叶叶高几何参数减小,导叶与蜗壳内压力脉动特性受叶轮-导叶动静干涉作用影响逐渐降低,叶轮-蜗壳动静干涉作用影响逐渐增强;采用半高导叶能有效改善内部流动的稳定性,蜗壳与导叶内流场分布更均匀,离心泵扬程曲线更平缓,最高效率逐渐增加,高效区变宽,且高效区向大流量偏移。

关键词:

中图分类号:TH311 文献标志码:A

文章编号:1672-7207(2021)04-1276-11

Numerical and experimental study of influence of semi-high guide vane on pressure fluctuation in centrifugal pump

JIANG Wei1, 2, ZHU Xiangyuan2, TIAN Hui3, LI Guojun2, WANG Yuchuan1

(1. College of Water Resources and Architectural Engineering , Northwest A&F University, Yanglin 712100, China;

2. Key Laboratory of Thermal Fluid Science and Engineering of MOE, Xi′an Jiaotong University, Xi′an 710049, China;

3. Department of Mechanical Engineering, Chengde Petroleum College, Chengde 067000, China)

Abstract: The SST k-ω turbulence model was used to the unsteady numerical analysis of the internal flow field in the centrifugal pump with different blade heights of semi-high guide vanes, the influence of semi-high guide vane on the pressure pulsation performance of centrifugal pump was studied through numerical simulation and experiment. The results show that with the decrease of the height of the guide vane, the impacts on the pressure pulsation characteristics of the vane and the volute are gradually reduced by rotor-stator interaction of the impeller-guide vane, and the influence of rotor-stator interaction of the impeller-volute is gradually enhanced. Using half height guide vane can effectively improve the stability of internal flow. And the flow field in volute and guide vane is more distributed, and the head curve of centrifugal pump is more gentle. Meantime, the highest efficiency is gradually increased, and the high efficiency area is widened.

Key words: semi-high guide vane; pressure pulsation; internal flow field; centrifugal pump; rotor-stator interaction

离心泵是一种应用十分广泛的通用机械,在农田灌溉、城市和工业给排水、原子能发电等领域应用极其广泛[1-2]。衡量离心泵性能优劣的重要指标主要由水泵的运行稳定性、汽蚀空化及效率等方面组成[3-4],其中效率关乎节能减排、能量高效利用,离心泵系统能否安全可靠运行与机组能否稳定运行有很大关系,因此,在保证离心泵水力效率或提高水力性能的同时,需尽量保证离心泵系统稳定可靠地运行。

与普通离心泵相比,尤其在偏离设计工况时,导叶式离心泵中叶轮、导叶及蜗壳内均会出现剧烈的湍流流动,并对泵的水力性能产生较大的影响[5-7]。在较小流量工况时,导叶式离心泵扬程曲线易出现蛇峰,且进一步减小流量时,由于叶轮进口处剧烈的非定常湍流流动,可能导致叶轮进口前盖板附近区域出现旋转汽蚀现象[8-10]。目前国内外许多学者主要集中于离心泵尤其针对多级离心泵[11-13]导叶结构的研究,而对于单级离心泵中导叶形式或多级离心泵末级导叶结构及导叶内部非定常流动研究较少。半高导叶由HOSHINO等[14]提出,其结构介于叶片式导叶与无叶导叶之间,能有效地改善叶轮机械内部流动状态,提高其稳定性[15],因此,在风机与压缩机中应用广泛。SITARAM等[16]采用试验方法研究了不同半高导叶叶高尺寸对离心压缩机内部流动影响,发现当半高导叶叶高与导叶流道宽度之比h/b=0.2~0.3时,其能量系数与静压系数最高,而随着流量增加,其叶轮与导叶等区域出现不均匀尾迹流。刘立军[17]采用数值模拟方法探讨了半高导叶式压缩机内部非稳态流动,发现半高导叶能较好地改善压缩机级内流场。LIU[18-21]等采用数值模拟与试验方法研究了不同结构半高导叶、不同半高导叶叶高参数等对压缩机稳定性及内部流场影响,结果表明合适的半高导叶结构与适当的叶高尺寸能有效改善压缩机内部流场,提高其稳定运行。由上述文献可知,压缩机或风机中半高导叶性能及其内部流场的研究较多,而对离心泵中半高导叶对其性能的影响研究较少[22]。为此,本文作者采用数值模拟与试验方法深入分析半高导叶对离心泵压力脉动的影响,以期为离心泵半高导叶设计与稳定性提供理论依据与参考。

