Microstructures of Ti-48%Ni shape memory melt-spun ribbons

XING Hong-yan(邢鸿雁)1, 2, H. Y. KIM2, S. MIYAZAKI2

1. College of Mechanical Engineering, Tianjin University of Science and Technology,

Tianjin 300222, China;

2. Institute of Materials Science, University of Tsukuba, Tsukuba 305-8573, Japan

Received 10 April 2006; accepted 25 April 2006

Abstract:

The effect of wheel speed on microstructures of Ti-48%Ni (mole fraction) melt-spun ribbons was investigated by X-ray diffractometry, scanning electron microscopy and transmission electron microscopy. When the wheel speed is 26 and 42 m/s, the as-spun ribbons are completely crystallized to the Ti-Ni B2 phase. The Ti-rich plate precipitates lying on {100} planes are observed in the as-spun ribbon fabricated with a wheel speed of 26 m/s. The spherical Ti2Ni precipitates are observed at grain boundaries in the as-spun ribbons fabricated with a wheel speed of 42 m/s. Amorphous and B2 phases coexist in the as-spun ribbon fabricated with a wheel speed of 52 m/s. The uniformity of grain size in heat treated ribbons decreases with increasing wheel speed.

Key words:

Ti-Ni; melt-spun ribbon; microstructure; shape memory alloy;

1 Introduction

It has been known that Ti-Ni thin films show shape memory effects comparable to those of bulk materials. The Ti-Ni shape memory alloy (SMA) thin films are expected to be utilized for various microactuators such as microvalves, micropumps and microgrippers [1-6]. The microstructures and shape memory effects of Ti-Ni SMA thin films fabricated by a sputter-deposition method have been studied extensively [7-11]. However, the composition of Ti-Ni thin films fabricated by the sputter-deposition methods is difficult to be adjusted precisely, because the composition of the deposited thin film is affected by the surface state of a target. In order to fabricate Ti-Ni SMA films, the melt-spinning technique has been applied recently, since Ti-Ni ribbons less than 20 μm in thickness can be fabricated easily. Controlling the composition of thin ribbons seems to be easier in comparison with the thin films fabricated by the sputter-deposition method. Microstructures of melt-spun ribbons sensitively depend on the processing parameters such as wheel speed, gas pressure and nozzle-wheel gap. Although many reports have been published on the melt-spun ribbons, the effect of processing parameters on microstructure and shape memory behavior has not been well clarified. In this study, the effect of the wheel speed on the microstructure of as-spun and heat treated ribbons were investigated. Only one parameter, i.e. the wheel speed was changed while the others such as ejection pressure, gas pressure and nozzle-wheel gap were fixed. Then the microstructure of Ti-48%Ni melt-spun ribbons fabricated at different wheel speeds were investigated by X-ray diffractometry (XRD), scanning electron microscopy (SEM) and transmission electron microscopy (TEM ).

2 Experimental

Ti-48.0%Ni (mole fraction) ingot was prepared by the Ar-arc melting method using high purity elemental Ti and Ni, and was cut into several pieces by a spark cutting machine. The pieces of ingots were used as raw materials for the fabrication of melt-spun ribbons. The pieces of ingots were remelted by an induction coil in a quartz crucible in an Ar atmosphere. The molten alloy was ejected onto a Cu wheel (200 mm in diameter) rotating with surface velocities of 26, 42 or 52 m/s. The melt-spun ribbons were heat-treated at 873 and 1 073 K for 3.6 ks in an Ar atmosphere. The crystal structures and phase constitution of the as-spun and heat-treated ribbons were examined by the XRD using Cu Kα radiation at 373 K. The surface structures were observed by SEM. The internal structures of the ribbons were observed by TEM. The specimens for TEM were prepared by a conventional twin-jet polishing technique. TEM observation was conducted using a JEOL2010F microscope operated at 200 kV.

3 Results and discussion

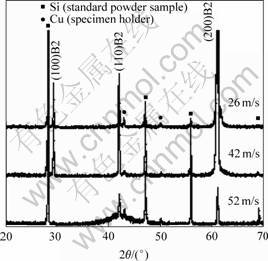

Fig.1 shows the XRD patterns of the Ti-48% Ni as-spun ribbons prepared with three different wheel speeds, i.e. 26, 42 and 52 m/s. The diffraction peaks corresponding to Cu and Si are obtained from a sample holder and standard sample powders, respectively. When the wheel surface velocity is 26 and 42 m/s, sharp and high Ti-Ni B2 peaks are clearly observed. This indicates that both as-spun ribbons are completely crystallized. On the other hand, when the wheel surface velocity is 52 m/s, a broad amorphous mound appears at around 2θ=42? in addition to Ti-Ni B2 peaks. This indicates that both amorphous and crystalline structures coexist in the as-spun ribbon fabricated with a wheel speed of 52 m/s. A peak corresponding to {200}B2 is observed in all as-spun ribbons. The intensity corresponding to the {200}B2 peak increases with decreasing wheel speed. The strong {200}B2 peak indicates that the crystalline area of these as-spun ribbons is strongly textured. This is consistent with a previous report that the as-spun ribbons of Ti-Ni SMA alloys exhibit a strong <200> fiber texture [12].

Fig.1 XRD patterns of Ti-48%Ni as-spun ribbons prepared at three different wheel speeds

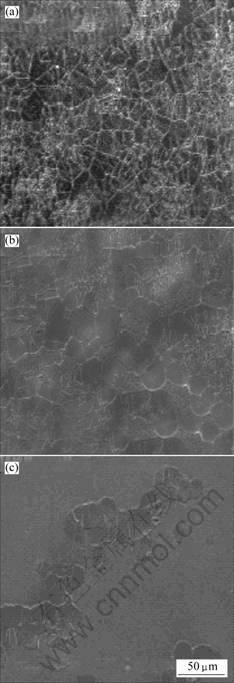

Fig.2 shows the SEM micrographs of the as-spun ribbons prepared with wheel speeds of 26, 42 and 52 m/s. When the wheel surface velocity is 26 m/s, the as-spun ribbon reveals a relatively uniform grain structure with an average grain size of 15 μm as shown in Fig.2(a). The as-spun ribbon fabricated with a wheel surface velocity of 42 m/s exhibits a larger grain size compared with the ribbon fabricated with a with a wheel speed of 26 m/s. It is noted that the spherical precipitates are seen at grain boundaries. It is confirmed that the spherical precipitates are Ti2Ni by electron probe micro-analysis. It is supposed that the Ti2Ni phase is formed in undercooled matrix prior to Ti-Ni B2 phase nucleation, and they are trapped by Ti-Ni grain boundaries after the crystallization of Ti-Ni B2 phase as suggested by NAGARAJAN and CHATTOPADHYAY [13]. In the

Fig.2 SEM micrographs of Ti-48%Ni as-spun ribbons fabricated at wheel speeds of 26 m/s(a), 42 m/s(b) and 52 m/s(c), respectively

case of ribbons fabricated with a wheel surface velocity of 52 m/s, the B2 grains with a size of 10-20 μm are seen within the amorphous as shown in Fig.2(c). These results indicate that a high wheel speed leads to a formation of amorphous structure. This is due to that the cooling rate increases with increasing wheel speed.

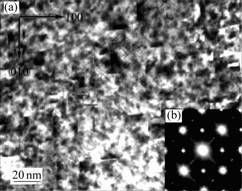

Fig.3(a) shows a bright field TEM micrograph taken from the 26 m/s as-spun ribbon. The corresponding selected area electron diffraction (SAED) pattern is shown in Fig.3(b). The zone axis of the diffraction pattern is [001] of the B2 structure of the parent phase. Fairly strong streaks along [100] and [010] directions are seen in Fig.3(b). It is considered that these are caused by very thin platelets observed in Fig.3(a), which lie on {100} planes. Each of these platelets is about 10 nm in length. It is also found that Ti-rich Ti-Ni sputter-deposited thin films show a nonequilibrim thin platelets, which has never been observed in bulk Ti-Ni alloys, when they are heat-treated at temperatures a little above the crystallization temperature [1,7].

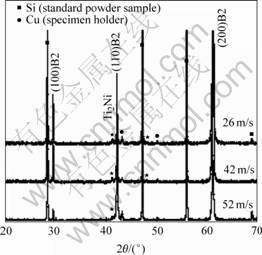

Fig.4 shows the XRD patterns of the ribbons heat treated at 873 K for 3.6 ks. The sharp peaks corresponding

Fig.3 TEM micrograph(a) of as-spun ribbon fabricated at wheel speed of 26 m/s and corresponding SAED pattern(b)

Fig.4 XRD patterns of Ti-48%Ni ribbons heat-treated at 873 K for 3.6 ks

to Ti-Ni B2 and Ti2Ni phases are observed in all heat-treated ribbons. This indicates that the ribbon fabricated with a wheel speed of 52 m/s was fully crystallized by the heat treatment. It is also noted that the intensity of Ti2Ni is similar in all ribbons, indicating that the composition of B2 phase becomes equilibrium.

Fig.5 shows the SEM micrographs of the ribbons heat treated at 1 073K for 3.6 ks. It is seen that the grain size becomes larger after heat-treatment when compared with the as-spun ribbons. In addition, it is seen that many black spherical precipitates, which are confirmed as Ti2Ni [14], are formed in the inside of a grain. On the other hand, it is clearly observed that larger grains are coexistent with small grains in the 52 m/s ribbons as shown in Fig.5(b). This result indicates that amorphous region in the as-spun ribbons shown in Fig.2(c) crystallizes to the small grains. As a result, it is concluded that the uniformity of microstructure decreases with increasing the wheel speed for the Ti-48%Ni ribbons.