1 基本参数与湍流模型

导叶式离心泵基本参数为:流量Qdes=40 m3/h,扬程

表1 设计参数

Table 1 Design parameters

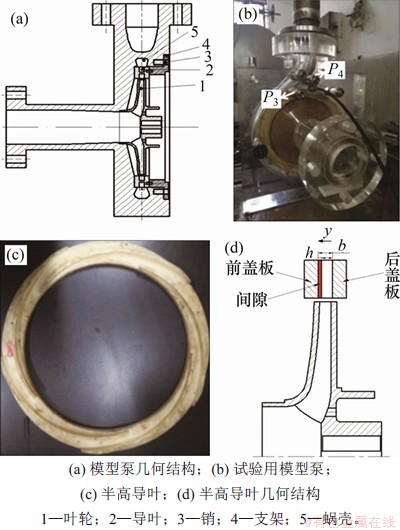

图1 模型试验泵

Fig. 1 Model test pump

表2 导叶端面间隙数值与试验方案

Table 2 Numerical and test scheme of guide vane clearance

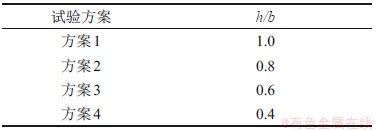

数值计算网格采用ICEM结构化网格见图2。半高导叶介于有叶与无叶导叶之间,故导叶叶高方向存在间隙,对其间隙区域网格采用边界层处理。各流部件(叶轮、导叶、蜗壳)网格数分别为568 761,765 337和881 295个,前后泵腔网格分别为421 802和448 013个,如图2所示。采用SST k-ω湍流模型,边界条件采用压力进口、质量流量出口、壁面无滑移。瞬态计算以稳态计算为初始计算条件,叶轮每转过1°为1个时间步,其时间步长5.75×10–5 s,1个周期计算360步,计算8个周期,采用最后1个周期进行流场分析。

图2 计算域网格

Fig. 2 Grid of computational domain

2 压力脉动实验研究

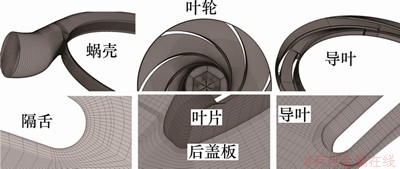

图3所示为不同导叶叶高时离心泵外特性曲线。从图3可见:随着导叶叶片与盖板之间间隙增加即h/b增大,离心泵扬程曲线更平缓,最高效率逐渐增加,高效区变宽,且高效区向大流量偏移,主要是减小导叶叶高提升了过流部件的过流能力;当h/b=1.0时,离心泵扬程曲线较陡,下降较快,其中,当Q=37.5 m3/h时,效率最大,为55.5%;当h/b=0.4~0.8时,离心泵扬程曲线较平缓,下降较慢,效率最高点向大流量偏移,其中效率最高点位于Q=42.5 m3/h处,为57.5%;在整个流量工况范围内,当h/b=0.8时,离心泵的扬程与效率最小,除h/b=0.8外,在小流量工况(Q=18~37 m3/h)范围内,h/b=1.0时离心泵的扬程、效率最高;在大流量工况(Q=37~60 m3/h)范围内,h/b=1.0时离心泵的扬程、效率远比其他h/b时的低。

图3 不同导叶叶高对离心泵外特性影响

Fig. 3 Influence of different guide vane heights on external characteristics of centrifugal pump

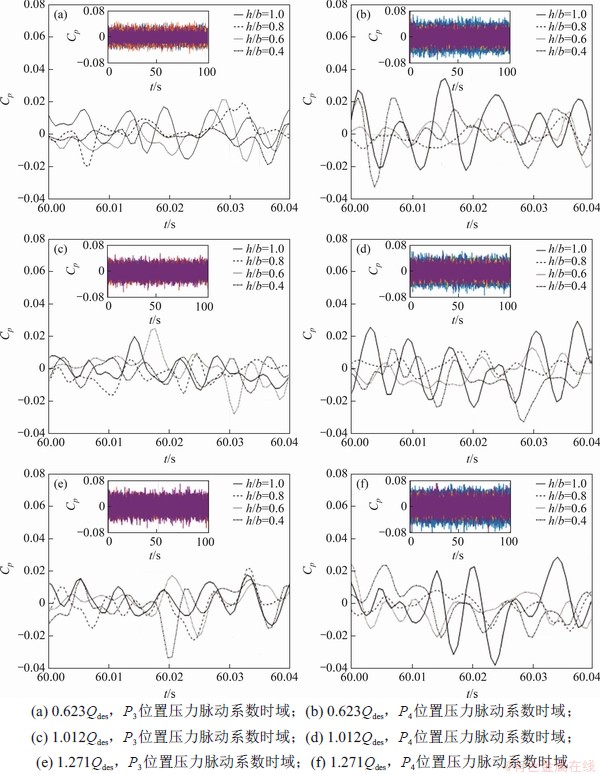

图4所示为不同流量、不同导叶叶高时监测点P3和P4的压力脉动系数随时间的变化曲线。由图4可见:在动静干涉作用下,监测点压力脉动系数呈周期性波动。因实际流动中复杂多变的流场结构,试验中压力脉动系数在每个波峰和波谷处的值并不相同,其波动并非呈严格的周期性波动;在不同导叶叶片高度下,监测点处压力脉动系数差别较大,当h/b=1.0时,压力脉动系数峰-谷值明显比采用半高导叶时的高;总体来看,监测点P3压力脉动规律性相对较差,其峰-谷值(波峰与波谷的差值)比监测点P4的低,表明P3处压力波动的强度较P4处小,但波动复杂;在P3处,当h/b=0.6时,压力脉动系数峰谷值最小,在P4处,当h/b=0.8时,压力脉动系数峰谷值最小。由试验结果可知半高导叶不仅影响离心泵外特性,而且对蜗壳内部流场产生明显的影响。

图4 不同流量工况时压力监测点处压力脉动系数变化

Fig. 4 Variation of pressure fluctuation coefficient at pressure monitoring point under different flow conditions

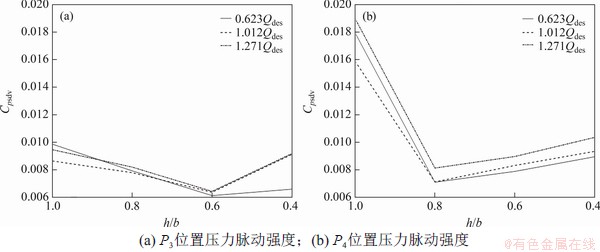

图5所示为不同流量工况和不同导叶叶高时,监测点P3和P4压力脉动强度变化。压力脉动强度由下式计算:

其中:ptm为瞬时压力;pave为平局压力;Cp为压力系数。由图5可见:不同导叶叶高时监测点P3及P4压力脉动强度变化较大。其中隔舌处监测点(P3)处的压力脉动强度在h/b=0.6时达到最小值,而隔舌下游(P4)的压力脉动强度在h/b=0.8时达到最小值;在P3位置,当采用传统叶片式导叶时(h/b=1.0),压力脉动强度明显比采用半高导叶时的高;当导叶叶片高度由h/b=1.0向h/b=0.6逐渐减小时,各工况下压力脉动强度逐渐减小;当h/b=0.6时,各工况下的压力脉动强度达到最小值,而后随着导叶叶高继续减小,压力脉动强度逐渐增大。这是由于随着导叶叶高减小,导叶间隙增大,在间隙流动的影响下压力脉动逐渐增强。其中,小流量下,压力脉动强度随叶高减小下降速度最快,并且在h/b=0.4时只有微小上升。在P4处,当导叶高度由h/b=1.0向h/b=0.8逐渐减小时,各工况下压力脉动强度逐渐减小,且当采用传统叶片式导叶时(h/b=1.0),压力脉动强度下降最快,当h/b=0.8时,各工况下的压力脉动强度达到最小值,而后随着导叶叶高继续减小,压力脉动强度逐渐增大。因此,半高导叶可以有效地减弱隔舌及其下游处的压力脉动强度,尤其在小流量下效果更佳,并且存在一个相对较优的导叶高度使得隔舌及其下游处压力脉动减小。