Fig.5 SEM micrographs of Ti-48%Ni ribbons heat-treated at 1 073 K for 3.6 ks: (a) 26 m/s; (b) 52 m/s

4 Conclusions

1) As-spun ribbons completely crystallizes to the Ti-Ni B2 phase when the wheel speed is lower than 42 m/s. Amorphous and B2 phase coexist in the as-spun ribbon fabricated with a wheel speed of 52 m/s.

2) Ti-rich plate precipitates which lies on {100} plans are observed in the as-spun ribbon prepared with a wheel speed of 26 m/s. Spherical Ti2Ni precipitates are observed at grain boundaries in the as-spun ribbons prepared with a wheel speed of 42 m/s.

3) The uniformity of grain size in the heat-treated ribbons decreases with increasing the wheel speed.

Acknowledgements

This work was partially supported by the 21 Century Center of Excellence Program and the Grants-in-Aid for Fundamental Scientific Research (KibanA(1999-2001), Kiban A(2002-2004) from the Ministry of Education, Culture, Sports, Science and Technology, Japan.

References

[1] MIYAZAKI S, ISHIDA A. Martensitic transformation and shape memory behavior in sputter-deposited TiNi-base thin films [J]. Mater Sci Eng A, 1999, A 273-275: 106-133.

[2] JOHNSON A D. Vacuum-deposited TiNi shape memory film: characterization and applications in microdevices [J]. J Micromech Microeng, 1991, 1: 34-41.

[3] TOMOZAWA M, OKUTSU K, KIM H Y, MIYAZAKI S. Characterization of high-speed microactuator utilizing shape memory alloy thin films [J]. Mater Sci Forum, 2005, 475-495: 2037-2042.

[4] MIYAZAKI S, HIRANO M, NO V H. Dynamic characteristics of diaphragm microactuators utilizing sputter-deposited TiNi shape memory thin films [J]. Mater Sci Forum, 2002, 394-395: 467-474.

[5] ISHIDA A, TAKEI A, MIYAZAKI S. Shape memory thin film of Ti-Ni formed by sputtering [J]. Thin Solid Films, 1993, 228: 210-214.

[6] KOHL M, JUST E, QUANDT E, WINZEK B, MIYAZAKI S, ALLEN D M. Shape memory microvalves based on rolled sheets or thin films [J]. Mater Sci Eng A, 1999, A 273-275: 784-788.

[7] KAJIWARA S, OGAWA K, KIKUCHI T, MATSUNAGA T, MIYAZAKI S. Formation of nanocrystals with an identical orientation in sputter-deposited Ti Ni thin films [J]. Philosophical Magazine Letters, 1996, 74: 395-404.

[8] KAJIWARA S, KIKUCHI T, OGAWA K, MATSUNAGA T, MIYAZAKI S. Strengthening of Ti-Ni shape-memory films by coherent subnanometric plate precipitates [J]. Philosophical Magazine Letters, 1996, 74: 137-144.

[9] ZHANG J X, SATO M, ISHIDA A. On the Ti2Ni precipitates and Guinier-Preston zones in Ti-rich Ti-Ni thin films [J]. Acta Materialia, 2003, 51: 3121-3130.

[10] MATSUNAGA T, KAJIWARA S, OGAWA K, KIKUCHI T, MIYAZAKI S. Effect of Ti-content on nanometric substructure and shape memory property in sputter-deposited Ti-rich thin films [J]. Mater Sci Forum, 2000, 327-328: 175-178.

[11] ISHIDA A, SATO M, MIYAZAKI S. Mechanical properties of Ti-Ni shape memory thin films formed by sputtering [J]. Mater Sci Eng A, 1999, A273-275: 754-757.

[12] KHANTACHAWANA A, MIZUBAYASHI H, MIYAZAKI S. Texture and microstructure of Ti-Ni melt-spun shape memory alloy ribbons [J]. Mater Trans, 2004, 45: 214-218.

[13] NAGARAJAN R, CHATTOPADHYAY. Intermetallic Ti2Ni/TiNi nanocomposite by rapid solidification [J]. Acta Metal Mater, 1994, 42: 947-958.

[14] XING H, KHANTACHAWANA A, KIM H Y, MIYAZAKI S. Effect of Ni-content on shape memory behavior of Ti-rich Ti-Ni melt-spun ribbons [J]. Mater Sci Forum, 2005, 475-479: 1925-1928.

Corresponding authors: XING Hong-yan; Tel/Fax: +86-22-60273495; E-mail: xhy02@sina.com

S. MIYAZAKI; Tel/Fax.:+81-29-8535283; E-mail: miyazaki@ims.tsukuba.ac.jp