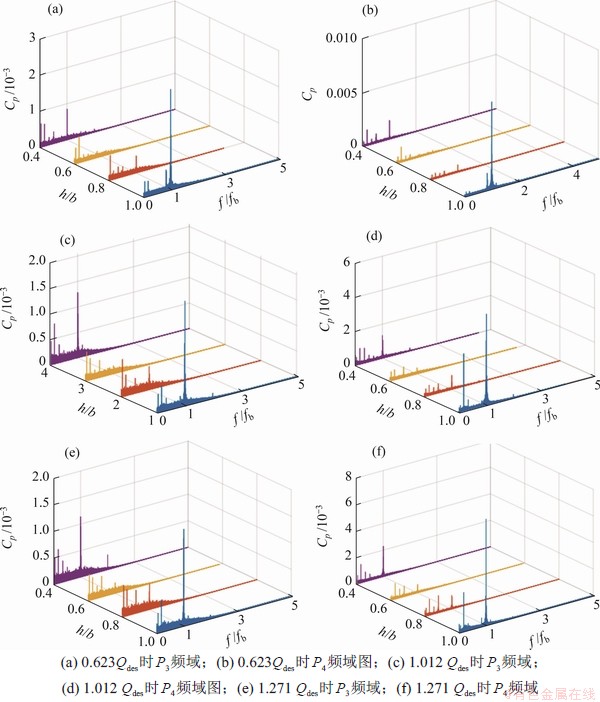

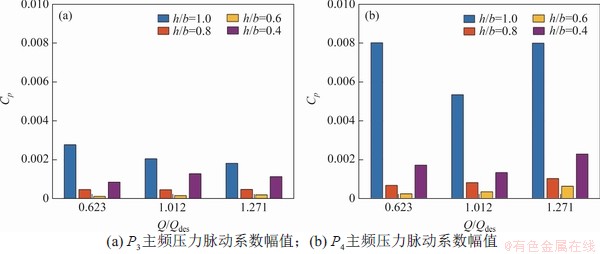

图6和图7所示分别为不同流量工况和不同导叶叶高时,监测点P3和P4处压力脉动系数的频域分布图及压力脉动系数在主频处的幅值对比,其中fb为叶片通过频率。由图6和图7可见:P3和P4处压力脉动以叶片通过频率为主,低频谐波为叶轮偏心及测点附近复杂流动导致;当采用传统导叶即h/b=1.0时,P3点的主频处压力脉动系数的幅值明显比P4时的小,但当采用半高导叶时,两监测点处幅值的差别明显减小;当采用半高导叶时,P3和P4压力脉动系数在主频出的幅值明显比采用传统导叶的小。当h/b=0.8和h/b=0.6时,主频处的压力脉动系数幅值最小,当h/b=0.4时,主频处的幅值虽然比h/b=0.8和h/b=0.6时的高,但明显比h/b=1.0时的低;在P4处,虽然h/b=0.6时主频处幅值比h/b=0.8时的低,但h/b=0.8时的压力脉动强度比h/b=0.6时的高,这是因为h/b=0.8低频波幅值较小。因此,减小导叶叶高可以有效地减小隔舌及其下游处压力脉动幅值,并且存在相对较优的导叶叶高使得隔舌及其下游处压力脉动幅值降低。

3 数值模拟结果分析

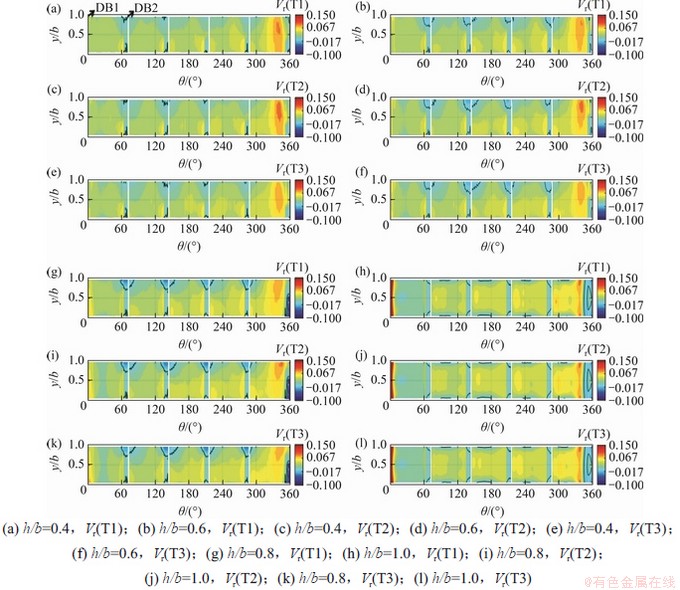

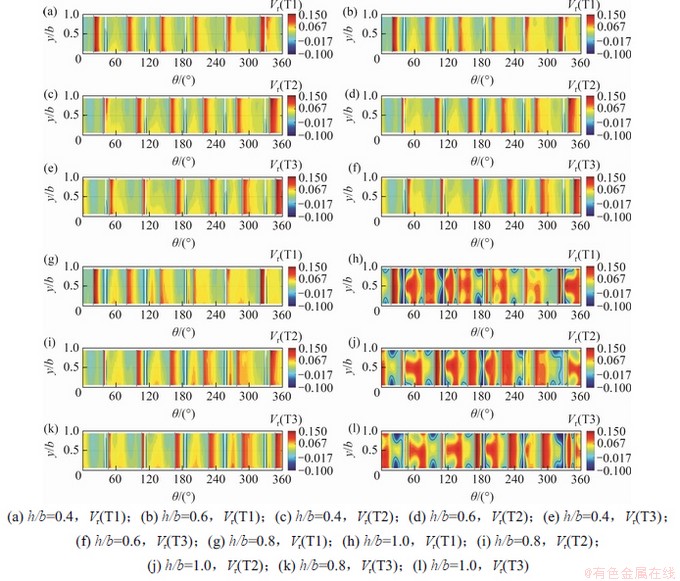

图8所示为1.0Qdes下、不同导叶叶高时,蜗壳-导叶间隙处径向速度Vr(Vr=vr /u2,其中vr为径向速度,u2为叶轮出口圆周速度)分布,白色线为导叶凹面尾缘。由图8可见:随着叶高减小,隔舌上游前部区域(350°~360°)的负径向速度区逐渐减小;当h/b=0.8时,隔舌前部靠叶轮轮毂侧(HS)依然存在负径向速度区,而靠前盖板侧(SS)负径向速度消失;当h/b=0.4时,隔舌前部(350°~360°)负径向速度完全消失,表明蜗壳隔舌前部的漩涡消失;随着导叶叶高减小,负径向速度区减小,同时,隔舌前部的高径向速度区(340°~350°)逐渐增大,并且高径向速度区偏向导叶间隙(前盖板SS侧);在远离隔舌的导叶叶片间隙处,出现负径向速度区;随着叶高的进一步减小,该负径向速度区逐渐减小。导叶尾缘间隙处的负径向速度区的存在主要是由于其叶片出口复杂流动,出现旋涡;随着导叶叶高减小,在隔舌处(0°)导叶叶片尾缘处径向速度减小,表明半高导叶能有效改善蜗壳进口压力沿圆周分布的均匀性;在导叶叶片DB1和DB2间流道范围内,蜗壳-导叶间隙内径向速度逐渐增大,其他导叶流道出口处径向速度有所减小。以导叶流道的角度来看,减小导叶叶高,各导叶流道出口径向速度差别减小,除隔舌前部(330°~350°)高径向速度区外,各导叶流道径向速度分布更加均匀,并且导叶叶片凹面尾缘处径向速度减小,因此,导叶叶高减小,对其叶片尾缘射流有一定的削减作用。与采用传统叶片式导叶相比,采用半高导叶时,随着叶轮旋转,各导叶流道出口处径向速度分布变化较小,表明叶轮-导叶的干涉作用对下游导叶出口即蜗壳进口处流场影响较小。

图5 压力监测点处压力脉动强度变化

Fig. 5 Pressure fluctuation intensity change at pressure monitoring point

图6 监测点处压力脉动系数频域分布

Fig. 6 Frequency domain distribution of pressure fluctuation coefficient at monitoring point

图7 监测点处压力脉动系数主频处幅值分布

Fig. 7 Amplitude distribution of pressure fluctuation coefficient on dominant frequency at monitoring point

图8 在1.0Qdes时,不同导叶叶高时蜗壳-导叶间隙内径向速度分布

Fig. 8 Radial velocity distribution of clearance between volute and diffuser with different guide vane height at 1.0 Qdes

图9 在1.0Qdes时,导叶-叶轮间隙内径向速度在不同导叶叶高时的分布图

Fig. 9 Radial velocity distribution of clearance between impeller and diffuser with different guide vane height under 1.0 Qdes

图9所示为1.0Qdes下、不同导叶叶高时,导叶-叶轮间隙处径向速度分布。由图9可见:导叶叶高对导叶进口流动参数影响很大;当采用传统叶片式导叶时,在导叶叶片进口边前后区域存在明显的负径向速度,采用半高导叶时这一问题明显减小;当h/b=0.8时,在导叶进口边两侧很小的区域依然存在负径向速度,随着叶高减小,负径向速度区逐渐减小但一直存在;随着导叶叶高减小,导叶前缘负径向速度区在靠近前盖板侧(SS)逐渐消失,这主要是由于在前盖板侧是无叶区,不存在流体绕流导叶前缘导致很小范围内的负径向速度产生。对比h/b=0.8与h/b=1.0时导叶进口径向速度分布可知:导叶叶高减小,在消除了负径向速度区的同时,还减小了高径向速度区的值,尤其在导叶进口边至叶轮叶片出口边之间的区域。当采用半高导叶时,导叶进口边高径向速度区主要出现在叶轮叶片尾缘处,并且随着叶轮的旋转,当叶片压力面尾缘逐渐靠近导叶叶片前缘时,径向速度逐渐增加。当采用半高导叶时,各导叶流道内流体分配更加均匀,叶轮-导叶干涉作用降低。

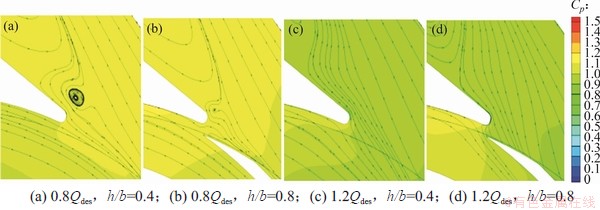

图10所示为0.8Qdes和1.2Qdes下,在不同导叶叶高时,隔舌处流线及压力系数分布。由图10可见:在小流量下,当h/b=0.4时,隔舌处存在漩涡,且此漩涡向蜗壳主流区偏移,对上游大涡有一定的阻塞作用,使得上游大涡对隔舌处影响降低,进而导致能量耗散降低;当h/b=0.8时,漩涡向隔舌处偏移,但漩涡强度明显减小;当导叶叶片叶高减小时,因隔舌处漩涡对下游蜗壳出口区域大涡的影响,使得隔舌附近区域流动更均匀,大涡影响范围减小,进而能量耗散减小;在1.2Qdes流量下,隔舌处漩涡消失,隔舌处流动更加均匀,在高速流体作用下,大涡的影响降低;采用半高导叶时,由于间隙处流速很大,当流体由导叶进入蜗壳时,在高速流体的夹带下,漩涡向主流及隔舌上部移动,进而减小了大涡的影响,降低了能量耗散。

图10 0.8Qdes和1.2Qdes时不同导叶叶高时隔舌处流线分布

Fig. 10 Streamline distribution at tongue with different guide vane heights at 0.8Qdes and 1.2Qdes

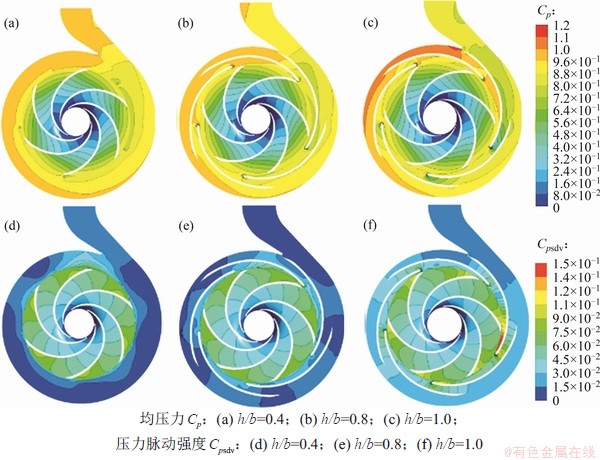

图11 在1.0Qdes时不同导叶叶高下时均压力及压力脉动强度分布

Fig. 11 Distribution of time average pressure and pressure fluctuation intensity at different guide vane heights at 1.0Qdes

图11所示为1.0Qdes、不同导叶叶高下中截面上时均压力及压力脉动强度分布。由图11中时均压力分布可见:采用半高导叶时叶轮内部压力分布相似,但采用半高导叶时蜗壳内压力明显比采用传统导叶时的大,说明蜗壳压力损失在采用传统导叶时高。总体来看,蜗壳内压力在采用半高导叶时比采用传统导叶时的高,同时,采用传统导叶时隔舌处存在较大的压力梯度。由压力脉动强度可见,采用半高导叶时叶轮、蜗壳和导叶内压力脉动强度显然比采用传统导叶时的低,泵内部流场波动减弱。

4 结论

1) 采用半高导叶时,隔舌处P3点及其下游蜗壳出口P4点处的压力脉动强度及主频处的幅值明显减小,尤其P2点处减小最明显。随着导叶叶高减小,压力脉动强度和主频处幅值逐渐减小,小流量下减小最快,但当导叶叶片减小到一定程度时(h/b=0.4),受间隙流动的影响,隔舌处及蜗壳出口处压力脉动开始增大。

2) 导叶叶高对离心泵外特性参数影响显著。在小流量工况下,与采用传统叶片式导叶相比,采用半高导叶的离心泵的扬程减小,其效率也减小;在设计流量下,导叶叶高影响较小;在大流量工况下,采用半高导叶的离心泵,其扬程和效率增大。

3) 采用半高导叶时,蜗壳进口压力沿圆周方向分布更加均匀,消除了隔舌处的高压力梯度现象。隔舌处回流涡消失,隔舌处负径向速度区消失,消除了隔舌处漩涡对导叶流道的堵塞作用,提高了导叶流道的过流性能,使得导叶出口的径向速度沿圆周方向更加均匀。导叶进口压力沿圆周方向分布较均匀,负径向速度区明显减小。当叶轮压力面尾缘逐渐接近导叶前缘时,径向速度逐渐增大,动静干涉作用对导叶内流场影响不可忽略。

参考文献:

[1] CHALGHOUM I, ELAOUD S, AKROUT M, et al. Transient behavior of a centrifugal pump during starting period[J]. Applied Acoustics, 2016, 109: 82-89.

[2] QU Wanshi, TAN Lei, CAO Shuliang, et al. Numerical investigation of clocking effect on a centrifugal pump with inlet guide vanes[J]. Engineering Computations, 2016, 33(2): 465-481.

[3] MENG Long, HE Min, ZHOU Lingjiu, et al. Influence of impeller-tongue interaction on the unsteady cavitation behavior in a centrifugal pump[J]. Engineering Computations, 2016, 33(1): 171-183.

[4] LI Wenguang. Effects of viscosity on turbine mode performance and flow of a low specific speed centrifugal pump[J]. Applied Mathematical Modelling, 2016, 40(2): 904-926.

[5] 王文杰, 袁寿其, 裴吉, 等. 时序效应对导叶式离心泵内部压力脉动影响的数值分析[J]. 机械工程学报, 2015, 51(4): 185-192.

WANG Wenjie, YUAN Shouqi, PEI Ji, et al. Numerical analysis of the clocking effect on the pressure fluctuation in the centrifugal pump with vaned diffuser[J]. Journal of Mechanical Engineering, 2015, 51(4): 185-192.

[6] PEI Ji, YIN Tingyun, YUAN Shouqi, et al. Cavitation optimization for a centrifugal pump impeller by using orthogonal design of experiment[J]. Chinese Journal of Mechanical Engineering, 2017, 30(1): 103-109.

[7] AKHRAS A R, EL HAJEM M , MOREL R, et al. Internal flow investigation of a centrifugal pump at the design point[J]. Journal of Visualization, 2001, 4(1): 91-98.

[8] TSUKIYA T, TATSUMI E, NISHINAKA T, et al. Design progress of the ultracompact integrated heart lung assist device: part 2: optimization of the diffuser vane profile[J]. Artificial Organs, 2003, 27(10): 914-919.

[9] HUANG Weiguang, GENG Shaojuan, ZHU Junqiang, et al. Numerical simulation of rotating stall in a centrifugal compressor with vaned diffuser[J]. Journal of Thermal Science, 2007, 16(2): 115-120.

[10] DAVIS M C, FLACK R D. Laser velocimetry measurements in a laboratory vaned diffuser[J]. Experiments in Fluids, 1990, 9(1/2): 33-42.

[11] SHI Baocheng, WEI Jinjia, ZHANG Yan. A novel experimental facility for measuring internal flow of Solid-liquid two-phase flow in a centrifugal pump by PIV[J]. International Journal of Multiphase Flow, 2017, 89: 266-276.

[12] ADAMKOWSKI A, HENKE A, LEWANDOWSKI M. Resonance of torsional vibrations of centrifugal pump shafts due to cavitation erosion of pump impellers[J]. Engineering Failure Analysis, 2016, 70: 56-72.

[13] BELLARY S A I, ADHAV R, SIDDIQUE M H, et al. Application of computational fluid dynamics and surrogate-coupled evolutionary computing to enhance centrifugal-pump performance[J]. Engineering Applications of Computational Fluid Mechanics, 2016, 10(1): 171-181.

[14] HOSHINO M, OHKI H, YOSHINAGA Y. The effect of guide vane height on the diffuser flow in centrifugal compressors[J]. Transactions of the Japan Society of Mechanical Engineers B, 1985, 51(470): 3366-3369.

[15] YOSHINAGA Y, KANEKI T, KOBAYASHI H, et al. A study of performance improvement for high specific speed centrifugal compressors by using diffusers with half guide vanes[J]. Journal of Fluids Engineering, 1987, 109(4): 359-366.

[16] SITARAM N, ISSAC J M. An experimental investigation of a centrifugal compressor with hub vane diffusers[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 1997, 211(5): 411-427.

[17] 刘立军. 离心压气机级内定常或非定常粘性流动的数值分析与实验研究[D].西安: 西安交通大学能源与动力工程学院, 1999: 1-2.

LIU lijun. Numerical analysis and experimental study of constant or unsteady viscous flow in centrifugal compressor[D]. Xi'an : Xi'an Jiaotong University. School of Energy and Power Engineering,1999: 1-2.

[18] LIU Ruitao, XU Zhong. Numerical investigation of a high-speed centrifugal compressor with hub vane diffusers[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2004, 218(3): 155-169.

[19] ISSAC J M, SITARAM N, GOVARDHAN M. Effect of diffuser vane height and position on the performance of a centrifugal compressor[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2004, 218(8): 647-654.

[20] ZHANG W, GONG W, FAN X, et al. The effect of half vane diffuser on the noise generated from a centrifugal fan[J]. Experimental Techniques, 2012, 36(3): 5-13.

[21] 刘宝军, 贺利生, 雷明洋, 等. 低稠度半高叶片扩压器的模型级性能研究[J]. 风机技术, 2011, 53(2): 10-14.

LIU Baojun, HE Lisheng, LEI Mingyang, et al. Performance research on model stage of half low solidity vaned diffuser[J]. Compressor,Blower & Fan Technology, 2011, 53(2): 10-14.

[22] 江伟, 陈帝伊, 秦钰祺, 等. 半高导叶端面间隙对离心泵水力性能影响的数值模拟与验证[J]. 农业工程学报, 2017, 33(17): 73-81.

JIANG Wei, CHEN Diyi, QIN Yuqi, et al. Numerical simulation and validation of influence of end clearance in half vane diffuser on hydraulic performance for centrifugal pump[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(17): 73-81.

(编辑 杨幼平)

收稿日期: 2020 -06-07; 修回日期: 2020 -08 -24

基金项目(Foundation item):国家自然科学基金资助项目(51809218);中国博士后科学基金资助项目(2018M643744);陕西省水利科技计划项目(2018slkj-8, 2017slkj-5);河北省高等学校科学技术研究项目(ZD2019122) (Project(51809218) supported by the National Natural Science Foundation of China; Project(2018M643744) supported by the Postdoctoral Science Foundation of China; Projects(2018slkj-8, 2017slkj-5) supported by the Scientific Research Foundation on Water Engineering of Shaanxi Province; Project(ZD2019122) supported by the Scientific Research Projects of Colleges and Universities in Hebei Province)

通信作者:李国君,博士,教授,从事叶轮机械优化设计研究; E mail:liguojun@ xjtu.edu.cn

引用格式: 江伟, 朱相源, 田辉, 等. 半高导叶对离心泵压力脉动影响的数值模拟与试验研究[J]. 中南大学学报(自然科学版), 2021, 52(4): 1276-1286.

Citation: JIANG Wei, ZHU Xiangyuan, TIAN Hui, et al. Numerical and experimental study of influence of semi-high guide vane on pressure fluctuation in centrifugal pump[J]. Journal of Central South University(Science and Technology), 2021, 52(4): 1276-1286.

摘要:采用SST k-ω湍流模型对不同半高导叶叶片高度时离心泵内部流场进行非稳态数值分析。通过数值模拟与试验方法探讨半高导叶对离心泵压力脉动性能的影响规律。研究结果表明:随着导叶叶高几何参数减小,导叶与蜗壳内压力脉动特性受叶轮-导叶动静干涉作用影响逐渐降低,叶轮-蜗壳动静干涉作用影响逐渐增强;采用半高导叶能有效改善内部流动的稳定性,蜗壳与导叶内流场分布更均匀,离心泵扬程曲线更平缓,最高效率逐渐增加,高效区变宽,且高效区向大流量偏移。

[5] 王文杰, 袁寿其, 裴吉, 等. 时序效应对导叶式离心泵内部压力脉动影响的数值分析[J]. 机械工程学报, 2015, 51(4): 185-192.

[17] 刘立军. 离心压气机级内定常或非定常粘性流动的数值分析与实验研究[D].西安: 西安交通大学能源与动力工程学院, 1999: 1-2.

[21] 刘宝军, 贺利生, 雷明洋, 等. 低稠度半高叶片扩压器的模型级性能研究[J]. 风机技术, 2011, 53(2): 10-14.

[22] 江伟, 陈帝伊, 秦钰祺, 等. 半高导叶端面间隙对离心泵水力性能影响的数值模拟与验证[J]. 农业工程学报, 2017, 33(17): 73-81.